I could use some help

-

@fcwilt it's 9:25 here.

I just Home Y'd the bed.

It smashed into the front adjustment bar.

In Status, Y is reporting the bed is at 110.0 (which is B.S.).

I can use the Y-jog buttons to move the bed back to 0.0, but that's as far as the bed will go.

So now I'm at Y=0.0.

The bed is in the middle of the metal ruler, at 244.475.

Status is saying that Y is 0.0.

-

@fcwilt M119 is reporting that all of the endstops are not stopped, which is true.

G91 has been sent to the printer.

G1 H1 Y-2- F3600 caused the bed to move back / to the rear approximately 1mm (instead of 20).

I sent the command again, the bed moved slightly more, but no where near 20mm's.

I sent the command again. I hear the sound of a motor spinning? But the bed when nowhere.

Clicking on the SEND command is producing varying results from no move to short moves to occasional long moves.

Mark

-

@mac said in I could use some help:

@fcwilt it's 9:25 here.

I just Home Y'd the bed.

It smashed into the front adjustment bar.

In Status, Y is reporting the bed is at 110.0 (which is B.S.).

I can use the Y-jog buttons to move the bed back to 0.0, but that's as far as the bed will go.

So now I'm at Y=0.0.

The bed is in the middle of the metal ruler, at 244.475.

Status is saying that Y is 0.0.

Anytime you cannot move the axis because it is at one limit or another just execute M564 S0 and the limits will be ignored - until you re-boot the printer.

We know homing of Y is not working and we have not made any changes (yet) that will fix that.

The steps I outlined will help us understand why homing is not working.

Here is a re-cap of what I posted:

You posted that you were having success doing G1 H1 Y-10 commands and it moved 10mm at a time and the DWC display for the position of Y was consistent with those moves.

Is that correct?

If it is correct I would like you to do another test, starting with the bed somewhere in the middle of it's travel, so it has a ways to go before it reaches the endstop switch.

Then from the DWC console:

- issue a M119 command to check the state of the endstops

- issue a G91 command to set relative movement mode which is necessary for homing

- issue as many G1 H1 Y-10 F3600 moves as it takes to get the bed to the position where the endstop switch is triggered

- check the DWC Y position display after each move to see if anything odd is happening

- when you finally reach the position were the endstop switch is triggered issue another M119 to again check the state of the endstops

What I am trying to check is if the problem only occurs when you try to do long Y moves but short Y moves, like 10mm, work fine.

So I am running around the house like a crazy person doing chores to get ready for our summer guests here at the lake.

But I will keep checking in to read your posts.

Hang in there.

Frederick

-

@fcwilt nah, man, that's a bad idea. Guests are way more important. You do your thang, okay? get ready for your guests, and enjoy the whole experience.

Get back to me when you really have the time.

Between now and then, I'll redo the tests according to the post I'm replying to, where you presented the information / instructions in bold face.

I'm upload the results to you, and you can get back to me when you really have the time.

Mark Out.

-

@mac said in I could use some help:

@fcwilt nah, man, that's a bad idea. Guests are way more important. You do your thang, okay? get ready for your guests, and enjoy the whole experience.

It's always nice to greet the guests when they arrive.

But you know the best part?

Waving to them when the leave.

Frederick

-

@fcwilt I redid the test. I shot a video of it. I'm uploading that to youtube as I write this.

The Status Display didn't provide any new information. Y remained at 0.0 the whole time.

I had to click SEND dozens of times to get the bed all the way back to the end-stop. When the bed refused to move any further, I looked at it, and tried to capture video of it. That's when I touched something with my phone, and turned the recording off.

But there's enough visual information in the video I'm uploading to show you the behavior of the bed.

I'm thinking there's a major band-width problem here. Whereas if I was sending a command where Y-50 or Y-110 was the setting, because it was one message sent to the board, the board would get that message, and act accordingly.

How to change / fix that, I don't know, but I'll see what I can do about it.

Enjoy the party!

Mark

-

-

@mac from the video it sounds like stepping issues, like if it was low current with way too high rpm.

But looking at this thread (wtf how is this 500+ replies in a few days

) im inclined to believe that has been thoroughly looked over in the config.g?

) im inclined to believe that has been thoroughly looked over in the config.g?And then I'd still look at the basics again before anything else. Is everything really wired properly.. I swear for me thats the issue 70% of the time

-

@mac I watched the video. Y axis is moving a random distance each time. I would say either:

- the motor can’t handle the current jerk or acceleration settings, or

- the pulley on the motor shaft is loose.

I’d actually think the second of those is most likely. Have you ever taken the pulley off the motor shaft? When you replaced it, it should have a grub (or set) screw that screws onto the flat on the motor shaft. Check this is tight.

Ian

Edit: to test, get a Sharpie and put a dot on the end of the motor shaft and pulley. Then move the axis, and see if the dot on the motor shaft and pulley go out of alignment.

-

just had to reply here for the reply count cheers maybe try an rc car???... best of luck and big up's to those trying to help out here

-

@rexx my last cr build was an SM800 Octocopter.

-

@droftarts good suggestions. I checked both set screws they were plenty tight.

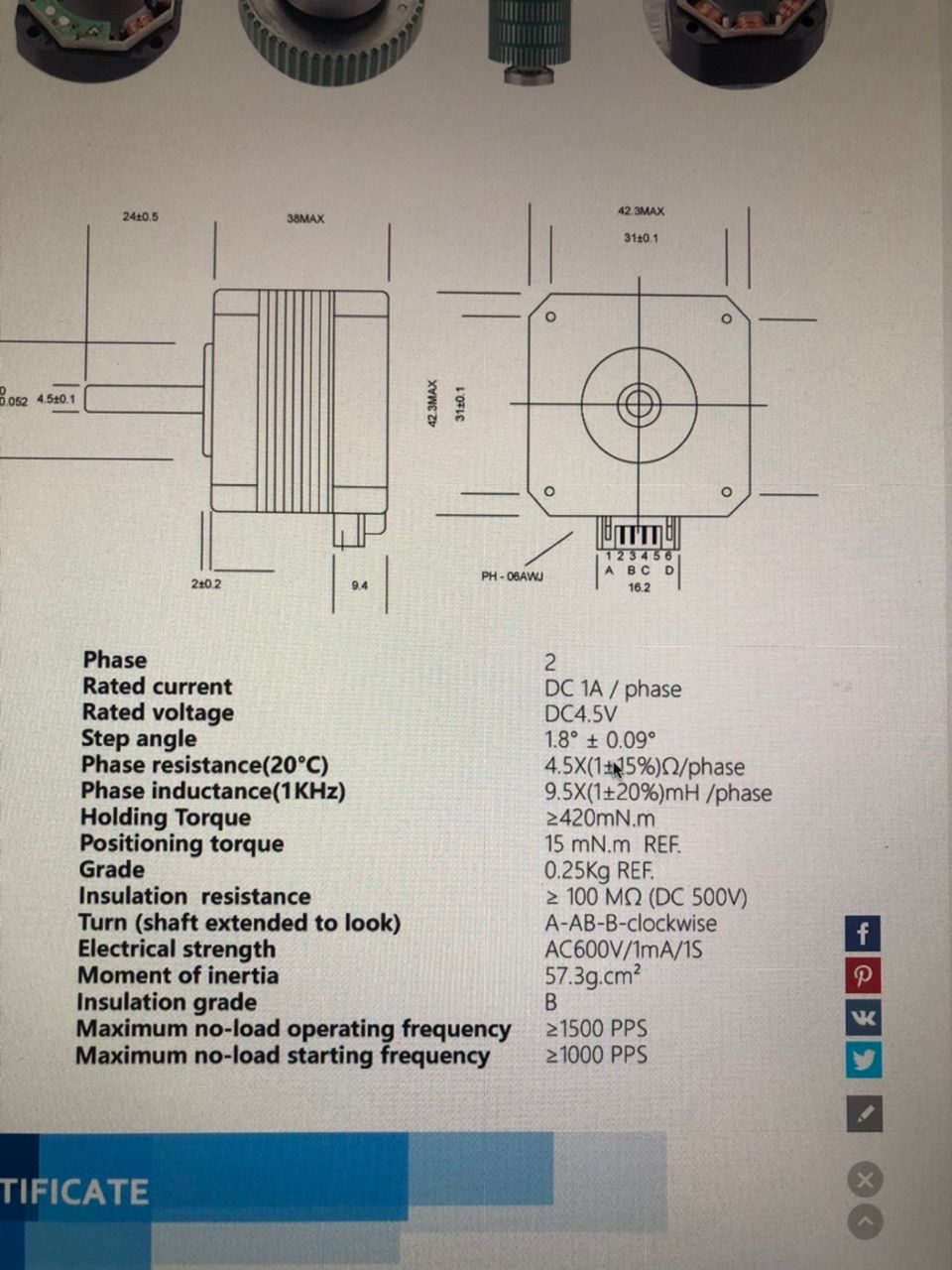

Ian, how would you represent the motor pictured above in my config.g?

Mac

-

@mac said in I could use some help:

This is the video I made of the test.

Thanks mac,

That was very informative. Something is seriously messed up.

Just to play it safe would you please post your current config.g file so we can check the stepper settings.

Frederick

-

@mac said in I could use some help:

This is the video I made of the test.

Is it possible the stepper and belt are moving fine but the bed is not staying firmly hooked to the belt?

I've never worked on one of these printers so I don't know how that connection is made.

Frederick

-

@mac nice ESC maddness or just one not formiliar with it specifically but i run a revolt 31"boat" well 2 but one is stock the other has leopard 36/74 1650kva on 6s 100C lipo's turning close to 26500 rpm's at 53 MPH 2 blade prop, that octocopter looks stable as a table

-

Maybe an output of M122 after this strange jogging could give some information?

-

@mac I'm wondering if the motors just aren't compatible. If that screen grab is correct, 4.5ohms per phase of resistance is high, as is 9.5mH per phase of inductance. There's another thread about high inductance motors struggling with the Trinamic drivers on the Mini 5+. It could be why you have such high coil whine (the constant squealing noise).

I think one thing that did help earlier in this thread, and you're not doing at the moment as far as I know, is to use StealthChop all the time. Add

D3 V0to all of the M569 motor commands in config.g.As for other settings, post your current config.g and I'll take another look.

Ian

-

@mac

Hi mac.

To add a bit of info to what @droftarts posted mentioning the resistance and inductance of your steppers, here are those specs from three of my printers

Yours Mine #1 Mine #2 Mine #3 Resistance 4.5 1.4 1.5 1.6 Inductance 9.5 3.0 3.8 2.8As you can see your numbers are a good deal higher, at least as far as steppers go.

I believe that droftarts may have found the problem - which would be grand.

Frederick

-

@fcwilt both ends of the belt are hooked to the front and rear sides of the frame that supports the bed, creating a continuous loop. Each end of the belt is folded over a hook, and zip-tied in two ways: around the loop, and across the loop including the hook. If the belt isn't tight, the pulley wheel at the rear of the frame and yank on it, and eventually break it.

-

@droftarts I'll try your suggestion, but Ian, if these motors are crap, I will immediately buy excellent motors to replace them if only you'll make a recommendation!