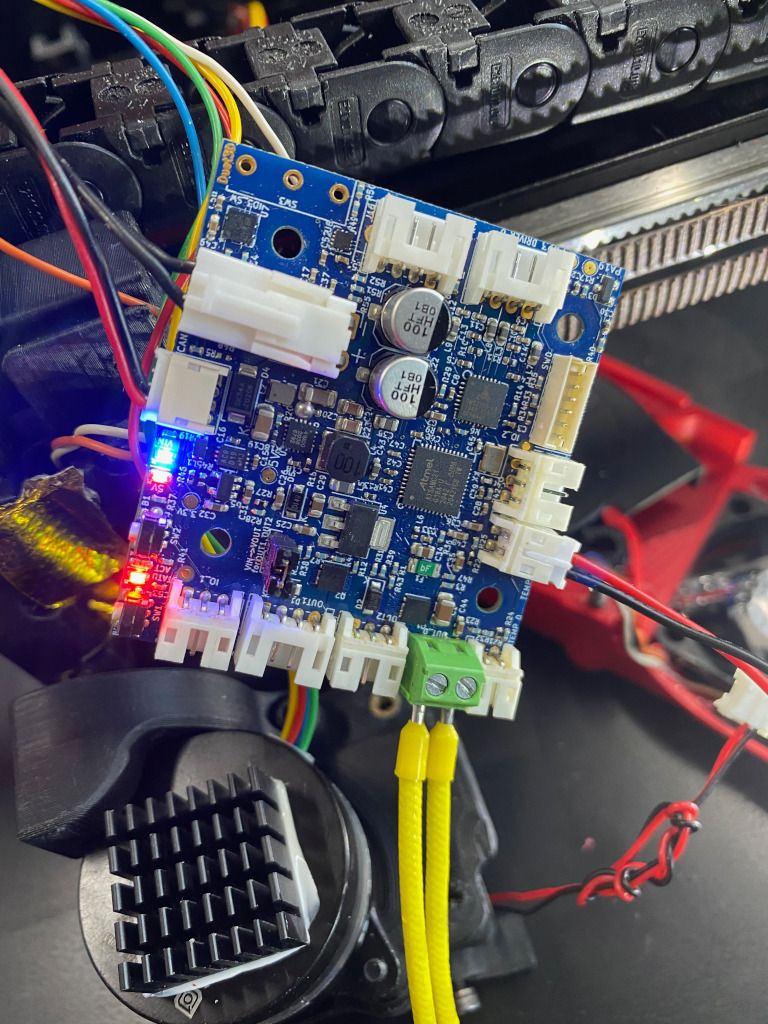

Faulty Toolboard 1LC V1.1?

-

I'm pulling my hairs out since this morning. Replaced a toolboard 1LC V1.0 with a V1.1 and since then I alway get Heater1 fault (hotend). In the meantime I replaced to heater and the thermistor, disconnected everything else from the toolboard but the error is still there. Absolutely no idea what to do now.

# # # G4 S1 ;wait for expansion boards to start ; General preferences M111 S0 ; Debugging off G21 ; Work in millimetres G90 ; Send absolute coordinates... M83 ; ...but relative extruder moves M669 K1 ; Select CoreXY mode M564 S1 H1 ; Forbid axis movements when not homed ; --- Z Drive map --- ; _______ ; | 3 | 4 | ; | ----- | ; | 2 | 5 | ; ------- ; front ; ; Drive directions M569 P0 S1 ; A (X) M569 P1 S1 ; B (Y) M569 P2 S1 ; Z1 M569 P3 S0 ; Z2 M569 P4 S1 ; Z3 M569 P5 S0 ; Z4 M569 P121.0 S1 ; E ; Motor mapping and steps per mm M584 X1 Y0 Z2:3:4:5 E121.0 M350 X16 Y16 Z16 E16 I1 ; Use 1/16 microstepping with interpolation everywhere M92 X80 Y80 Z400 E760.22 ; Set XYZE steps per mm (1.8deg motors) ; Drive currents M906 X1500 Y1500 Z1500 E500 ; XYZ and E current M906 I30 ; Idle current percentage M84 S120 ; Idle timeout ; Accelerations and speed ;M566 X1000 Y1000 Z60 E10000 ; Set maximum instantaneous speed changes (mm/min) M566 X600 Y600 Z60 E8000 ; Set maximum instantaneous speed changes (mm/min) M203 X18000 Y18000 Z3000 E15000 ; Set maximum speeds (mm/min) M201 X5000 Y5000 Z250 E1800 ; Set maximum accelerations (mm/s^2) ;M204 P4000 T1000 ; Set printing acceleration and travel accelerations ; PA, DAA M572 D0 S0.026 ; Pressure Advance ;M593 P"daa" F81 ; use DAA to cancel ringing ;M593 F46.75 S0.2 M593 F38 S0.2 ;M593 F42.5 ; Accelerometer ;M955 P121.0 I05 ; Axis travel limits M208 X5 Y-5 Z0 S1 ; Set axis minima M208 X350 Y350 Z375 S0 ; Set axis maxima ; Endstops M574 X2 S1 P"^io1.in" ; Xmax endstop on hall effect board M574 Y2 S1 P"^io2.in" ; Ymax endstop on hall effect board ;M574 Z1 S1 P"^io3.in" ; Z endstop switch M574 Z0 P"nil" ; No Z endstop ; Z probes ;M558 P8 C"^121.io0.in" T18000 F120 H5 A5 S0.01 R0.2 ; Omron M558 P8 C"^121.io0.in" T18000 F400 H10 A31 S0.003 ; Klicky Probe ;G31 K0 P500 X0 Y25 Z0 ; Omron ;G31 K0 P500 X0 Y19.75 Z6.42 ; Klicky Probe G31 K0 P500 X0 Y19.75 Z8.42 ; Klicky Probe M558 K1 P8 C"^io3.in" T18000 F240:120 H5 A10 S0.005 R0.2 ;G31 K1 P500 X0 Y0 Z0.53 ; Z switch offset (if positive, greater value = lower nozzle. if negative, more negative = higher nozzle) ; Filament Sensor M950 J1 C"121.io2.in" M581 P1 T2 S0 R1 ; Bed leveling M671 X-53:-53:400:400 Y-5:420:420:-5 S20 ; Define Z belts locations (Front_Left, Back_Left, Back_Right, Front_Right) M557 X20:330 Y20:300 P5:5 ; Define bed mesh grid (inductive probe, positions include the Y offset!) ; Bed heater (dual thermistor setup) M308 S0 P"temp0" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin temp1 M950 H0 C"out1" T0 ; create bed heater output on out1 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C ; Hotend heater M308 S1 P"121.temp1" Y"thermistor" T100000 B3950 M950 H1 C"121.out0" T1 ; create nozzle heater output on out2 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S350 ; Set temperature limit for heater 1 to 350C ; Chamber Thermistor M308 S2 P"temp1" A"Chamber" Y"thermistor" T100000 B3950 ; MCU sensors M308 S3 Y"mcu-temp" A"MCU" M308 S4 Y"drivers" A"Drivers" M912 P0 S-13 ; MCU temp calibration ; Fans M950 F0 C"121.out1" Q10 ; create fan 1 on pin out5 and set its frequency M106 P0 C"Bed" S0 H-1 B0.2 M950 F1 C"121.out2" ; create fan 1 on pin out5 and set its frequency M106 P1 C"Hotend" L1 X1 H1 T70 S1 M950 F2 C"out7" Q10 ; create fan 1 on pin out5 and set its frequency M106 P2 C"Filter" S0 H-1 B0.2 M950 F3 C"out4" Q24000 ; create fan 2 on pin out6 and set its frequency M106 P3 S0.50 H-1 B1 C"Bay Left" ; set fan 2 value. Thermostatic control is turned off M950 F4 C"1.out3" Q24000 ; create fan 2 on pin out6 and set its frequency M106 P4 S0 H-1 B1 C"Bay Right" ; set fan 2 value. Thermostatic control is turned off M950 F5 C"out5" ; create fan 3 on pin out7 and set its frequency M106 P5 S0.2 H-1 C"SBC" M950 F6 C"out6" ; create fan 2 on pin fan2 M106 P6 S1 H-1 C"Light" ; Tools M563 P0 S"Hotend" D0 H1 F1 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Enable debugging via USB ;M111 S1 P0 ; Platform ;M111 S1 P1 ; Network ;M111 S1 P2 ; Webserver ;M111 S1 P3 ; GCodes ;M111 S1 P4 ; Move ;M111 S1 P5 ; Heat ;M111 S1 P6 ; DAA ;M111 S1 P7 ; Roland ;M111 S1 P8 ; Scanner ;M111 S1 P9 ; PrintMonitor ;M111 S1 P10 ; Storage ;M111 S1 P11 ; PortControl ;M111 S1 P12 ; DuetExpansion ;M111 S1 P13 ; FilamentSensor ;M111 S1 P14 ; Wifi ;M111 S1 P15 ; Display ;M111 S1 P16 ; LinuxInterface ;M111 S1 P17 ; CAN M575 P1 S1 B115200 ; enable support for PanelDue M501 ; load config-override.g T0 ; select tool 031/07/2021, 16:52:11 M122 === Diagnostics === RepRapFirmware for Duet 3 MB6HC version 3.3 (2021-06-15 21:45:47) running on Duet 3 MB6HC v1.01 or later (SBC mode) Board ID: 08DJM-9P63L-DJ3T0-6J1DL-3SN6Q-KS33A Used output buffers: 6 of 40 (19 max) === RTOS === Static ram: 150904 Dynamic ram: 62600 of which 180 recycled Never used RAM 140508, free system stack 190 words Tasks: SBC(ready,4.9%,306) HEAT(delaying,0.0%,325) Move(notifyWait,0.0%,302) CanReceiv(notifyWait,0.0%,774) CanSender(notifyWait,0.0%,374) CanClock(delaying,0.0%,339) TMC(notifyWait,7.3%,93) MAIN(running,87.7%,922) IDLE(ready,0.0%,29), total 100.0% Owned mutexes: HTTP(MAIN) === Platform === Last reset 00:09:48 ago, cause: power up Last software reset at 2021-07-31 16:24, reason: User, GCodes spinning, available RAM 140508, slot 0 Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x00400000 BFAR 0x00000000 SP 0x00000000 Task SBC Freestk 0 n/a Error status: 0x00 Aux0 errors 0,0,0 Step timer max interval 163 MCU temperature: min 28.1, current 28.3, max 41.3 Supply voltage: min 23.9, current 23.9, max 24.0, under voltage events: 0, over voltage events: 0, power good: yes 12V rail voltage: min 12.1, current 12.2, max 12.2, under voltage events: 0 Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0 Driver 0: position 0, standstill, reads 63109, writes 14 timeouts 0, SG min/max 0/0 Driver 1: position 0, standstill, reads 63109, writes 14 timeouts 0, SG min/max 0/0 Driver 2: position 0, standstill, reads 63109, writes 14 timeouts 0, SG min/max 0/0 Driver 3: position 0, standstill, reads 63109, writes 14 timeouts 0, SG min/max 0/0 Driver 4: position 0, standstill, reads 63110, writes 14 timeouts 0, SG min/max 0/0 Driver 5: position 0, standstill, reads 63110, writes 14 timeouts 0, SG min/max 0/0 Date/time: 2021-07-31 16:52:10 Slowest loop: 1.94ms; fastest: 0.05ms === Storage === Free file entries: 10 SD card 0 not detected, interface speed: 37.5MBytes/sec SD card longest read time 0.0ms, write time 0.0ms, max retries 0 === Move === DMs created 125, maxWait 0ms, bed compensation in use: none, comp offset 0.000 === MainDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === AuxDDARing === Scheduled moves 0, completed moves 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1 === Heat === Bed heaters = 0 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamberHeaters = -1 -1 -1 -1 === GCodes === Segments left: 0 Movement lock held by null HTTP* is doing "M122" in state(s) 0 Telnet is idle in state(s) 0 File is idle in state(s) 0 USB is idle in state(s) 0 Aux is idle in state(s) 0 Trigger* is idle in state(s) 0 Queue is idle in state(s) 0 LCD is idle in state(s) 0 SBC is idle in state(s) 0 Daemon is idle in state(s) 0 Aux2 is idle in state(s) 0 Autopause is idle in state(s) 0 Code queue is empty. === CAN === Messages queued 5166, received 6622, lost 0, longest wait 3ms for reply type 6049, peak Tx sync delay 7, free buffers 49 (min 48), ts 2944/2943/0 Tx timeouts 0,0,0,0,0,0 === SBC interface === State: 4, failed transfers: 1, checksum errors: 0 Last transfer: 2ms ago RX/TX seq numbers: 19861/19861 SPI underruns 0, overruns 0 Disconnects: 0, timeouts: 0, IAP RAM available 0x2c83c Buffer RX/TX: 0/0-0 === Duet Control Server === Duet Control Server v3.3.0 Code buffer space: 4096 Configured SPI speed: 8000000Hz Full transfers per second: 35.92, max wait times: 7.0ms/0.0ms Codes per second: 0.16 Maximum length of RX/TX data transfers: 5552/744 -

You have to connect the temp sensor to the toolboard

Edit:

It's commented out in the config -

Damn....forgot to change back to the original config. This was just for testing. Sorry. I edited my post and now it shows the right config.

-

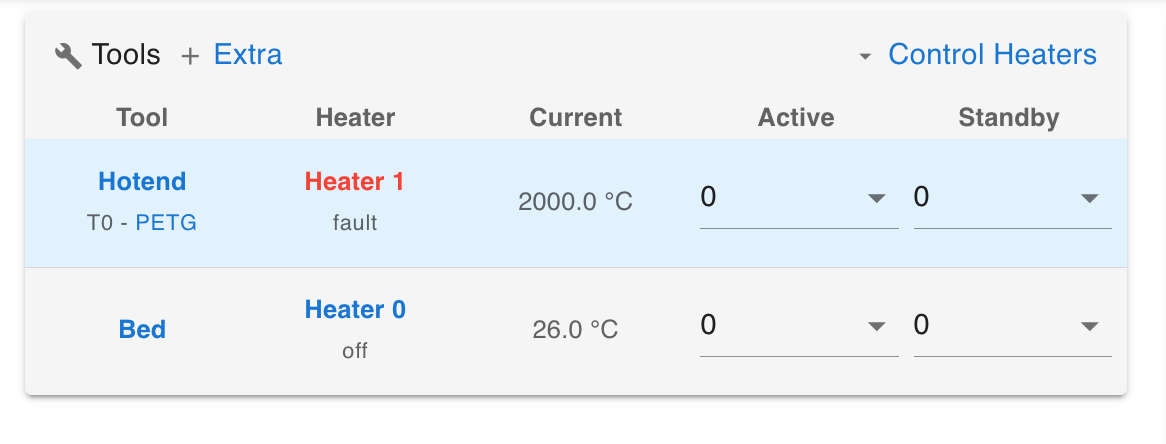

@martinnyhc does DWC show a sensible temperature reading from sensor 1/heater 1 ?

Have you run M303 tuning on that heater or tool?

Are you running firmware 3.3 on the main board [edit: yes you are according to your M122 report] and on the tool board?

-

DWC shows heater fault and a temperature of 2000. And yes, all boards are running 3.3.

-

31/07/2021, 18:39:30 M122 B121 Diagnostics for board 121: Duet TOOL1LC firmware version 3.3 (2021-06-15 16:12:58) Bootloader ID: SAMC21 bootloader version 2.3 (2021-01-26b1) Never used RAM 2592, free system stack 2789 words Tasks: Move(notifyWait,0.0%,153) HEAT(delaying,0.0%,117) CanAsync(notifyWait,0.0%,65) CanRecv(notifyWait,0.0%,76) CanClock(notifyWait,0.0%,65) ACCEL(notifyWait,0.0%,61) TMC(notifyWait,2.8%,57) MAIN(running,92.1%,352) IDLE(ready,0.0%,27) AIN(delaying,4.9%,142), total 100.0% Last reset 00:00:51 ago, cause: power up Last software reset data not available Driver 0: position 0, 760.2 steps/mm, standstill, SG min/max 0/0, read errors 0, write errors 0, ifcnt 12, reads 25486, writes 12, timeouts 0, DMA errors 0, steps req 0 done 0 Moves scheduled 0, completed 0, in progress 0, hiccups 0, step errors 0, maxPrep 0, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0 Peak sync jitter 0/5, peak Rx sync delay 192, resyncs 0/0, no step interrupt scheduled VIN: 24.0V MCU temperature: min 25.9C, current 30.5C, max 30.5C Ticks since heat task active 27, ADC conversions started 51022, completed 51021, timed out 0, errs 0 Last sensors broadcast 0x00000002 found 1 32 ticks ago, loop time 0 CAN messages queued 297, send timeouts 0, received 367, lost 0, free buffers 37, min 37, error reg 0 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 0 Accelerometer detected: yes, status: 00 I2C bus errors 0, naks 0, other errors 0 -

-

Oh yes, and i forgot to mention that there is also a Duet3 3HC expansion board.

Duet3 6HC -> Duet3 3HC expansion -> Duet 1LC

31/07/2021, 18:41:29 M122 B1 Diagnostics for board 1: Duet EXP3HC firmware version 3.3 (2021-06-15 16:12:41) Bootloader ID: not available Never used RAM 159016, free system stack 4400 words Tasks: Move(notifyWait,0.0%,160) HEAT(delaying,0.0%,118) CanAsync(notifyWait,0.0%,69) CanRecv(notifyWait,0.0%,82) CanClock(notifyWait,0.0%,71) TMC(notifyWait,7.3%,63) MAIN(running,91.4%,410) IDLE(ready,0.0%,39) AIN(delaying,1.3%,263), total 100.0% Last reset 00:02:49 ago, cause: software Last software reset at 1970-01-01 04:33, reason: HardFault, available RAM 159104, slot 2 Software reset code 0x0060 HFSR 0x40000000 CFSR 0x00000001 ICSR 0x00000803 BFAR 0xe000ed38 SP 0x20005ad8 Task MAIN Freestk 3093 ok Stack: 00000000 00000000 200014d8 a5a5a5a5 00000003 00013325 a5a5a5a4 41000000 bf800000 00000000 e200c224 4112e83a 610a0114 3020e80e 010588c4 01288500 42ae4720 24430008 0a240c0b 79340290 3a36d584 41280000 40c9d979 3f3567d9 80000010 a5a5a5a5 a5a5a5a5 Driver 0: position 0, 80.0 steps/mm, standstill, reads 955, writes 11 timeouts 0, SG min/max 0/0, steps req 0 done 0 Driver 1: position 0, 80.0 steps/mm, standstill, reads 956, writes 11 timeouts 0, SG min/max 0/0, steps req 0 done 0 Driver 2: position 0, 80.0 steps/mm, standstill, reads 957, writes 11 timeouts 0, SG min/max 0/0, steps req 0 done 0 Moves scheduled 0, completed 0, in progress 0, hiccups 0, step errors 0, maxPrep 0, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0 Peak sync jitter -1/10, peak Rx sync delay 180, resyncs 0/0, no step interrupt scheduled VIN: 24.0V, V12: 12.2V MCU temperature: min 26.6C, current 32.2C, max 32.2C Ticks since heat task active 235, ADC conversions started 170164, completed 170163, timed out 0, errs 0 Last sensors broadcast 0x00000000 found 0 240 ticks ago, loop time 0 CAN messages queued 594, send timeouts 0, received 1982, lost 0, free buffers 37, min 37, error reg 100000 dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 0 -

Just disconnected the 3HC expansion board and connected the 1LC directly to the main board. Result is the same.

-

Check all connections to/from 1LC

-

Did that several times. I'm debugging since the morning when I simply replaced the toolboard.

There are only two, power and CAN bus. That's the reason why I'm using it

-

@martinnyhc

Also using V1, had this problem = bad connection on CAN or the thermistor. -

@martinnyhc if you send M308 S1 what response do you get?

Have you tried using the temp0 connector on the tool board instead of temp1?

-

31/07/2021, 19:34:26 M308 S1 Sensor 1 type Thermistor using pin 121.temp1, reading 2000.0, last error: bad Vssa, T:100000.0 B:3950.0 C:0.00e+0 R:2200.0 L:-22 H:-1 -

@martinnyhc if you disconnect the thermistor from the tool board, do you still get the "bad VSSA" response to that command?

-

Yes, it's the same result.

And yes, I already tried temp1. I tried everything I could think of

Tried to isolate the problem but unfortunately without success. Lucky me, that I have so many spare parts except a toolboard.

Tried to isolate the problem but unfortunately without success. Lucky me, that I have so many spare parts except a toolboard.31/07/2021, 19:39:18 M308 S1 Sensor 1 type Thermistor using pin 121.temp1, reading 2000.0, last error: bad Vssa, T:100000.0 B:3950.0 C:0.00e+0 R:2200.0 L:-22 H:-1 -

@martinnyhc the "bad VSSA" error even with no thermistors connected suggests a faulty tool board. Please send an email to warranty@duet3d.com.

-

Will do so. Thanks for our support.

Will do so. Thanks for our support. -

Looking at the picture there is no CAN terminator or is there?

-