Issues with print quality, wall surface rough.

-

@Phaedrux I've replaced both

-

@Corexy I will check out the reprap forums too! Should have build a voron, or a railcore....

-

@CorvoDewittV2 said in Issues with print quality, wall surface rough.:

@Corexy I will check out the reprap forums too! Should have build a voron, or a railcore....

That might not be totally fair...there's a bunch of V cores out there (and here).

Just keep going over it, you'll get it. 3D printing is a total pain in the arse on its best day, they are fickle machines.

Use those settings and let's see some pics.. Those prints aren't that bad. I've seen plenty worse on here.

-

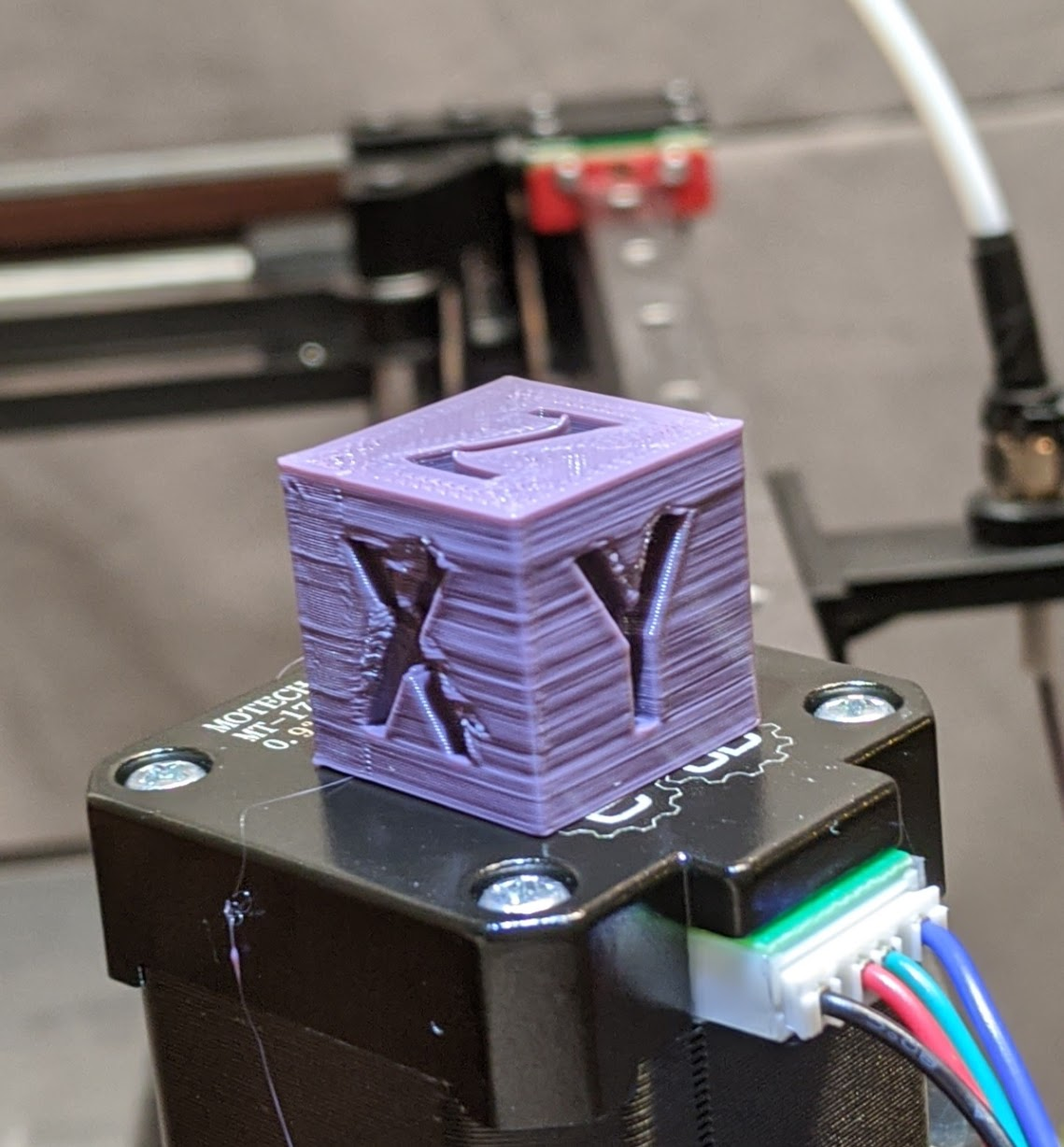

Its just for the money I've spent tying to solve this, it should be better. I am wondering if the lead screws or nuts are bad. I started a print before I left for work with a cube right next to each lead screw, to see if its better or worse by one. We will see. I also had forgot spacers inside the idle pulleys between the bearings, but reassembled that properly, no difference. I am running out of things to change. Maybe I need to change our the printed parts? The only printed parts are the ones that hold the idle pulleys, maybe I should print them out of something other then PETG. I mean that's what they suggest, but I am really running out of things to try. I could try swapping around some of the Z axis motors too. I tried a lower current for the extruder, no difference. What jerk and acceleration should I be using for a genuine e3d Titan?

-

Did you do a temp tower test? Also did you look into moving the fans down a bit? I think they’re blowing right in the heat block.

Since you’re closer on temps and resolved the backlash nut issues, It might be to do another test with the fans off.

If you have a the step or stl files for your hotend, please post them and I’ll design proper ducts for you.

-

@mwolter OMG really?????? That would be amazing. I tried with like 40% fan but it didn't look better, ill try with no fan tonight, and post the step files. I went with the 40x10 fans to keep the hotend as small as possible, but I also would be fine with losing a bit of print volume for a better cooling solution. Thank you so much!!!

Edit: Yeah I have done temp towers, 200-230 all kinda look the same.

-

-

@mwolter @Corexy I am also using these, do you think that is a problem? I will try the stock spring type when I get home. Maybe I should try printing some too.

https://www.amazon.com/Befenybay-Aluminium-Flexible-Coupling-Connector/dp/B07RMZCLZ3/ref=sr_1_3?dchild=1&keywords=3d+printer+coupling&qid=1594218589&sr=8-3 -

@CorvoDewittV2 personally I prefer the solid couplers. They provide more support and are typically more axially concentric. IMO spring or spider (like in your link) couplers are only used to make up for design or construction flaws.

-

@mwolter I'll try printing some solid ones as my lead screws are straight and aligned. 5 walls of PETG should be good?

-

-

Have you tried those settings yet? I'd do that before you work on it mechanically.

One trick I've found with PETG is that if you are getting blobs building up on the nozzle tip, drop the extrusion multiplier (not the esteps) until it stops happening. PETG prefers to be slightly under extruded.

I've got those same plum couplings on my other printers and haven't had any problems with them. Why did you change them from the standard ones anyway?

I've got nothing else I can tell you from the information you've given until you do the steps I listed on post some pics. Best you do the same cube an benchy for comparison. Definitely there's some Z wobble there, but lets see it without the over extrusion first.

-

@Corexy Not yet I am still at work, ill be home in 2 hours. I just though spring ones were dumb, I changed them when I build the thing, IDK if I even printed much of anything with the stock couplings. Do you think the 0.9 deg motors would cause an issue on the XY?

-

@CorvoDewittV2 said in Issues with print quality, wall surface rough.:

@Corexy Not yet I am still at work, ill be home in 2 hours. I just though spring ones were dumb, I changed them when I build the thing, IDK if I even printed much of anything with the stock couplings. Do you think the 0.9 deg motors would cause an issue on the XY?

0.9 deg motors are supposed to be the correct ones to use for X and Y, Z as well I am told.

You need to run all of your steppers at 75-85% of their rated current. That's the done thing apparently, and is better than guessing.

I haven't seen what your fan duct is doing, but it is definitely not good to have it blowing on the heater block.

Let's see how those prints work out, and take it from there.

-

@Corexy Ok thank you, I'll get back to you soon

-

@mwolter Here are the step files, thanks again!!!

Front Cover.STEP

Main Carriage TITAN.STEP

BLTouch mount for V2.STEP

fan mount 2.STEP

-

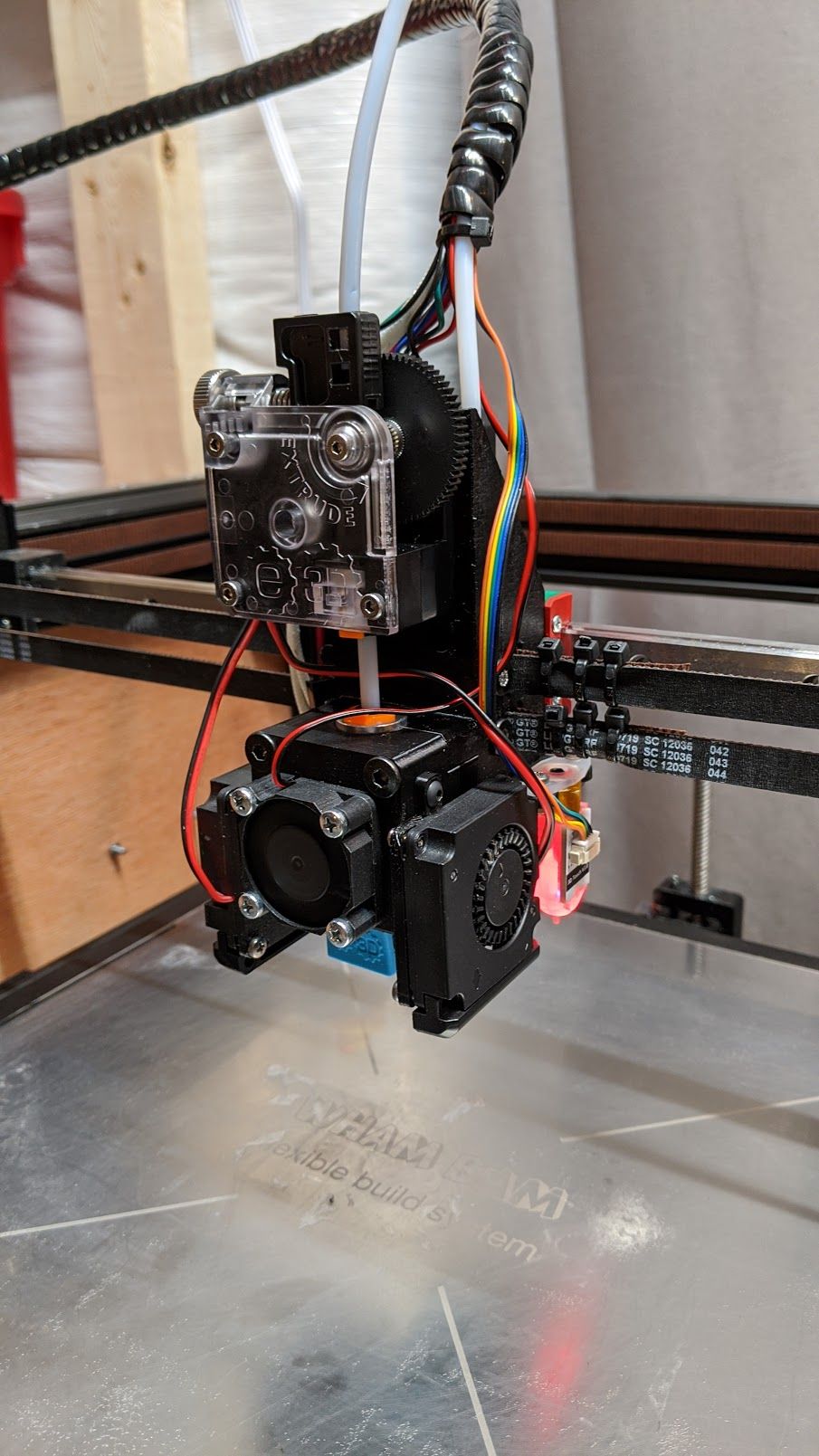

From this pic it doesn't seem that the fan is blatantly blowing on the heat block, and you've got a silicone cover on it as well. Sure you could certainly have a better fan shroud, but I don't think it's a major cause of any problems. I'd stick with the 40x10 blowers myself, but I tend to use as little fan as possible in my prints. I generally go with 10-20% fan on materials like PLA/PETG, and with the exception of bridging never go over 60%.

It would be nice to print some sort of U shaped cover to go over the doubled sections of belt, then use a cable tie to hold it in place. Nothing to do with print quality, but would jut be a nicer fit and finish.

I'm happy with my choice of a Bondtech BMG for my V-core printer. I'm a bit unsure about that E3D one, just looking at it.

-

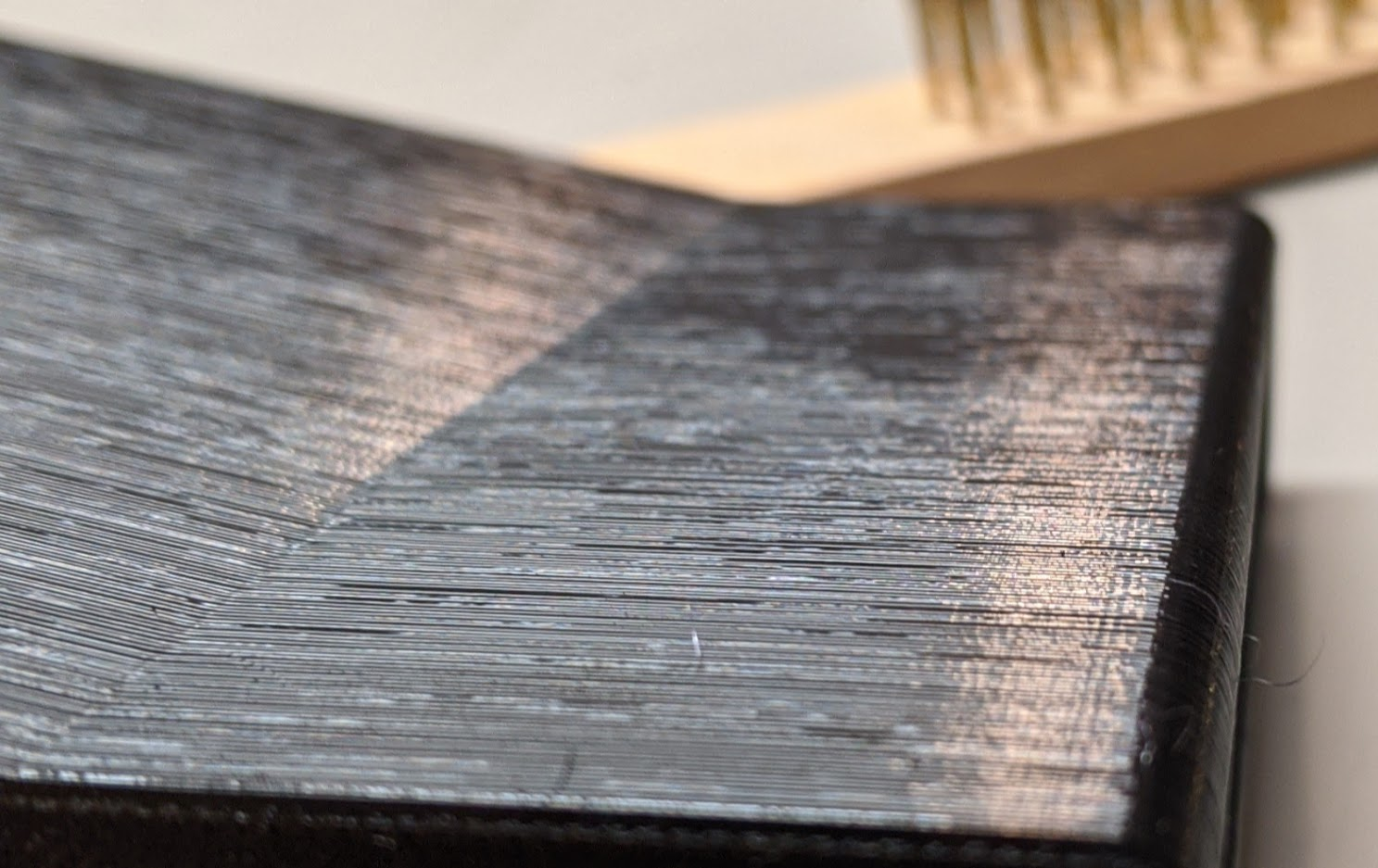

@Corexy So i ran with you setting (but 30% fan bc they won't spin at 20%) and its...different. the blobby nature is gone, but the z wobble is worse? What do you think?

-

Wow! That looks awful.

OK...so that's after you set the esteps?

What extrusion multiplier are you running in the slicer?

I'm a bit blown away by the curling of the corners on the top surfaces...I've never had that happen. It looks like a combination of over extruding and too much heat.

It would appear that the coast/retraction settings aren't working for that setup. Try removing the coast altogether ans dropping retraction to 0.5mm please.

Again, let's just leave the Z wobble for now and get the extrusion/retraction/temp right.

**EDIT.

I'd drop the extrusion multiplier to 90%/0.9 now as well as above comments.

I'd also leave the fan setting and drop 5 deg C on both first and second layers respectively.

This will be a slow process, but at least we can see the differences as we try things.

-

@Corexy It sure does look awful! lol Yes that is after checking the esteps (within 0.1mm of 100mm at 1mm/s) and 94% flow rate, 30mm/s and all the settings you told me to do earlier. Sooo....now what? I can try lowering the fans as low as possible and do like 60% fan.