Problem with rear side of Test Cube

-

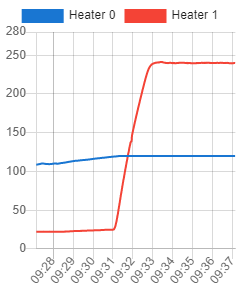

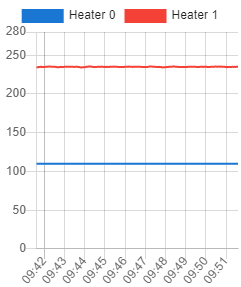

I haven't recalibrated the extruder, but I think my temperature is consistent. The window in the browser that shows the temp is consistent. I'm just running the cube now, so that I can post the temp readouts.

-

@dmbgo said in Problem with rear side of Test Cube:

I haven't recalibrated the extruder, but I think my temperature is consistent. The window in the browser that shows the temp is consistent. I'm just running the cube now, so that I can post the temp readouts.

I didn't see that you mentioned the kind of filament you are using.

For PLA I use 200 for the extruder and 60 for the bed but keep in mind my 200/60 may not match you 200/60 - it all depends on the thermistors and how correct the thermistor configuration values are.

For speed I use 60 mm/s to 90 mm/s depending on desired quality with the first layer at 15 mm/s.

Frederick

-

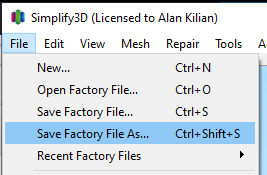

@dmbgo Can you File->Save Factory File as... and post it?

That way I can see your slicer settings and all that.

-

Thanks Fredrick, I am using ABS.

-

No worries @alankilian here it is:

[0_1610836772941_xyzCalibration_cube.factory](Uploading 100%) -

@dmbgo Try that upload again please.

Also, what filament are you using?

-

I print PLA at 60C bed and 205C extruder, so you're significantly hotter than I am.

-

I'll try renaming it to *.txt, you'll have to change it to *.factory:

xyzCalibration_cube.factory.txt -

I am using ABS filament.

-

On the filament roll, it recommends Extruder 220 to 260C Bed 100 to 110C

-

-

@dmbgo said in Problem with rear side of Test Cube:

I am using ABS filament.

Do you have a heated enclosure?

Frederick

-

I'm afraid I'm out of my experience zone with ABS.

I have read not to use fans for the first 3 layers, but that's not your problem.

Do you see filament extruding on the back cornets?

Do you hear your extruder struggling/clicking when that happens?

Can you rotate the cube 180-degrees to see if it then happens on the front?

Can you rotate the entire printer 180-degrees to see if it changes due to airflow?

Do you have an enclosure?

My only ABS experience is using a Stratasys where everything is controlled for me and it works perfectly.

Someone with more ABS experience will probably jump in next and hopefully be able to help you more than I can.

-

I do have, but the printer isn't in it at present while I'm working on it. I usually drop the bed temp down when the printer's in there.

-

From what I have read ABS really needs a heated enclosure BUT I don't know if that is related to your problem.

Frederick

-

@alankilian said in Problem with rear side of Test Cube:

1/ Do you see filament extruding on the back cornets?

2/ Do you hear your extruder struggling/clicking when that happens?

3/ Can you rotate the cube 180-degrees to see if it then happens on the front?

4/Can you rotate the entire printer 180-degrees to see if it changes due to airflow?

5/Do you have an enclosure?1/ Back cornets?

2/No clicking, extruding nicely when I move it up and extrude some filament.

3/I should have mentioned that I had done that, it still happens on the rear (mainly)

4/The pinter is on a wheeled trolley, I have tried that. Ambient temp is 18.4C atm. -

"From what I have read ABS really needs a heated enclosure BUT I don't know if that is related to your problem. Frederick"

Yes, I found that out a while ago, which is why I made the one in the pic. It is made from 50mm expanded foam, coated with thin fiberglass panels. The material came from an old coolroom.

-

But the issue remains. Any other helpful suggestions, they've been good so far?

-

@dmbgo said in Problem with rear side of Test Cube:

But the issue remains. Any other helpful suggestions, they've been good so far?

Instead of printing a cube can you create a model of a disc, say, 50 mm in diameter and 5 mm thick?

If you can print it using you normal settings.

Frederick

-

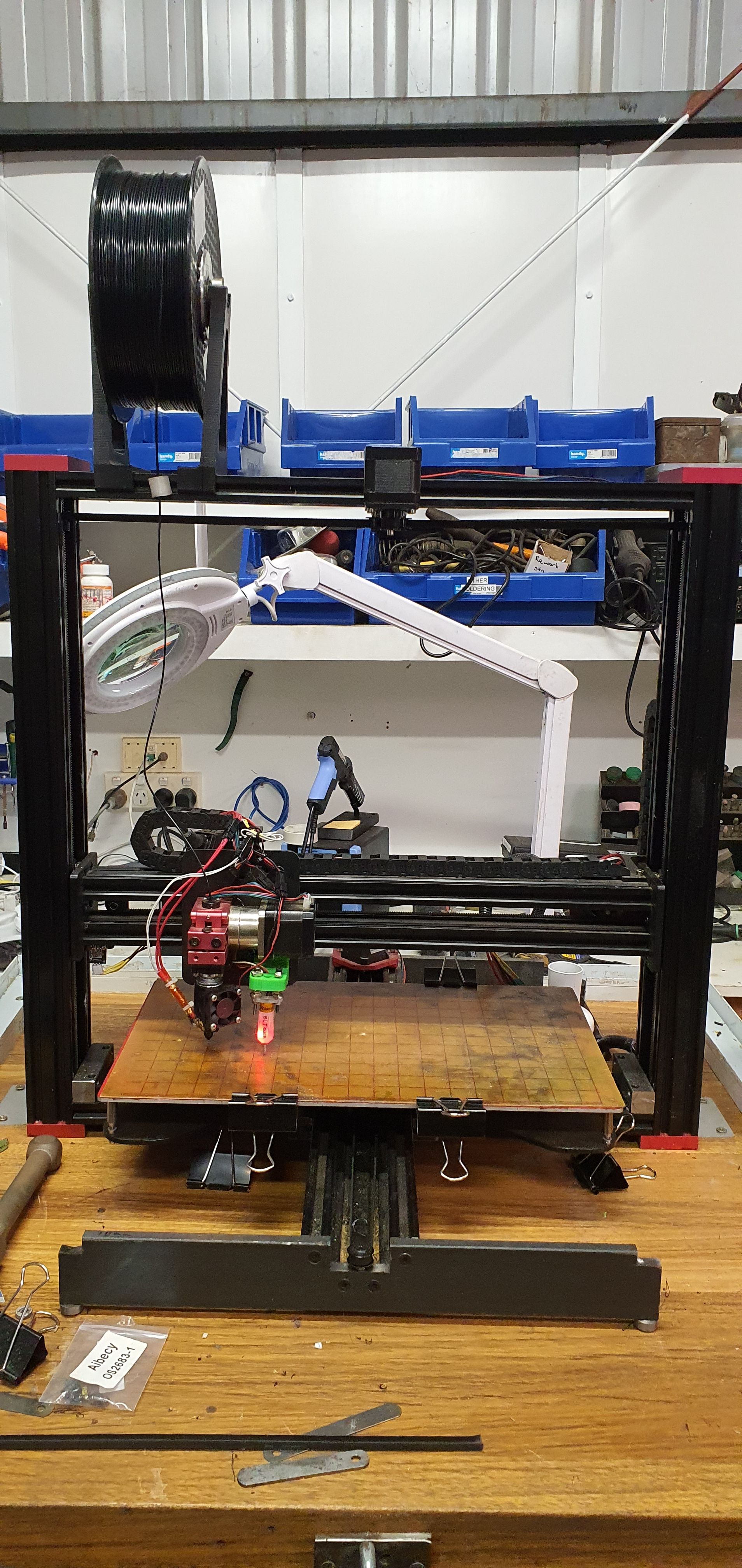

Here's a pic of the printer: