How can I calibrate the temperature of my bed

-

@axiom said in How can I calibrate the temperature of my bed:

H0 R0.283 K0.463:0.000 D7.17 E1.35 S1.00 B0

is this the same procedure for the print heads (nozzles)?

-

@axiom said:

According to the manufacturer, it's a PT100 sensor

I’m not so sure. From the data sheet @axiom posted:

Thermal Protection & Control: On board thermal fuse, thermostat, thermistor and PT100 are available as part of your thermal management solution.

After my suggestion to try standard values with M308 (and to measure the thermistor’s resistance), @axiom returned:

I measured the resistance and it is correct: At 23.6 degrees (room/bed temperature) I have a resistance of 106 ohms. I swapped the line and the correct temperature is displayed...great!!

Given that the readings at room temperature match expectations, I assumed @axiom omitted the „k“ from his measurement of the thermal sensing device.

@droftarts: From the posts, I conclude we face a thermistor. The successful tuning gives further evidence. However: Thx for your immediate reaction!

@axiom: When you told @droftarts you got a PT100 sensor, @droftarts had no choice: you should have followed his urgent warning to turn the printer off immediately. Be glad that he had an eye on this and takes care!

-

I'm doing the M303 H0 S70 command

So you tuned the bed heater with a target temperature of 70°C.

Auto tuning heater 0 completed after 3 idle and 5 tuning cycles in 1199 seconds.

Just 20 minutes? That’s fast! Can you please elaborate your setup: Was the heater glued to the bed or did you test the silicon mat in plain air? If the mat was glued to the bed: how thick is that metal plate? I wonder how such an assembly could heat up and cool down so quickly multiple times.

If you have a reasonable explanation for this, you can adjust your config.g according to the tuning results:

This heater needs the following M307 command:

M307 H0 R0.283 K0.463:0.000 D7.17 E1.35 S1.00 B0

Edit the M307 H0 command in config.g to match this.But where exactly do I have to write that?

In your config, you have (or had) this line (after

M308 S0 …andM950 H0 …) :M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limitReplace that with the line you got from your tuning:

M307 H0 R0.283 K0.463:0.000 D7.17 E1.35 S1.00 B0 ; bed heater: enter tuning results, disable bang-bang -

@infiniteloop Unfortunately a PT100 at 20C reads about 107Ohms so that reading if it was reported accurately could be a PT100.

@axiom Was the resistance of the temperature sensor at room temperature 106Ohms or 106KOhms?

-

@gloomyandy said in How can I calibrate the temperature of my bed:

Unfortunately a PT100 at 20C reads about 107Ohms so that reading if it was reported accurately could be a PT100.

Right, that's why I'm really glad @droftarts intervened. However, the temperature readings resulting from the

M308parameters in the config would be quite different, especially as the OP stated that his PT100 boards were "not currently in use". -

It's ohms not kiloohms...according to the manufacturer, the bed has a PT100 sensor on it...but I haven't connected it to the PT100 daughterboard yet, but first to the onboard input...I just wanted to test all 4 mats connect parallel to the output and test again

-

@axiom Please see @droftarts comments above. If you really do have a PT100 continuing to operate your heated bed may cause damage.

-

@axiom said in How can I calibrate the temperature of my bed:

It's ohms not kiloohms...according to the manufacturer, the bed has a PT100 sensor on it...

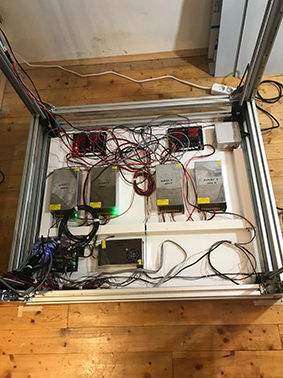

To clarify: could you please post a screenshot or a photo of the heater's data sheet? In addition, I would like to see an image of the heater's wiring. Thanks.

-

@infiniteloop

Technical Data of Silicone Heaters:Supply Voltage: 0~400 V, 1 or 3 phase

Insulation Material: Fiberglass reinforced Silicone Rubber

Max. Operating Temp.: 260 Deg C or 500 Deg F

Min. Element Temp.: -50 Deg C or -58 Deg F

Max.Power Density: 5 w/sq.cm depending on application

Resistance Tolerance: about +/- 5%

Standard Thickness: 1.5 mm

Flammability: Flame Retardant

Moisture Absorption: Moisture proof

Thermal Protection & Control: On board thermal fuse, thermostat, thermistor and PT100 are available as part of your thermal management solution.

Power Leads: 1 meter by default,other length available upon request -

-

@axiom Thank you.

From the technical data:

Thermal Protection & Control: On board thermal fuse, thermostat, thermistor and PT100 are available

Sorry, but from your photos, I can't see any signal lines from neither a thermistor nor a PT100. Are there separate lines, or is there just one cable with two leads? In other words: if there are both a thermistor and a PT100 as the seller states, how can I select one of these?

-

2 wires for the power supply/mosfet and 2 wires for the sensor. I think the PT100 is welded into the mat and the sensor output is then the connection

-

@axiom said in How can I calibrate the temperature of my bed:

I think the PT100 is welded into the mat and the sensor output is then the connection

That's what I think. But where is then the thermistor?

On the one hand, you have a configuration for a thermistor (at least I think so):

M308 S0 P"bedtemp" Y"thermistor" R4700 T100000 B3950 ; configure sensor 0 as thermistor on pin bedtemp… proper temperature readings, and - as it looks - a successful tuning. That tells me: your bed heater has a thermistor. You can't get all this with a PT100 at 106 Ohm resistance and wired without a daughterboard.

On the other hand, your measurement of the sensor's resistance says: there's a PT100 built in.

Which side should I believe? Can you perhaps give me a link to the manufacturer where he elaborates on the "thermal management solution" he proclaims?

-

@infiniteloop Hello, this is the link from the dealer for the heating mats. I have 4 pieces 400x400x24V.

Today I would then like to connect the mats to the PT100 daugterboards and then connect the outputs in parallel.

then I want to do the autotune. Is an average value then automatically calculated for the sensors? At least that's how I understood the description. -

@axiom please post your current config.g. Until we understand if you have PT100 or thermistor, it is difficult to advise you.

Ian

-

@axiom Moin,

Thank you for the link. Unfortunately, it isn’t very descriptive, especially concerning the thermal sensors. As far as I understand it, they provide either a thermistor or a PT100, not both. What you get depends on what you order from them. So the problem remains: we don’t know whether your heaters are equipped with thermistors or PT100 sensors.

Today I would then like to connect the mats to the PT100 daugterboards and then connect the outputs in parallel. Then I want to do the autotune.

As long as we are not sure what sensors you got, this is a bad idea. Instead, you can try to configure a single heater with a PT100 daughterboard and see what readings you get at room temperature. Please don’t power the heaters at this stage!

-

@infiniteloop Ok, then I'll wait, but what should I do?

-

@infiniteloop I just got it now...I should just connect a sensor to the daughterboard and see what is displayed?

-

@axiom Please post your config.g. It will show what command you are using to get the sensor to show the correct room temperature. This will tell us if it's a thermistor or PT100.

Ian

-

As discussed, I have now connected the bed sensor to a PT100 daughterboard.

The console shows 2000 degrees!!!!!Here is the current code:Configuration file for Duet WiFi (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.10 on Tue Jul 26 2022 17:05:20 GMT+0200 (Mitteleuropäische Sommerzeit); General preferences

M575 P1 S1 B57600 ; enable support for PanelDue

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"Don axoiom" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P4 S1 ; physical drive 4 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M584 X0 Y1 Z2 E4:3 ; set drive mapping

M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E420.00:420.00 ; set steps per mm

M566 X900.00 Y900.00 Z60.00 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E1200.00:1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00:250.00 ; set accelerations (mm/s^2)

M906 X1800 Y1600 Z1600 E1600:1600 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X500 Y500 Z500 S0 ; set axis maxima; Endstops

M574 X1 S1 P"xstop" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop

M574 Z2 S1 P"zstop" ; configure switch-type (e.g. microswitch) endstop for high end on Z via pin zstop; Z-Probe

M558 P1 C"zprobe.in" H5 F300 T6000 ; set Z probe type to unmodulated and the dive height + speeds

G31 P500 X20 Y20 Z2.5 ; set Z probe trigger value, offset and trigger height

M557 X15:215 Y15:195 S20 ; define mesh grid; Heaters

M308 S0 P"spi.cs1" Y"rtd-max31865" ; configure sensor 0 as PT100 on pin spi.cs1

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S280 ; set temperature limit for heater 1 to 280C

M308 S2 P"e1temp" Y"thermistor" T100000 B4138 ; configure sensor 2 as thermistor on pin e1temp

M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2

M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit

M143 H2 S280 ; set temperature limit for heater 2 to 280C; Fans

M950 F0 C"fan1" Q500 ; create fan 0 on pin fan1 and set its frequency

M106 P0 S1 H0 T45 ; set fan 0 value. Thermostatic control is turned on

M950 F1 C"fan0" Q500 ; create fan 1 on pin fan0 and set its frequency

M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on; Tools

M563 P0 S"Filament" D0 H1 F0 ; define tool 0

G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 S"Stuetzkonstruktion" D1 H2 F0 ; define tool 1

G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C; Custom settings are not defined