Problem setting up core XY

-

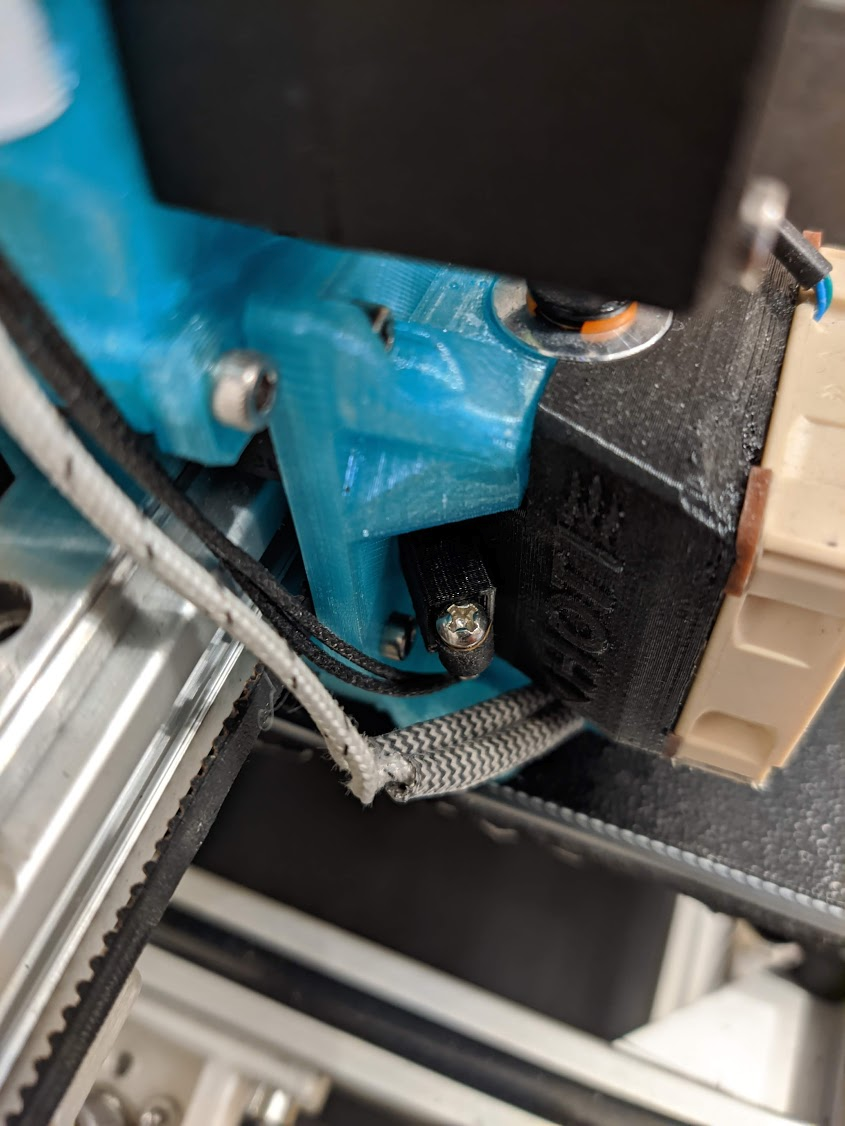

Here are static photos of the machine and the setup of a BLV CUBE. I am working on videos of the problem

-

One thing that's obvious from the first photo is that the belt running from the left end of the X axis to the extruder carriage (fixed with a purple zip-tie) is not parallel to the X axis guide rail. Are you sure the belt is anchored to the right spot on the carriage? Can you take a picture looking down on the machine, showing the entire corexy mechanism?

That type of error will at the least cause belt tension to vary with the extruder carriage position, and may create more problems than that depending on how far out of parallel it is. If you tensioned the belts and movement makes them get tighter, your motors may skip steps because the tension becomes too high. It's also possible for belt to slip on the drive pulley if the tension goes the other way when the extruder carriage moves. The belt tension should be constant no matter where the extruder carriage is in XY space. That is accomplished by keeping the belts parallel to the guide rails. See: https://drmrehorst.blogspot.com/2018/08/corexy-mechanism-layout-and-belt.html

Was that a kit? Make sure you assembled it correctly, and if it's right, I suggest you demand your money back!

-

@mrehorstdmd said in Problem setting up core XY:

if it's right, I suggest you demand your money back!

the original blv had a slight problem with that. but in this kit its very bad.

there is an original metal kit

https://www.aliexpress.com/item/1005001323243487.html

that does not have that problem -

@Veti I was wondering if there was a problem with the parts I purchased from a supplier in China BLV Does not promote that supplier anymore.

-

Does @mmartin == @william3d or are there two different machines/problems/people here?

-

A lot of great comments and information and I appreciate the time that everyone is put into helping me solve this issue. I'm continuing to read through and try everything everyone said I am continuing to have the same issue where I cannot move either X or Y By themselves The web controller shows example X25 Y25 I move to X25 Y200 The web controller shows X25 Y200 but You can tell X has moved to 150 and Y is at 200.

-

@william3d

can you post a picture of the x carriage from the side. -

@mrehorstdmd Just me and my core XY cube build

-

@william3d said in Problem setting up core XY:

I move to X25 Y200

what is the exact command you issued?

-

-

@Veti G1 X25 Y250

G1 H0 X25 Y250

H1

H2

AND

G0 X25 Y250These are some of the formats I've tried and I have not used the H3.

-

@william3d said in Problem setting up core XY:

G0 X25 Y250

This is the correct one.

For movement tests with positions leave out the H part completely

Post the output of M669

-

@mmartin said in Problem setting up core XY:

Does Cura automatically use my bed leveling mesh or do I need to run it in the starting Gcode?

You need to load the saved mesh or re-probe the entire bed before the print is started. This means adding G29 S1 to the slicer start gcode after the G28 that homes the printer.

-

here is a crude fix for your belt problem.

run the belt through the hole from behind and have a loop out in front.

put a bolt (a large screw or something) through the loop to stop the belt from pulling out.here is a fix i did for this on the plastic parts

-

@Phaedrux

he posted in this thread by accident. -

@Veti said in Problem setting up core XY:

@Phaedrux

he posted in this thread by accident.Oh well, I still answered on purpose.

-

@Phaedrux is there a way to add bed heat before the homing and also bed probing? My sensor needs the bed to be heated to produce accurate results. I've been doing it manually but it would be nice to automate this process as well.

-

@mmartin

please dont hijack other peoples threads with different probems. -

@Veti ummmm ok...

-

it gets confusing.

as you can see you already confused @mrehorstdmd