BL Touch Installation what is Servo Pin?

-

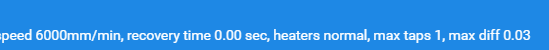

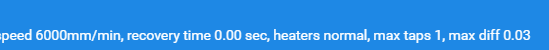

@fcwilt I set the A to 1, the Max Taps was 1.

The method your describing is what I have done, I must touch it multiple time (different number each time. I even change the S Parameter to 5 and tested it with the same result. I have since changed it back.

-

I have tested by inputting G30 in the command line with the same result

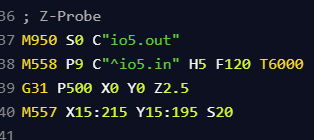

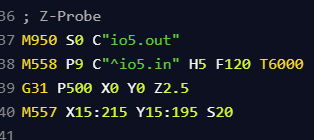

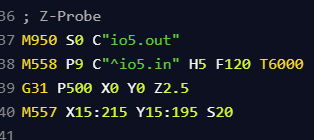

; Configuration file for Duet 3 (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.0 on Sat Aug 21 2021 12:25:45 GMT-0400 (Eastern Daylight Time) ; General preferences M575 P1 S1 B57600 ; enable support for PanelDue G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Duet 3" ; set printer name ; Drives M569 P40.0 S1 ; physical drive 40.0 goes forwards M569 P41.0 S1 ; physical drive 40.0 goes forwards M569 P42.0 S1 ; physical drive 42.0 goes forwards M569 P43.0 S1 ; physical drive 42.0 goes forwards ;M569 P125.0 S1 ; physical drive 125.0 goes forwards M584 X40.0:41.0 Y42.0 Z43.0 ;E125.0 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X160.00 Y200.00 Z200.00 E420.00 ; set steps per mm M566 X900.00 Y900.00 Z900.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z2000.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z250.00 E250.00 ; set accelerations (mm/s^2) M906 X2500 Y1200 Z1200 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X2300 Y1300 Z304 S0 ; set axis maxima ; Endstops M574 X1 S1 P"!^40.io1.in" ; configure active-high endstop for low end on X via pin !^40.io1.in M574 Y1 S1 P"!^42.io1.in" ; configure active-high endstop for low end on Y via pin !^41.io1.in M574 Z1 S1 P"!^43.io1.in" ; configure active-high endstop for low end on Z via pin !^43.io1.in ; Z-Probe M950 S0 C"io5.out" ; create servo pin 0 for BLTouch M558 P9 C"io5.in" H5 F120 T6000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X0 Y0 Z2.5 ; set Z probe trigger value, offset and trigger height M557 X15:215 Y15:195 S20 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M308 S1 P"spi.cs1" Y"rtd-max31865" ; configure sensor 1 as thermocouple via CS pin spi.cs1 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S500 ; set temperature limit for heater 1 to 500C ; Fans M950 F0 C"out4" Q500 ; create fan 0 on pin out4 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"out5" Q500 ; create fan 1 on pin out5 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined; homeall.g ; called to home all axes ; ; generated by RepRapFirmware Configuration Tool v3.3.0 on Sat Aug 21 2021 12:06:10 GMT-0400 (Eastern Daylight Time) G91 ; relative positioning G1 H2 Z30 F6000 ; lift Z relative to current position G1 H1 X-2305 Y-1305 F3000 ; move quickly to X and Y axis endstops and stop there (first pass) G1 H2 X5 Y5 F6000 ; go back a few mm G1 H1 X-2305 Y-1305 F180 ; move slowly to X and Y axis endstops once more (second pass) G90 ; absolute positioning G1 X250 Y650 F3000 ;move probe to centre of bed G30 ; probe bed ; Uncomment the following lines to lift Z after probing G91 ; relative positioning G1 Z20 F1800 ; lift Z relative to current position G90 ; absolute positioning; homez.g ; called to home the Z axis ; ; generated by RepRapFirmware Configuration Tool v3.3.0 on Sat Aug 21 2021 12:06:11 GMT-0400 (Eastern Daylight Time) G91 ; relative positioning G1 H2 Z10 F6000 ; lift Z relative to current position G1 H1 Z-309 F2500 ; move Z down until the endstop is triggered G1 H2 Z5 F6000 ; go back a few mm G1 H1 Z-20Y F180 ; move slowly to Z axis endstops once more (second pass) ;G92 Z0 ; set Z position to axis minimum (you may want to adjust this) G30 ; probe bed ; Uncomment the following lines to lift Z after probing G91 ; relative positioning G1 Z20 F2500 ; lift Z relative to current position G90 ; absolute positioning -

@signpostman said in BL Touch Installation what is Servo Pin?:

@fcwilt I set the A to 1, the Max Taps was 1.

The method your describing is what I have done, I must touch it multiple time (different number each time. I even change the S Parameter to 5 and tested it with the same result. I have since changed it back.

That would seem to confirm my belief that the signal from the probe to the board is inconsistent.

I have two printers with a BLTouch but the wire lengths are perhaps 1 meter.

One difference I have from your setup is the M558 command prefixes the pin name with the ^ character.

What sort of wire is used to extended the black/white pair back to the board?

Frederick

-

@fcwilt I have tried CAT 5 cable and now I have 18 gauge 4 conductor that is not twisted pair

-

Should it look like this?

-

@signpostman said in BL Touch Installation what is Servo Pin?:

@fcwilt I have tried CAT 5 cable and now I have 18 gauge 4 conductor that is not twisted pair

I would remove one twisted pair from the CAT cable and use that. And I would make sure to route it away from any source of noise, like stepper wiring.

Frederick

-

-

Adding ^ didn't seem to help

-

@signpostman said in BL Touch Installation what is Servo Pin?:

Adding ^ didn't seem to help

And you re-booted after making the change?

It was worth a try.

Frederick

-

@signpostman said in BL Touch Installation what is Servo Pin?:

Should it look like this?

On the Duet3 the pullup should not be enabled.

-

@phaedrux said in BL Touch Installation what is Servo Pin?:

@signpostman said in BL Touch Installation what is Servo Pin?:

Should it look like this?

On the Duet3 the pullup should not be enabled.

True but at this point any change might help point to the problem.

Frederick

-

@fcwilt said in BL Touch Installation what is Servo Pin?:

@signpostman said in BL Touch Installation what is Servo Pin?:

@fcwilt I have tried CAT 5 cable and now I have 18 gauge 4 conductor that is not twisted pair

I would remove one twisted pair from the CAT cable and use that. And I would make sure to route it away from any source of noise, like stepper wiring.

Frederick

This might be your best bet. Short of a toolboard.

As a sanity check can you test the bltouch with a much shorter length of wire with the probe not mounted on the print head? Keep it vertical and trigger it by hand to see if it will stop the Z axis.

-

@fcwilt Agree

-

@phaedrux What other probe do you suggest that would work with a long cable?

-

Maybe a good quality Normally Closed microswitch that you could manually mount before probing with some good quality shielded wire? Or a conductive touch plate that could be moved under the nozzle?

With a printer that size options may be limited?

With better wire the BLTouch may be viable as well.

-

@signpostman said in BL Touch Installation what is Servo Pin?:

@phaedrux What other probe do you suggest that would work with a long cable?

What sort of bed do you have? What is it made of. What sort of surface do you print on?

Thanks.

Frederick

-

@fcwilt Right now I have a piece of corrugated plastic, so the probe does not get destroyed. I am going to have a aluminum with steel overlay when complete.

-

@signpostman said in BL Touch Installation what is Servo Pin?:

@fcwilt Right now I have a piece of corrugated plastic, so the probe does not get destroyed. I am going to have a aluminum with steel overlay when complete.

Will there be any magnets involved like you find in the Buildtak system?

Thanks.

Frederick

-

@phaedrux I just shortened the cables and put new fittings on the end

-

Still have exactly same issue.