Feature Request - workpiece angle compensation CNC

-

I am using RRF on a fairly big CNC.

There will be times when I want to cut parts using material that is the correct dimensions in one or two directions. Its also going to be difficult to position the material perpendicular to the X or Y axis.So the request is the ability to probe the material on one or two axis and angle/skew the gcode accordingly.

Here's an example of how HAAS do it https://www.youtube.com/watch?v=amWolMgEM-Q

-

The first thing we would need to do is implement G68 and G69. Looks like there are (at least) two different forms of syntax for G68 (Fanuc and Mach3), however it would be possible to support both because their parameters don't conflict.

After that, a probing cycle to calculate the rotation would be needed. Rather than define a new G-code to do this, I think it could be done in a macro using conditional GCode.

I'll add supporting G68 and G69 to the RRF 3.3 work list.

-

@jay_s_uk I am not 100% if

M556Axis skew compensation could achieve the angle compensation but if so then you could get away with a combination ofG38.xto find the locations,G60to save those points and some arithmetic to calculate the required angles. -

i know this thread is already mor then 1 year old but is there any progress in adding the G68/G69 ?

Or is there an other option to set the rotation of the workpiece? I consider to upgrade my CNC to a Duet but this is very important function.

-

@jrentschler01

We wont be adding more new features to 3.4 so this will be under consideration for 3.5. -

@jay_s_uk @jrentschler01 it appears that G69 cancels any current coordinate rotation; however I can't find a precise definition for G68 because it isn't NIST-standard. Here are some questions:

- Is it acceptable to support rotation only in the XY plane? That's all Mach3 seems to support, although Fanuc supports rotation in any plane.

- If you have coordinate rotation in force and you issue a G17/18/19 command, what happens? Stop the job with an error? Or cancel the coordinate rotation?

- There appear to be two conventions about how to specify the coordinates of the centre of rotation. Fanuc uses the two coordinate letters depending on which plane is selected (e.g. X and Y). Mach3 always uses A and B. Any preference? Or should we support both?

- If I do an initial implementation, would you be able to test it? You would need to test: G0 G1 G2 G3, interaction with G17/18/19, and the reporting of the rotation in the object model.

-

- I would be happy with just X and Y rotation.

- I have not yet made use of G17/18/19

- Both notations would be the best of both worlds but I don't know how easily that could be implemented

- Yes, I would be in a position to test this. I would of course have to ask @gloomyandy to provide me with a build as my CNC runs on an SKR Pro

-

@dc42 Yes the XY plane is all I need because if you want do somthing precise you need to know the exact position (with rotation) of the work piece in xy plane.

I don't really care wich command its neccesarry to use for it if we can acomplish it with G17 its fine. But it should be nothing that we have program in the Postprocessor bcs at this time we don't know how the workpiece will be at the table.

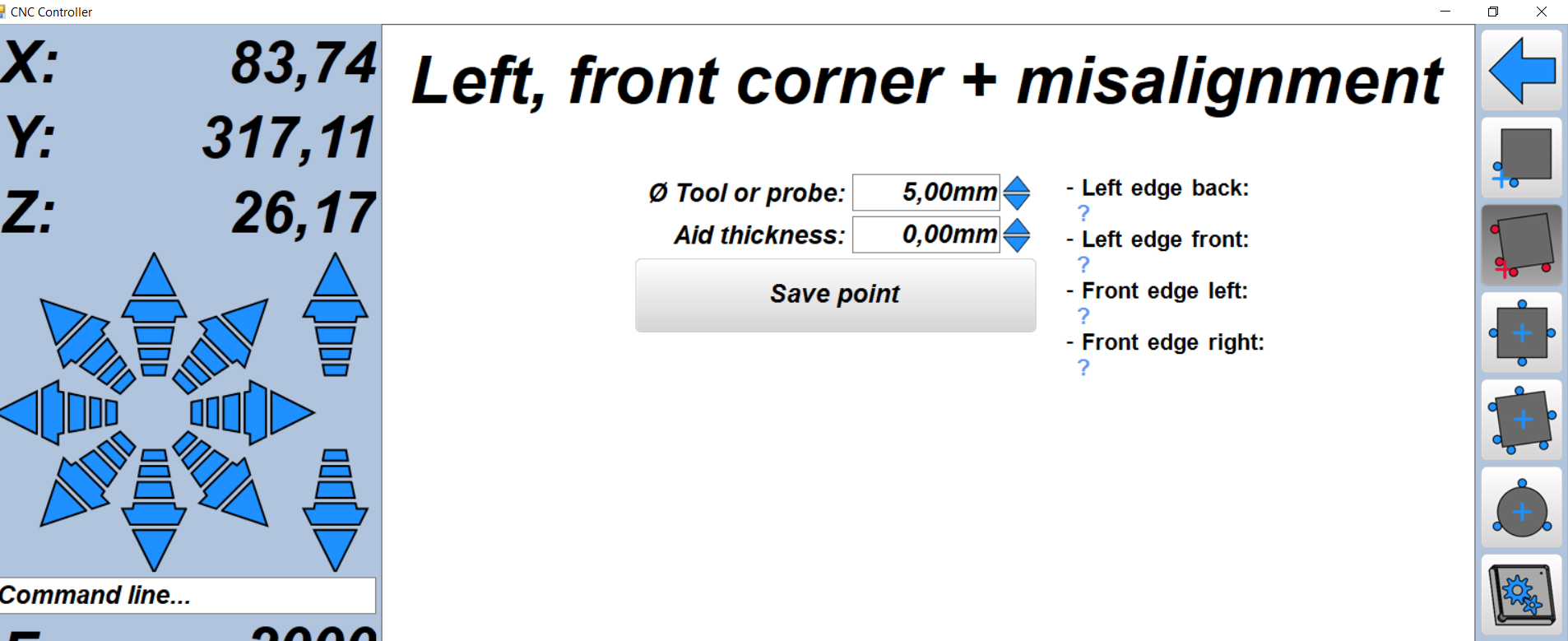

I used Estelcam as CNC conroller (and Fusion 360 for CAM) but right now I'm doing a upgrade with new electronics and I have a duet2 here that im going to hook up and it should be done by end of the week to run first tests. But I got concerned when I didn't find a method to input the workpiece rotation like I was able to do it in Estelcam:

Sure the edge probing could be done in a macro an the calculate the xy 0 and the rotation.

Do you think that's possible with G17? I would be able to test it.

-

@jrentschler01 let me know when you are ready to test this feature, then I will provide you with an internal build of RRF. Which Duet do you have?

-

@dc42 duet2 wifi with fw 3.3

-

@jrentschler01 There is a test build here: https://www.dropbox.com/sh/xeu30go894p9xbs/AAB5U66SH4wbjKIcX0snUbKxa?dl=0

If you are not already running 3.4b5 please upgrade to that before upgrading to this (and check the upgrade notes).Note this is untested so proceed with caution.

-

@t3p3tony said in Feature Request - workpiece angle compensation CNC:

the

@T3P3Tony Thank you I'm close to start to test, wiring tooks a little longer but I hope I should have everthing running by tomorrow.

But how should be the procedure for the compensation? -

@jrentschler01 i've written a macro.

this in theory should work but I haven't tested it yet.var y_first_measurement = 0 var y_second_measurement = 0 var y_length = 0 var x_first_measurement = 0 var x_second_measurement = 0 var x_length = 0 var y_over_x = 0 var y_x_tan_rads = 0 var y_x_tan_deg = 0 M291 P"Put the probe on the left hand side of the bottom edge" S2 X1 Y1 Z1 ; Pop up box asking for operator input M558 F1500 ; Set the initial probing speed G38.2 Y600 P0 K0 ; Probe the material as a first pass G1 Y{move.axes[1].machinePosition-5} ; Move 5mm away from the material M558 F150 ; Set the final probing speed G38.2 Y600 P0 K0 ; Probe the material again M400 ; Make sure all movement is complete set var.y_first_measurement=move.axes[1].machinePosition ; Record the stop position y_first_measurement set var.x_first_measurement=move.axes[0].machinePosition ; Record the stop position x_first_measurement M400 ; Make sure all data recording is complete G1 Y{move.axes[1].machinePosition-5} ; Move 5mm away from the material G1 X{move.axes[0].machinePosition+50} ; Move along the workpiece in X M558 F1500 ; Set the initial probing speed G38.2 Y600 P0 K0 ; Probe the material as a first pass G1 Y{move.axes[1].machinePosition-5} ; Move 5mm away from the material M558 F150 ; Set the final probing speed G38.2 Y600 P0 K0 ; Probe the material again M400 ; Make sure all movement is complete set var.y_second_measurement=move.axes[1].machinePosition ; Record the stop position y_second_measurement set var.x_second_measurement=move.axes[0].machinePosition ; Record the stop position x_second_measurement M400 ; Make sure all data recording is complete set var.y_length={var.y_second_measurement-var.y_first_measurement} set var.x_length={var.x_second_measurement-var.x_first_measurement} set var.y_over_x={var.y_length/var.x_length} set var.y_x_tan_rads=atan(var.y_over_x) set var.y_x_tan_deg=degrees(var.y_x_tan_rads) G68 A0 B0 R{var.y_x_tan_deg}Now this will ask you to jog to the bottom edge of your material, ideally you should go to somewhere near the bottom left.

This is of course assuming you're using a probe that can probe in X, Y and Z and its set as K0. I use a vers.by probe.

It uses G38.2 and stores the X and Y coordinates of each point. Once it probes the first point, it moves 50mm in X and probes again.

The angle is then calculated and fed into G68.

If you don't want to set it that way, its set usingG68 Ax Bx Rxwhere Ax is the centre point to rotate around in X, Bx is the centre point to rotate around in Y and Rx is the angle to offset and is counterclockwise -

After days of reading through this forum I managed now to get my machine wokring somehow but there are still a lot off issues that i found with using the duet as CNC Controller. But I guess I should put this in a seperate thread, right?

@t3p3tony But now I was able to test the angle compensation, I was a little confused with the other threads that I thought you will do it differently then the G68 command that's why I asked for the procedure.

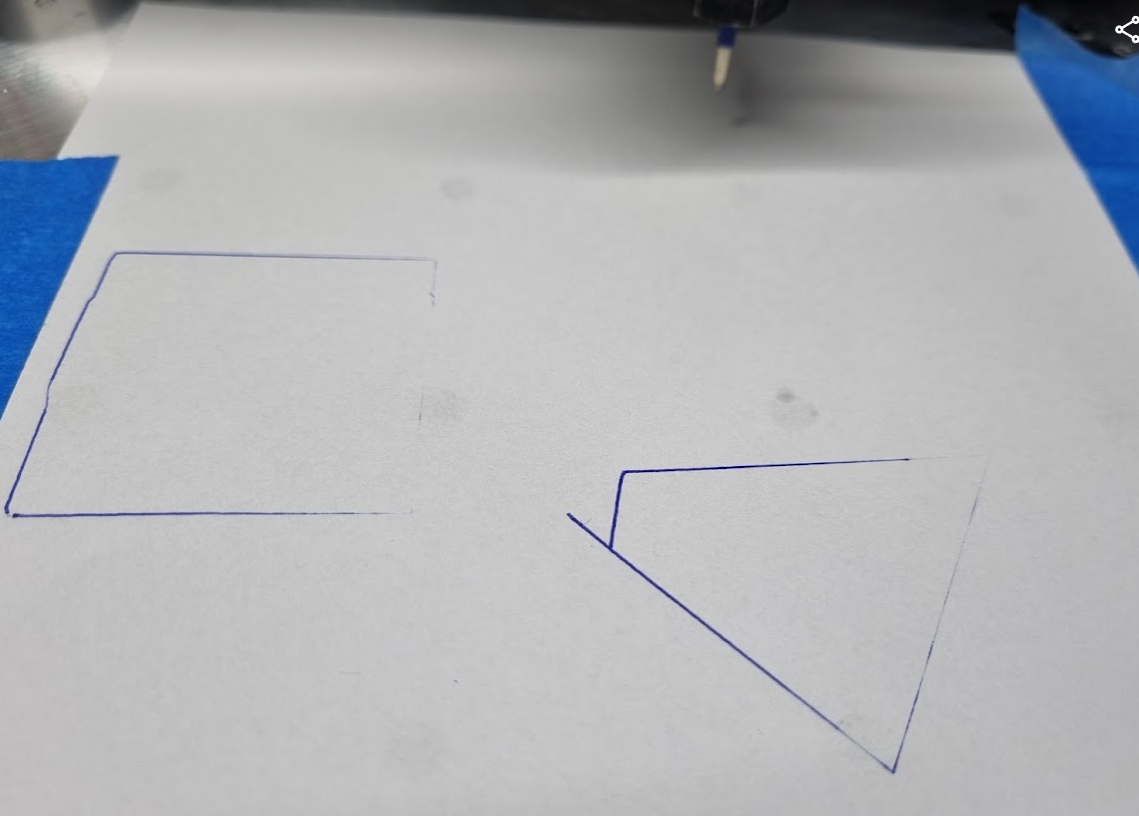

I tryed it with the RRF 3.4b5 in the link and the G68 command but it was a fail. Here is what I did:I drawed a simple rectangle with this G-Code

;simple rectangle for test G90 G21 G1 F500 G1 X50 G1 Y50 G1 X0 G1 Y0Then I just moved the X Work offset +70 and entered

G68 A0 B0 R45

and run the same G-Code again but the result was far away from what I expected:

the left rectange is normal without G68 and the right one is with the 68.I think just the first move looks right with the 45° angle. What could be the Problem?

-

@jrentschler01 i am not sure, it will take me quite some time to get setup to test this right now so i wonder if @jay_s_uk has had a chance to test it and if its working for him?

-

@t3p3tony not had a chance to test it yet. I'll see if I can set something up later on

-

@jay_s_uk do you think you can help in this?

Let me know if you you guys need more information or anthing I should test.I knkow i needed quite some time to get ready but I'm not sure how long I keep this setup with the duet because this will be one of the essential functions I need and some other issues that I faced with using RepRap for CNC. I might moving on to linuxcnc soon.

-

@jrentschler01 maybe post about your other issues?

-

@jrentschler01 I confirm, G68 is not working properly. I'm looking at it now.

-

undefined jrentschler01 referenced this topic

undefined jrentschler01 referenced this topic

-

undefined jrentschler01 referenced this topic

undefined jrentschler01 referenced this topic

-

undefined jrentschler01 referenced this topic

undefined jrentschler01 referenced this topic

-

@jay_s_uk I did in a seperate thread:

https://forum.duet3d.com/topic/25848/found-issues-using-duet-as-cnc-controller