Auto tune failed due to bad curve fit

-

Hello,

i got the following message when i try to PID Tune Tool0 with the slice engineering PT1000 Sensor on on a Toolboard LC1.

Auto tune failed due to bad curve fit (R=1.946, 1/C=0.0048:0.0036, D=11.6) Warning: heater behaviour was not consistent during tuningi defined the pt1000 with

M308 S1 P"121.temp0" Y"pt1000" M950 H1 C"121.out0" T1 M307 H1 B0 S1.00 M143 H1 S500RRF3.3beta1

Duet3 Mainbord + sbc + ToolboardThe Tuning works optical perfect, every time the same curve, even when the fan tuning starts , the temp is cycling without any big difference in the same range

and after around one hour i got this error message

what could that be ?

Regards Frederik

-

Hi,

Could you, as a test, connect those parts to the 6HC and see if it works there?

I suggest that only because there are some indications, as yet unconfirmed, that there may be CAN bus issues in the firmware.

Frederick

-

@Frederik said in Auto tune failed due to bad curve fit:

Warning: heater behaviour was not consistent during tuning

It means that the heating and cooling rates didn't settle down to consistent values after several cycles. One possible reason is noise in the temperature sensor readings, which would be apparent in temperature graph.

Possibly noise or poor connection in the sensor wiring as well.

-

@Phaedrux said in Auto tune failed due to bad curve fit:

@Frederik said in Auto tune failed due to bad curve fit:

Warning: heater behaviour was not consistent during tuning

It means that the heating and cooling rates didn't settle down to consistent values after several cycles. One possible reason is noise in the temperature sensor readings, which would be apparent in temperature graph.

Possibly noise or poor connection in the sensor wiring as well.

Understood.

Frederick

-

@fcwilt said in Auto tune failed due to bad curve fit:

Understood.

That's what DC42 tells me anyway. I barely understand it myself.

-

@fcwilt said in Auto tune failed due to bad curve fit:

Could you, as a test, connect those parts to the 6HC and see if it works there?

This would be an interesting test.

-

@Phaedrux @fcwilt

good morning,

Yes, I can test that

The wiring is complete new from sensor and heater + the sensors itself.

It shows the correct room temperature.Its a 65W heater and the slice engineering rtd pt1000 sensor. Perhaps with 8cm of cable lenght from sensor to toolboard

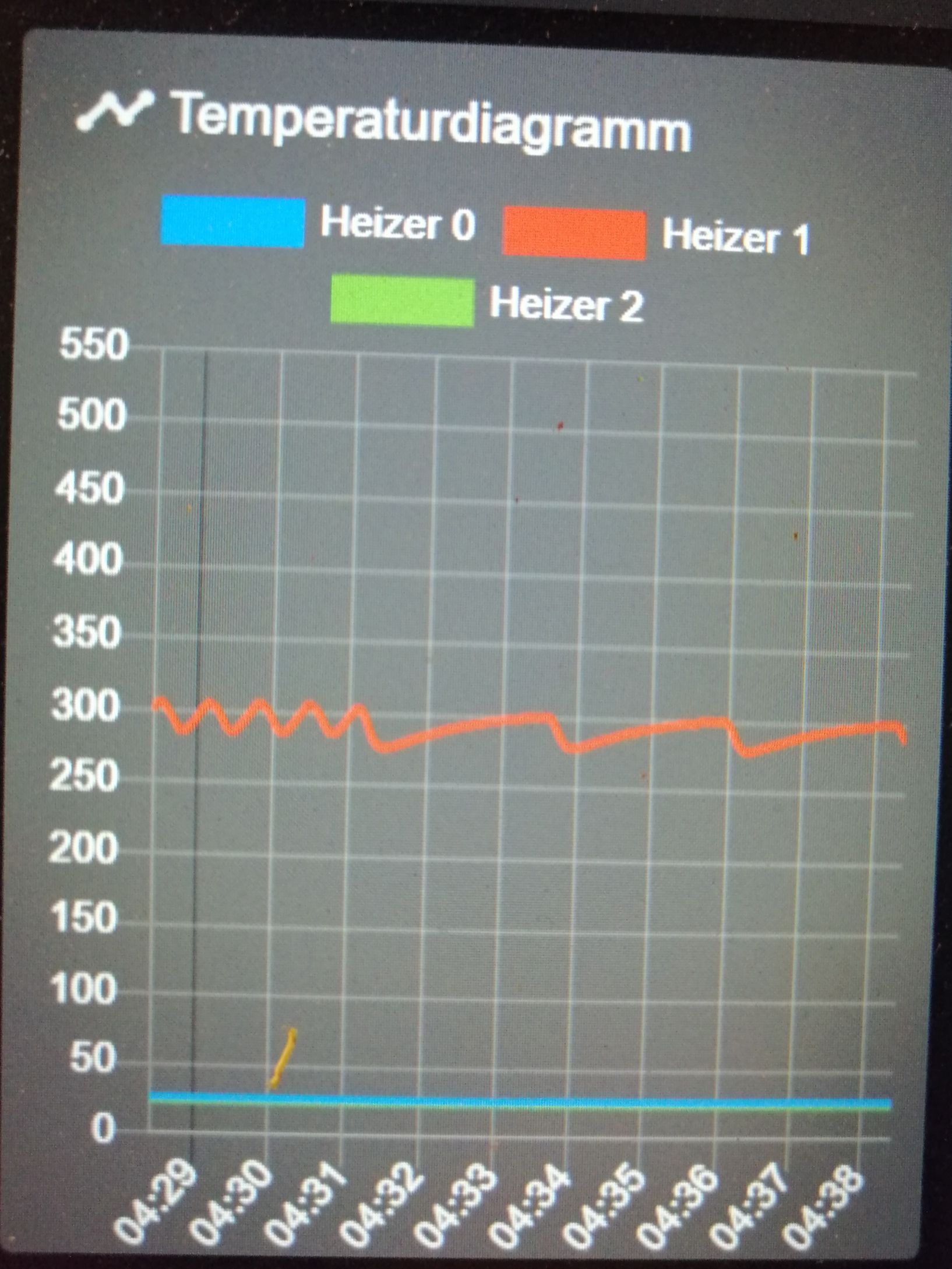

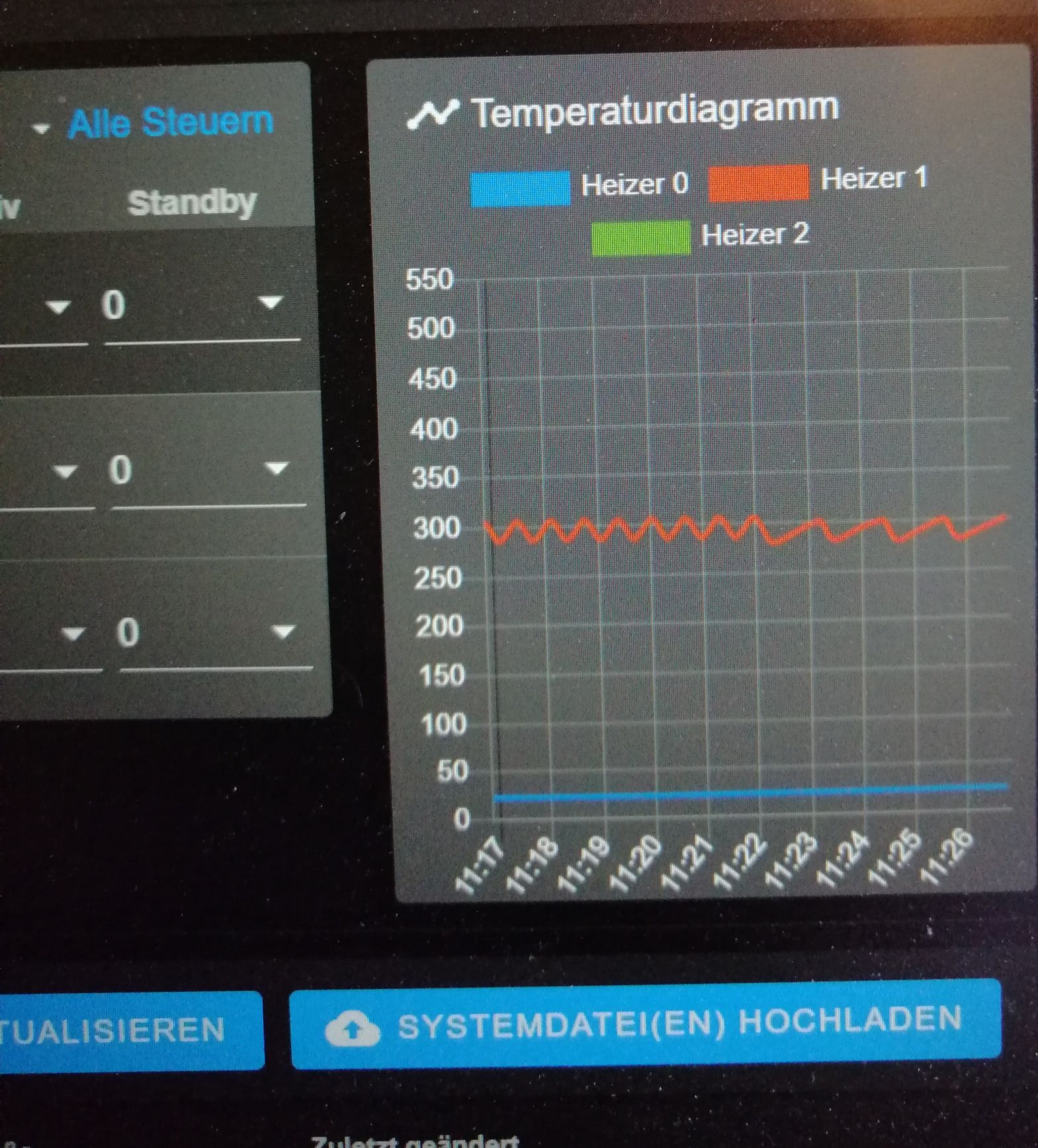

This Pic is shit from the transition tool fan off to on

-

@Frederik said in Auto tune failed due to bad curve fit:

Hello,

i got the following message when i try to PID Tune Tool0 with the slice engineering PT1000 Sensor on on a Toolboard LC1.

Auto tune failed due to bad curve fit (R=1.946, 1/C=0.0048:0.0036, D=11.6) Warning: heater behaviour was not consistent during tuning ... RRF3.3beta1 Duet3 Mainbord + sbc + Toolboard The Tuning works optical perfect, every time the same curve, even when the fan tuning starts , the temp is cycling without any big difference in the same range and after around one hour i got this error message what could that be ?The reason it's failing is that the measured cooling rate with the fan on is actually lower than with the fan off:

1/C=0.0048:0.0036The second figure should be higher than the first one, unless there is a mechanism I haven't thought of whereby turning on the print cooling fan actually reduces the cooling of the hot end. Assuming that the print cooling fan is configured correctly, it seems that turning on the print cooling fan has negligible cooling effect on your hot end, and there is sufficient variability in the measurements that the second cooling rate measurement is lower than the first one.

I suggest you tune that hot end using M303 with H parameter instead of with T parameter, so that it doesn't tune it with fan off and then with fan on.What type of hot end is it?

EDIT: you published your temperature graph as I was composing that message. That graph does show that turning on the fan has an effect.

-

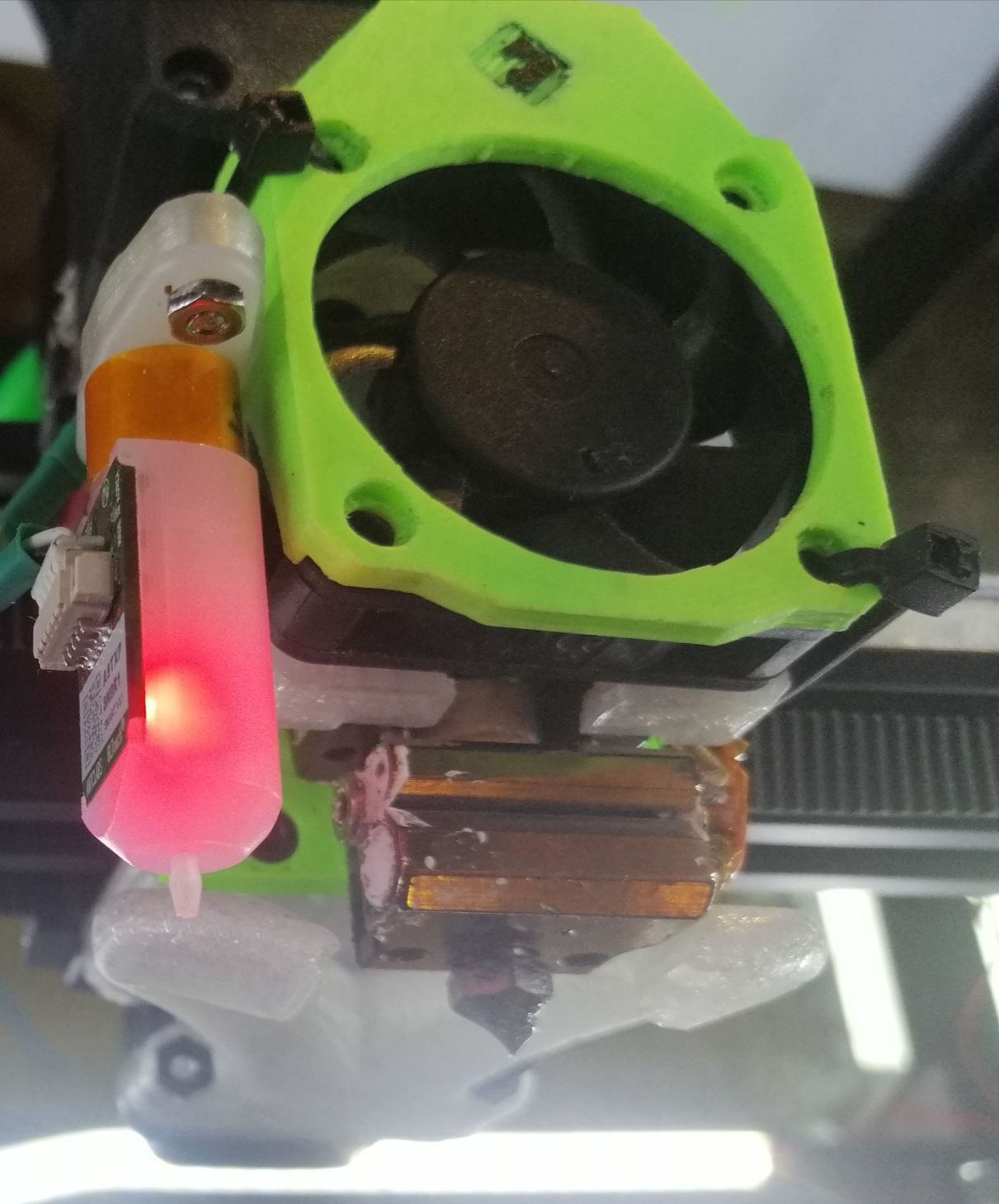

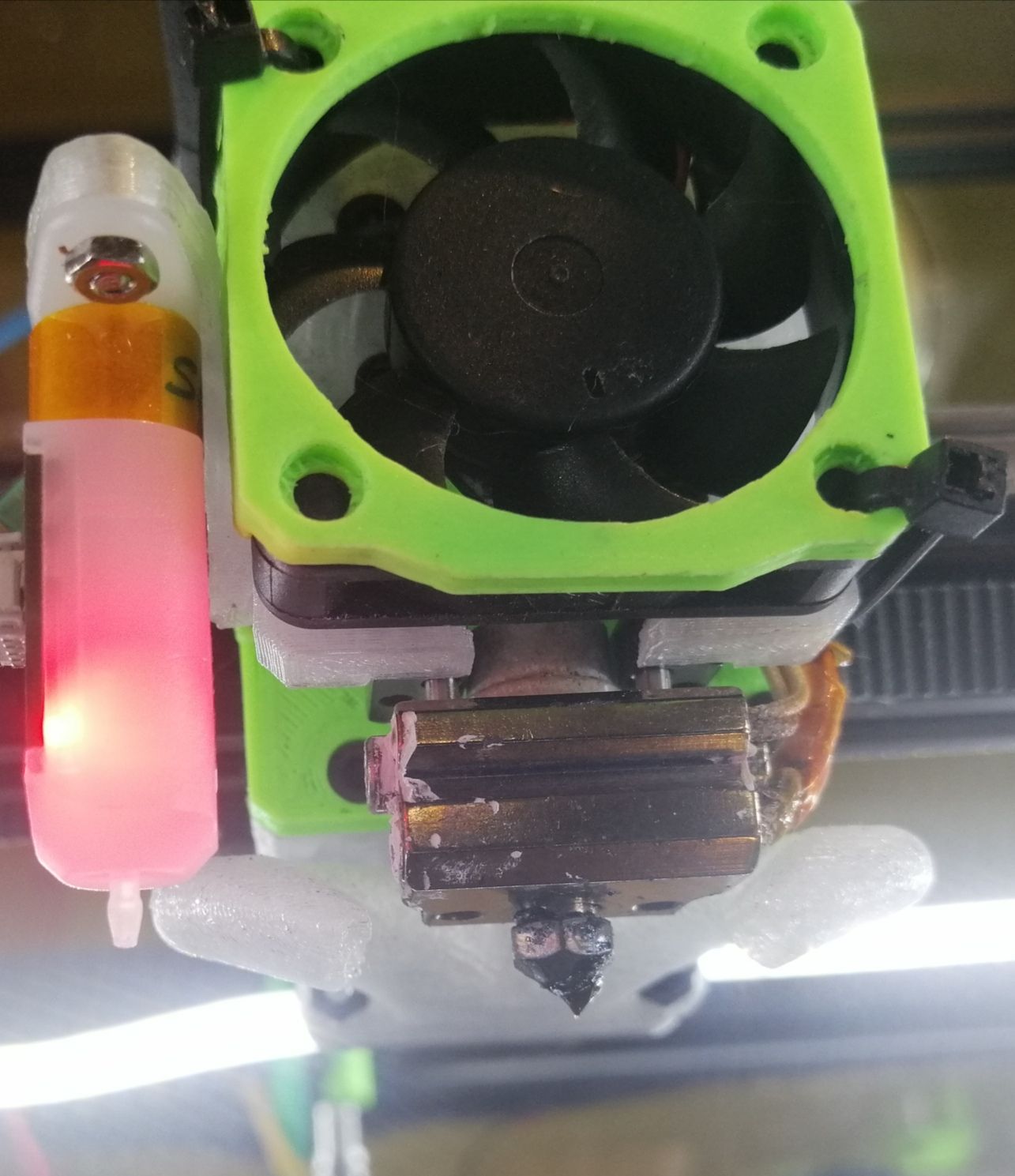

@dc42 it's a original mosquito magnum with a 65W heater and the white thermal insulation ring installed. Nozzle is nickel plated copper.

But I am running it with a 40mm fan instead of the 25mm one at around 25%

The picture above was a pid tune at 300°C with all fans at 100%

Another pid tu e I tried was 400°C with the tool fan at 40% and the part cooling fan at 35% with the same results.

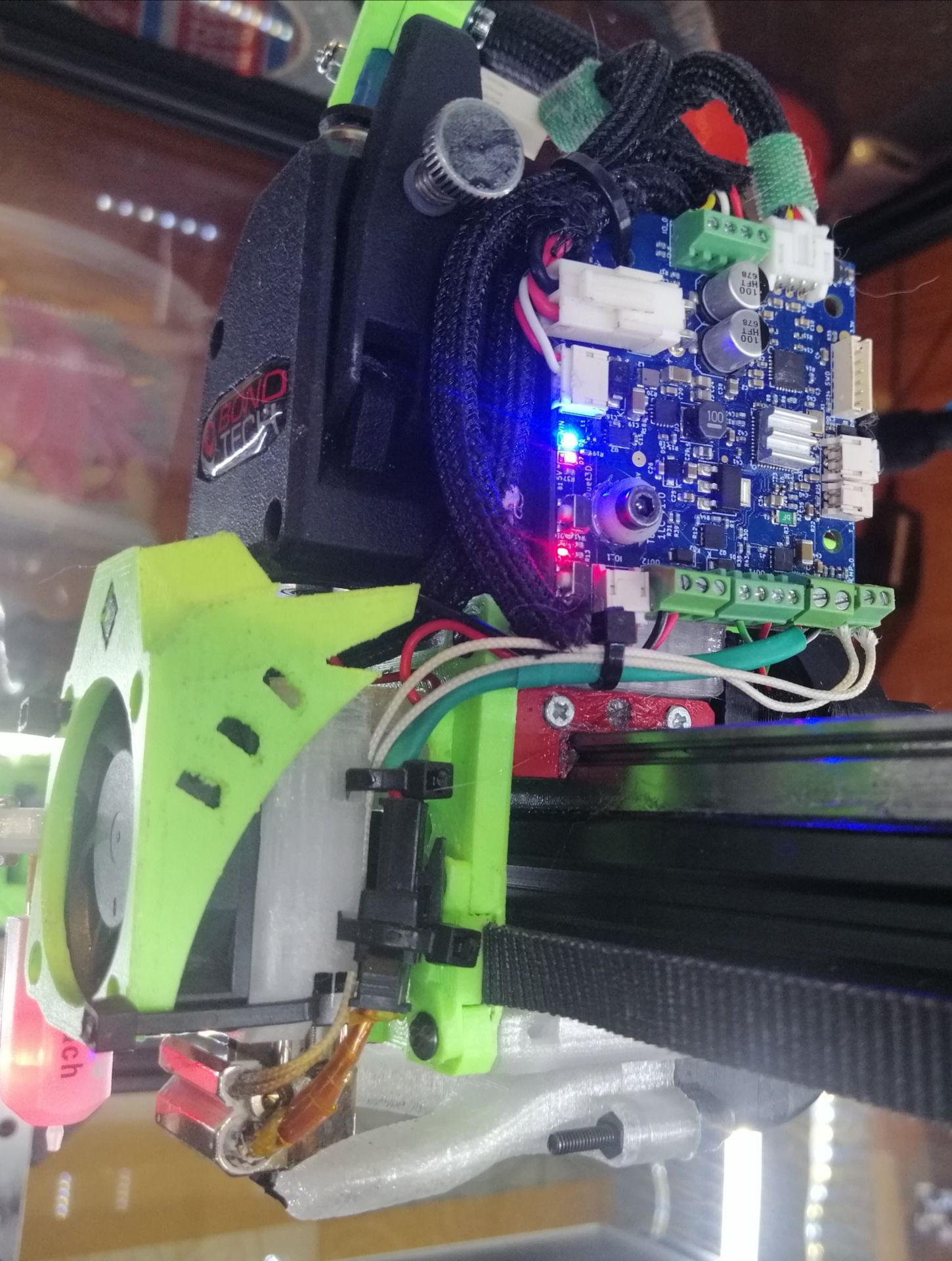

This is my Printhead with cabling and fan duct out of PC

-

Thanks. I will check how the cooling rate with fan on is calculated from the data. In your temperature graph, it looks like the cooling segments have much the same lengths with fan on as with fan off, however the heating segments are much longer with fan on.

-

@dc42 I will try a tune with a lower temperature and a tune with the heater and sensor connected to the mainboard

-

@Frederik said in Auto tune failed due to bad curve fit:

@dc42 I will try a tune with a lower temperature and a tune with the heater and sensor connected to the mainboard

When you tune it with it connected to the main board, please use the same temperature as you did before, so that I can compare the results directly.

-

@dc42 ok, I will test it as soon as I am back from work

-

@dc42

Hello,Today i had time to test the PID Tuning with the sensors connected to the duet 3 Mainboard.

The Tuning completed succesfully wih the following message:

Auto tuning heater 1 completed after 4 idle and 21 tuning cycles in 1540 seconds. This heater needs the following M307 command: M307 H1 R2.420 C186.9:181.7 D9.54 S1.00 V24.0I made a new photo at the moment from tuning with fan off, to fan on

All other parameters where the same

M303 T0 300

-

Thanks! I can see that this time it measured a slightly higher cooling rate with the fan on (which is why tuning worked), however the temperature graph shows that the temperature rises much more slowly with the fan on, indicating that the fan has a substantial effect. I will review how RRF measures the cooling rate.

-

@dc42 Ok, Thank you

The Part Fan is one 5015 Blower and the Hotend cooling Fan a 40mm Sunon that is running for testing between 40 and 100 %