I could use some help

-

@mac from the video it sounds like stepping issues, like if it was low current with way too high rpm.

But looking at this thread (wtf how is this 500+ replies in a few days

) im inclined to believe that has been thoroughly looked over in the config.g?

) im inclined to believe that has been thoroughly looked over in the config.g?And then I'd still look at the basics again before anything else. Is everything really wired properly.. I swear for me thats the issue 70% of the time

-

@mac I watched the video. Y axis is moving a random distance each time. I would say either:

- the motor can’t handle the current jerk or acceleration settings, or

- the pulley on the motor shaft is loose.

I’d actually think the second of those is most likely. Have you ever taken the pulley off the motor shaft? When you replaced it, it should have a grub (or set) screw that screws onto the flat on the motor shaft. Check this is tight.

Ian

Edit: to test, get a Sharpie and put a dot on the end of the motor shaft and pulley. Then move the axis, and see if the dot on the motor shaft and pulley go out of alignment.

-

just had to reply here for the reply count cheers maybe try an rc car???... best of luck and big up's to those trying to help out here

-

@rexx my last cr build was an SM800 Octocopter.

-

@droftarts good suggestions. I checked both set screws they were plenty tight.

Ian, how would you represent the motor pictured above in my config.g?

Mac

-

@mac said in I could use some help:

This is the video I made of the test.

Thanks mac,

That was very informative. Something is seriously messed up.

Just to play it safe would you please post your current config.g file so we can check the stepper settings.

Frederick

-

@mac said in I could use some help:

This is the video I made of the test.

Is it possible the stepper and belt are moving fine but the bed is not staying firmly hooked to the belt?

I've never worked on one of these printers so I don't know how that connection is made.

Frederick

-

@mac nice ESC maddness or just one not formiliar with it specifically but i run a revolt 31"boat" well 2 but one is stock the other has leopard 36/74 1650kva on 6s 100C lipo's turning close to 26500 rpm's at 53 MPH 2 blade prop, that octocopter looks stable as a table

-

Maybe an output of M122 after this strange jogging could give some information?

-

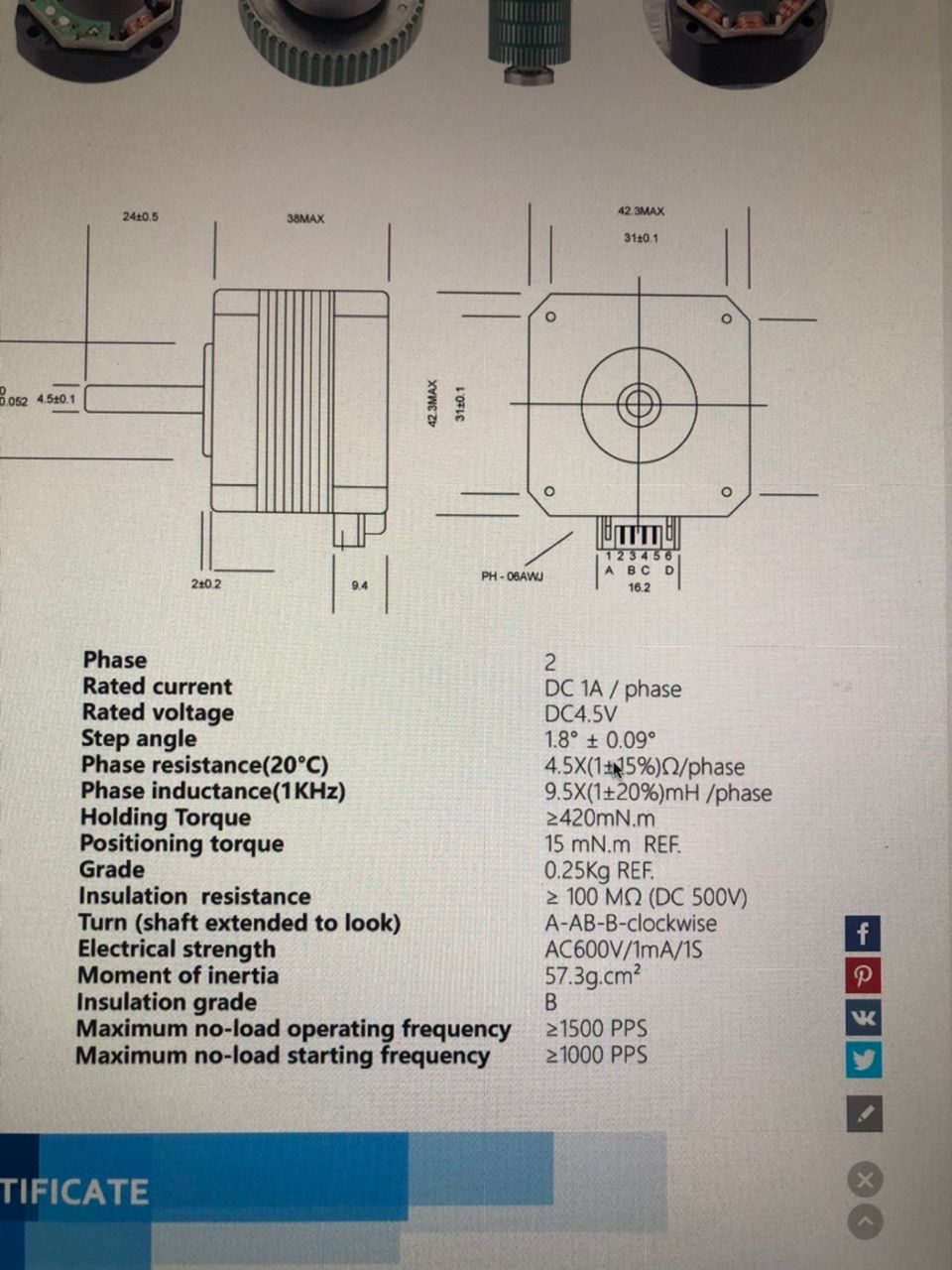

@mac I'm wondering if the motors just aren't compatible. If that screen grab is correct, 4.5ohms per phase of resistance is high, as is 9.5mH per phase of inductance. There's another thread about high inductance motors struggling with the Trinamic drivers on the Mini 5+. It could be why you have such high coil whine (the constant squealing noise).

I think one thing that did help earlier in this thread, and you're not doing at the moment as far as I know, is to use StealthChop all the time. Add

D3 V0to all of the M569 motor commands in config.g.As for other settings, post your current config.g and I'll take another look.

Ian

-

@mac

Hi mac.

To add a bit of info to what @droftarts posted mentioning the resistance and inductance of your steppers, here are those specs from three of my printers

Yours Mine #1 Mine #2 Mine #3 Resistance 4.5 1.4 1.5 1.6 Inductance 9.5 3.0 3.8 2.8As you can see your numbers are a good deal higher, at least as far as steppers go.

I believe that droftarts may have found the problem - which would be grand.

Frederick

-

@fcwilt both ends of the belt are hooked to the front and rear sides of the frame that supports the bed, creating a continuous loop. Each end of the belt is folded over a hook, and zip-tied in two ways: around the loop, and across the loop including the hook. If the belt isn't tight, the pulley wheel at the rear of the frame and yank on it, and eventually break it.

-

@droftarts I'll try your suggestion, but Ian, if these motors are crap, I will immediately buy excellent motors to replace them if only you'll make a recommendation!

-

Here's the newest config.g

; Configuration file for Duet 3 Mini 5+ (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.10 on Mon Jun 27 2022 12:50:38 GMT-0700 (Pacific Daylight Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Frankenstein's Cinderella" ; set printer name ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 D3 V0 S1 ; physical drive 0.0 goes forwards M569 P0.1 D3 V0 S0 ; physical drive 0.1 goes backwards M569 P0.2 D3 V0 S1 ; physical drive 0.2 goes forwards M569 P0.3 D3 V0 S1 ; physical drive 0.3 goes forwards M584 X0.0 Y0.1 Z0.2 E0.3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X100.000 Y100.00 Z4000.00 E420.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z600.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z200.00 E250.00 ; set accelerations (mm/s^2) M906 X600 Y600 Z600 E600 ; set motor currents (mA) M84 S0 ; Disable motor idle current reduction ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X220 Y220 Z240 S0 ; set axis maxima ; Endstops M574 X1 S1 P"!io5.in" ; configure switch-type (e.g. microswitch) endstop for high end on X via pin !^io5.in M574 Y1 S1 P"!io6.in" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin !^io6.in M574 Z1 S1 P"!io2.in" ; configure switch-type (e.g. microswitch) endstop for high end on Z via pin !^io2.in ; Z-Probe M950 S0 C"io3.out" ; create servo pin 0 for BLTouch M558 P9 C"io3.in" H5 F120 T3600 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X15.875 Y0.625 Z2.5 ; set Z probe trigger value, offset and trigger height M557 X5:190 Y5:215 S10 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S33 ; set temperature limit for heater 0 to 33C M308 S1 P"temp1" Y"thermistor" T100000 B4092 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S100 ; set temperature limit for heater 1 to 100C ; Fans M950 F0 C"out3" Q500 ; create fan 0 on pin out3 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"out4" Q500 ; create fan 1 on pin out4 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 S"optional" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M501 ; load saved parameters from non-volatile memory M911 S21 R23 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

@mac said in I could use some help:

@fcwilt both ends of the belt are hooked to the front and rear sides of the frame that supports the bed, creating a continuous loop. Each end of the belt is folded over a hook, and zip-tied in two ways: around the loop, and across the loop including the hook. If the belt isn't tight, the pulley wheel at the rear of the frame and yank on it, and eventually break it.

It sounds secure so @droftarts suggestion about changing the M569 settings is an excellent next step.

Are you going to have a chance to do that soon?

If you do get to make the changes, just do again what you did in the video and see if now each click on "move by 10" actually moves the bed by 10, visually that is, not by the DWC display, it will always show the correct value even if the bed did not move at all.

Let's hope the problem has been found.

Hope you are feeling better.

Frederick

-

@rexx I had it in the air for up to twenty minutes at a time. And then the FAA shut us down.

I'm hoping to get a Mini 3 soon.

-

@fcwilt ahhh, from my reading of Ian's comment, the D3 V0 will quiet the motors, but it won't address the resistance issues. I need to get better motors. Can you please suggest something. I'll order on Amazon, and have them in by the weekend if I'm quick enough.

-

; Configuration file for Duet 3 Mini 5+ (firmware version 3.3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.3.10 on Mon Jun 27 2022 12:50:38 GMT-0700 (Pacific Daylight Time) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Frankenstein's Cinderella" ; set printer name ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0.0 D3 V0 S1 ; physical drive 0.0 goes forwards M569 P0.1 D3 V0 S0 ; physical drive 0.1 goes backwards M569 P0.2 D3 V0 S1 ; physical drive 0.2 goes forwards M569 P0.3 D3 V0 S1 ; physical drive 0.3 goes forwards M584 X0.0 Y0.1 Z0.2 E0.3 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X100.000 Y100.00 Z4000.00 E420.00 ; set steps per mm M566 X900.00 Y900.00 Z60.00 E120.00 ; set maximum instantaneous speed changes (mm/min) M203 X6000.00 Y6000.00 Z600.00 E1200.00 ; set maximum speeds (mm/min) M201 X500.00 Y500.00 Z200.00 E250.00 ; set accelerations (mm/s^2) M906 X600 Y600 Z600 E600 ; set motor currents (mA) M84 S0 ; Disable motor idle current reduction ; Axis Limits M208 X0 Y0 Z0 S1 ; set axis minima M208 X220 Y220 Z240 S0 ; set axis maxima ; Endstops M574 X1 S1 P"!io5.in" ; configure switch-type (e.g. microswitch) endstop for high end on X via pin !^io5.in M574 Y1 S1 P"!io6.in" ; configure switch-type (e.g. microswitch) endstop for high end on Y via pin !^io6.in M574 Z1 S1 P"!io2.in" ; configure switch-type (e.g. microswitch) endstop for high end on Z via pin !^io2.in ; Z-Probe M950 S0 C"io3.out" ; create servo pin 0 for BLTouch M558 P9 C"io3.in" H5 F120 T3600 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X15.875 Y0.625 Z2.5 ; set Z probe trigger value, offset and trigger height M557 X5:190 Y5:215 S10 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B4092 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M143 H0 S33 ; set temperature limit for heater 0 to 33C M308 S1 P"temp1" Y"thermistor" T100000 B4092 ; configure sensor 1 as thermistor on pin temp1 M950 H1 C"out1" T1 ; create nozzle heater output on out1 and map it to sensor 1 M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M143 H1 S100 ; set temperature limit for heater 1 to 100C ; Fans M950 F0 C"out3" Q500 ; create fan 0 on pin out3 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"out4" Q500 ; create fan 1 on pin out4 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on ; Tools M563 P0 S"optional" D0 H1 F0 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; Custom settings are not defined ; Miscellaneous M501 ; load saved parameters from non-volatile memory M911 S21 R23 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

@mac said in I could use some help:

@droftarts I'll try your suggestion, but Ian, if these motors are crap, I will immediately buy excellent motors to replace them if only you'll make a recommendation!

I get my steppers from Stepperonline usually.

All NEMA 17 steppers will be the same frame size but they can vary in length. Yours are listed as 38mm long whereas mine are 48mm.

Only you can determine how much space you have to go beyond 38mm.

I could not find any NEMA 17 38mm steppers at Stepperonline.

Frederick

-

@mac said in I could use some help:

@fcwilt ahhh, from my reading of Ian's comment, the D3 V0 will quiet the motors, but it won't address the resistance issues. I need to get better motors. Can you please suggest something. I'll order on Amazon, and have them in by the weekend if I'm quick enough.

It may well do more than quiet them, the noise is just a symptom.

It actually may allow them to work as they should.

Frederick