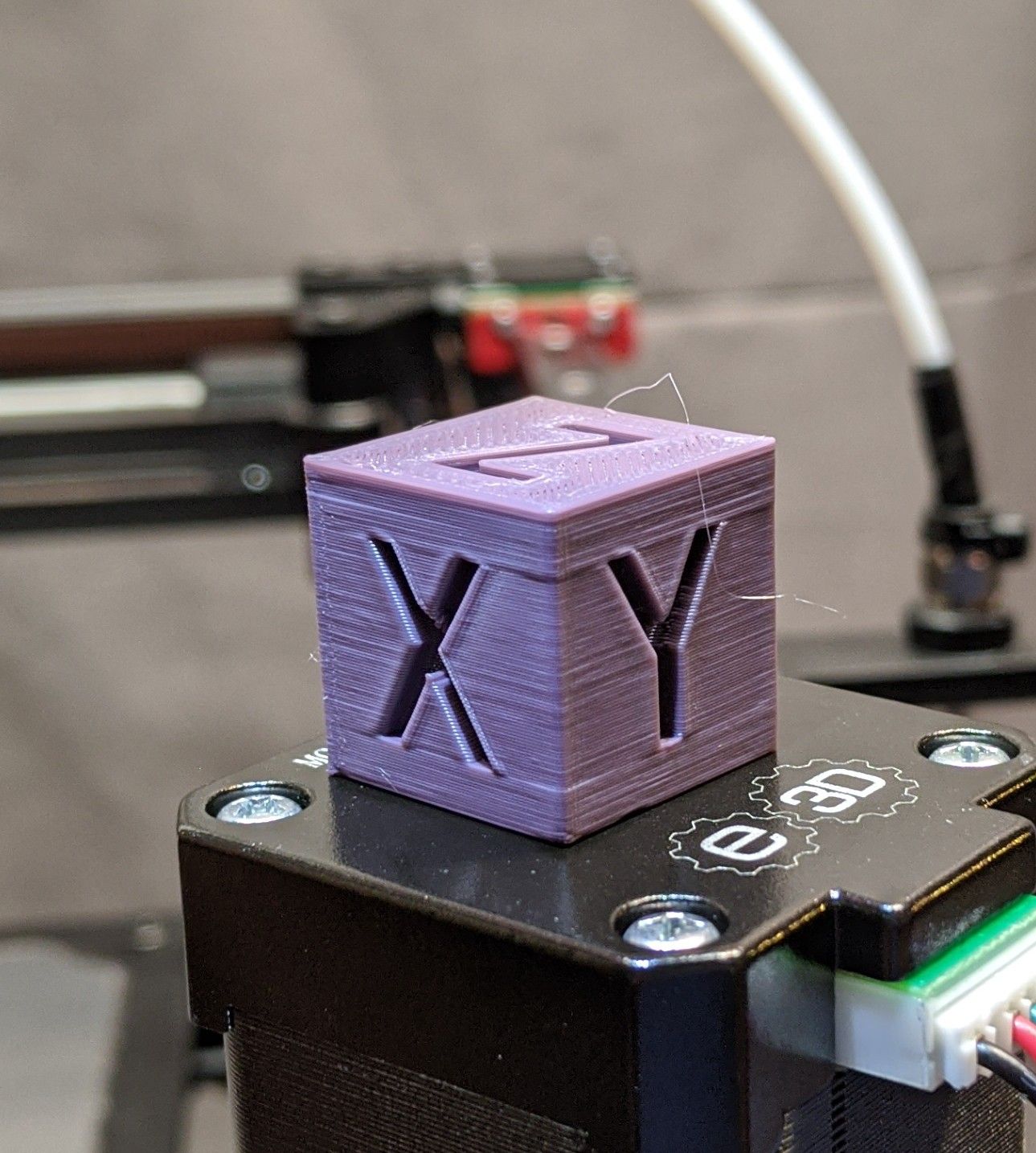

Issues with print quality, wall surface rough.

-

To me, the 220 107% print is bulging and looks melted. Like a marshmallow.

-

I had a similar issue on a machine that showed vertical walls like in your picture. In my case, my extruder current was my issue. I increased my current from 600mA to 800mA in config.g and that took care of the weird striping issues. I'm assuming the backpressure inside the nozzle caused it to over/under extrude on a regular basis creating the bulging.

It's an easy test to increase your extruder motor current and then print again. Just something I've experienced with similar results as in your picture.

-

Have you PID tuned the bed and hot end heaters?

-

@PDBeal I will try that when I get home!

-

@Phaedrux Yep, temp is very stable, about +/-0.6c

-

@mwolter not as tasty tho haha, I'm probably printing too hot then. I'll go down to 205? 195 felt a bit weak to me.

-

I might try swapping out the backlash nuts for regular nuts and seeing if it's a binding issue.

-

@Phaedrux Can I just back off the backlash adjustors? They are this style nut :

https://openbuildspartstore.com/anti-backlash-nut-block-for-8mm-metric-acme-lead-screw/ -

Well here is 950mA on the extruder, temp 205. Really starting to think it's an extruder problem again:

-

Or... It's a z problem... Backed off the antibacklash nuts, same setting as last posts

-

I think it's a mechanical issue relating to the Z axis.

You are certainly over extruding in most of these pics, but 0.93-0.95 has always been the right extrusion multiplier for PLA for me....IF the esteps are set correctly. I always set my esteps through a nozzle at the temp I intend to print at. Usually at 195-205 deg for PLA, maybe just try a round number of 200. Set your esteps using a full 100mm extrude @ 5mm/sec, not just 20mm.

I didn't read what slicer you used, but for direct drive in S3D I just use 1mm retraction @30mm/sec, 1mm coast and 5mm wipe. Nice and simple.

In the V-core, I'd loosen all the mounts for the backlash nuts, Z steppers and even the rails, then push the bed up and down by hand to align it all. Keep doing that as you nip things up tighter, a look for any binding at all. I'd level the bed mechanically using a 0.2mm feeler gauge under the nozzle, with the bed and nozzle at temp (200 noz/ 50 bed) and check the backlash nuts are very lightly/evenly tensioned, as well as lubricated.

If you can get the bed pretty level mechanically, maybe disable the bed leveling mesh map and just set a nozzle height/offset at the start of the print. If you're using the triple Z motors that might be giving you some sort of trouble.

In short, there are some extrusion rate/slicer setting issues there, but that Z banding looks mechanical to me.

Hope that helps.

-

@Corexy Thank you for the info, I will try that tonight after work. I really don't like the design of the Z axis on the V-Core, leaves a lot to be desired in my mind. Also not a huge fan of lead screws. Do you use wipe and coast with linear advance? I heard that they do not play well. My bed is a bit of a banana, but flat enough to do a 20x20 cube, so I could try no bed leveling. If you have any design suggestions for a better Z, please let me know! What do you think is causing the bulging right above and below the X and Y? Cooling? Or still Z related.

OH could it be bad idle pulleys? It's the only thing I haven't changed in the XY system.

-

@CorvoDewittV2 said in Issues with print quality, wall surface rough.:

@Corexy Thank you for the info, I will try that tonight after work. I really don't like the design of the Z axis on the V-Core, leaves a lot to be desired in my mind. Also not a huge fan of lead screws. Do you use wipe and coast with linear advance? I heard that they do not play well. My bed is a bit of a banana, but flat enough to do a 20x20 cube, so I could try no bed leveling. If you have any design suggestions for a better Z, please let me know! What do you think is causing the bulging right above and below the X and Y? Cooling? Or still Z related.

OH could it be bad idle pulleys? It's the only thing I haven't changed in the XY system.

I don't use linear advance, just the settings I've described above. I really focus on esteps, and set extrusion multiplier by watching actual prints I'm doing, not measuring thin walls etc.

I don't like the way they set up the z axis on the V-core's either, and have already taken steps to do mine differently, including a conversion to single Z motor with a belt driving all 3 screws.

My bed is a banana too, which is why I'll probably convert to a cast aluminium plate.

I think the bulging is from the issues I mentioned, best start there. If you can switch off the bed leveling and print this little model on a flat bit, you can try those old school setting first. You could have a look at the current setting for your extruder motor. Sometimes too high a current there can cause print issues, but it's usually a wavy looking pattern on the surface.

- Do the loosening/tightening of Z components mentioned above.

- Set extruder current.

- Poke a correct size cleaning wire into the hot nozzle, just to be sure.

- Set esteps carefully using 100mm extrusion @ 5mm/sec

- Set slicer at 0.94 extrusion multiplier, 30mm/sec print speed, 1mm retraction, 1mm coast.

- First layer 205/55, zero fan. Second layer 195/50 20% fan.

Don't buy new parts, it's most likely assembly and slicer settings. Try that first.

Hope that helps again

-

@CorvoDewittV2 Did you buy it as a kit ? Did you ask them (where you bought it from or the guys who designed it) if the have experience with this issues ? Perhaps it is a common issue and they know the most common cause in their design that can cause it.

-

@Corexy Thank you for the advice! I went through the Z axis very carefully, and made no change to the print quality

I will try those setting tomorrow! I will also try a lower extruder current, cause why not at this point lol. You said you have a V-Core, how did you set it up so it works as intended???? I've been at this for 2 months and have made little change!!! Thanks again!

I will try those setting tomorrow! I will also try a lower extruder current, cause why not at this point lol. You said you have a V-Core, how did you set it up so it works as intended???? I've been at this for 2 months and have made little change!!! Thanks again! -

@Scachi They have a Facebook group I have been posting in, with no help from the mods. One guy has actually been helping a lot, we are still chit-chatting about this thing. I really don't understand why I am having such an issue. It's so frustrating.

-

@CorvoDewittV2 said in Issues with print quality, wall surface rough.:

@Corexy Thank you for the advice! I went through the Z axis very carefully, and made no change to the print quality

I will try those setting tomorrow! I will also try a lower extruder current, cause why not at this point lol. You said you have a V-Core, how did you set it up so it works as intended???? I've been at this for 2 months and have made little change!!! Thanks again!

I will try those setting tomorrow! I will also try a lower extruder current, cause why not at this point lol. You said you have a V-Core, how did you set it up so it works as intended???? I've been at this for 2 months and have made little change!!! Thanks again!Mine's still new in the box, untouched. Been to busy with work and a house reno job to start it.

I have preemptively ordered some bits to do the Z axis and bed how I want though, and will start a build thread when I kick it off.

-

@CorvoDewittV2 said in Issues with print quality, wall surface rough.:

@Scachi They have a Facebook group I have been posting in, with no help from the mods. One guy has actually been helping a lot, we are still chit-chatting about this thing. I really don't understand why I am having such an issue. It's so frustrating.

It's certainly not a kit to learn on, moreso a base on which to start an advanced build I'd say.

I must say it's smart of them to stick with selling the mechanical bits rather than a finished printer, as it removes a lot of responsibility for print quality etc.

You might try posting in the reprap forums "corexy" section, as there's a few experts available there too.

-

Worn nozzle or PTFE tube perhaps?

-

@Phaedrux I've replaced both