massive overextrusion, E-Steps are calibrated

-

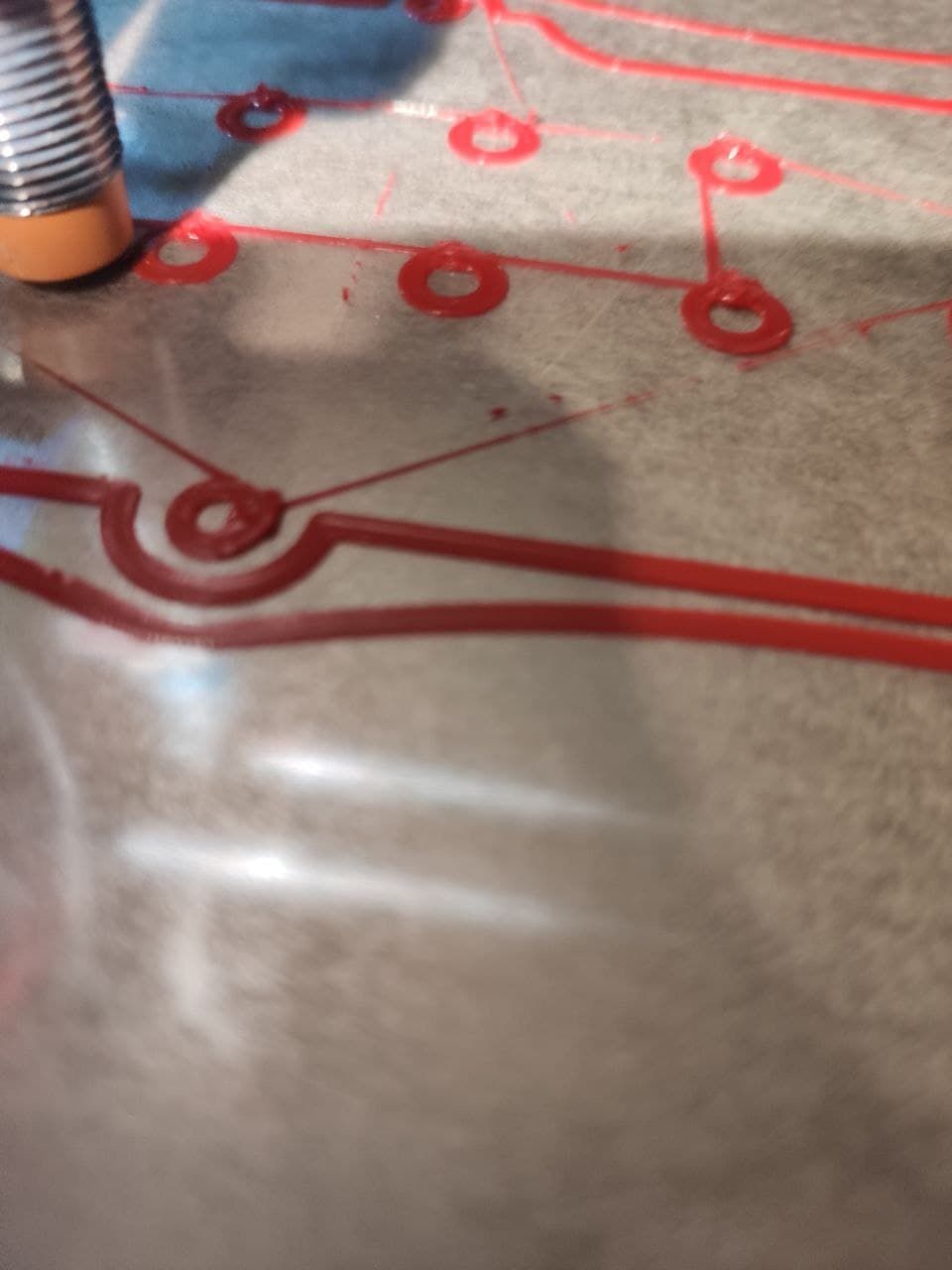

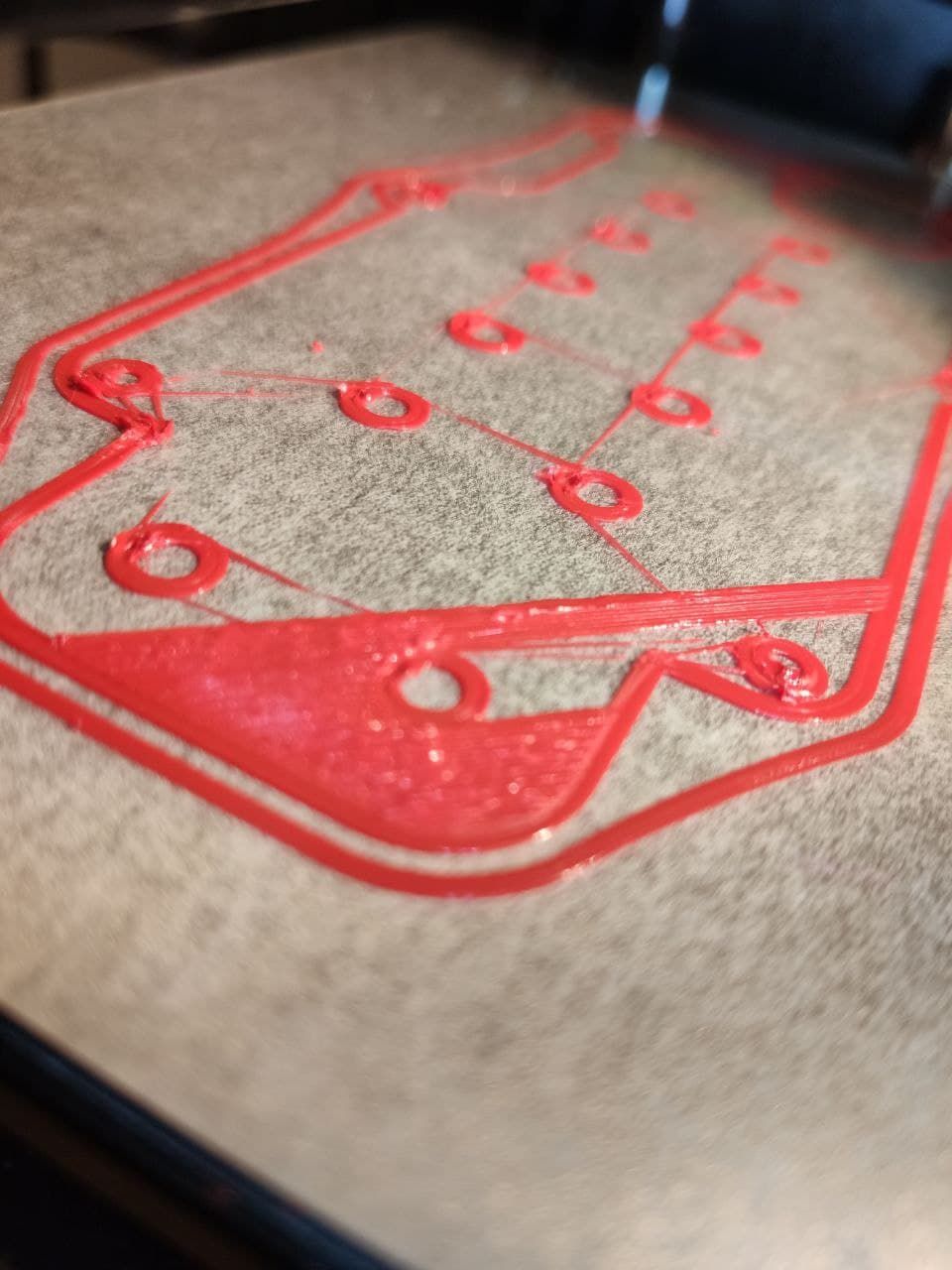

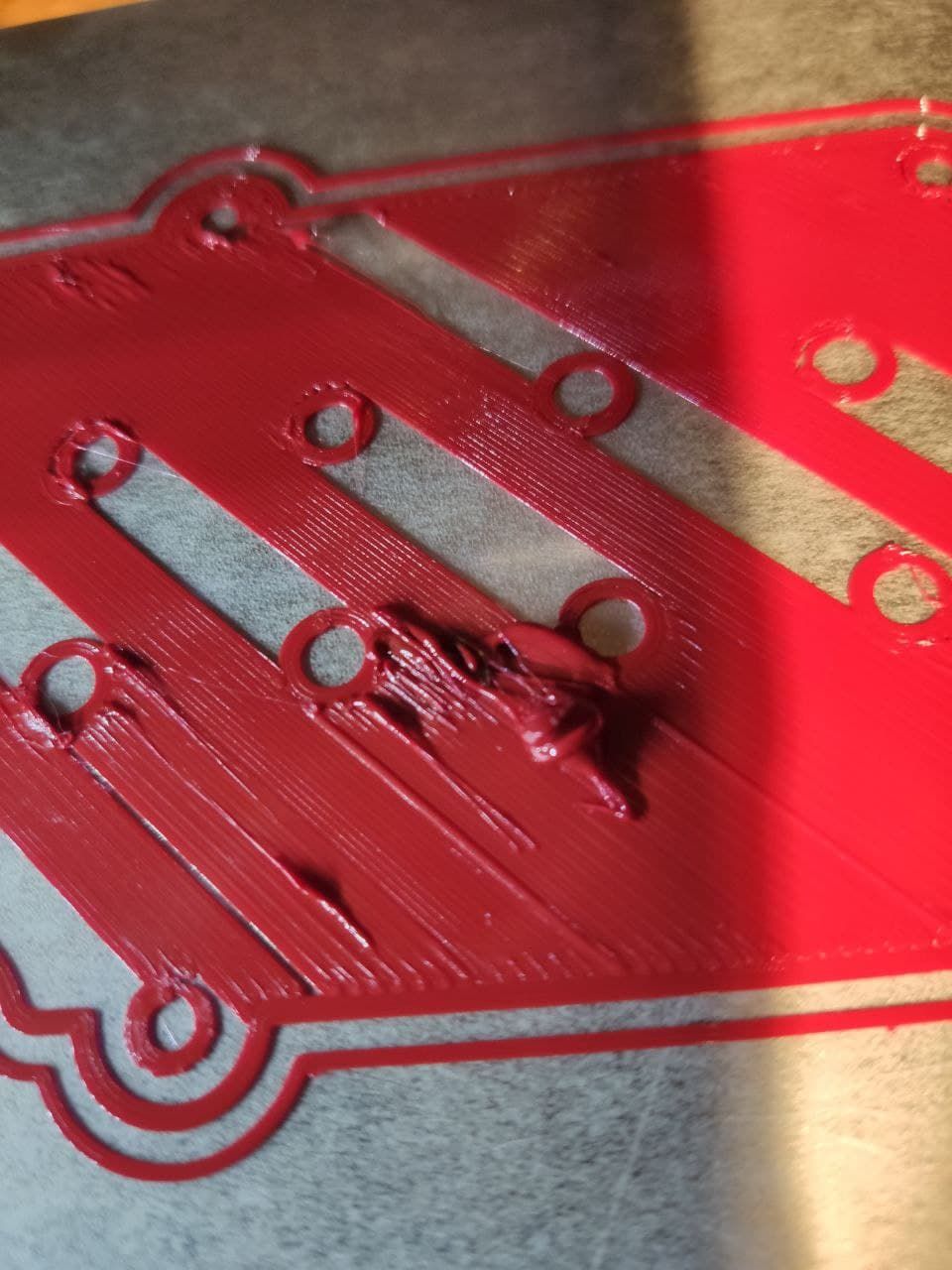

Now are some Photos with more distance to the bed, leveling should be in the "range of ok":

-

Here's a thought.

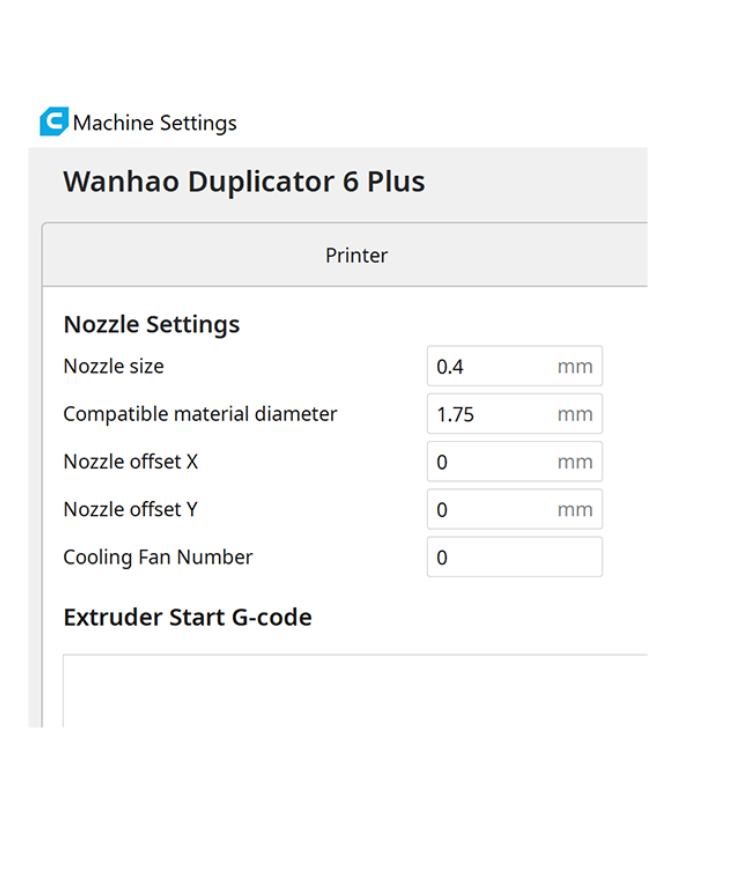

I experienced some strange over extruding a while back when testing a new slicer.

It turned out that the filament size in the slicer was set to 2.85 instead of 1.75.

Frederick

-

@Enpixa There are still streaks on the moves between the circular features, which ought to be non-print moves. That might be because of pressure build up or lack of retraction, but it might also be that the nozzle/bed gap needs to be increased a bit more. Try another 0.1mm baby stepping to see if that helps.

-

@fcwilt said in massive overextrusion, E-Steps are calibrated:

Here's a thought.

I experienced some strange over extruding a while back when testing a new slicer.

It turned out that the filament size in the slicer was set to 2.85 instead of 1.75.

Frederick

-

@deckingman said in massive overextrusion, E-Steps are calibrated:

@Enpixa There are still streaks on the moves between the circular features, which ought to be non-print moves. That might be because of pressure build up or lack of retraction, but it might also be that the nozzle/bed gap needs to be increased a bit more. Try another 0.1mm baby stepping to see if that helps.

Did some more iterations. This time with Simplify3D, as there i got better retraction- settings for ooze-prevention. First looks ok, but imo lines are far too thick. (also use these slicers with my other 3d-printers, no problems) Distance to printbed is quite far, can easily remove print with my fingers by just gently touching.

After printing a while:

Second attempt, same Settings:

There is some heavy jamming going on at 100% flow.... Filament also came out of my hotendblock.

I still think there is some issue with my config or in the firmware.

Sure it could be some complete wrong settings i made in the slicers, but i checked everything i was thinking of the last days and they are working with my other printers. -

@Enpixa said in massive overextrusion, E-Steps are calibrated:

Filament also came out of my hotendblock.

Like out the heat break side? I think you might need to re-visit the hotend assembly.

fw 3.2 is available now. Probably a good idea to update. Not likely to solve your problems I don't think, but lots of fixes regardless.

Upload to your system tab. https://github.com/Duet3D/RepRapFirmware/releases/download/3.2/Duet2and3Firmware-3.2.zip

-

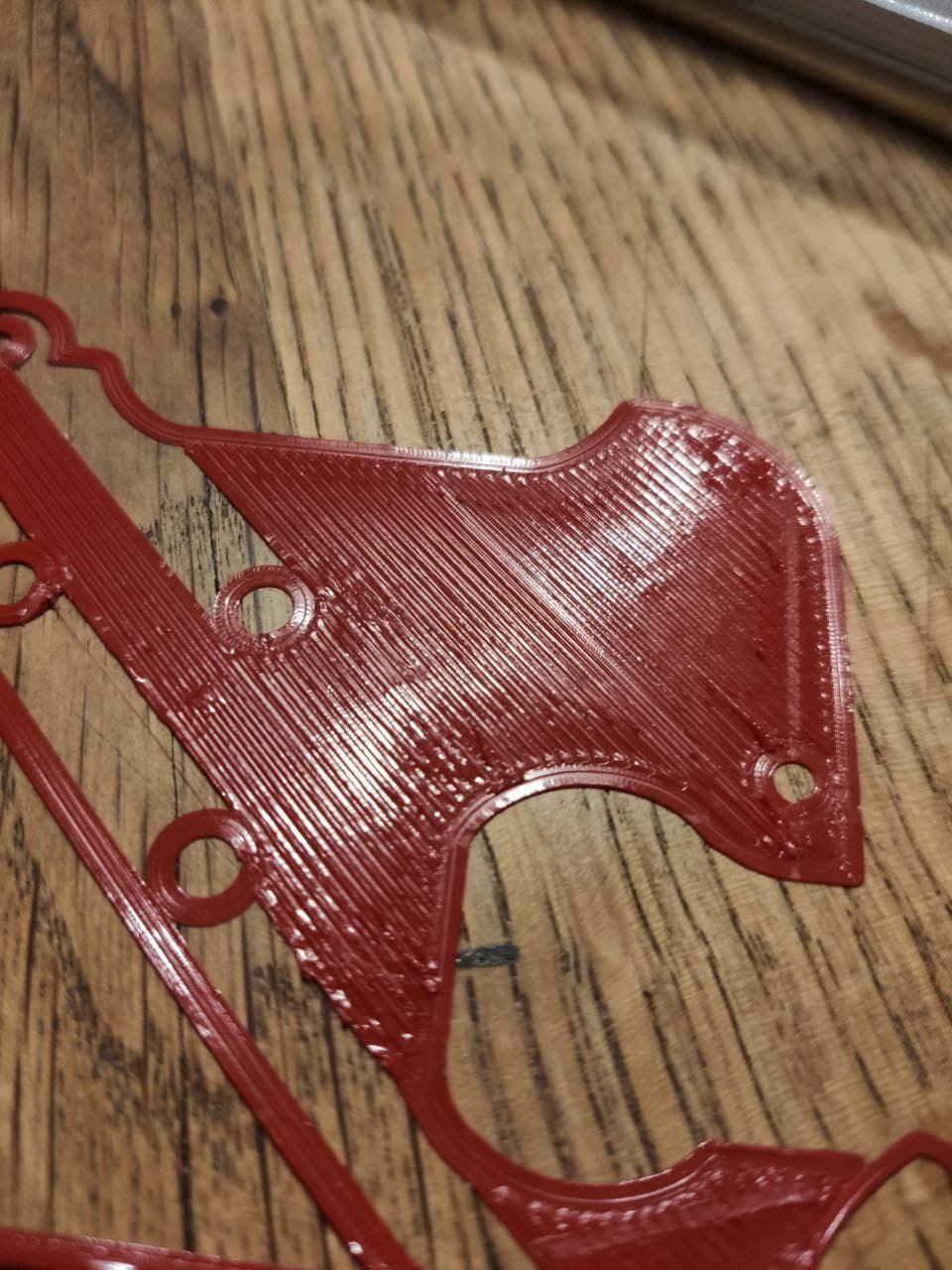

Little Update: Updated to RRF3 V3.2 now. Also disassembled and reassembled complete Hotend-Block, heatbreak and nozzle. Was no fun as there was a lot of melted filament caused by over-extrusion and clogging all over.

Pitty to tell : Same behaviour. Needs a ~50% Filament Flow to get a kind of "ok" print. I am lacking of new ideas what to try next.

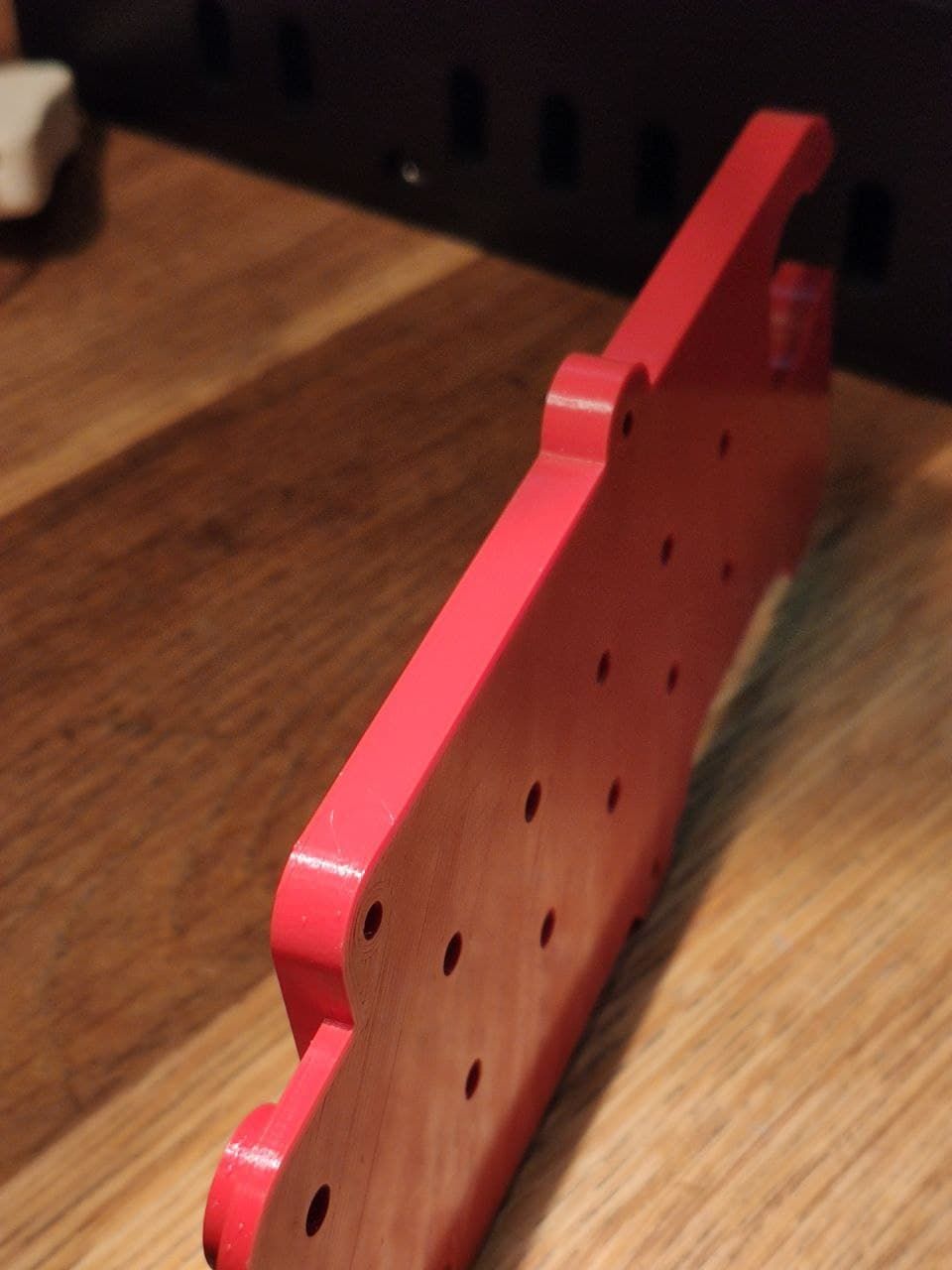

This was printed with ~50% Filament Flow. Switched at higher layers to about ~60% as there was a little space between the lines.

-

@Enpixa said in massive overextrusion, E-Steps are calibrated:

~50% Filament Flow.

that is really strange. are you sure the motor on the extruder is 1.8 degrees? it would explain the result

-

...as mentioned when i do a "G92 E0" followed by "G1 E100" from console it transports 100mm raw filament. Behaves like it should imo.

-

What is the motor?

-

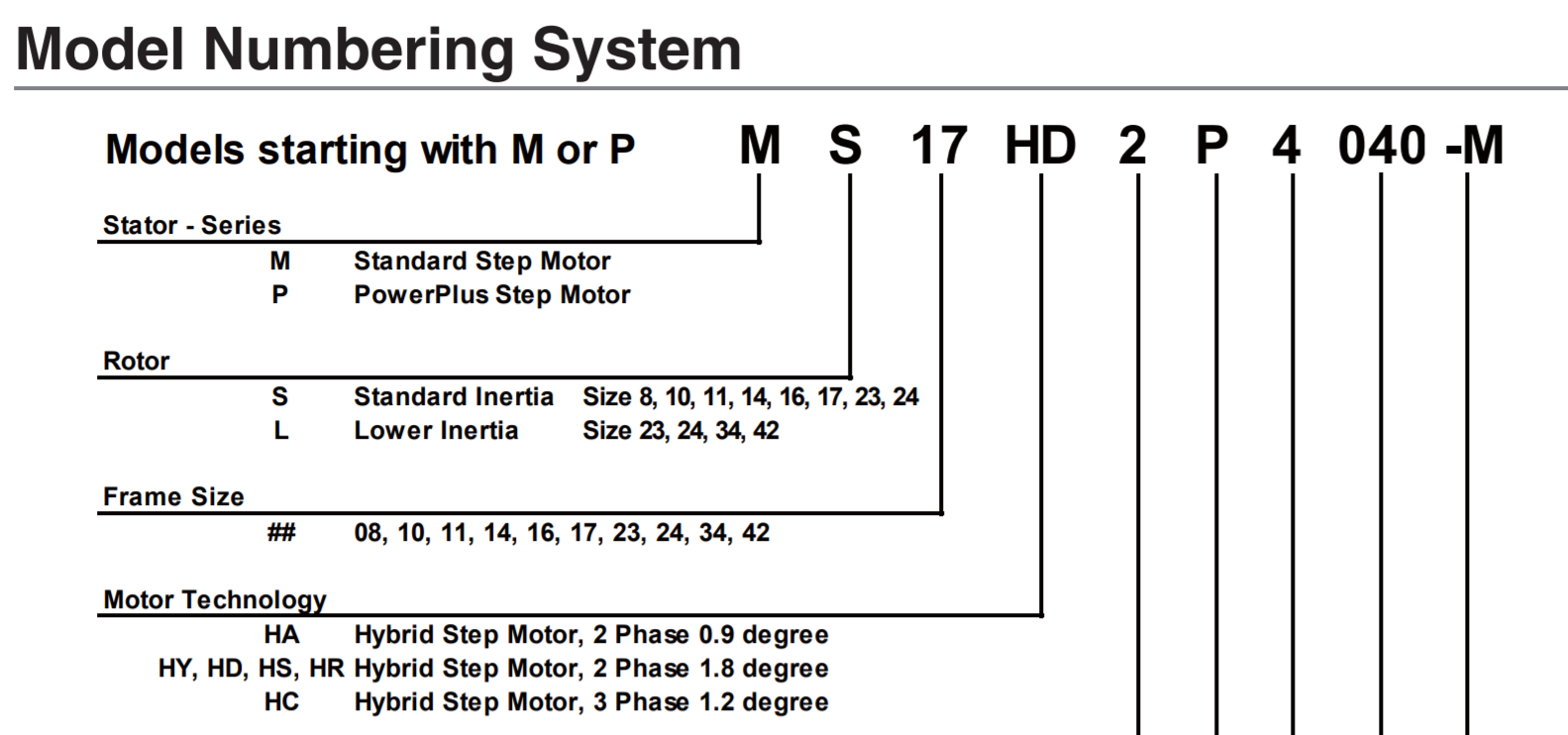

After 2 hours searching i found the specs

The Extruder-Stepper (same stepper also used for Z-Axis) used in the Wanhao Duplicator 6 Plus is a Moons Stepping Motor C17HD40102-05NAccording to Moons Numbering System found in a PDF for different steppers it should be a standard 1.8degree stepper (HD) which is specified for the motor technology of 2 different Moons Series, so i guess, that is is the same for the C17-Series.

Also installed this, but still using original stepper:

-

@Enpixa said in massive overextrusion, E-Steps are calibrated:

...as mentioned when i do a "G92 E0" followed by "G1 E100" from console it transports 100mm raw filament. Behaves like it should imo.

Is this with the hotend attached or just pushing the filament through the extruder gears?

-

Also, are you measuring 100mm of filament going INTO the extruder or 100mm of filament coming OUT of the extruder?

(I'm not implying you're an idiot, just trying to check non obvious things since SOMETHING strange is going on and we're not nailing it down yet.)

-

@Phaedrux: It is with hotend attached.

@alankilian: Measuring Filament going into extruder.

One Idea came to my mind: as it is extruding right, when doing a do a "G92 E0" followed by "G1 E100" from console.

Could it be that there is something buggy with the DWC extrusion factor when used, that it calculates twice or something like that.

Is the DWC extrusion factor also used when doing a "G1 E100" from console, or only when printing a file ?

-

do you have something like non linear extrusion enabled?

-

This post is deleted! -

@Veti said in massive overextrusion, E-Steps are calibrated:

do you have something like non linear extrusion enabled?

What exactly do you mean ? Which commands / Gcodes ? So far only tested absolute and relative extrusion. No Volumetric / Advanced Pressure printing tested nor activated.

-

-

@Veti said in massive overextrusion, E-Steps are calibrated:

https://duet3d.dozuki.com/Wiki/Gcode#Section_M592_Configure_nonlinear_extrusion

No M592 in config or Gcode of 3D printed file found.

-

@Enpixa Just to rule out something changing the config.g values, send the following after resetting the Duet:

M92 M350 M221

which should respond with something like (my settings):Steps/mm: X: 80.000, Y: 80.000, Z: 800.000, E: 612.000 Microstepping - X:16(on), Y:16(on), Z:16(on), E:16(on) Extrusion factor(s) for current tool: 100.0%Then send again once you have started a file printing. If there's a gcode somewhere changing these settings, the firmware should report it.

Just as a sense check, I looked at the snippet of gcode you posted. It shows a 12.5mm move with a 0.75mm extrusion move (roughly). For 1.75mm filament this is:

π(1.75/2)^2 x 0.75 = 1.8mm^2For a 0.4mm nozzle (0.4mm extrusion width; yours may be bigger) with a layer height of 0.3mm, for this distance you should be extruding (again, roughly):

0.4 x 0.3 x 12.5 = 1.5mm^2 of filamentSo it looks (from this tiny fragment of gcode) that the extrusion commanded is in the right ballpark; I'd guess you have an extrusion width of 0.5mm, which gives 1.875mm^2 of filament. However, check the settings in your slicer for the first layer, as they are often different from other layers.

Ian