First layer issues-Extrusion volume dropping on first layer?

-

@fcwilt First layer speed is 20mm/sec

First Layer height is 0.2mmIn a post above I have attached screenshots of most of the slicer settings.

-

@rkaronde said in First layer issues-Extrusion volume dropping on first layer?:

@fcwilt First layer speed is 20mm/sec

First Layer height is 0.2mmIn a post above I have attached screenshots of most of the slicer settings.

Thanks.

Those settings seem good.

Frederick

-

@rkaronde Maybe another silly question but have you tried cleaning your bed? I regularly clean my bed with isopropyl alcohol but once in a while I have to clean it with hot water and washing-up liquid and that can be the difference between night and day sometimes. Even though I never ever touch my bed and it looks squeaky clean there can be some residue on it.

-

@tmicke Yes, the bed is clean.

The bed has PEI steel sheet on it.

With all the tweaking to solve this I do sometimes get finger prints/oil on the bed.

I normally just wash with soap and water. -

@rkaronde said in First layer issues-Extrusion volume dropping on first layer?:

not sure if there is any way to measure the skipping.

Some people can read a lot from the M122 diagnose output. Issue a diagnose right after the first layer (pause and diag) and post it here.

Let the first layer run without babystepping, we want to provoke the errors... -

Loose grub screw on a lead screw or z motor that's letting it walk up during mesh compensation adjustments but then binding enough to keep it from walking back down?

-

@rkaronde said in First layer issues-Extrusion volume dropping on first layer?:

Back to the subject:

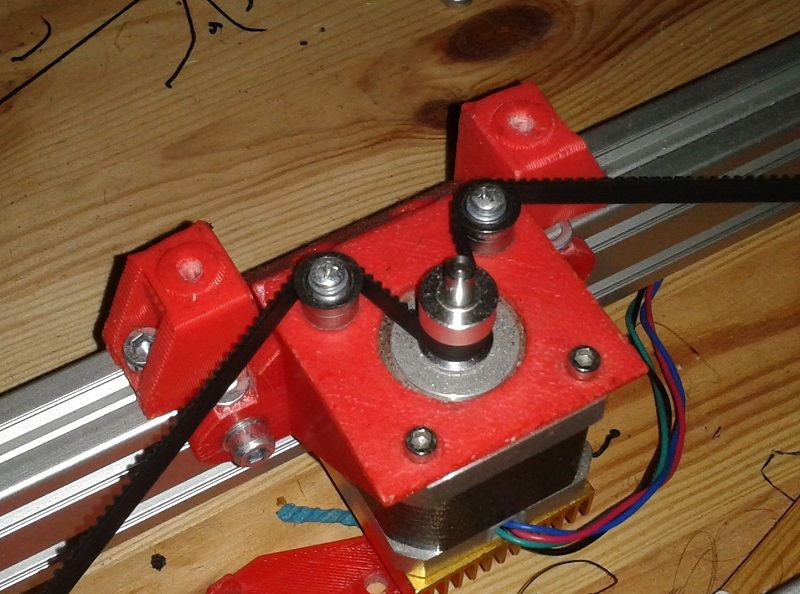

I had a closer look on your Z-axis and saw anti-backlash nuts and springs around the bed adjuster. Just wondering, if the extruder pressure adds enough counterforce to the bed to provoke the skipped steps we discussed earlier?There's also room for improvement regarding belt-wrap around the drive pulleys. I simply added a few flanged bearings on mine.

They run on two of the stepper mounting screws, so you could easily add them too. Maybe have to turn all pulleys around with the belt-side facing downwards to run the belt closer to the stepper bracket. (reducing load on the bearings)

-

@rkaronde I can see two likely reasons:

-

The bed and hot end temperatures are not stable between when you probe the bed to set up mesh compensation and when you print the end of the first layer. Don't just heat the bed, heat the hot end too.

-

Your Z probe does not have a constant trigger height across the bed. So although your height map looks flat, it isn't really. At several XY positions on the bed, use G30 S-1 to lower the nozzle until the probe triggers, then measure the height of the nozzle above the bed using feeler gauges.

-

-

@phaedrux Checked the grub screws again, and they were tight.

-

@o_lampe Thanks. I will see if the Z belt path can be changed as you suggested.

I did a M122 after first layer was done, and before print ends, and the drag did not show any skipped steps.

-

@dc42 Thanks for the suggestions.

-

Probing is being done after both then bed and hot end are upto temp. I have also tried probing with a 5min wait after both hot end and bed are heated.

-

Once I get G30 S-1 at various points and find the difference in trigger heights, is there a way to use that information?

I think the X gantry has a sag, and that is why I put the Z Probe on a X=0 offset, but that did not seem to help.

-

-

@rkaronde even just moving your z motors in and the idlers put will increase the number of teeth in contact for the motor pulley.

On the anti backlash nuts, there's probably no real need for them on the z axis. Unless you're planning on accelerating your bed at over 10000mm/s^2 downwards, gravity will always win and there won't be any backlash! Over time though the extra friction from using the backlash nuts might cause some wear.