Problem setting up core XY

-

@william3d said in Problem setting up core XY:

G0 X25 Y250

This is the correct one.

For movement tests with positions leave out the H part completely

Post the output of M669

-

@mmartin said in Problem setting up core XY:

Does Cura automatically use my bed leveling mesh or do I need to run it in the starting Gcode?

You need to load the saved mesh or re-probe the entire bed before the print is started. This means adding G29 S1 to the slicer start gcode after the G28 that homes the printer.

-

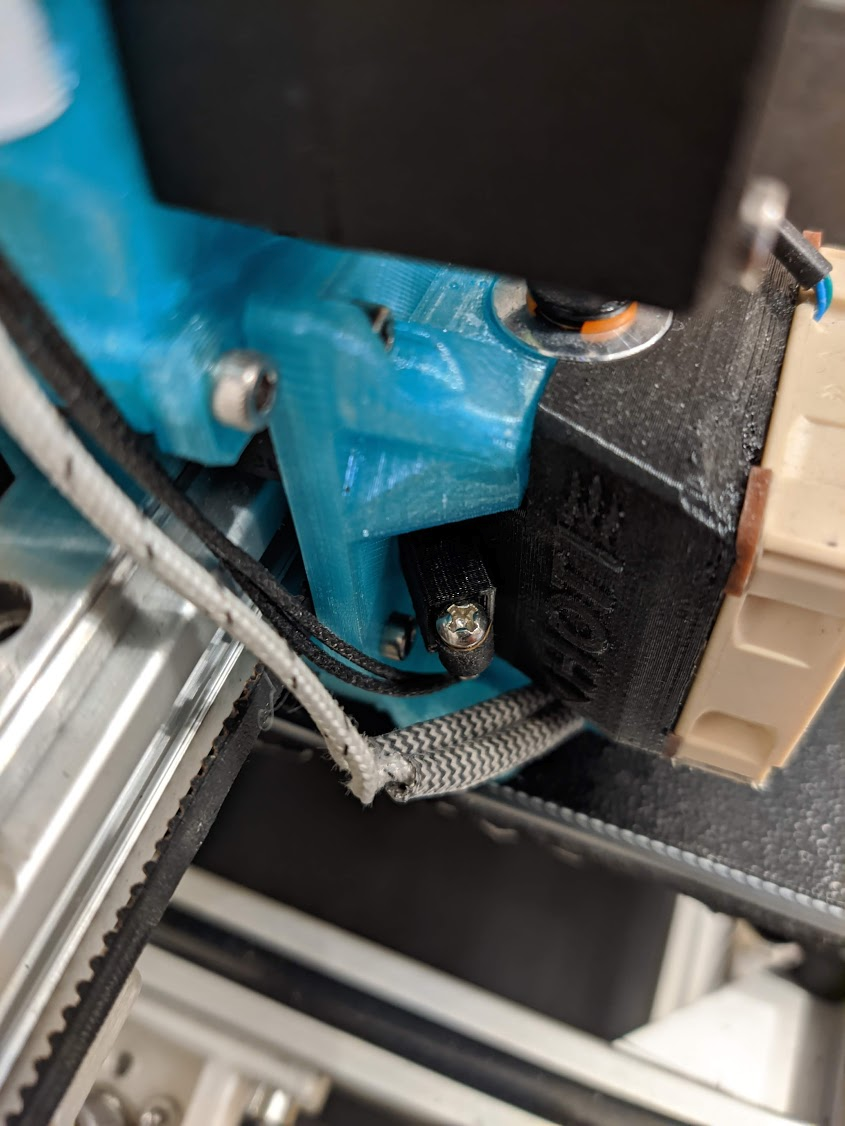

here is a crude fix for your belt problem.

run the belt through the hole from behind and have a loop out in front.

put a bolt (a large screw or something) through the loop to stop the belt from pulling out.here is a fix i did for this on the plastic parts

-

@Phaedrux

he posted in this thread by accident. -

@Veti said in Problem setting up core XY:

@Phaedrux

he posted in this thread by accident.Oh well, I still answered on purpose.

-

@Phaedrux is there a way to add bed heat before the homing and also bed probing? My sensor needs the bed to be heated to produce accurate results. I've been doing it manually but it would be nice to automate this process as well.

-

@mmartin

please dont hijack other peoples threads with different probems. -

@Veti ummmm ok...

-

it gets confusing.

as you can see you already confused @mrehorstdmd -

@Veti said in Problem setting up core XY:

My original reply was within context of his post about the bed origins. Regardless have a good one!

-

@Veti M669

Kinematics is CoreXY, matrix:

1.00 1.00 0

1.00 -1.00 0

0 0 1.00 -

can you move any of the belts by hand while the motors are energised ?

-

@Veti When the motors are on After homing and energized I cannot move by hand

-

I'm easily confused.

The belt angles don't look so bad from above.

What are the motor specs?

-

@william3d said in Problem setting up core XY:

X Moves correctly

Y Moves correctlyThe web controller shows example X25 Y25 I move to X25 Y200 The web controller shows X25 Y200 but You can tell X has moved to 150 and Y is at 200.

i am also getting confused as this does not match

could you please restate your problem.

stating exactly which command you are issuing. -

@william3d said in Problem setting up core XY:

M92 X160.00 Y160.00

a normal blv setup has 16 tooth pulley which would give you X200 Y200

are you sure both motors are 0.9 degrees? if one is 1.8 that could give very strange results.

-

@mrehorstdmd

Electrical Specification

Bipolar/Unipolar Bipolar

Holding Torque(Ncm) 46

Holding Torque(oz.in) 65.1

Inductance(mH) 3

Phase Resistance(ohm) 1.4

Rated Current(A) 2

Step Angle(°) 0.9

Physical Specification

Body Length(mm) 48

Frame Size(mm) 42 x 42

Single Shaft/Dual Shaft Single Shaft

Shaft Type D-Cut

Shaft Diameter(mm) 5

Shaft Length(mm) 24

No. of Lead 4

Lead Length(mm) 500

Weight(g) 400 -

@william3d said in Problem setting up core XY:

Shaft Type D-Cut

blv require full d-cut shafts. could the pulleys be slipping?

-

@Veti You could be onto something the two motors on X and Y Part numbers are different and I think it means one is .9 and one is 1.8 Looking up and trying to verify right now.

17HS19-2004S2

17HS19-2004S1 -

@william3d said in Problem setting up core XY:

17HS19-2004S2 1.8 deg

17HS19-2004S1 0.9 deg