Duet 2 Wifi TronXY X5SA Z probe setup 2

-

@phaedrux said in Duet 2 Wifi TronXY X5SA Z probe setup 2:

I am getting no errors.

I think the Z motors are homing in the wrong direction.

If I use M564 S0 H0 I can hit Z+ in the dashboard and it does in fact move up correctly. But when I home, it goes down. Should I remove that '!' in the line droftarts posted?Here is my current config.g:

; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sat May 29 2021 18:31:29 GMT-0500 (Central Daylight Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"TronXY X5SA-500-Pro" ; set printer name M669 K1 ; select CoreXY mode ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S1 ; physical drive 0 goes forwards M569 P1 S1 ; physical drive 1 goes forwards M569 P2 S1 ; physical drive 2 goes forwards M569 P3 S1 ; physical drive 3 goes forwards M584 X0 Y1 Z2 E3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X80.00 Y80.00 Z400.00 E92.60 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z180.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2) M906 X1200 Y1200 Z1700 E1000 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X500 Y500 Z600 S0 ; set axis maxima ; Endstops M574 X1 S1 P"xstop" ; configure active-high endstop for low end on X via pin xstop M574 Y1 S1 P"ystop" ; configure active-high endstop for low end on Y via pin ystop M574 Z2 S2 ; configure Z-probe endstop for high end on Z ; Z-Probe M558 P5 C"!^zprobe.in" H5 F120 T6000 A10 R0.5 S0.005 B0 ; Set Z probe type to modulated and the dive height + speeds G31 P500 X-35 Y0 Z0.26 ; Set Z probe trigger value, offset and trigger height M557 X10:300 Y20:310 S50 ; Define mesh grid ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M575 P1 S1 B57600 ; enable support for PanelDue M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power lossLord have mercy I think my end stops are reversed...! I can move the print head until it touches the X and Y endstops (I see the lights on the Duet), but when I run M119 like you said, I get "M119

Endstops - X: not stopped, Y: not stopped, Z: not stopped, Z probe: not stopped". If I move the print head off the end stops (no endstop lights are lit), I get "M119

Endstops - X: at min stop, Y: at min stop, Z: not stopped, Z probe: not stopped" -

@pyper said in Duet 2 Wifi TronXY X5SA Z probe setup 2:

If I use M564 S0 H0 I can hit Z+ in the dashboard and it does in fact move up correctly. But when I home, it goes down.

I'm confused. Or maybe you're confused.

Z+ should move the bed and nozzle farther apart.

Z- should move them closer together.If you need to change the direction of the Z motors use the M569 S to change direction right at the driver settings.

-

@pyper moving the bed in a positive direction should increase the distance between the nozzle and bed, so move the bed down, and a negative move reduces the distance between bad and nozzle, so the bed goes up. So sounds like your Z motors are going the wrong way. You can flip the direction by changing the S parameter in the M569 command that relates to the Z axis in config.g.

The comments in the commands are, unfortunately, a little confusing, as they assume the machine is a Prusa-style bed slinger, where the X axis is mounted on the Z, so the nozzle moves ‘up’ with positive Z move.

Edit: ninja’d (again) by @Phaedrux !

Ian

-

@phaedrux

Perhaps I am confused. I assumed Z+ moved the bed UP and Z- moved the bed DOWN.. for a CoreXY? -

@pyper said in Duet 2 Wifi TronXY X5SA Z probe setup 2:

I think my end stops are reversed...! I can move the print head until it touches the X and Y endstops (I see the lights on the Duet), but when I run M119 like you said, I get "M119

Endstops - X: not stopped, Y: not stopped, Z: not stopped, Z probe: not stopped". If I move the print head off the end stops (no endstop lights are lit), I get "M119

Endstops - X: at min stop, Y: at min stop, Z: not stopped, Z probe: not stopped"In that case you invert the signal by adding a

!to the pin name.ex:

M574 X1 S1 P"xstop"becomesM574 X1 S1 P"!xstop" -

@pyper said in Duet 2 Wifi TronXY X5SA Z probe setup 2:

@phaedrux

Perhaps I am confused. I assumed Z+ moved the bed UP and Z- moved the bed DOWN.. for a CoreXY?No. Think of it as the distance between the bed and nozzle becoming larger or smaller.

-

@phaedrux

Ok, after reversing the Z motor and the endstops, it homed on all axis!

Thank you so much, I'm sure everyone is thinking "how does this guy drive a car?" haha

Onward! -

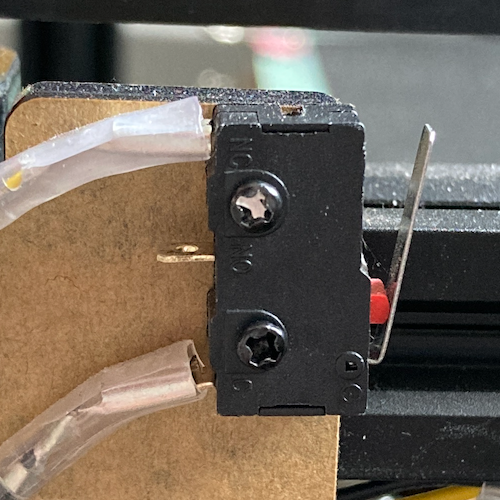

@pyper the micro switches used as endstops on my TronXY X5S were wired NO (normally open); wires connected to the centre pin and the common pin (one of the outer pins) on the micro switch. I expect your X5SA is the same. We recommend wiring micro switch endstops as NC (normally closed) as it reduces false triggering. To do this, simply move the wire connected to the centre pin to the other outside pin (there are only three pins). You also then don’t need to invert the endstop signal with the ! character. I have done this on my machine See https://duet3d.dozuki.com/Wiki/Connecting_endstop_switches#Section_Microswitch

Ian

-

@droftarts

Ian,

I checked my switches and the outer pin does nothing that I can see. I used a multi meter and checked continuity on the outer-outer and inner-outer for that pin, and it never had any continuity for any switch setting. Should I get new end stop switches? -

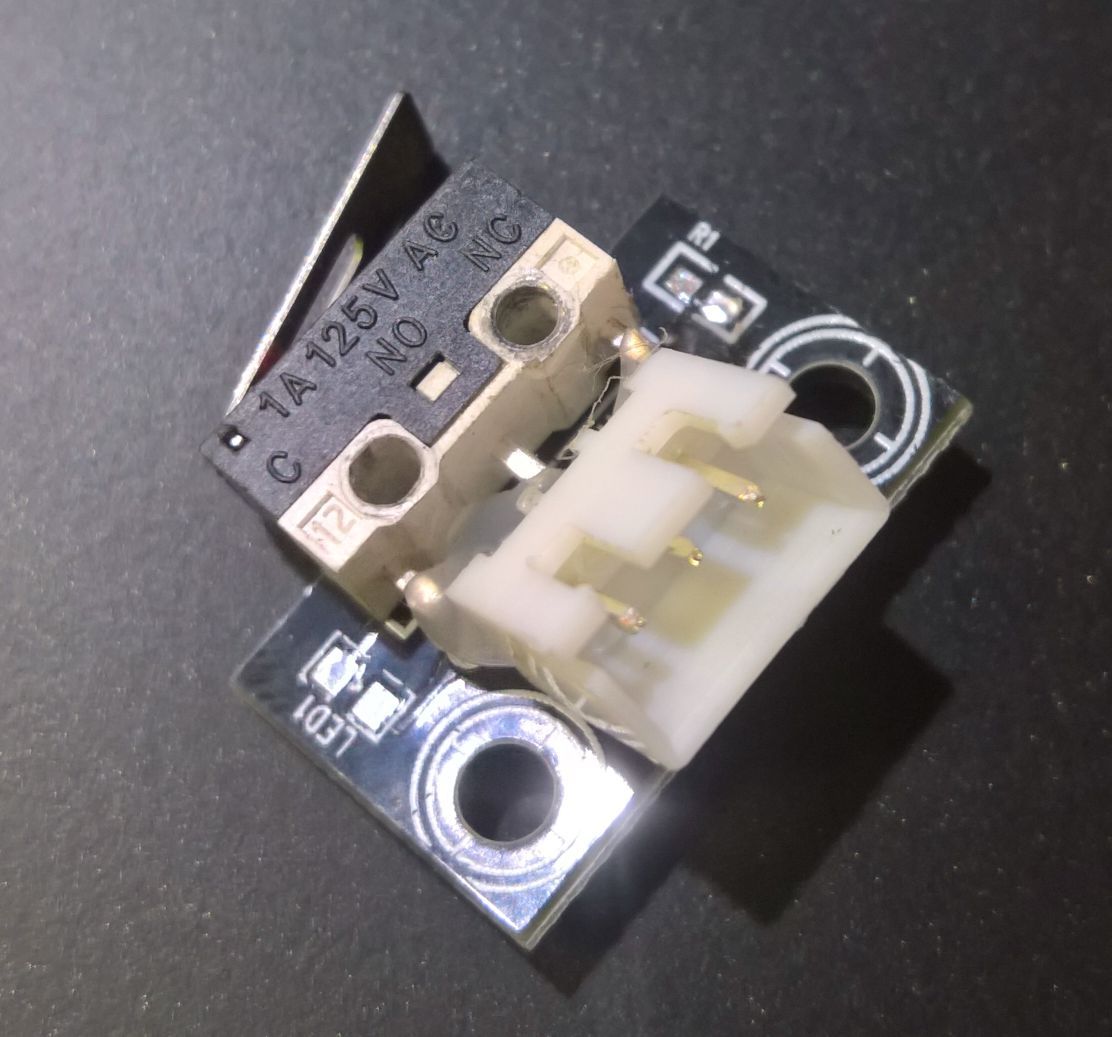

@pyper The pins should be labelled C (Common), NO (normally open, centre pin) and NC (normally closed). You should have continuity between NC and C when switch is not depressed, and continuity between NO and C when not depressed. There is no continuity between NO and NC. If you don't have continuity between NC and C, then possibly it's just a really cheap switch packaged as a microswitch!

It's usually not too much of a problem having the microswitches wired NO, but the voltage is floating, so any interference (eg from high voltage such as heater wires or stepper motor wires) can possibly trigger the endstop. This doesn't happen when wired NC.

Here's mine, wire NC, pin labels just about visible:

Ian

-

@droftarts

Ahh, I see you wired up directly to the switch.

I was probing through the 3-wire jack. I guess they didn't even run traces for NC.

Will check on that.