RRF 3.4 input shaping preview available

-

@dc42

I did some testing.

Look like ie3 works best

With PA enabled and zvd - i had a layer shift - mainly in xAfter PA disabled i could finish print with all settings

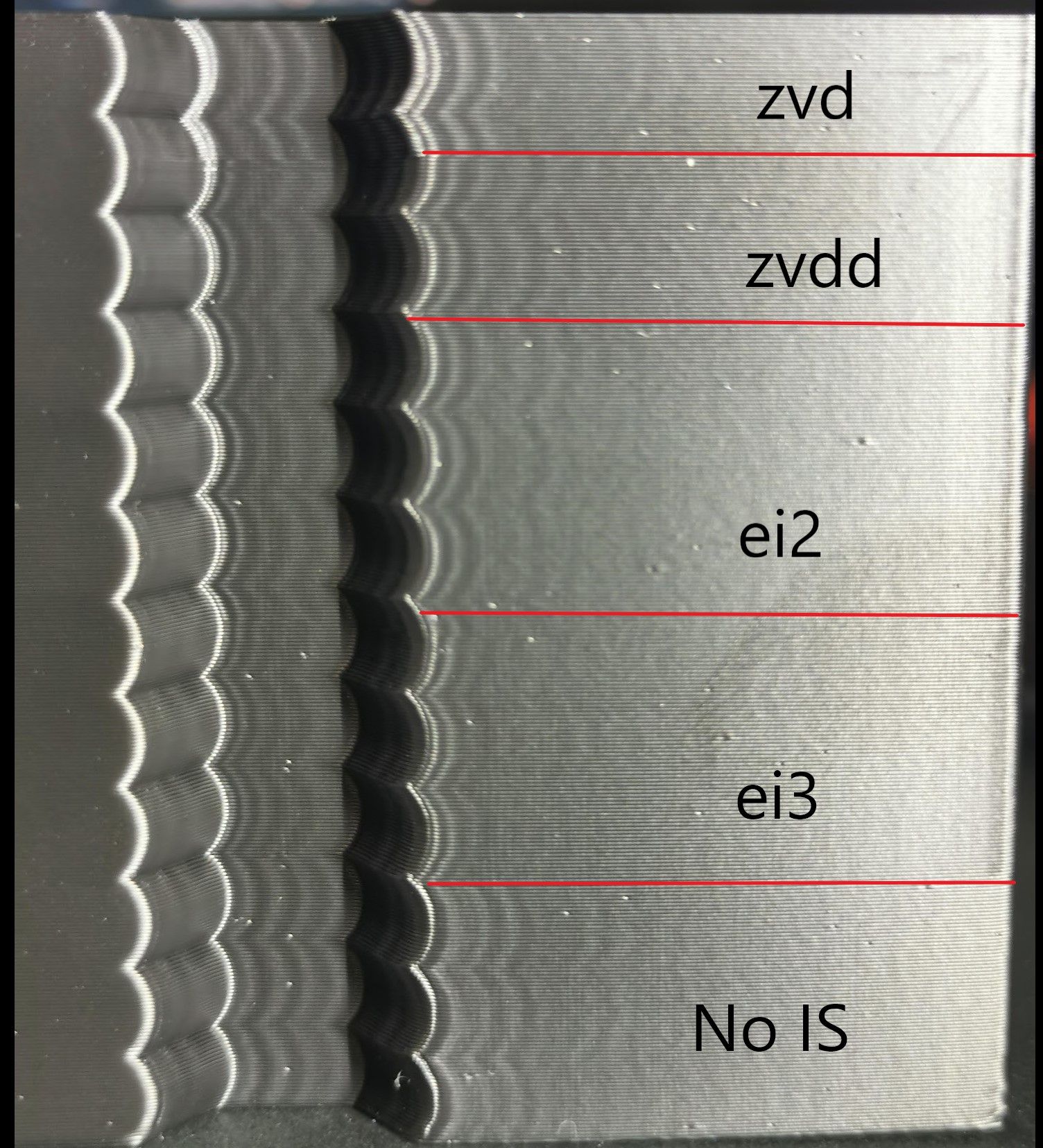

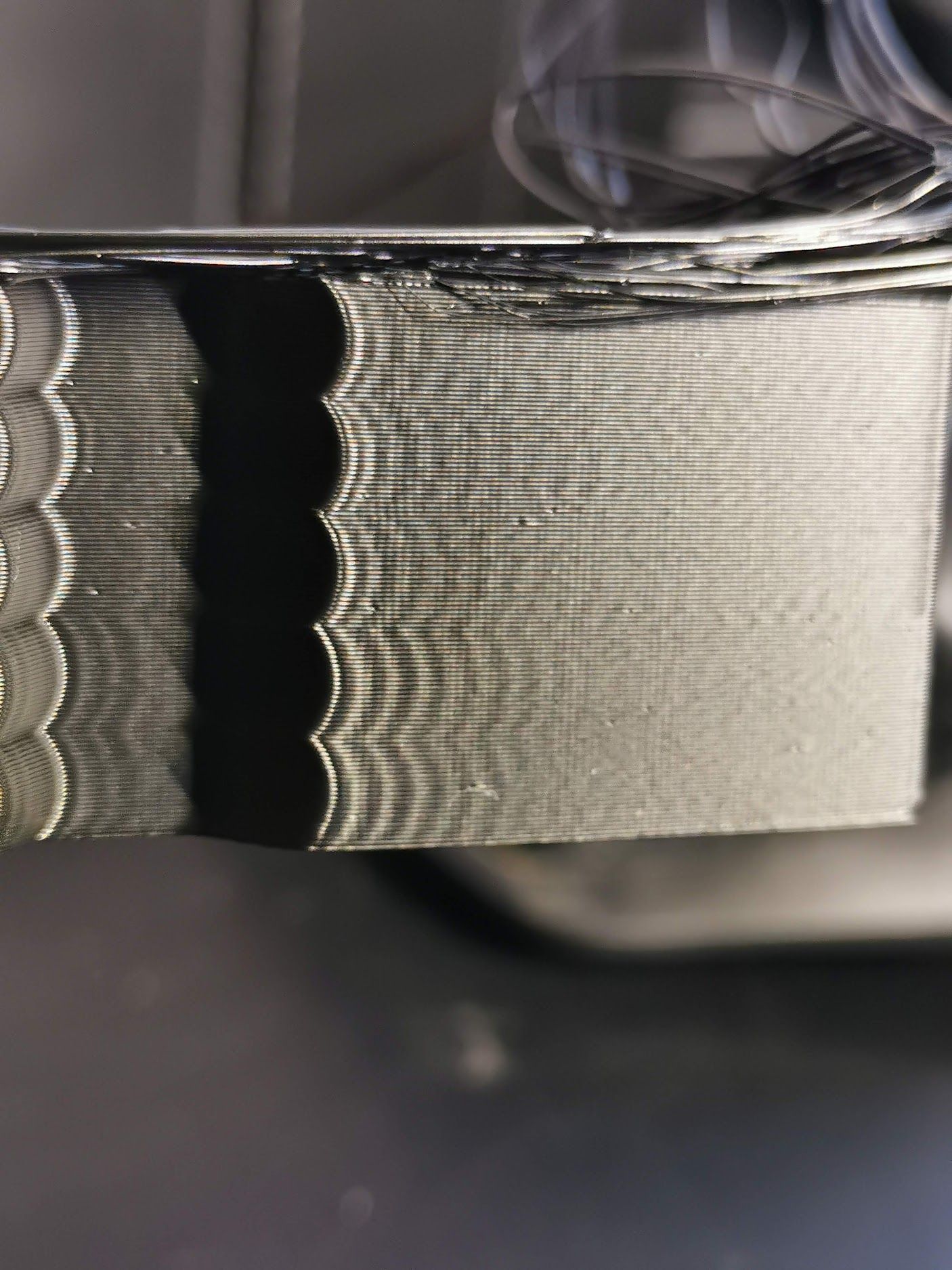

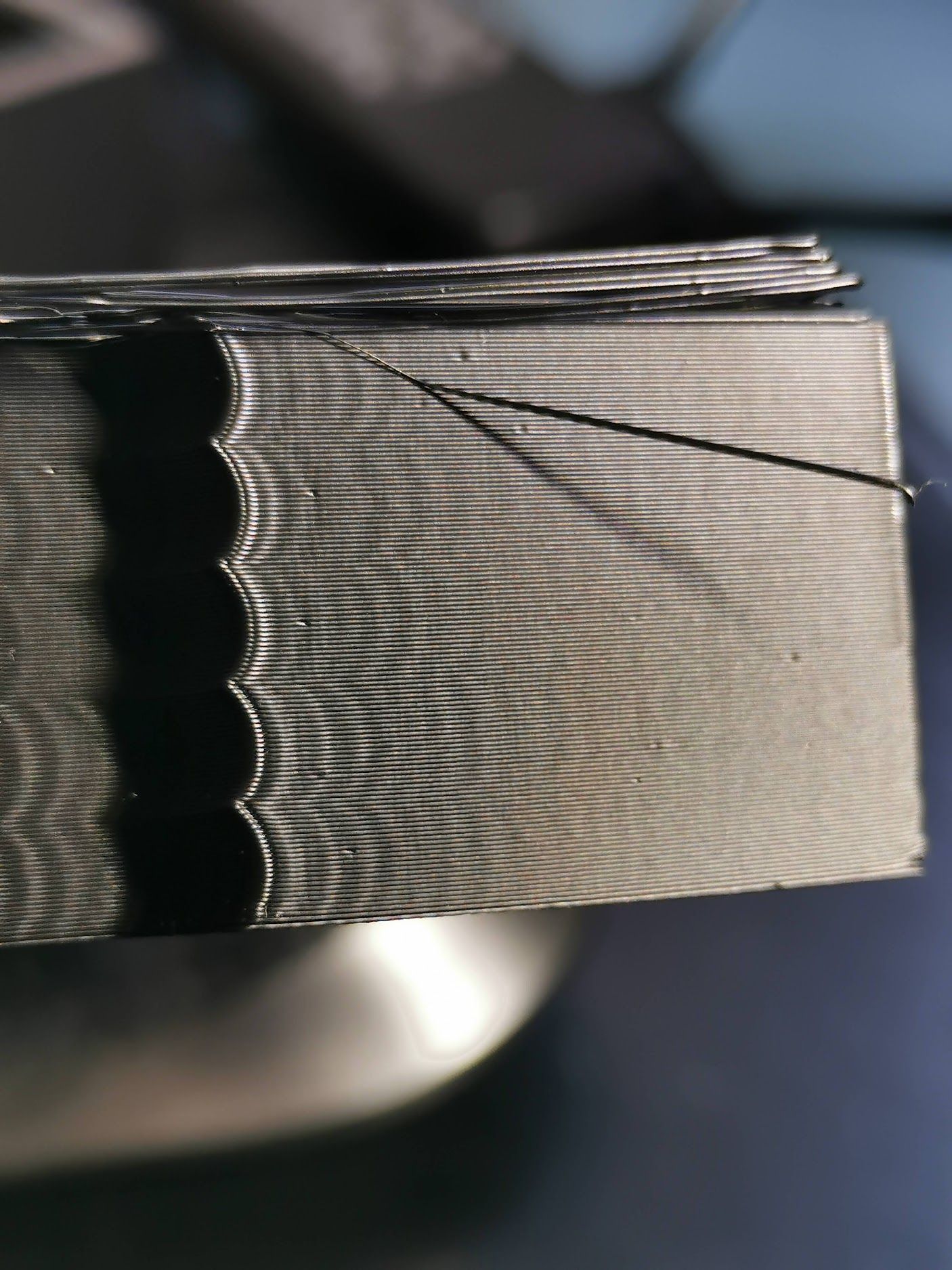

Counted from bottom - "no IS","ie3", "ie2", "zvdd", "zvd"

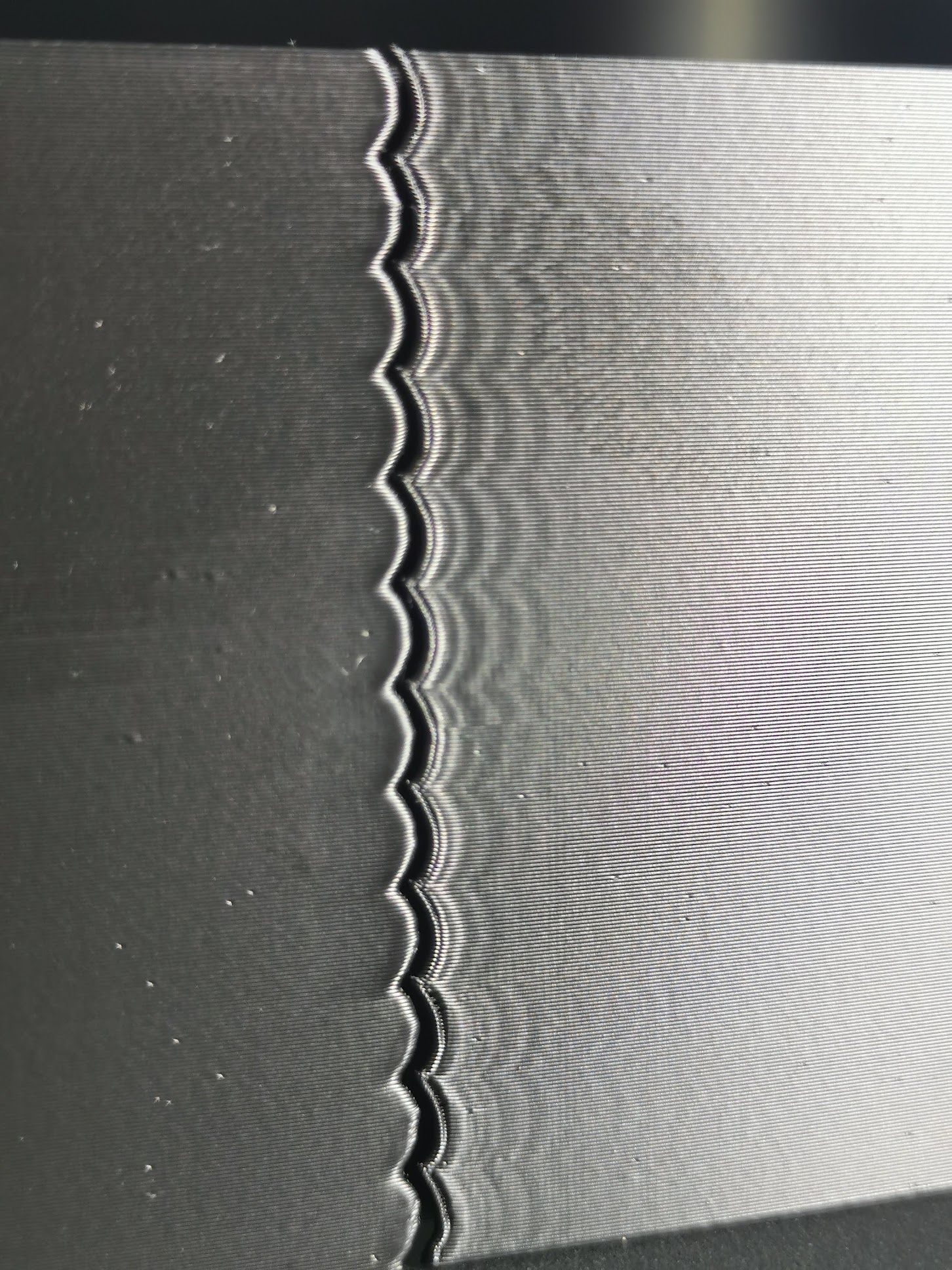

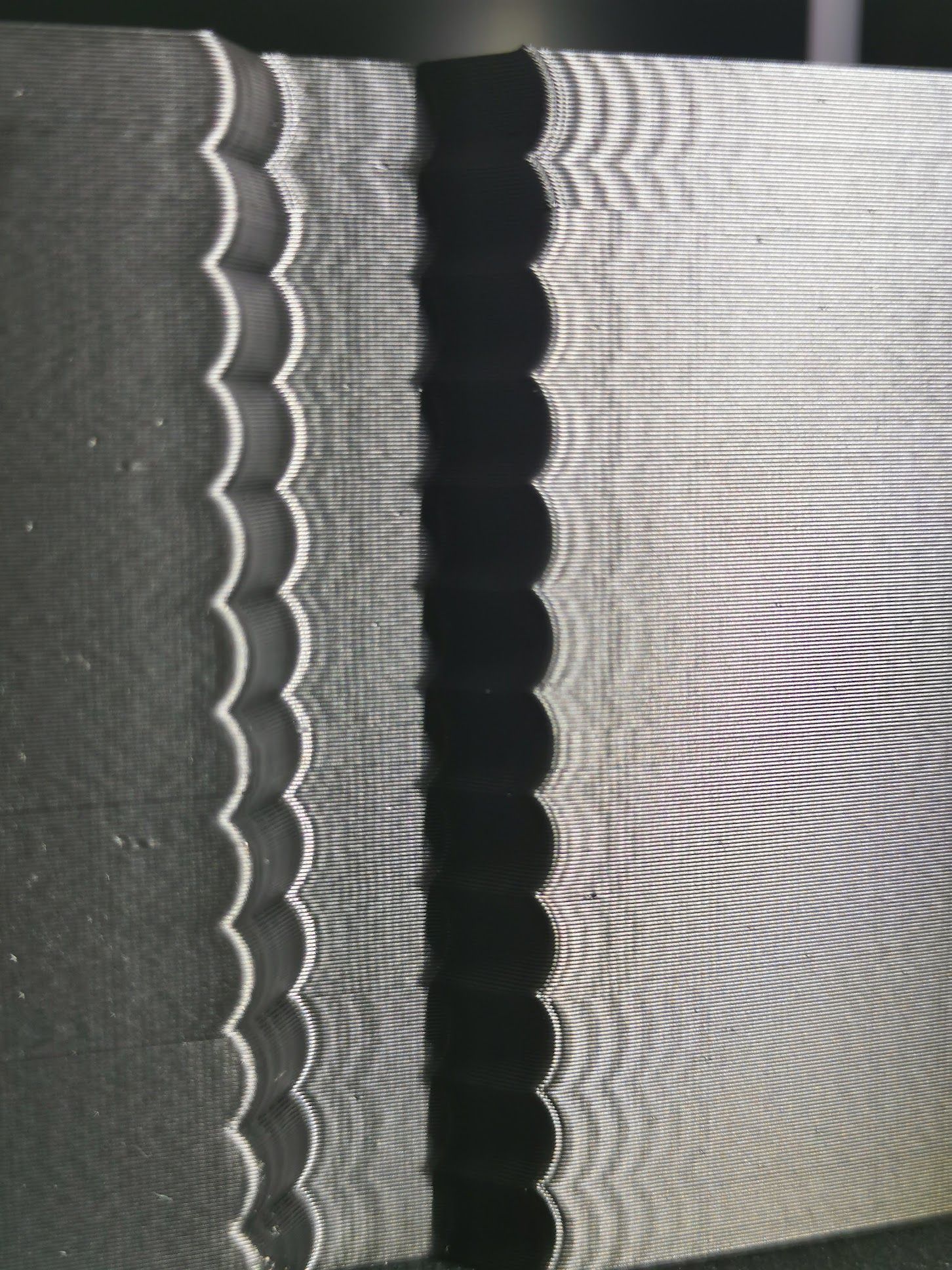

first two pictures - x-axis

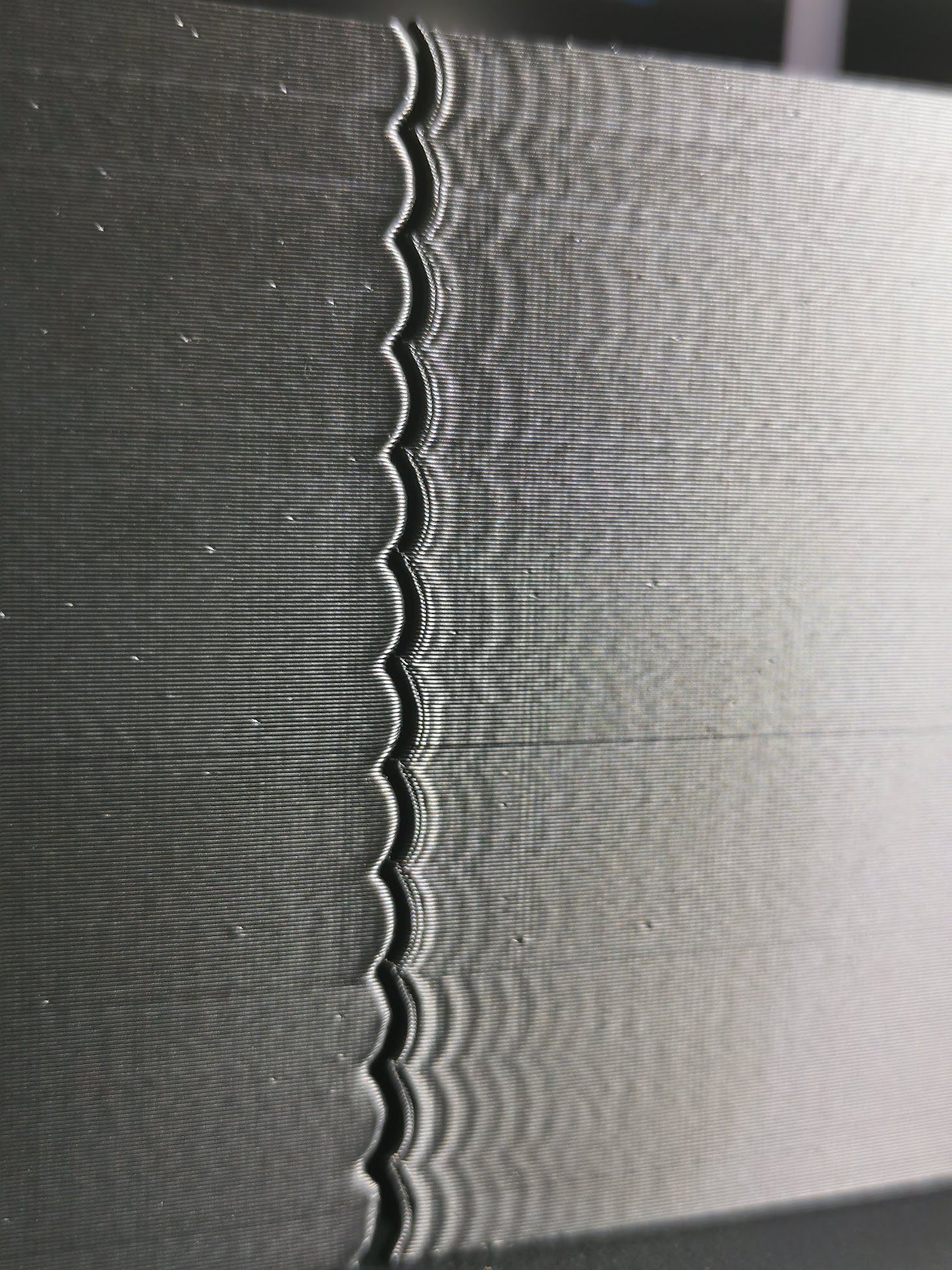

and next two y-axis

-

@dc42 The clunking is definitely something new from 3.3. I printed about a metric ton of calibration cubes when tuning my printer for various things with PA enabled on 3.3, and never heard noises like that. Of course now I also have input shaping on, so maybe it's the "new normal", but it doesn't sound like things are functioning properly.

I should add that the stepper errors seem to occur near the end of the print, and can't be responsible for the clunking it would seem. Lots of "hiccups" though, the quantity of those would correlate more with the amount of weird noises I hear, maybe..

-

@adrian52 interesting that you got a layer shift also.. I assumed it was related to me disabling PA because it happened at roughly the same point as when I turned off PA to mercifully end the clunking, but sounds like maybe it would have happened no matter what... probably an input shaping bug then.

-

@skrotz @Adrian52 @CadetC @sebkritikel I found and fixed the cause of the stepper errors and associated layer shift, and I updated the binaries at https://www.dropbox.com/sh/ja08b7qdzsl8kjc/AAAwUbkN2XJvurq5CuQTgx5Wa?dl=0. I don't yet know whether this also caused the extruder clunking or that is a different issue.

-

@dc42 with pa at my usual 0.8, and shaping set to ei3, the new binary still gives pauses and clunking. Towards the top of my cal cube I got a big progressive layer shift in the y direction. M122 gave 5908 hiccups in 17015moves, but no step errors or underruns.

I then set pa to 0 at the console, and without changing anything else, the cube printed smoothly with a nice result; 0 hiccups, 0 step errors, 0 underruns in 18073 moves. -

@dc42

Thanks for a update, I'll do test print with change every 25 layers(5mm) as follow "no IS", daa, ei2, ei3, zvdd, zvd -PA set to 0.022 and acceleration 4000, print speed 100m/s -

@dc42

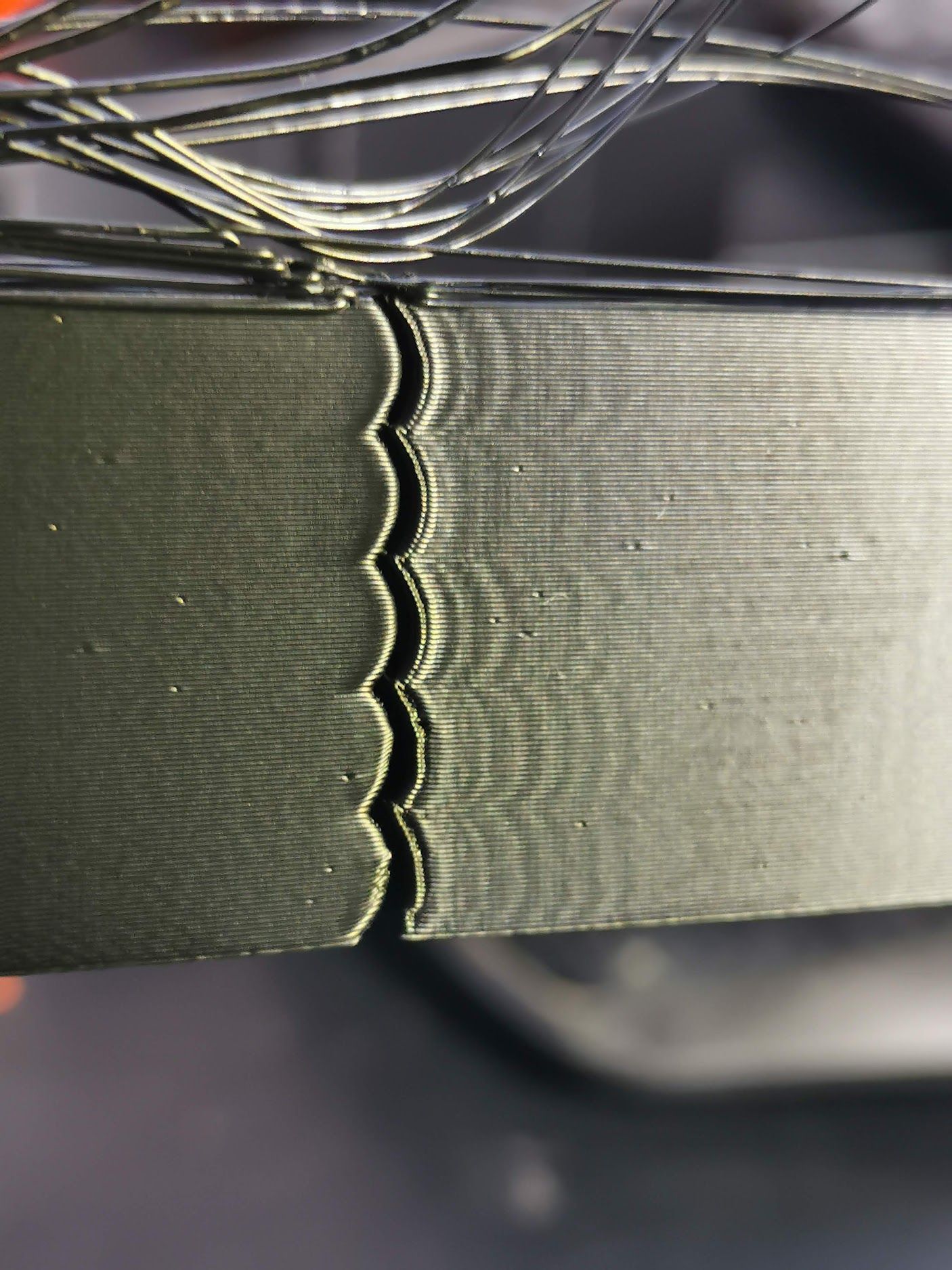

Print finished/stopped - again best results with ei3 - on pictures from bottom -"no IS", daa, ei2, ei3, zvdd, zvd(failed print stopped)

Everything was fine until the zvd was turned on - . below is a picture of the printout and a link to a video showing clunking noise - you would think that the head is blocking on the rails - which of course is not true

https://photos.app.goo.gl/HxsHQNMvrhbaPJAu5

With PA disabled all is OK

-

@cadetc ei3 has so far seemed to be the best for me as well on my core XY printer in initial testing.

-

@cadetc please post the GCode file and your config.g.g file,then I will try to reproduce it.

-

@dc42 said in RRF 3.4 input shaping preview available:

@cadetc please post the GCode file and your config.g.g file,then I will try to reproduce it.

Gcode

ringing_tower_ABS1h12m.gConfig,g

config (4).g; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Sat Apr 17 2021 20:39:32 GMT+0200 (czas środkowoeuropejski letni) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Duet 3" ; set printer name M669 K1 ; select CoreXY mode G4 S5 ;wait for expansion boards to start ; Drives M569 P0.5 S0 ; x axis physical drive 0.5 goes forward M569 P0.4 S0 ; y axis physical drive 0.4 goes forward M569 P0.2 S1 ; Fron right bed physical drive 0.2 goes forwards M569 P121.0 S1 ;extruder physical drive 121.0 goes forwards M569 P0.0 S1 ; Front left bed physical drive 0.0 goes forwards M569 P0.1 S1 ; Rear bed physical drive 0.1 goes forwards M584 X0.5 Y0.4 Z0.0:0.1:0.2 E121.0 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X160.00 Y160.00 Z800.00 E409.00 ; set steps per mm M566 X1200.00 Y1200.00 Z30.00 E1200.00 ; set maximum instantaneous speed changes (mm/min) M203 X30000.00 Y30000.00 Z1800.00 E3000.00 ; set maximum speeds (mm/min) M201 X4000.00 Y4000.00 Z200.00 E2000.00 ; set accelerations (mm/s^2) M906 X2000 Y2000 Z1200 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout M671 X-27.4:147.5:322.4 Y-4.5:324.5:-4.5 S20 ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X290 Y280 Z290 S0 ; set axis maxima M955 P121.0 I41 ; Endstops M574 X2 S1 P"121.io1.in" ; configure active-high endstop for high end on X via pin 121.io1.in M574 Y1 S1 P"io1.in" ; configure active-high endstop for low end on Y via pin io1.in M574 Z1 S2 ; configure Z-probe endstop for low end on Z ; Z-Probe M950 S0 C"121.io0.out" ; create servo pin 0 for BLTouch M558 P9 C"^121.io0.in" H15 F240 T9000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X-1 Y-32 Z2.50 ; set Z probe trigger value, offset and trigger height M557 X10:290 Y3:290 S30 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S130 ; set temperature limit for heater 0 to 120C M308 S1 P"121.temp0" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin 121.temp0 M950 H1 C"121.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S300 ; set temperature limit for heater 1 to 300C ; Fans M950 F0 C"out7" Q500 ; create fan 0 on pin out7 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"121.out2" Q500 ; create fan 1 on pin 121.out2 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M572 D0 S0.022 ;enable pressure advance -value of 0.02 M575 P1 S1 B57600 ; enable support for PanelDue M501 ; load saved parameters from non-volatile memory M911 S22 R23.5 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

@dc42 since it seems like PA is still having issues, I printed a calibration cube with ei3 input shaping on but PA disabled, and things were fine except for it still having the same extrusion bubbles/zits that aren't present in RRF 3.3 with DAA on and PA disabled (or enabled). No stepper errors or hiccups or clunking while printing with PA off:

=== Move ===

DMs created 83, segments created 35, maxWait 23082ms, bed compensation in use: mesh, comp offset 0.000

=== MainDDARing ===

Scheduled moves 11545, completed moves 11545, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 -

@skrotz does PA still have problems if you turn input shaping off?

-

@skrotz said in RRF 3.4 input shaping preview available:

extrusion bubbles/zits that aren't present in RRF 3.3 with DAA on and PA disabled (or enabled).

I realize this may be a bit of a stretch - are you sure the bubbles/zits problem is not caused by the wet filament? - have you tried going back to RRF 3.3 to check using the same filament that this problem does not exist?

-

@dc42 Is the LIS3DSH already implemented in these beta binaries? If so i could give it a try and check if PA and IS are giving problem also on my build running fine with the stable 3.3. I've already printed some part that i can compare

-

@mikes said in RRF 3.4 input shaping preview available:

@dc42 Is the LIS3DSH already implemented in these beta binaries? If so i could give it a try and check if PA and IS are giving problem also on my build running fine with the stable 3.3. I've already printed some part that i can compare

Yes, but only when connected directly to the main board via SPI at present.

-

@dc42 it does for me. Cal cube gave similar clunking and pausing, and 6306 hiccups in18073 moves. No step errors, and underruns [0,0,3]. Y shift less, but poor finish.

-

@skrotz I got a nice result with pa disabled using ei3.

-

@cadetc cubes printed on RRF 3.3 with same filament are fine, and the extrusion issues on 3.4 are not random, they happen at the same exact place each print. It’s not the filament.

-

@skrotz said in RRF 3.4 input shaping preview available:

@cadetc cubes printed on RRF 3.3 with same filament are fine, and the extrusion issues on 3.4 are not random, they happen at the same exact place each print. It’s not the filament.

Is this with input shaping disabled and PA enabled; or some other combination?

-

@dc42 said in RRF 3.4 input shaping preview available:

@mikes said in RRF 3.4 input shaping preview available:

@dc42 Is the LIS3DSH already implemented in these beta binaries? If so i could give it a try and check if PA and IS are giving problem also on my build running fine with the stable 3.3. I've already printed some part that i can compare

Yes, but only when connected directly to the main board via SPI at present.

if I understand correctly i can use it connected to the duex5 with a duet2wifi right?