Prints are warping

-

OK, you're getting peeling up from the build plate.

I've done several things in the past to help with that:

- More "squoosh" on the first layer. (Lower first layer height)

- Elmers glue on the build plate.

- Blue tape on the build plate.

- Add a brim around the edge of the part.

- PEI sheet applied to the build plate.

The thing that worked best was when I added the PEI sheet. That works for 99% of my prints and when I have problems, I add glue, then I add a brim if necessary.

https://www.microcenter.com/product/629546/creality-ender-5-plus-pei-magnetic-build-plate

What have you tried so far?

-

@alankilian My initial layer layer height is 0.3, what should I change it to. I am using a 0.4mm nozzle, with a .25 layer height on the rest of the layers.

-

This post is deleted! -

I use 0.3mm as my layer height also, but I use the "Z babystep" function to lower the printhead until I get the first layer really squooshed into the bed. I don't know what the actual height is.

So the printer is extruding as though the print head is 0.3mm away from the bed, but I'm maybe 0.15 or 0.1mm away, so it squooshes out and really attaches to the bed.

Also, it makes an "elephant foot" which doesn't bother me if I can get the print to stop peeling.

I only use this for prints that are not behaving well and are peeling.

-

@alankilian OK, thank you I will go pick up the PEI plate from Microcenter today and let you know if it works.

-

@tratoon first thing i always do when prints dont want to stick is wash the bed with hot water and dawn dish soap

-

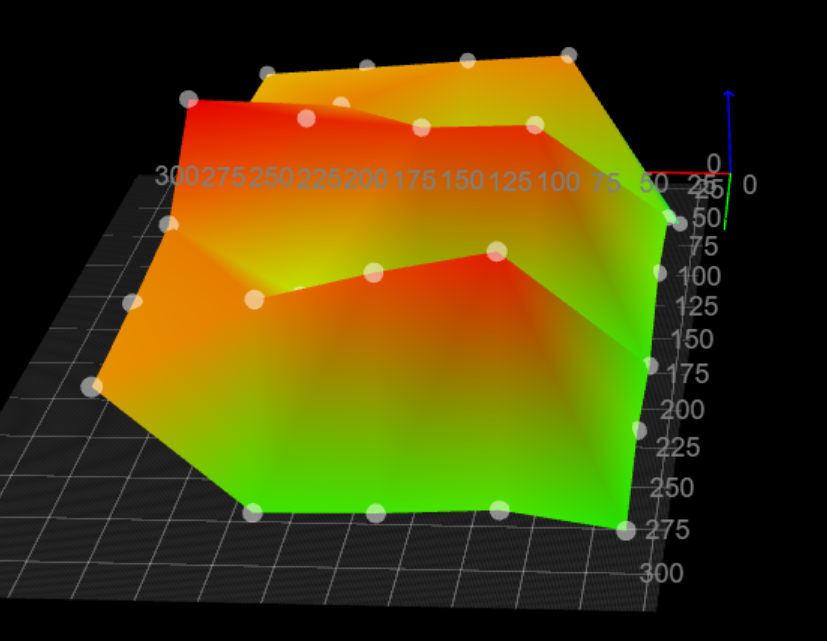

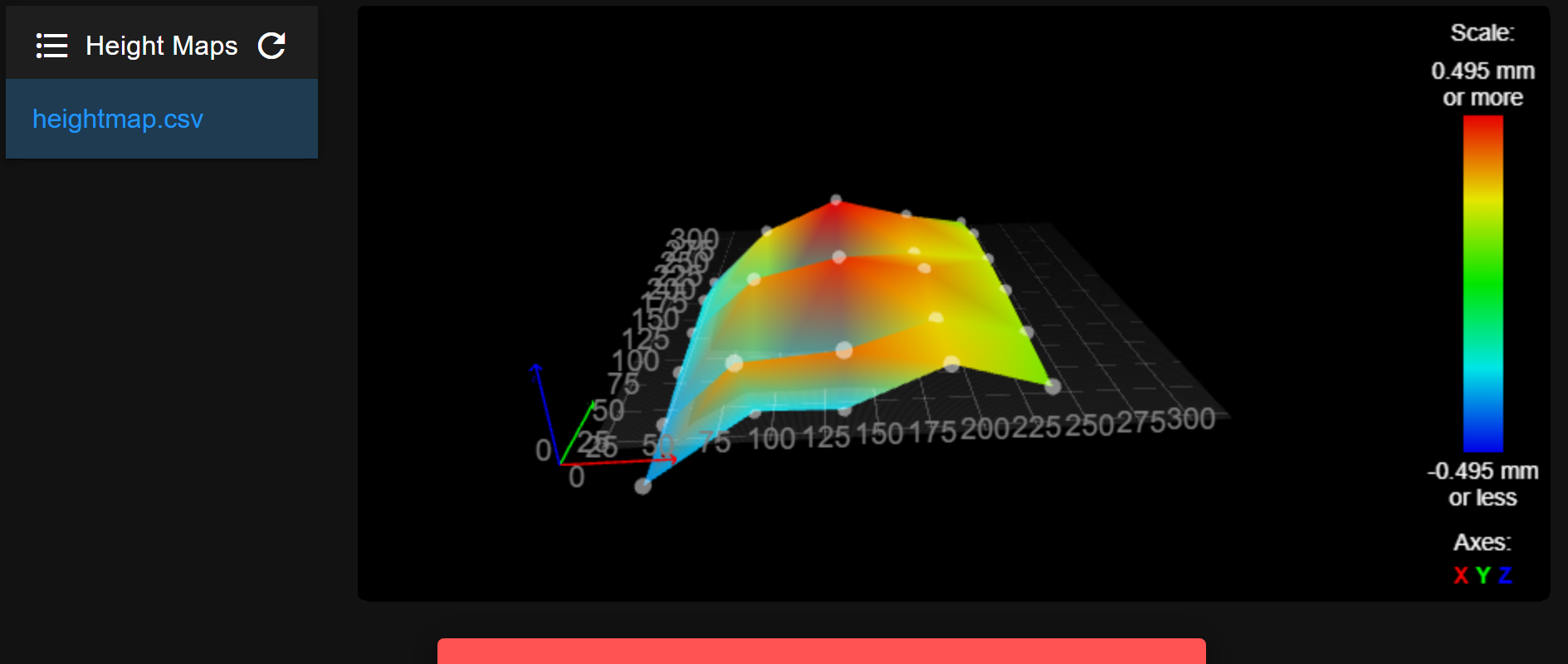

@alankilian I installed the PEI Sheet, but the bed is very unlevel and adjusting crews won't cut it. Therefore, my Z-Offset varies and I get under extrusion and over extrusion, which causes problems with my filament sensor and clogs my extruder. I will attach a height map.

-

@tratoon One thing that may help, your build surface looks rather thick in the pictures. I assume it is either a piece of glass or something similar. I'm also assuming it is sitting on the stock heatbed. If your parts are beginning to peel up at the corners, I would highly suggest increasing your bed temperature. I know you said you were printing at 60C heatbed, but if my assumptions are correct that temperature is underneath your build surface at the heated bed itself. Your build plate surface is probably not at 60C due to heat loss. Generally speaking, your heatbed should be at or near the glass transition temperature of the material you are printing. Depending on the brand of PLA, sometimes this is 60C others are higher. I have found 70C works very well when I use eSun PLA+. So I would recommend you increase your heatbed to 70C or even 75C to compensate for the thick build plate and see if you see any improvements.

Personally, I detest using any sort of glue or hairspray or brim when most times a clean build plate and a hot build plate will make for great bed adhesion assuming you don't have external factors cooling stuff off before the print is finished.

-

@pdbeal Thank you I never thought of that

-

I will attach a height map.

Is this a plot of the Swiss alps? You use a grid with about 30 probing points - use a narrow mesh with 300 - 400 points instead. Maybe you have to lower the probing speed, too (that is the F parameter of your

M591GCode). -

@tratoon

Oh you fat egg... that's extreme.

On one of the photos the tip of the BLTouch looks a bit bent, does the BLTouch work correctly or does it sometimes get stuck?You have 25 measuring points, I have 36.

In my opinion, more measuring points will not bring you to your goal, because there must be a problem here that should be eliminated.

Is it a magnetic pressure plate?

The BLTouch works with a HAL sensor that reacts to magnetic fields.A good tip posted here is to slow down the speed of the BLTouch.

0.9° stepper motors also make the BLTouch a little more accurate, which I could clearly see from the measurement data on my printer.

For several years I have mounted the Duet3D IR Probe, which has a more accurate measurement repetition.I would be interested in a photo of your new printing plate and the ; Z Probe Part of your config.g file.

And a bit more of the heightmap screenshot would have been good to see the determined values next to the image.Google Translate

----- Original Text -----Ach Du dickes Ei... das ist ja mal extrem.

Auf einem der Fotos sieht die Spitze des BLTouch etwas verbogen aus, funktioniert der BLTouch Fehlerfrei oder bleibt er manches mal stecken ?Du hast 25 Messpunkte, bei mir sind es 36.

Mehr Messpunkte werden Dich meiner Meinung nach nicht ans Ziel bringen, denn hier muss ein Problem vorliegen welches beseitigt werden sollte.

Ist es eine magnetische Druckplatte ?

Der BLTouch funktioniert mit einem HAL-Sensor der auf Magnetfelder reagiert.Ein guter Tipp der hier gepostet wurde ist die Geschwindigkeit des BLTouch zu verringern.

0,9° Stepper Motoren machen den BLTouch auch noch etwas genauer, dass konnte ich bei meinem Drucker anhand der Messdaten deutlich erkennen.

Seit einigen Jahren habe ich den Duet3D IR Probe montiert, der nochmal eine genauere Messwiederholung hat.Ein Foto Deiner neuen Druckplatte würde mich interessieren und den ; Z Probe Teil Deiner config.g Datei.

Und etwas mehr vom Heightmap Screenshot wäre gut gewesen um die ermittelten Werte zu sehen die neben dem Bild stehen. -

@günter-jibben I fixed the bent BL Touch and this height map is after the replacement tip. Also, I just installed a magnetic PEI sheet and the height map for the PEI sheet and Glass plate look similar. MY Z-Probe config:

M950 S0 C"exp.heater3" ; create servo pin 0 for BLTouch M558 P9 C"^zprobe.in" H5 F1800 T12000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X-41 Y-2 Z.64 ; set Z probe trigger value, offset and trigger height, 1.7 for 0.6mm Nozzle, 2,32,0.631 M557 X35:275 Y35:295 S50 -

@infiniteloop I don't think I have enough space for 300-400 points.

-

@infiniteloop @Günter-Jibben Updated height map, where I changed the F parameter to 600 instead of 1800

-

@tratoon Reduced probing points

-

@tratoon Keep in mind my build plate used to be level before I installed a magnetic sheet and PEI Sheet, so maybe the magnetic sheet cuased issues? I'm not sure.

-

@tratoon Increased number of probe points:

-

@tratoon said in Prints are warping:

I don't think I have enough space for 300-400 points.

Sure you have. Just narrow your mesh down. Have a look at the documentation to see how to do this:

Here's M557. With the X and Y parameters, you define the size of the probing area, with S, you set the probe point spacing. Alternatively, you use P to set the number of points to probe on both axes.

-

@tratoon said in Prints are warping:

Increased number of probe points:

The graph doesn't represent your bed. Instead, the sawtooth pattern reveals mechanical problems with your motion system. The first thing to do is to lower speeds of all movements.

-

Does the gantry or bed move in the Y axis? I agree, it really seems repetitive and I'm wondering if you have some shmutz (or a bad bearing) on the at least one wheel, which hits every time it makes a revolution. The fact that it more or less tapers on one side would indicate that one side of the bed/gantry is lifting up a little when it hits that point.