Problems with input shaping

-

@Lee The 'Data Collection Cancelled' problem was solved by @chrishamm. Refer to this post by @alexjx

Go down to the google drive link provided and get the latest version of DWC.

It is very important to get the axes correct with the I parameter but I have no idea how to do that for a delta printer. This link should help you get the orientation right (I think they use the same board as you):

https://forum.duet3d.com/topic/31411/lis3dsh-orientation-on-a-delta-printer/6 -

@droftarts Here are pictures of the cabel it selfe i have connected the shielding oh the wire to ground (underneath The shrink tubing)

continuity is good aswell -

@tas https://forum.duet3d.com/topic/31411/lis3dsh-orientation-on-a-delta-printer/6

I have checked I16 seems to be right for me.I have installed the the version you suggested i am was able to finish the data collection.

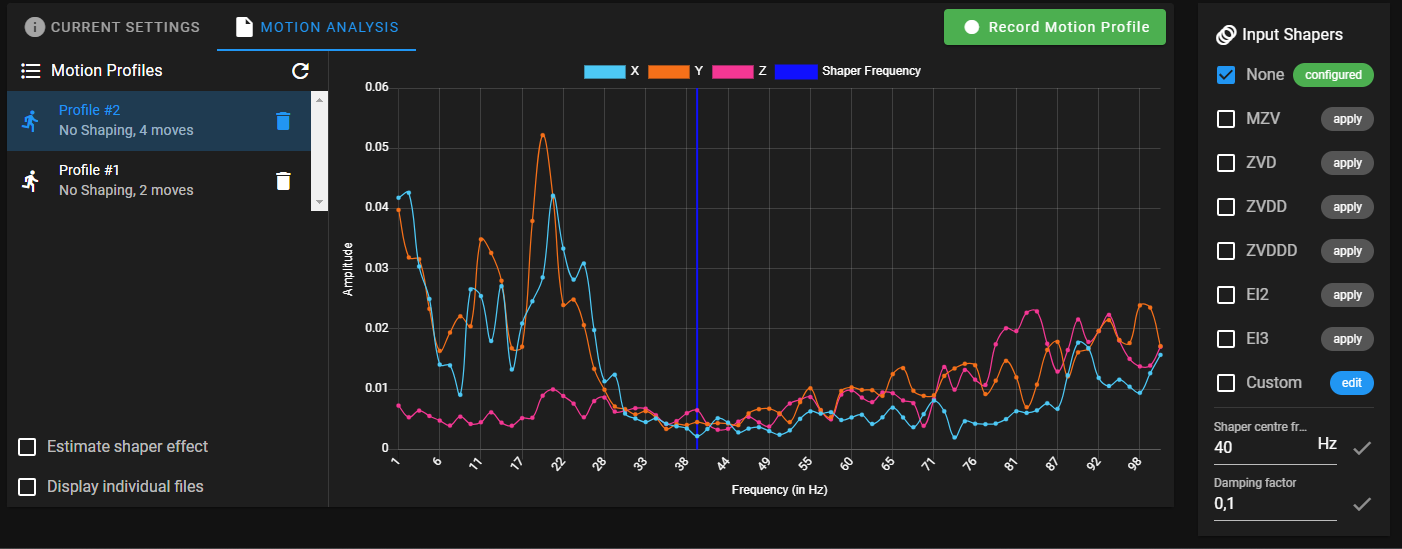

here are the results: (using M566 X150.00 Y150.00 Z150.00)

-

-

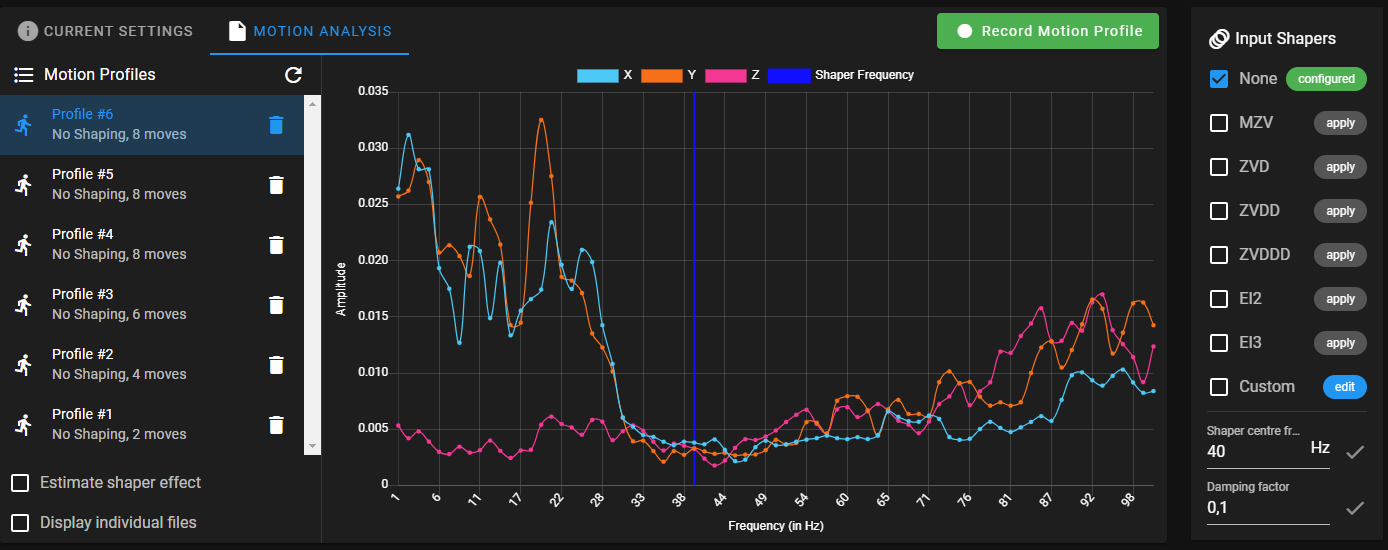

@tas I have run some more recordings and they all look almost Identical.

-

-

@droftarts I have not run a test print jett but i will start on now

-

This was printed ad 60 mm/S and M593 P"ZVDDD" F19,5 S0

-

@Lee Keep in mind I have no delta experience but the pattern of thin vertical lines looks like Very Fine Artifacts to me. That will not be addressed by input shaping.

The echoes of the scallop pattern are what you want to examine. There do appear to be some first layer issues you may want to deal with first.

-

@Lee I finally got my Ender 5 Plus back up and running today with new E3D 0.9 degree stepper motors (trying to get rid of my VFAs!). I will have to do a full recalibration so I will do some Input Shaping tests and see if I can come up with something of help to you.

-

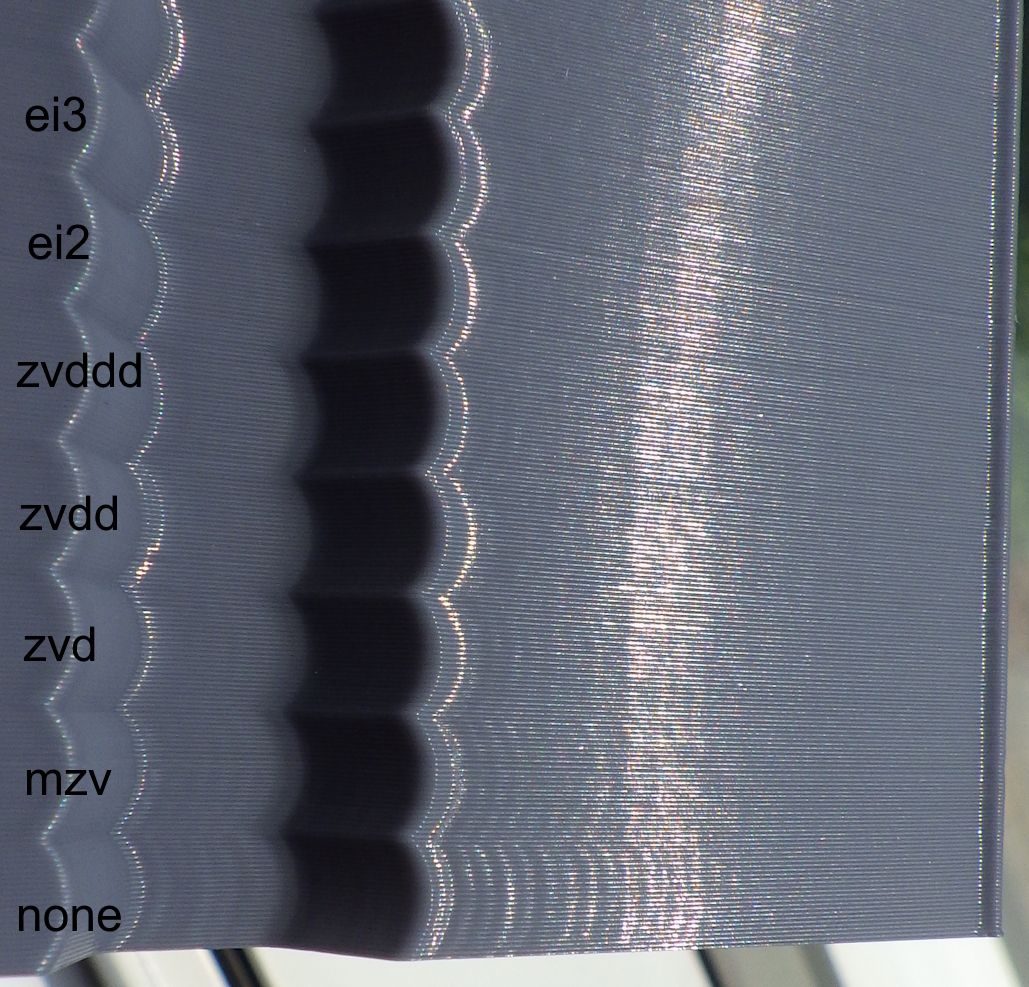

@Lee I did some tests.

I now have the E3D 0.9 degree motors for X and Y. This has changed a lot for me so I have to do a full recalibration of the printer. For these tests I used my original values though and enabled only input shaping using my new center frequency of 39 Hz. So Acceleration of 1400 and Jerk max of 900. M593 P"EI3" F39.0 S0.0.

I used PrusaSlicer 2.6.0 with the following custom g-code in Printer Settings>After Layer Change G-Code:

;Try Input Shapers

{if layer_z >= 0.2}M593 P"none"{endif}

{if layer_z >= 5.0}M593 P"mzv" F39 S0.0{endif}

{if layer_z >= 10.0}M593 P"zvd" F39 S0.0{endif}

{if layer_z >= 15.0}M593 P"zvdd" F39 S0.0{endif}

{if layer_z >= 20.0}M593 P"zvddd" F39 S0.0{endif}

{if layer_z >= 25.0}M593 P"ei2" F39 S0.0{endif}

{if layer_z >= 30.0}M593 P"ei3" F39 S0.0{endif}Using the Klipper Ringing_Tower.stl as you did the above code chooses another Input Shaper at each new scallop.

So first sample, Acceleration 1400, Jerk 900, speed 50mm/s, no PA. I apologize in advance for my photography. Not great.

There is a slight difference at each corner for the different input shapers. This does not show up in my photos. For some shapers the start side of the corner looks better, for others the end side. For 'none' there is prolonged ringing and varying (but much less ringing) for the input shapers.

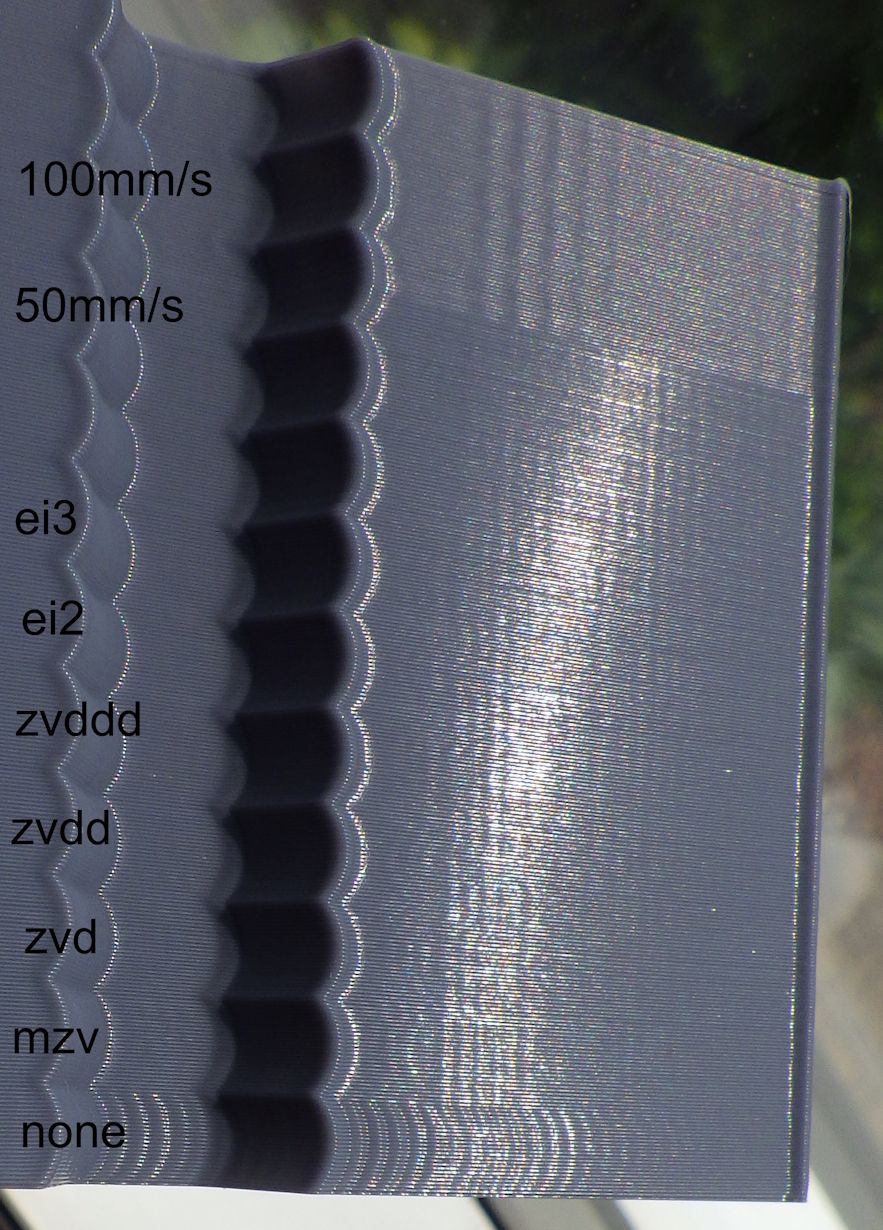

For the second sample I changed Jerk to 100 from 900. On the last three scallops at the top I doubled the speed to 100mm/s. A shallow wave appeared at that speed. Jerk gives worse ringing at 100 with no input shaper because the 1400 acceleration worked best with 900 jerk (and my old motors). However the lower jerk looks much better with input shaping. There is definitely less ringing.

.

.You should definitely see a difference with input shaping enabled.

-

@Lee As others have said the resonance frequency you are targeting (19.5Hz in the above is very low) and my understanding is that input shaping does not work well below approx 25Hz. This is a comment from the Klipper documentation:

Another consideration is that if a resonance frequency is too low (below 20-25 Hz), it might be a good idea to increase the printer stiffness or reduce the moving mass. Otherwise, acceleration and printing speed may be limited due too much smoothing now instead of ringing. -

@gloomyandy but what frequency should i use than? No matter what I do the results are almost identical every time

-

@tas I also have the e3d 0.9 degree motor i will try printing with the g code modifiers you used

-

@Lee can you show how you are mounting the accelerometer?

-

@jay_s_uk There us a picture above it is mounted at the back of the tool head

-

@Lee you may need to improve the mounting to make it more fixed

-

@jay_s_uk I will try tighteing the screw that holding the accelerometer.

-

@Lee you probably need more than just 1 screw

-

@jay_s_uk ok than i will design a new holder