Problems with Heaters

-

Hi all. I need help again.

My 3D printer has been working well and nothing has changed that should affect the heaters, but here we are. Today it has gone from being able to print something fully, then next print went to error state part way through the print, and now it's making no sense to me. Possibly a hardware issue but what? It seem crazy but appears to be affecting both heaters or somehow interpreting heater 1 (nozzle) as heater 0 (bed). I haven't made any config changes just recently.

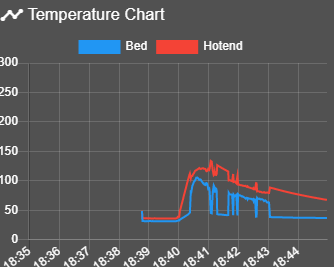

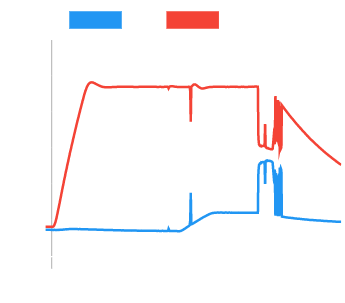

Note that the attached temp chart shows the bed going to 100 C, but the set temperature was 70 C, and 240 for the hotend.

-

It looks like bad wiring or interference. That's a good place to start.

-

Yes, I had checked all relevant connections as far as I can and they appear/measure good. Steady 24.1V supplying the Duet. There's little interference in that area but I'd swicthed off the other printers and there was no improvement.

Can you suggest any spectic checks and tests to help identify the problem?

-

@tomf Given that it seems very unlikely that the bed temperature can actually change that fast, I'd be looking very closely at the bed thermistor and the associated connections. It looks to me like the noise on the hotend may have been caused by whatever is happening with the bed. But it is hard to be sure. I suppose another possibility is the psu, but I would hope that would show up in the Duet power monitoring.

-

@tomf It looks like noise of some sort. The temperature excursions are too short and sharp to be anything else. A heater cartridge can't react that quickly so it has to be the sensors. It's odd that both sensors have pretty much the same pattern. So I'd look for some sort of of noise/interference that is common to both sensors. For example, are the wires bundled together with something else like a stepper motors?

There are problems with your config.g in that you have have M308 S1 for the hot end coming after the M950 and also the M563 tool definition. . Also, the M307 for heater 1 is commented out. If that's because you have stored the values in config-override then you need and M501 in config.g to access and read them. As it stands, you have no PID values for the hot end heater.

Edit. Given the above configuration issues, I'm surprised that the printer has been working well up to this point.

-

@deckingman

Thanks for the feedback!

The hotend sensor wiring is bundled with the extruder & fan motor wiring coming back from the hotend, by necessity. Othewise not much interference that I can see.

Interesting comments regards the heater setup. For the hotend I took the following direct from SLice Engineering:"...use the following values in your M305 or M308 command.

T100000 B4680 C6.455513e-8"I can't say why the M307 is commented out, or why the M950 and M563 is the way it is, other than my limited understanding and attempts to get the printer running so it is quite possible that these need to be improved and I thank you for the heads up.

It does seem to work though, and right now I'm have the heaters doing a soak test and no problems yet this morning. But could be same as yesterday when it tripped after a couple hours and then the faults were more frequent. If the same happens today, could it be a processor that gets flaky as it heats up (note the board is fan cooled)?

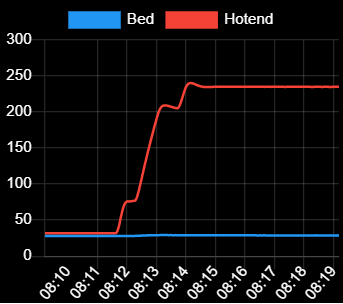

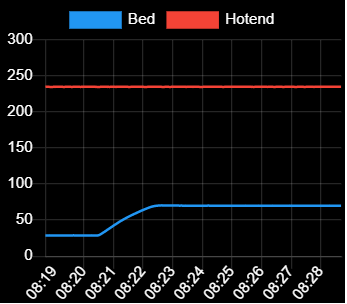

At start of heating

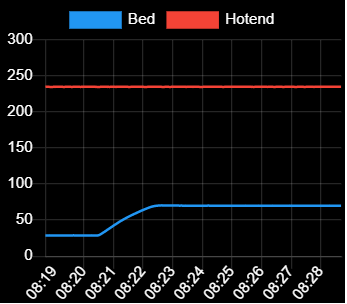

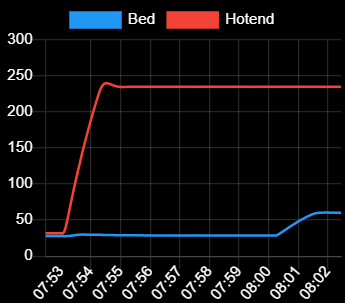

Stable temperatures

These are the M308 reports:

20/07/2022, 08:20:48 M308 S1

Sensor 1 (Hotend) type Thermistor using pin temp1, reading 235.0, last error: sensor not ready, T:100000.0 B:4680.0 C:6.46e-8 R:2200.0 L:5 H:-4

20/07/2022, 08:10:32 M308 S0

Sensor 0 (Bed) type Thermistor using pin temp0, reading 27.9, last error: sensor not ready, T:100000.0 B:3950.0 C:0.00e+0 R:2200.0 L:4 H:-5 -

@tomf said in Problems with Heaters:

@deckingman

Thanks for the feedback!

The hotend sensor wiring is bundled with the extruder & fan motor wiring coming back from the hotend, by necessity. Othewise not much interference that I can see.

Interesting comments regards the heater setup. For the hotend I took the following direct from SLice Engineering:"...use the following values in your M305 or M308 command.

T100000 B4680 C6.455513e-8"I can't say why the M307 is commented out, or why the M950 and M563 is the way it is, other than my limited understanding and attempts to get the printer running so it is quite possible that these need to be improved and I thank you for the heads up.

It does seem to work though, and right now I'm have the heaters doing a soak test and no problems yet this morning. But could be same as yesterday when it tripped after a couple hours and then the faults were more frequent. If the same happens today, could it be a processor that gets flaky as it heats up (note the board is fan cooled)?

At start of heating

Stable temperatures

These are the M308 reports:

20/07/2022, 08:20:48 M308 S1

Sensor 1 (Hotend) type Thermistor using pin temp1, reading 235.0, last error: sensor not ready, T:100000.0 B:4680.0 C:6.46e-8 R:2200.0 L:5 H:-4

20/07/2022, 08:10:32 M308 S0

Sensor 0 (Bed) type Thermistor using pin temp0, reading 27.9, last error: sensor not ready, T:100000.0 B:3950.0 C:0.00e+0 R:2200.0 L:4 H:-5It's not the values within M308 but the where in the file that M308 is located. See here https://docs.duet3d.com/User_manual/Reference/Gcodes#m308-set-or-report-sensor-parameters

Especially take note of the following extract (quote) .....

"When converting from older versions of RRF to RRF3 you must replace each M305 command by a similar M308 command, which must be earlier in config.g than any M950 command that uses it. You must also use M950 to define each heater that you use, because there are no default heaters."

That aside, while you are doing your soak test, try extruding some filament and observe the temperature plot to see if the noise is due to the sensor wires being bundled with the extruder. Also try running any fans that might be in the same wiring bundle.

-

I have made changes to order of commands the config.g file

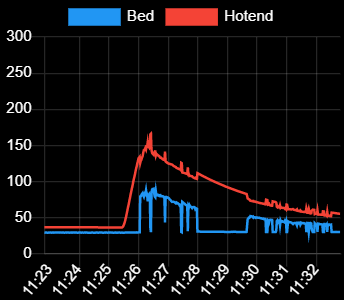

config2.txtBut it doesn't seem to help the immediate problem. Here is the result when I set the hotend to 200 C. I did not set any bed temperature, but as you can see it 'follows' the hotend, although there is no physical change in the bed temperature, which stayed cold to touch. The sudden (false) rise in temperature of the bed triggered the alarm.

I find this very weird and is similar to what was happening before the config change.

-

@tomf That's weird. So setting the hot end to heat has an effect on the reading for the bed temperature as well. It seems to me that there must be some sort of short circuit between pin temp1 and pin temp0 but I don't know enough about the hardware to comment any further. It needs a moderator such as @Phaedrux or @droftarts to take a look so by mentioning them, it should flag this post for their attention. Which board are you using? The M122 you posted indicates that it's a Duet mini 5+ is that correct?

-

Yes correct, RepRapFirmware for Duet 3 Mini 5+ version 3.4.0 (2022-03-15 18:59:15) running on Duet 3 Mini5plus WiFi (standalone mode)

I'm starting to think there's something wrong with the board. If I leave it off for several hours it seems okay but when I do the same test (You can see the different charts from this 08:10 morning when all seemed okay, and later at 11:25 when there was the linkage between hotend and bed sensor readings) that suggest to me there is something flaky in the processor. Similar behavoir yesterday.

I wish I could prove or disprove this theory as I don't want the expense in time and money of another board only to find it was something else. Hopefully @Phaedrux or @droftarts can help

-

Can you show us some photos of the wiring so we can see how it's run?

As I said originally it seems like wiring and/or interference.

I would start by taking the thermistor wiring out from any bundles and running it free and clear outside the printer and testing it that way to see if the problem resolves.

-

Sure. Photos and a short video at this link: https://1drv.ms/u/s!AuxTgg3LI_8tiYQEdhhkTluv53i83w?e=Ker6js

Let me know if you need anything else or have some suggestions.

-

As an easier test, rather than tearing apart the hotend wiring bundle, could you run a new thermistor wire outside of the bundle? Do you have a spare alternate thermistor?

-

@tomf it looks to me like an intermittent short between the hot end thermistor wire and the heater power, possibly via the hot end metalwork. That would explain why the bed temperature reading is affected too.

-

I don't have a spare sensor so I moved the wiring outside the bundle. See 'sensor wiring ext...' photos here: https://1drv.ms/u/s!AuxTgg3LI_8tiYQEdhhkTluv53i83w?e=QgUF8Y

The behavior was similar to yesterday:

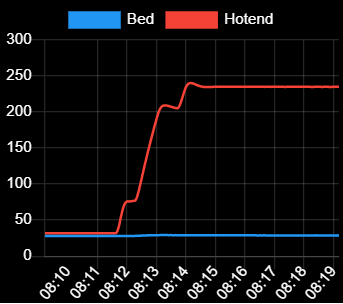

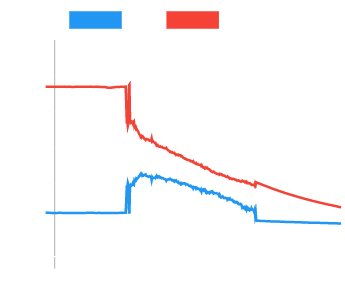

Set temperatures and soak:

Try extruding (from 0811)

(sorry, I saved the image differently so difficult to read)

?Your comment "..an intermittent short between the hot end thermistor wire and the heater power, possibly via the hot end metalwork" That is an interesting idea, although I don't understand how the bed can link in.

Following the above test I moved the sensor and heater faces just away from the hotend block in case there were any stray wires (looked okay) - see photo 'sensor heater aligned' in the same linked folder as above.

Repeat test:

This didnt resolve the issue, but any clues?

-

any clues?

At this stage, I think we can rule-out interference as a reason.

Obviously, the two thermistor signals of bed and hotend are related in a way that a drop in the readings from the hotend results in a rise of the bed’s signal. Further to note: this "relationship" is intermittent, I.e. the readings are not coupled all of the time.

The latter observation tells us that we face an irregularity: either a bad crimp, broken wire, faulty connector, or a temporary short with GND, VIN (any voltage), or another signal.

As both readings are affected when this irregularity happens, a single intermittent signal line is unlikely to cause this effect. This leaves us with just two possible culprits:

Either an intermittent short - along the lines, on/below the board or to metal printer parts (that’s @DC’s most prominent guess) …

Or some unstable voltage on a region of the board - either there’s something with the 3.3V rail, insufficient 5V power or improper GND. That's just a faint suspicion - I'm no expert at all.

To narrow down on the culprit, you can disconnect single components from the Duet, one at a time (and only with an unpowered board): replace the thermistors (one at a time) with a 100k resistor - for that, you can solder a plug with the resistor across the two pins.

Then, you can disconnect the bed heater from the board, both lines. However, if you bed is mains powered, you must remove those lines, too. Only try this if you know what you do, else, your life is in danger. Seriously.

Separate the hotend with heater and thermistor from the print head, but keep the lines connected. Put it on some ceramic plate so that you can run it without fire hazard. If that works, you know that you have a GND problem with metal printer parts.

Another way to prove this is to carefully ground all parts of you printer, including the hotend. I think you should do this anyway.

-

Thanks for the detailed analysis. I tried the following, and need to do more but I've run out of time for today and wont be able to get back to it for another 24 hours, so I wanted to get this out there:

- Plugged old thermistor (in lieu of 100k resistor) into bed thermistor socket. Problem still occurred when attempt made to heat the hotend.

- Hotend removed and ground wire connected to heat block. Problem still occurred when attempt made to heat the hotend.

For the next step, of component disconnection, I'm not sure what will happen when I try removing components from the board, but wouldn't it generally show up as fault when reconnected? I'm not good on electronics or software, so your patience is appreciated!

-

@tomf First, I would like to know what conditions you need in order to see the "problem": Obviously, you have to fire up the hotend. But do you need to heat the bed, too? Does the error only show up during a print? Or must the print head be in a specific location, must it be moving?

Second, please explain how you note the error: can you just see the irregularities in DWC's temperature plot, or are there other symptoms? Maybe a dimmed LED on the board, an error or warning in the console? …

I just want to learn more about the path towards the error. How many variables are required? The less, the better. In a second step, it would be nice to establish a simple and repeatable procedure for testing.

-

@tomf I suggest you replace both the hot end thermistor and the hot end heater cartridge. I think one or both of them have an intermittent short between the element and case when hot. I assume you have already checked the hot end thermistor wires for possible shorting.

-

@infiniteloop said in Problems with Heaters:

@tomf First, I would like to know what conditions you need in order to see the "problem": Obviously, you have to fire up the hotend. But do you need to heat the bed, too? Does the error only show up during a print? Or must the print head be in a specific location, must it be moving?

Second, please explain how you note the error: can you just see the irregularities in DWC's temperature plot, or are there other symptoms? Maybe a dimmed LED on the board, an error or warning in the console? …

I just want to learn more about the path towards the error. How many variables are required? The less, the better. In a second step, it would be nice to establish a simple and repeatable procedure for testing.

I set the hotend first (typically 235C) and observe the chart.

If the printer's been switched off for a long period (more than 2 hours), the temperature rises normally and is steady. I then switch on the bed (60C) and that is also steady. When I try to do anything (extrude material, home axes typically) the problem then happens, as seen in the temperature plots.

After the first incident of the day, the problem recurrs without the bed heater being switched on and without needing to do anything else. It doesn't matter where the print head is. The bed can be cold to the touch throughout.

When the problem occurs there is a fault message and heaters are automatically disabled.

There are no other symptoms, at least none that I have seen.

The problem has been getting worse, evidenced by taking less time to occur.