MFM recurring error

-

I've been dealing with a long-term recurring issue with my MFM where I keep getting the following error:

Filament error on extruder 0: tooLittleMovement

There seems to be no rhyme or reason behind it. I've run off several of the same print, sometimes I get no errors, sometimes I get multiple errors such as below. At this point, I am able to resume from the Status page button with no other action.

The only common thread with this issue is that it seems to happen with greater frequency when printing PLA. I am able to print a complete PLA job with the MFM disabled but that leaves me with no filament run-out protection.

I dont want to toss the MFM out but I'm getting pretty frustrated by this problem.

HW Info:

Board: Duet 2 WiFi (2WiFi)

Firmware: RepRapFirmware for Duet 2 WiFi/Ethernet 3.4.0beta7+7 (2022-01-14)

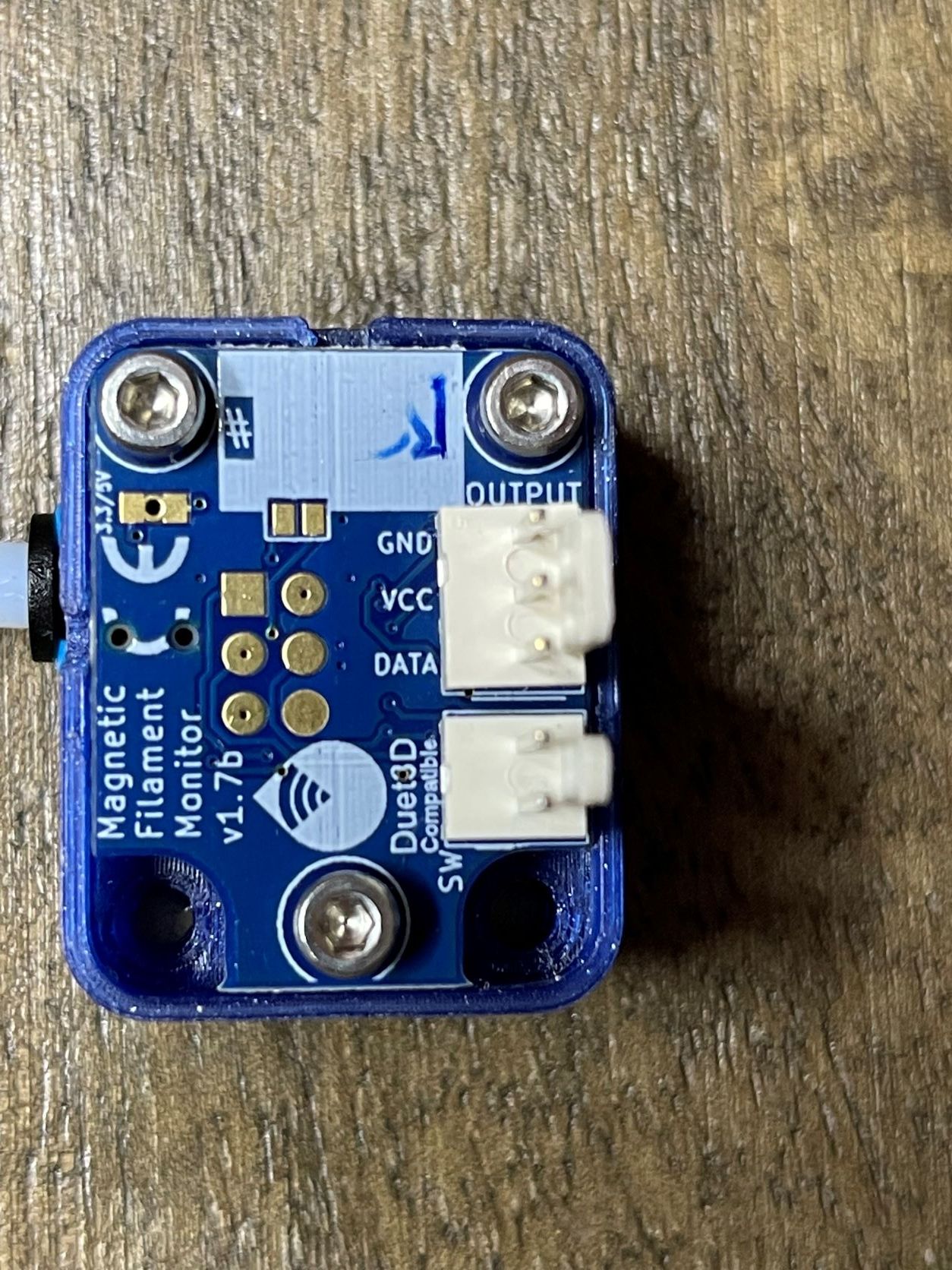

Duet WiFi Server Version: 1.26MFM is V 1.7a

Sample M591 d0 outputs:

2/18/2022, 7:48:34 AM m591 d0

Duet3D rotating magnet filament monitor v3 on pin e0stop, enabled, sensitivity 26.26mm/rev, allow 1% to 200%, check printing moves every 3.0mm, version 3, mag 131 agc 63, measured sensitivity 27.19mm/rev, min 1% max 108% over 207.6mm

2/18/2022, 7:46:53 AM Resume state saved

2/18/2022, 7:46:50 AM Error: Filament error on extruder 0: tooLittleMovement

2/18/2022, 7:45:07 AM M24

Printing resumed

2/18/2022, 7:44:58 AM m591 d0

Duet3D rotating magnet filament monitor v3 on pin e0stop, enabled, sensitivity 26.26mm/rev, allow 1% to 200%, check printing moves every 3.0mm, version 3, mag 131 agc 63, measured sensitivity 29.36mm/rev, min 0% max 116% over 59.0mm

2/18/2022, 7:44:55 AM Resume state saved

2/18/2022, 7:44:51 AM Error: Filament error on extruder 0: tooLittleMovement

2/18/2022, 7:44:25 AM M24

Printing resumed

2/18/2022, 7:43:42 AM m591 d0

Duet3D rotating magnet filament monitor v3 on pin e0stop, enabled, sensitivity 26.26mm/rev, allow 1% to 200%, check printing moves every 3.0mm, version 3, mag 130 agc 63, measured sensitivity 26.02mm/rev, min 0% max 104% over 600.0mm

2/18/2022, 7:43:05 AM Resume state saved

2/18/2022, 7:43:02 AM Error: Filament error on extruder 0: tooLittleMovement

2/18/2022, 7:38:04 AM M24

Printing resumed

2/18/2022, 7:34:22 AM m591 d0

Duet3D rotating magnet filament monitor v3 on pin e0stop, enabled, sensitivity 26.26mm/rev, allow 1% to 200%, check printing moves every 3.0mm, version 3, mag 132 agc 63, measured sensitivity 25.79mm/rev, min -1% max 103% over 2959.5mm -

@wouldstain said in MFM recurring error:

agc 63

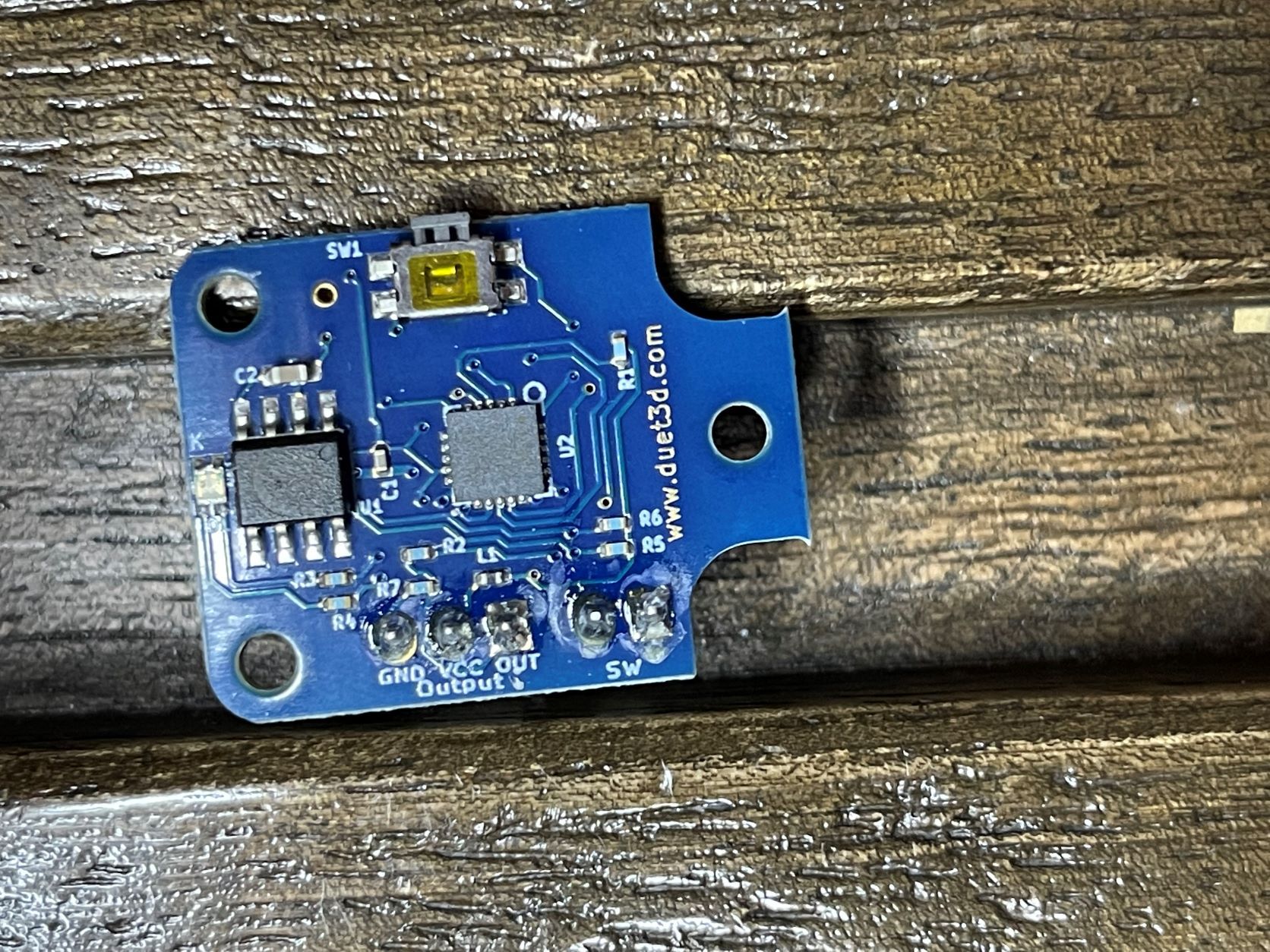

Your AGC is on the low side of the range which MIGHT indicate the magnet is too close to the sensor IC and it may be rubbing on the top of the sensor.

That would cause a "Too little movement" indication.

I would take it apart and check.

-

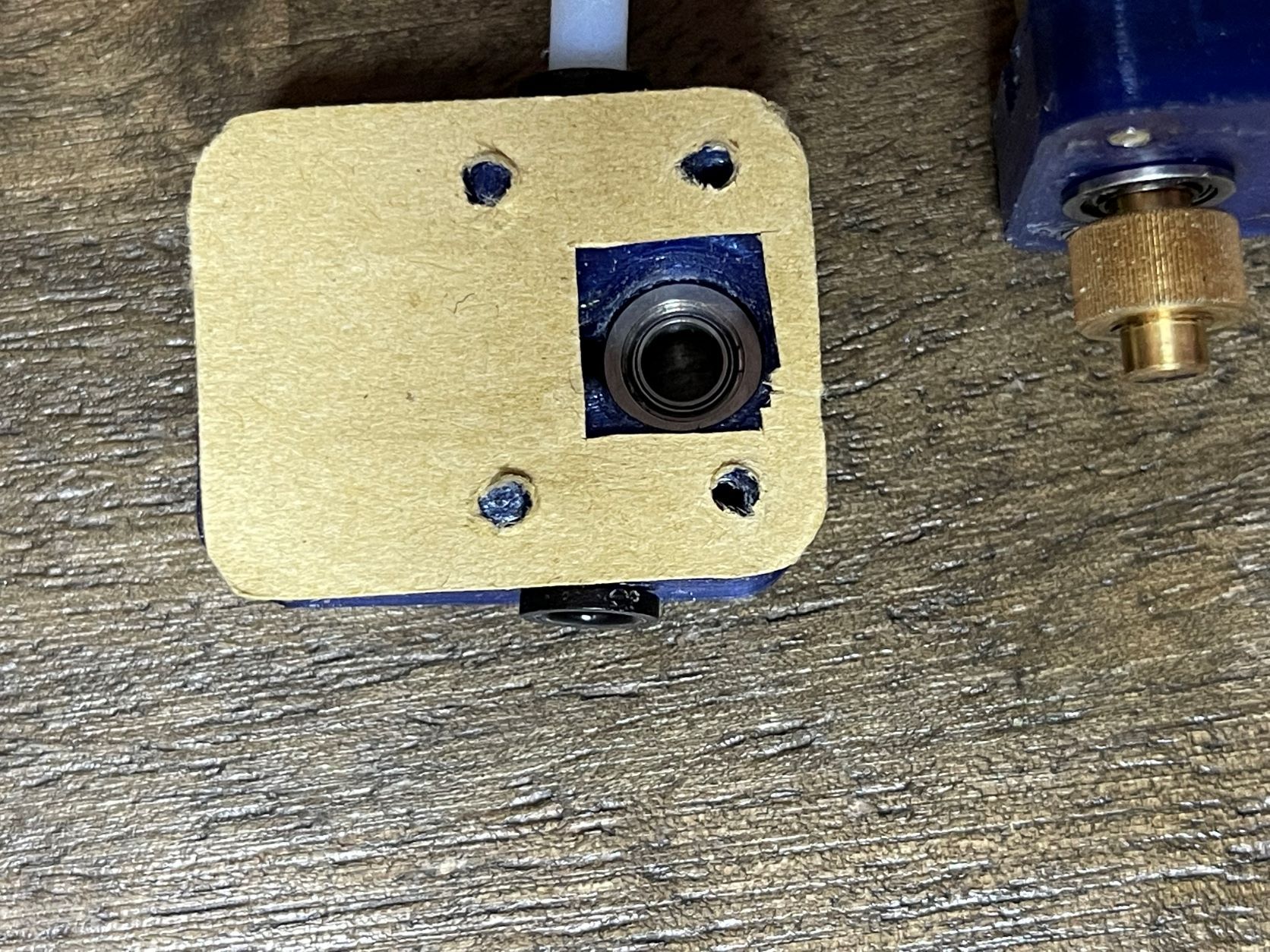

@wouldstain Electrically, your MFM looks fine. I can imagine a mechanical reason for the "drop-outs" you encounter: maybe the magnet does not always rotate? One possible reason is a "hanging" idler - tolerances of the design are a bit narrow for FFM printers. In my case, some filing on the two idler parts, especially to clear the path of the bearing, made the MFM go smooth.

-

@alankilian Thanks for this. I've been having issues. My agc is 63 also. The center bearing was rubbing on the sensor. Hopefully it's not destroyed, there was a pretty nice ring rubbed into it.

-

@infiniteloop I actually marked the idler so I can see it moving. Also.. when I put it together I did some filing to makes sure stuff was moving freely. I can pull filament through it manually and it feels like it moves smoothly.

-

@alankilian I had not looked at distance between sensor and magnet as a possibility. Any suggestions on what the distance should be?

-

@wouldstain THIS page says the target distance is 0.25mm and that the AGC should be between 50 and 105 so your AGC is not out-of-range, just on the low-side of the range.

Since you're getting excellent above-desired reading of 104% to 116% and you're getting 0% minimum it seemed to be that your magnet was getting stuck and not turning.

So take a look and see if you see any marks on the top of the sensor and if so, add a sheet of paper or two to the case and see if your AGC gets larger and if it works better.

(My AGC is 123 which is out-of-range high, but it seems to work so I'm not going to fiddle with it.)

-

@alankilian Thank you!

I'll definitely give that a try later! -

@alankilian Do you know of any reason the AGC would climb during a print? I took some plastic sheet and shimmed the monitor. My AGC started at 75, and I have been pulling the states throughout the print, and now it has climbed to 90. I also have had 2 false "Too little movement" on a 45 minute print so far, so it doesn't seem to have fixed anything.

-

Rats, it was worth a shot anyway.

The AGC would go up if the space between the magnet and sensor was increasing. Maybe your paper is springing-back somehow?

Anyway, I'm sorry it didn't help.

I think one of the duet gang can jump on and see if they have any further suggestions.

-

@wouldstain Let's look further. In my setup, the filament can go into the MFM with an angle - if it was too much bent, I got false readings, especially with stiff filaments. If you can exclude mechanical problems, you might want to check print moves at a higher distance (currently, you stick with the recommended 3 mm). Try 5-10 mm instead.

Finally, there is a hot debate about the usefulness of adding a capacitor to the power lines of the MFM, you can look it up here. But I think this will only help in case of unstable supply voltage.

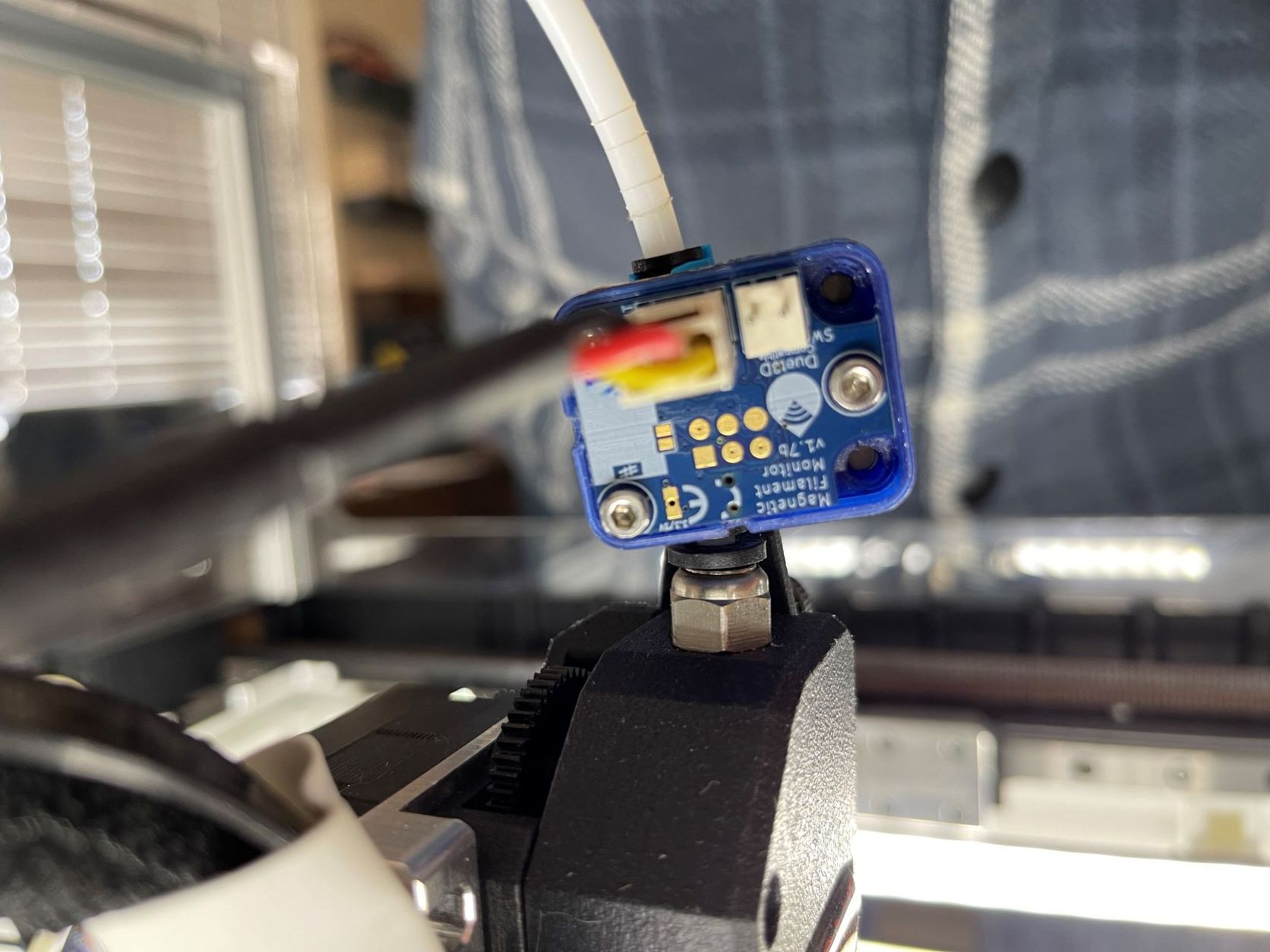

One last question: where do you locate your MFM, and how fix is the distance between it and the extruder?

-

@alankilian gapped with some paper as suggested.

Same issue:

m591 d0

Duet3D rotating magnet filament monitor v3 on pin e0stop, enabled, sensitivity 25.63mm/rev, allow 1% to 200%, check printing moves every 3.0mm, version 3, mag 131 agc 74, measured sensitivity 33.09mm/rev, min 1% max 132% over 61.4mm -

Bummer!!!

As an experiment and even though it's wasteful, maybe helpful.

Try:

- Raising the extruder temp a LOT. 15C or so.

- Moving the extruder 20mm away from the bed.

- Run your print.

You'll be making spaghetti, but this will demonstrate if the extruder is clogging or if there's some interaction between the extruder and the print that's jamming the filament.

If it "prints" without an under-length move we'll figure out more experiments.

-

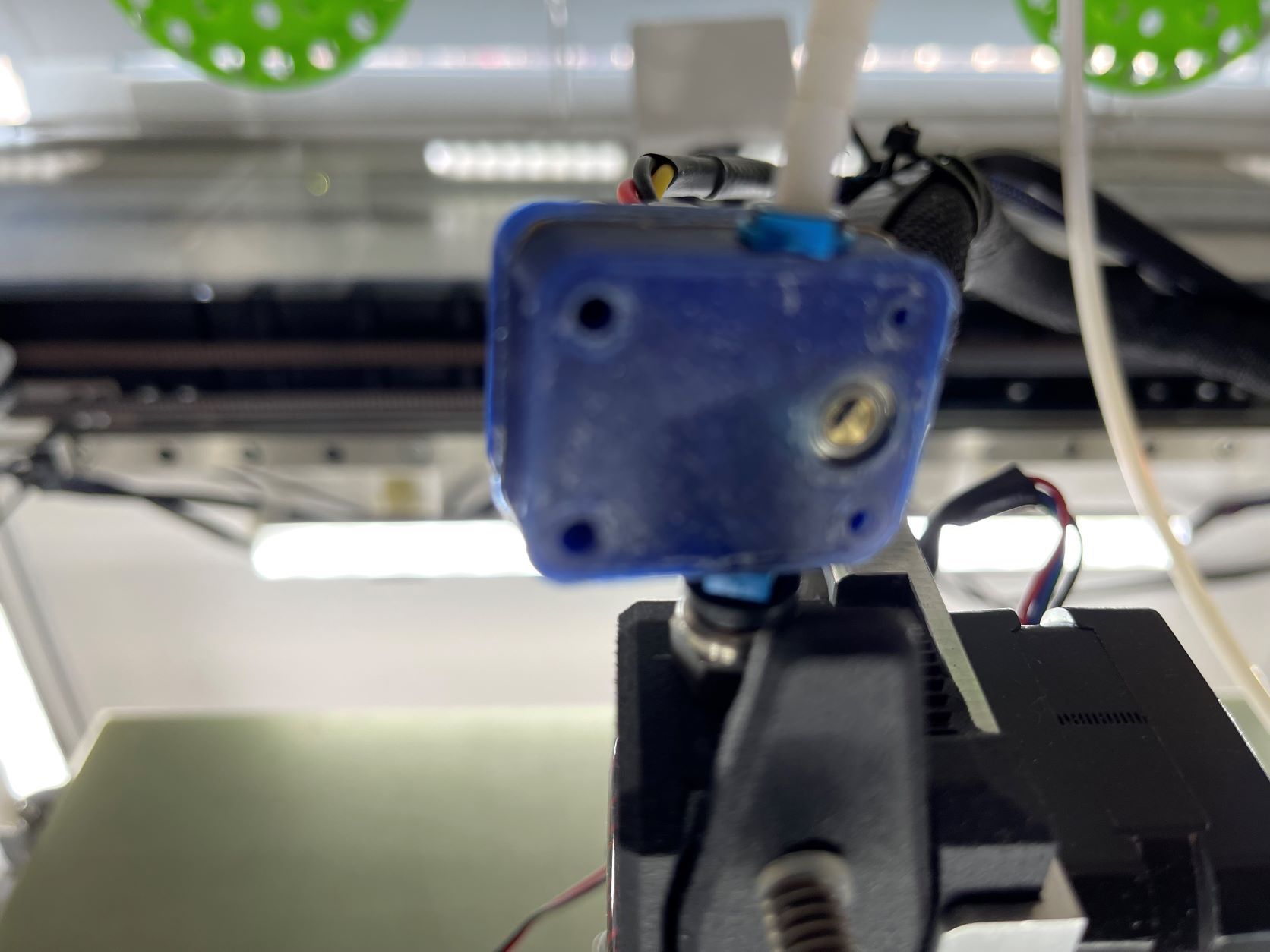

Photos of your sensor setup and printer? Maybe we can spot something.

-

@alankilian I can tell you for certain the extruder is not clogging.

I've actually set up a macro to disable the MFM when printing PLA:M591 d0 s0This allows me to run entire PLA jobs without interruption but also without the protection of run-out detection. I was able to finish off the tail ends of two spools yesterday thanks to having the MFM enabled but there were several false-stops during the process.

-

@phaedrux As soon as the current job is complete I'll get some photos.

Assuming you want to see it mounted as well as on the bench and disassembled. -

-

Have you tried re-printing the casing in higher quality?

-

@phaedrux I havent but I can although the casing is clean on the inside. I had some first layer issues IIRC and it still has some dry bedweld on it (got distracted and forgot to rinse).

-

@infiniteloop I have the MFM sitting directly atop the extruder and the PTFE tube comes in close to vertical so I'm not concerned about the angle of the filament path.

I am considering picking up a piece of copper tube from McMaster and replacing the bit of PTFE tubing connecting the MFM to the extruder but I really dont think that's where the problem is.

I'm inclined to print a new casing and giving that a try as I noticed that the ring on the MFM sensor from the magnet rubbing was a partial circle which would indicate to me that there's a slight tilt to the magnet.

I think an injection molded case would remove any uncertainty around it but I'm not certain that would resolve this issue.