Strange Blobbing on Layer Change

-

@JadonM said in Strange Blobbing on Layer Change:

I'm using Simplify3D V4.1.2. Interestingly, they don't seem to show up with Cura.

Load up the gcode in a detailed gcode viewer and see what they do differently at the seam.

Is Cura using wipe and S3D isn't? Or vice versa?

Have you tried changing the jerk policy? M566 P1?

-

@Phaedrux said in Strange Blobbing on Layer Change:

Load up the gcode in a detailed gcode viewer and see what they do differently at the seam.

Is Cura using wipe and S3D isn't? Or vice versa?

Have you tried changing the jerk policy? M566 P1?Thanks for your time Phaedrux!

- S3D doesn't accept Cura's code comments, so it all shows as travel moves. Because of that, I chucked the files into gcode.ws and while hard to see, there is a slight difference. Cura seems to do it's wipe by backtracking a bit, then moving to the middle of the part. S3D simply backtracks then travels where it needs to go. Pictures below. I initially thought it could be wipe, but enabling it in S3D, even crazy amounts like 8mm, did nothing for the blobs. At this point, I'm frustrated and have no clue what the issue is.

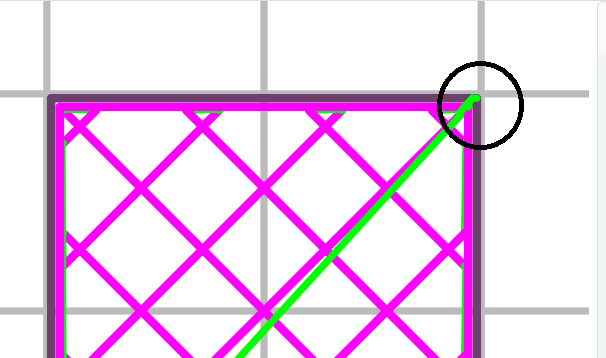

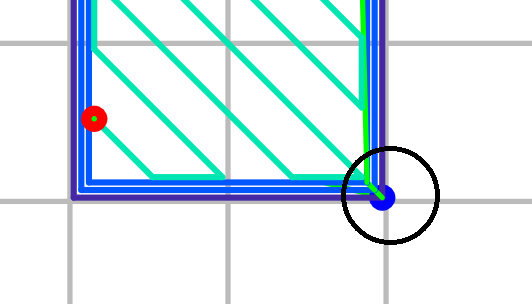

Cura:

Simplify3D (The circles are its indication of retraction.)

-

Cura defaults to a 0.8mm wipe, but like I said, it doesn't seem to make a difference to the blobs.

-

I don't fully understand the difference, but I tried both jerk policies and the prints were the same except for a strange stuttering(?) effect with P1.

My prints had no blobs before I converted the machine. If someone else could post a working set of settings for a V6 or Lite6 on a BMG, I'd be glad to try it out!

Thanks for your help!

Jadon -

Hey guys!

I wasn't having any luck with this, so I decided to wait a few weeks and come back with an open mind. Here we are.

I printed a benchy, and figured out that my silver PLA shows the blobs marvelously! (That is a good thing for testing, but bad otherwise!)

The pictures of the print are below, and what astounds me is that some of the layer changes make horrible blobs, and some are much less noticeable. (See the difference between different parts of the same print?)

I'm open to any suggestions, and I'd really appreciate a working E3d V6 or Lite6 profile, especially if you have a direct - drive Bondtech.

Thanks for your help, and I really appreciate any ideas you can give me! Thanks!

-

Can you look at your gcode and tell me if these blobs appear in places where the feedrate of the preceding print move was much greater than the perimeter showing the blob?

I have a thread going on this forum about this, called "Enhancing pressure advance." I have enlisted the help of Edgars-Batna and we have made some progress in testing solutions.

-

Are you looking for a config.g or slicer settings?

I can give you my settings for Cura. I don't use S3D.

I think these are the main generalized things for seam/blob minimization

- Inner before outer layers

- retract on layer change

- retract for travels

- quick and responsive Z and E axis

- reatraction and PA tuned

- quick unretracts and slower reprimes

- try and maintain consistent volumetric flow rates between moves ( use same speed for internal and external perimeters. The version of Cura I use has the option to slow down on overhangs only. I'm usually trying to maximize my volumetric flow rate anyway.)

- travel speeds and accelerations as fast as you can without skipping steps

- carefully choose where the seam will be depending on the model. Some models have lots of nooks and crannies to hideit, others do not. Sometimes it's better to force it to a single side of a model.

E3D Titan Aero with 0.6 nozzle

M203 X12000 Y12000 Z600 E4000 ; Set maximum speeds (mm/min) M201 X6000 Y6000 Z240 E3000 ; Set maximum accelerations (mm/s^2) M204 P1000 T2500 ; Set printing and travel accelerations M566 X1200 Y1200 Z120 E3000 ; Set maximum instantaneous speed changes (mm/min) (Jerk) M566 P1 ; Set jerk policy to mimic Marlin and uses jerk between all moves. M572 D0 S0.04 ; set extruder 0 pressure advance. M207 S0.9 R0.0 F3600 T2700 Z0.0 ; firmware retraction settings -

The blobs on your part look like they are starting at the beginning of the perimeter. This is the case especially if negative restart distance helps. I had the same issue and Recommend trying higher pressure advance values. I found a PA of .085 was necessary on a printer with a short 12mm Bowden tube between the hotend and bondtech extruder. Try values higher than 0.1 and see what you get. Can’t hurt.

-

@bot Thanks for your suggestion! I had noticed your thread and didn't think much about it at the time.

I read through the thread (a feat in itself

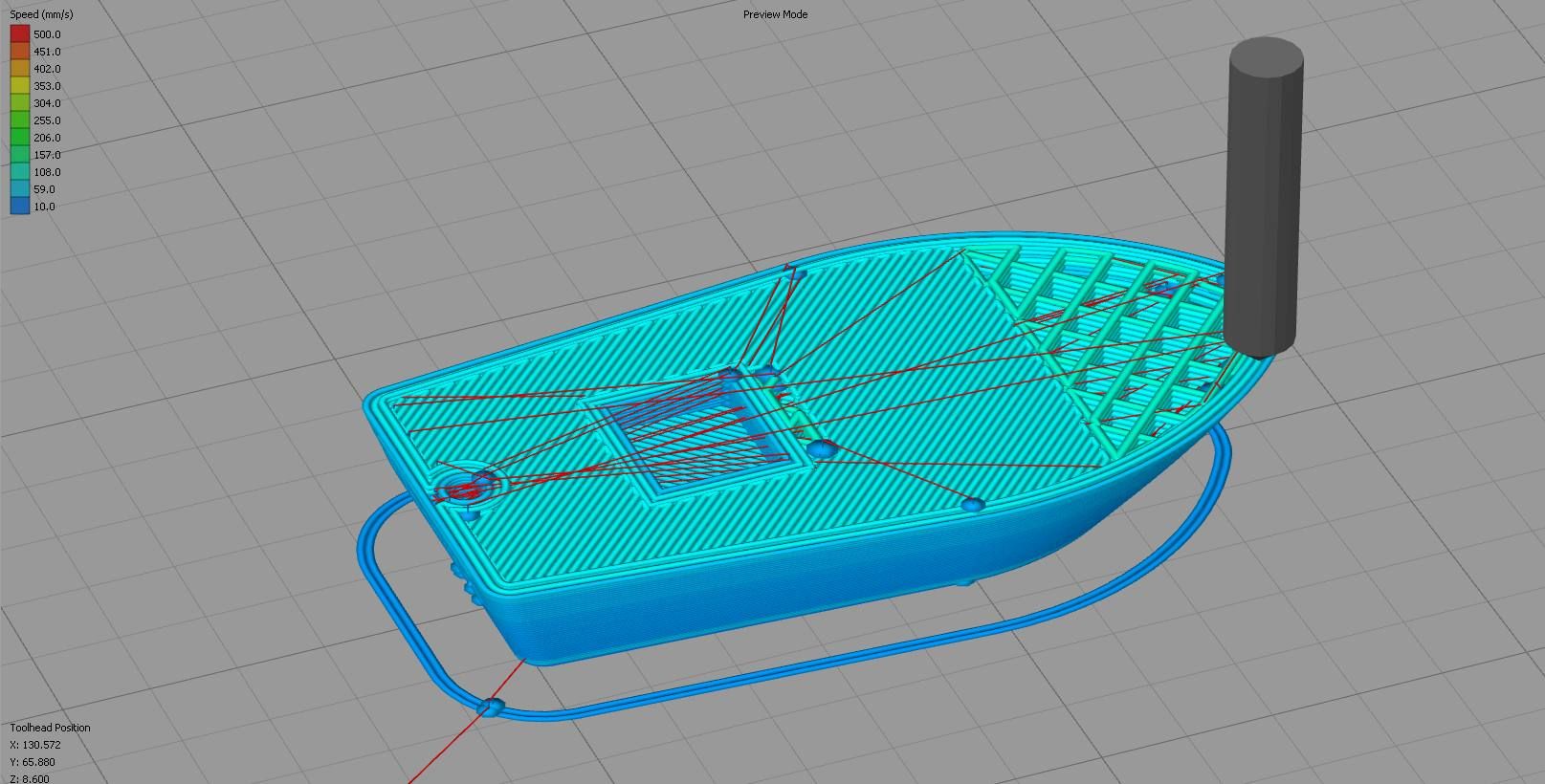

) and it seems to be a very plausible reason for my blobs. I'm using the "Unnamed Not-Yet-V5" Slicer. (S3D for those who haven't experienced the frustration) This leads to the result below. The "blobs" are S3D's way of showing retraction, but they are where the blobs occur on the print. As you can see, the print head screams in at 500mm/s, than screeches to an almost-halt at 60mm/s.

) and it seems to be a very plausible reason for my blobs. I'm using the "Unnamed Not-Yet-V5" Slicer. (S3D for those who haven't experienced the frustration) This leads to the result below. The "blobs" are S3D's way of showing retraction, but they are where the blobs occur on the print. As you can see, the print head screams in at 500mm/s, than screeches to an almost-halt at 60mm/s.I used to get very good Z-seams before I converted, but that was with a completely different extruder-hotend setup. Here's a picture from before I converted. You can see a slight Z-seam artifact by the back of the benchy.

I'm printing a benchy right now with travel moves at 60mm/s, so the travel moves match the proceeding moves almost identically. We'll see what happens, but I am hopeful.

@Phaedrux Thanks for your help! I'm looking for slicer settings, but your information will almost certainly be a help!

@mwolter Yes, the blobs are at the start and end of the perimeter. I already tried the Extra Restart Distance, and managed to tune it in almost perfectly using that, but it varies dramatically between prints! A 20mm cylindar prints awesomely, but a benchy prints like the silver one above.

I had also tried pressure advance, but I had to adjust it so extremely that it ruined the rest of the print. Thanks for your idea though! I appreciate any help - I'm stumped!

-

@bot Unfortunatly, it seems that didn't do a single thing except make the stringing worse. Any other ideas? Thanks!

-

@JadonM I didn't mean that travel moves of a certain speed could affect this, but the print move that happens before that travel move.

It looks like your print moves vary slightly in speed based on the notV5 visualization. Try a print where all of the print moves are exactly the same feed rate.

-

@bot said in Strange Blobbing on Layer Change:

@JadonM I didn't mean that travel moves of a certain speed could affect this, but the print move that happens before that travel move.

It looks like your print moves vary slightly in speed based on the notV5 visualization. Try a print where all of the print moves are exactly the same feed rate.

Here's a print with all the moves exactly the same speed. Any other ideas? Thanks for your help this far!

-

@JadonM Haha dang!

Maybe I'm chasing a wild goose at the moment myself.

What is your retraction speed? Another suspect of mine for things like this is the unretraction speed "flinging" material out of the nozzle way faster than it should. At least in my case, the unretraction speed is about 100 times greater than a typical extrusion speed (in my controlled slowed down tests).

-

I read you don't wish to use Cura. So i suppose you should find the respective entries in Symplify3D

I had the same exact problem . I was able to fix it managing with 3 parameters in the slicer (Cura):

Materials -

1)retraction.

2)extra prime amount.

Experimental-

1)coasting (and its sub entries) (this si really useful to me).

The Z-seam without the right coasting will not be good either.

Wipe distance is irrelevant for the task.

I have near 60cm of tube. -

@bot said in Strange Blobbing on Layer Change:

Maybe I'm chasing a wild goose at the moment myself.

What is your retraction speed? Another suspect of mine for things like this is the unretraction speed "flinging" material out of the nozzle way faster than it should. At least in my case, the unretraction speed is about 100 times greater than a typical extrusion speed (in my controlled slowed down tests).Sorry for the slow response. I've been busy.

I don't think you're on a wild goose chase, because the artifact you reference on the skirt is quite common on my prints! However, it seems that isn't the problem here.

I'm running 50mm/s retractions. I've played with that number a little bit, but what do you recommend?

@giostark said in Strange Blobbing on Layer Change:

I read you don't wish to use Cura.

It's not that I'm really against Cura, in fact, I'm testing it right now. Back when I started 3D printing, Simplify3D was unquestionally the best, but it seems like it's starting to shift otherwise.

@giostark said in Strange Blobbing on Layer Change:

1)retraction.

2)extra prime amount.

Experimental-

1)coasting (and its sub entries) (this si really useful to me).

The Z-seam without the right coasting will not be good either.

Wipe distance is irrelevant for the task.

I have near 60cm of tube.Those were my first ideas, so I tried and tuned them using a test cylinder. The problem is that the size of the blob changes based on where the Z-seam is on the print and the size of the print. So with it tuned in perfectly for a 15mm cylinder it makes even worse blobs on something like a Benchy.

Thanks for your help! Any other ideas?

-

Ok step 2:

With the extra prime amount and the coasting you should reach even holes.

If you cant see holes and you steel see blobs , you have to change values. With those settings is possible eliminate totally the blobs.

Activate , Speed - "equalize flow" . This will make accelerate the nozzle instead retraction and you will keep a more uniform extrusion.

Activate , Infill - "Connect infill lines" (it will reduce the retraction and add a more solid continue infill lines)

Disable "retraction at layer change" and enable combing "ALL". In this way it will retract just changing area and will take a more uniform flow.

For a more secure moving I enable also z-hop at retraction (2mm).

With those settings when you have to change layer in a close range you will avoid at all retraction.

Now, look at the seam of this part:

It come even missing a little too much material. So, the settings were exaggerated. BUT before this result (3rd attempt) I had much bigger blobs of your.

So I'm really confident that if you play with those settings you will eliminate at all the blobs. -

Hey guys! Thank you all for your help!

I've been tinkering with it a lot lately, and I think I'm finally making progress! The benchy-count is now getting close to 30, but my latest model looks quite hopeful!

I've tinkered with pressure advance before with this problem, but I wasn't having any luck. (I went up to about 0.1) Yesterday I tried going to 0.2 just to see what would happen, and the z seam looked amazing!

Now, for the question bugging me since then: can anyone tell me why I need 0.2 pressure advance on a direct drive Bondtech? I expected around 0.05.

Thanks!

Jadon -

@JadonM

Have you checked the filament path in the extruder? On the clones it is very common that they are aligned too close to the weel. This leads to friction. You can try to drill them little bit bigger. -

@DIY-O-Sphere

Hey, thanks for the tip! I noticed on my first printer that the clearance was very tight and it made filament loading extremely finicky. Since the extruder only cost $15, I decided to try drilling it out on this printer to make it more reliable. I don't remember how big of a bit I used, but I drilled the filament path slightly larger and have had no issues with loading. Is it possible that made the slop high enough to warrant such high pressure advance?I completely forgot that I drilled it out until you suggested that! Does that sound like a plausible explanation for the blobs - that it would act more like a sloppy bowden from the extruder gears to the hotend?

Once I get this tuned in well I'll let you guys know and mark it as solved. Thanks for all your help, and I think this'll fix it.

-

@JadonM said in Strange Blobbing on Layer Change:

Is it possible that made the slop high enough to warrant such high pressure advance?

If you haven't widened it to much...

I have drilled mine too. Diameter maybe around 2.2 mm.

I had to use high values for pressure advance too (only checked in a bowden setup).

I had bought the BMG more or less as a reference for a self build one.

For a direct setup I will go for a Hemera (if it's available again).For me the blobs are not related to the extruder.

My experience is, that issues on the hardware side in most cases are caused by the hotend....... -

@JadonM Glad that worked

-

So basically we can have different approach to the blobs problems.

Tune the pressure advance via firmware or tune the slicer side. Or maybe both together.

If we use different materials that have different characteristics we should save different profiles.@DIY-O-Sphere said in Strange Blobbing on Layer Change:

My experience is, that issues on the hardware side in most cases are caused by the hotend.......

Can you explain a little bit ? I'm interested in understand it.

![20200406_193021[1].jpg](/assets/uploads/files/1586261347653-20200406_193021-1-resized.jpg)