Five bar parallel Scara Prototypes

-

I want to share my first prototype of parallel Scara, Prototype 1:

I created a workmode 2 printer with a GT2 based about 1:30 gear between stepper and 300 mm diameter wheels (low backlash) from wood and 45x45 aluminium extrusions. I've not measured speed yet, but I think it is sufficient even with the 1:30 reduction.

The ball gearing on top allow easy calibration of the wheels. The endstops restrict the arm movements too much, I will go into bodus' direction of placing them in position 180 and 0 degree in the next prototype. The counterweights on the wheel help stabilizing Z.

Configuration: I found defining the C parameter of M669 very useful, because it automatically defines the print area and avoids damage. Finding the precise angle for the B parameter is tricky.

It is a real pleasure to use Duet's possibility to directly change settings on the fly and try different ideas.

-

@JoergS5 Fantastic! Looks very hacky in a RepStrap kind of way. Love it!

Ian

-

@droftarts I've learned a lot by iterating the different possibilities. And by using wood there is no waste, will become firewood.

-

Before I loose it, here is my configuration of Prototype 1:

Duet 2 Wifi 1.03, RRF 3.01-RC4, DWC 2.07

Steppers: 1.8 degree 17HS19

Stepper teeth 16, big wheels diameter 300 mm, 6 mm GT2 fiberglas

Endstops XSS-5GL with closed position while not activated

home5barscara.g

config.g -

I've tested now some movements. Negative degrees are no problem, and I changed the arm form to extend possible angles a few degrees. The left arm is lying on the surface of the big wheel, which helps stabilizing Z. I will possibly keep this gliding mechanism. Other improvements are better hinges with ball bearings and good mechanical endstops. One problem is that the arms often come up against the vertical extrusion, so I will move the extusions behind the wheels. A minor improvement is to stabilize the "hotend" and using closed belts. The curved lines are when the distal arms approach singularity (small angle between them).

An image of the currect install. I've shortended the distal arms to 30 cm, the printable area is now about 50x20 cm.

The next step is introduction of the hotend and reconstruction of the upper axis stabilizer and a better adjustment of the big wheels.

The config look like this now:

config.g home5barscara.g -

There is a bug in the current code that you might encounter. I have fixed it but not yet committed it.

The angle logic has some strange cases related to IsContinuousRotationAxis(), if you do a move that would have to move an arm more than 180 degrees it may take the shorter "back route", ignoring the angle limits.

I implemented some logic similar to what is in the serial scara. If your angle limits for the proximal joints are >360 degrees it will allow the "back route" shortcuts, i.e. IsContinuousRotationAxis() returns true. -

@bondus yes I experienced the bug by crashing

I am aware that you committed the change some time ago, thank you for doing this.

I am aware that you committed the change some time ago, thank you for doing this. -

@JoergS5 That "bugfix" was not a good bugfix. It fixed some things, broke others.

Interesting machine you have built. The long distal arms allows you to make strange poses, like the one in the picture.

-

@bondus The angles are left "proximal" arm (wheel) from 242 to >90 degree and right proximal from -52 (ie 308) to 90 degree, and the kinematics are ok for workmode 2. I'll optimize the arm forms further so they "wind around the wheel" axis a lot more.

-

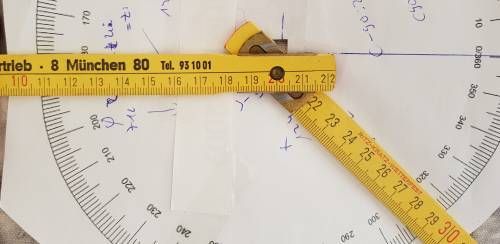

BTW I measure the angles the following way: axis diameters for wheels and hinge the same 8 mm, measuring the angle in two steps are exact for about one degree:

(angle bevel, german: Schmiege)

-

@JoergS5 The old tool I made a while back that draws the work areas and shows the arm is quite useful when you want to pick arm lengths and work modes.

https://github.com/bondus/5barscara/tree/master/JS

Clone it and open test.html in your browser. Some options are in the GUI and others have to be modified in scara.js. It will push your browser to it's limits, it's a hack. -

@bondus Thanks a lot for the link, I searched it a few days ago and didn't find it.

-

undefined JoergS5 referenced this topic

undefined JoergS5 referenced this topic