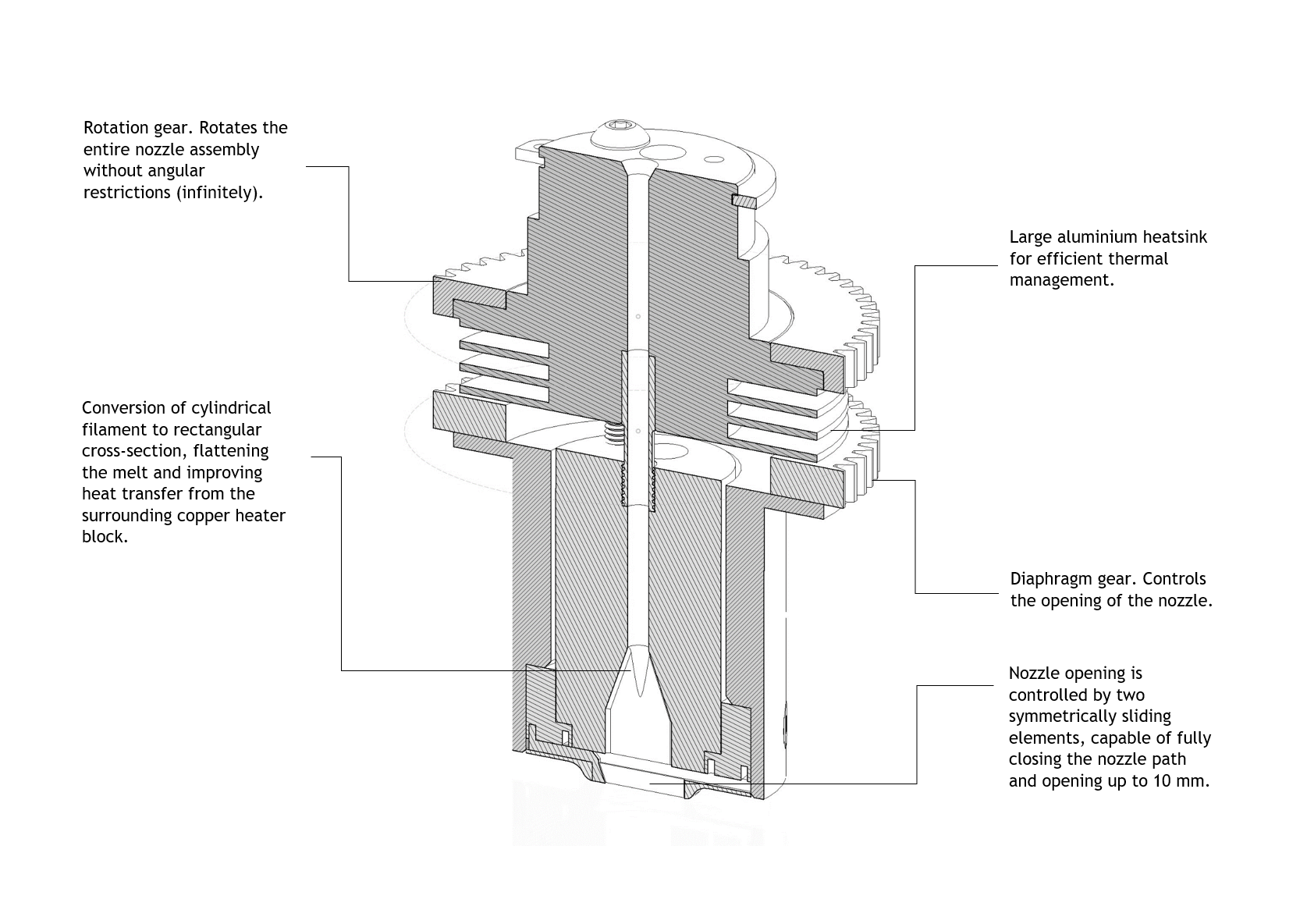

Variable Width Nozzle (Sculpman)

-

-

Interesting concept but it's got a ways to go before it becomes practical. The three most glaring issues:

- Slicers need to support the nozzle

- How does this nozzle deal with abrasive filament and how do you clear a blockage?

- How much weight does this add to the carriage?

-

-

Arguably, due to die swell, pretty much any nozzle is variable width.

-

Yeah they were at Formnext. Developing their own custom slicer, also have a rotary axis for the extruder so they can put the "thin" side of the nozzle into corners etc.

-

Where is heater and thermistor?

No more oozing is quite nice. You close the nozzle instead of retracting filament. That allows using remote Bowden tube extruders.

I only hope it works smooth at different nozzle temps and in heated chambers...so many different material expansion-rates to deal with.