reference the X-axis on both rails

-

What expansion board are you using?

On my 3 Z stepper printer I am using Duet 2 boards: Duet WiFi and a Duex5.

My M574 for the Z endstops looks like this:

M574 Z1 S1 P"!duex.e2stop + !duex.e3stop + !duex.e4stop" ; configure active-high endstop for low end on ZThe Z endstop sensors are connected to the Duex5 and I included the duex. prefix. I recall that it was necessary.

Frederick

-

@axiom said in reference the X-axis on both rails:

M574 Z1 S1 P"e2stop + e3stop + e4stop + e5stop"

If you send M98 P"config.g" you'll probably get an error saying invalid pin or something like that for that line.

-

@fcwilt as @Phaedrux says, the pin names are wrong. See https://docs.duet3d.com/Duet3D_hardware/Duet_2_family/DueX2_and_DueX5#pin-names

Should be duex.e2stop etc.

Ian

-

@droftarts

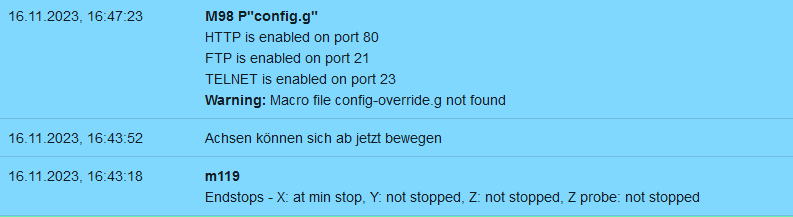

I have now adjusted the names, but the endstops are still not accepted. Here is the message from the m119 command and the M98 P"config.g" command. And below again my adapted codeM98 P"config.g"

HTTP is enabled on port 80

FTP is enabled on port 21

TELNET is enabled on port 23

Error: in file macro line 50 column 65: M574: string too long

Warning: Macro file config-override.g not found

16.11.2023, 15:50:48m119

Endstops - X: at min stop, Y: not stopped, Z: no endstop, Z probe: not stoppedAll control LEDs respond...The 4 motors on the expansion board react and can be controlled

I think it's not a hardware error it is a DueX5 xspansionboard

again my adapted code:

; Configuration file for Duet WiFi (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.16 on Sun May 28 2023 15:23:44 GMT+0200 (Mitteleuropäische Sommerzeit); General preferences

M575 P1 S1 B57600 ; enable support for PanelDue

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"DUKA1300" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S1 ; enable FTP

M586 P2 S1 ; enable Telnet; Drives

;M569 P4 R-1 ; Treiber 4 deaktivieren

;M569 P3 R-1 ; Treiber 4 deaktivieren

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M569 P4 S0 ; physical drive 3 goes forwards

M569 P5 S1 ; physical drive 3 goes forwards Expansionboard

M569 P6 S1 ; physical drive 3 goes forwards Expansionboard

M569 P7 S1 ; physical drive 3 goes forwards Expansionboard

M569 P8 S1 ; physical drive 3 goes forwards Expansionboard

;M584 X0 Z2 E1 ; set drive mapping

;M584 X0 Z2 E1 ; set drive mapping

;M584 X0:4 Y1 Z2 E3 ; set drive mapping

M584 X0:4 Y1 Z5:6:7:8 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z640 E322.58 ; set steps per mm

M566 X900.00 Y900.00 Z100.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z300.00 E1200.00 ; set maximum speeds (mm/min)

;M201 X500.00 Y500.00 Z20.00 E250.00 ; set accelerations (mm/s^2)

M201 X500.00 Y500.00 Z40.00 E250.00 ; set accelerations (mm/s^2)

M906 X1800 Y1800 Z1700 E1600 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X100 Y0 Z0 S1 ; set axis minima

M208 X750 Y640 Z1220 S0 ; set axis maxima; Endstops

M574 X1 S1 P"xstop + e0stop" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop

M574 Z1 S1 P"duex.e2stop + duex.e3stop + duex.e4stop + duex.e5stop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop; Z-Probe

;M558 K0 P1 C"e1stop" ;H5 F120 T6000

M558 K0 P5 C"!zprobe.in" H5 F120 T6000 ; set Z probe type to unmodulated and the dive height + speeds (Kapazitiver Sensor)

;M557 X0:735 Y-27:573 S35 ; define mesh grid; Z-Probe two of them

;M558 K0 P1 C"!zprobe.in" H5 F120 T6000 ; set Z probe type to unmodulated and the dive height + speeds (Kapazitiver Sensor)

;M558 K1 P8 A2 S0.2 C"!zstop" H5 F80 T3000

;G31 P1000 K0 X-1 Y-61 Z0.484 ; set Z probe trigger value, offset and trigger height (Kapazitiver Sensor)

;G31 P1000 K1 X0 Y0 Z12.664 ; Second Z-offset

;M557 X0:735 Y-27:573 S35 ; define mesh grid; Heaters

; Bed

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

;M307 H0 B1 S1.00 ; enable bang-bang mode for the bed heater and set PWM limit

;M307 H2 R0.283 K0.463:0.000 D7.17 E1.35 S1.00 B0 ; enable bang-bang mode for the bed heater and set PWM limit

M307 H0 R0.283 K0.463:0.000 D7.17 E1.35 S1.00 B0 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S280 ; set temperature limit for heater 0 to 120C;Hotend

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 R1.797 K0.742:0.000 D7.57 E1.35 S1.00 B0 V23.8 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S400 ; set temperature limit for heater 1 to 400C; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F2 C"fan2" Q350 ; create fan 2 on pin fan2 and set its frequency

M106 P2 S1 H1 T60 ; set fan 2 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 1

G10 P0 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P0 R0 S0 ; set initial tool 1 active and standby temperatures to 0C; Filamentsensor

;M591 D0 P1 C"zstop" S1 ;R40:120 E3.0 S1 Filament Sensor;Auto Z-Offset

; Custom settings are not defined

M501 -

Did you try shortening the line? I believe the comment is included when it comes to being too long.

And you can remove the M501 at the end if you wish to silence the error about config-override.g being missing.

Frederick

-

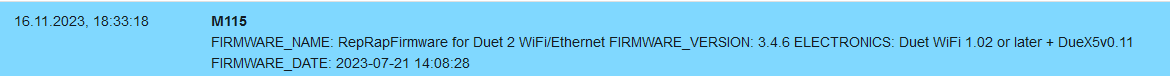

@axiom What firmware version are you on? This has come up before, and it's because the string for the endstops is too long. See https://forum.duet3d.com/topic/32954/duet-2-wifi-voron-2-4-multiple-z-endstops-query

This was fixed in RRF 3.4.6, with an increase from 50 to 61.However, I think you just need to take out the spaces in yours to get under the 50 character limit, ie

M574 Z1 S1 P"duex.e2stop+duex.e3stop+duex.e4stop+duex.e5stop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystopThat's 47 characters.

Ian

-

@droftarts Deleting the spaces was the solution...it no longer gives an error

message and the g1 h1 z0 command works and the bed stops at the endstops...now I can continue researching! Thank you so much!!!!

message and the g1 h1 z0 command works and the bed stops at the endstops...now I can continue researching! Thank you so much!!!! -

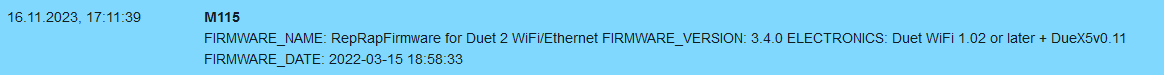

@axiom What firmware version? Send M115 in the console and post response, please.

Ian

-

-

@axiom You'll probably find it easier if you update to RRF 3.4.6, the current release. You shouldn't have to change your configuration.

Ian

-

@droftarts said in reference the X-axis on both rails:

You'll probably find it easier if you update to RRF 3.4.6, the current release. You shouldn't have to change your configuration.

IanCan I just click on it here, or do I have to prepare something?

-

@axiom download "Duet2and3Firmware-3.4.6.zip" from https://github.com/Duet3D/RepRapFirmware/releases/tag/3.4.6 without unzipping it, then upload it to the Duet. It will unpack it and install the firmware update.

There's a whole wiki page on firmware updates: https://docs.duet3d.com/User_manual/RepRapFirmware/Updating_firmware

Ian

-

@droftarts Is there something to update for the Due5 expansion board...or is that okay?

-

The Duex does not have it's own firmware.

-

@fcwiltI have now adapted the home files according to your stage directions (see below) and removed the homeall.g as you said. when I click the reference button on the user interface

, the error message comes up:

, the error message comes up:

Now I don't know what homeall.g should look like?Here are my new homing files:

; homex.g

; called to home the X axis

;

; generated by RepRapFirmware Configuration Tool v3.3.16 on Sun May 28 2023 15:23:44 GMT+0200 (Mitteleuropäische Sommerzeit)

G91 ; relative positioning

G1 H1 Z5 F6000 ; lift Z relative to current position

G1 H1 X-755 F6000 ; move quickly to X axis endstop and stop there (first pass)

G1 H1 X10 ; go back a few mm

G1 H1 X-10 F600 ; move slowly to X axis endstop once more (second pass)

G1 H1 Z-5 F6000 ; lower Z again

G92 X0 ; where ### is the actual axis position when the motion stopped - usually determined by testing; homey.g

; called to home the Y axis

;

; generated by RepRapFirmware Configuration Tool v3.3.16 on Sun May 28 2023 15:23:44 GMT+0200 (Mitteleuropäische Sommerzeit)

G91 ; relative positioning

G1 H1 Z5 F6000 ; lift Z relative to current position

G1 H1 Y-643 F6000 ; move quickly to Y axis endstop and stop there (first pass)

G1 H2 Y10 ; go back a few mm

G1 H1 Y-10 F600 ; move slowly to Y axis endstop once more (second pass)

G1 H2 Z-5 F6000 ; lower Z again

G92 Y0 ;where ### is the actual axis position when the motion stopped - usually determined by testing; homez.g

; called to home the Z axis

;

; generated by RepRapFirmware Configuration Tool v3.3.16 on Sun May 28 2023 15:23:44 GMT+0200 (Mitteleuropäische Sommerzeit)

G91 ; relative positioning

G1 H1 Z-1230 F6000 ; lift Z relative to current position

G1 Z20 ; back off a bit

G1 H1 Z-20 F300 ; slow move to min endstop

G92 Z7,1 ; home Z by probing the bed -

I don't recall saying to remove the homeALL.g file.

What I think I said was I don't duplicate homing code so my homeALL.g file looks something like this:

M98 P"homeZ.g" M98 P"homeX.g" M98 P"homeY.g"The results are the same but there is no actual "homing" code in homeALL.g.

Frederick

-

And since you now have Z endstops you don't need to use the type of homing code the configuration tool generates.

I also suggest you work towards not using the configuration tool and learn how to create your own code.

Your code will likely be better and fixing code related problems will be easier since you fully understand what you coded.

Didn't I post examples of what your basic homing files would look like?

Basically you do:

- a fast G1 H1 move toward the endstop

- a short fast move G1 move away from the endstop

- a slow G1 H1 move toward the endstop

- a possible G92 to set the logical position of the axis being homed to match the physical position

Assume a printer where the X endstop is at the min end of the X axis and the axis has a range of motion of 300mm:

G1 H1 X-310 F6000 G1 X20 G1 H1 X-25 F600 G92 X=nnn ; where nnn is actual position of the X axis after the 3 moves aboveFrederocl

-

I'm just stuck...if my z-endstops are set to 4 and I want to reference...but the bed is already above the end stops, e.g. 2...then the bed moves into the head. So I currently have to move the bed below the endstops before referencing...how can I correct this in the z-home. Here are my files again:

; homez.g

; called to home the Z axis

;

; generated by RepRapFirmware Configuration Tool v3.3.16 on Sun May 28 2023 15:23:44 GMT+0200 (Mitteleuropäische Sommerzeit)

G91 ; relative positioning

G1 H1 Z-1225 F4000 ; lift Z relative to current position

G1 Z10 ; back off a bit

G1 H1 Z-10 F300; slow move to min endstop

G92 Z4 ; home Z by probing the bed; homex.g

; called to home the X axis

;

; generated by RepRapFirmware Configuration Tool v3.3.16 on Sun May 28 2023 15:23:44 GMT+0200 (Mitteleuropäische Sommerzeit)

G91 ; relative positioning

G1 H1 Z5 F4000 ; lift Z relative to current position

G1 H1 X-755 F4000 ; move quickly to X axis endstop and stop there (first pass)

G1 H1 X10 ; go back a few mm

G1 H1 X-10 F300 ; move slowly to X axis endstop once more (second pass)

G1 H1 Z-5 F4000 ; lower Z again

G92 X0 ; where ### is the actual axis position when the motion stopped - usually determined by testing

G1 x10; homey.g

; called to home the Y axis

;

; generated by RepRapFirmware Configuration Tool v3.3.16 on Sun May 28 2023 15:23:44 GMT+0200 (Mitteleuropäische Sommerzeit)

G91 ; relative positioning

G1 H1 Z5 F4000 ; lift Z relative to current position

G1 H1 Y-643 F4000 ; move quickly to Y axis endstop and stop there (first pass)

G1 H2 Y10 ; go back a few mm

G1 H1 Y-10 F300 ; move slowly to Y axis endstop once more (second pass)

G1 H2 Z-5 F64000 ; lower Z again

G92 Y0 ;where ### is the actual axis position when the motion stopped - usually determined by testing

G1 y10and homeall:

M98 P"homeY.g"

M98 P"homeX.g"

M98 P"homeZ.g"

; Configuration file for Duet WiFi (firmware version 3.3)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v3.3.16 on Sun May 28 2023 15:23:44 GMT+0200 (Mitteleuropäische Sommerzeit); General preferences

M575 P1 S1 B57600 ; enable support for PanelDue

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"DUKA1300" ; set printer name; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S1 ; enable FTP

M586 P2 S1 ; enable Telnet; Drives

;M569 P4 R-1 ; Treiber 4 deaktivieren

;M569 P3 R-1 ; Treiber 4 deaktivieren

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S1 ; physical drive 3 goes forwards

M569 P4 S0 ; physical drive 3 goes forwards

M569 P5 S1 ; physical drive 3 goes forwards Expansionboard

M569 P6 S1 ; physical drive 3 goes forwards Expansionboard

M569 P7 S1 ; physical drive 3 goes forwards Expansionboard

M569 P8 S1 ; physical drive 3 goes forwards Expansionboard

;M584 X0 Z2 E1 ; set drive mapping

;M584 X0 Z2 E1 ; set drive mapping

;M584 X0:4 Y1 Z2 E3 ; set drive mapping

M584 X0:4 Y1 Z5:6:7:8 E3 ; set drive mapping

M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation

M92 X80.00 Y80.00 Z640 E322.58 ; set steps per mm

M566 X900.00 Y900.00 Z100.00 E120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z300.00 E1200.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z40.00 E250.00 ; set accelerations (mm/s^2)

M906 X1800 Y1800 Z1700 E1600 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X750 Y643 Z1220 S0 ; set axis maxima; Endstops

M574 X1 S1 P"xstop + e0stop" ; configure switch-type (e.g. microswitch) endstop for low end on X via pin xstop

M574 Y1 S1 P"ystop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop

M574 Z1 S1 P"duex.e2stop+duex.e3stop+duex.e4stop+duex.e5stop" ; configure switch-type (e.g. microswitch) endstop for low end on Y via pin ystop; Z-Probe

M558 K0 P5 C"!zprobe.in" H5 F120 T6000 ; set Z probe type to unmodulated and the dive height + speeds (Kapazitiver Sensor)

M558 K1 P8 A2 S7 C"duex.e6stop" H5 F80 T3000

G31 P1000 K0 X0 Y-25 Z0.817 ; set Z probe trigger value, offset and trigger height (Kapazitiver Sensor)

M557 X0:735 Y-25:573 S35 ; define mesh grid; Heaters

; Bed

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0

M307 H0 R0.283 K0.463:0.000 D7.17 E1.35 S1.00 B0 ; enable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S280 ; set temperature limit for heater 0 to 120C;Hotend

M308 S1 P"e0temp" Y"thermistor" T100000 B4138 ; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 R1.797 K0.742:0.000 D7.57 E1.35 S1.00 B0 V23.8 ; disable bang-bang mode for heater and set PWM limit

M143 H1 S400 ; set temperature limit for heater 1 to 400C; Fans

M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency

M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off

M950 F2 C"fan1" Q350 ; create fan 2 on pin fan2 and set its frequency

M106 P2 S1 H1 T60 ; set fan 2 value. Thermostatic control is turned on; Tools

M563 P0 D0 H1 F0 ; define tool 1

G10 P0 X0 Y0 Z0 ; set tool 1 axis offsets

G10 P0 R0 S0 ; set initial tool 1 active and standby temperatures to 0C; Filamentsensor

M591 D0 P1 C"e1stop" S1 ;R40:120 E3.0 S1 Filament Sensor;Auto Z-Offset

; Custom settings are not defined

M501 -

You have to design the mounting of the endstops so they are triggered to the very end of travel.

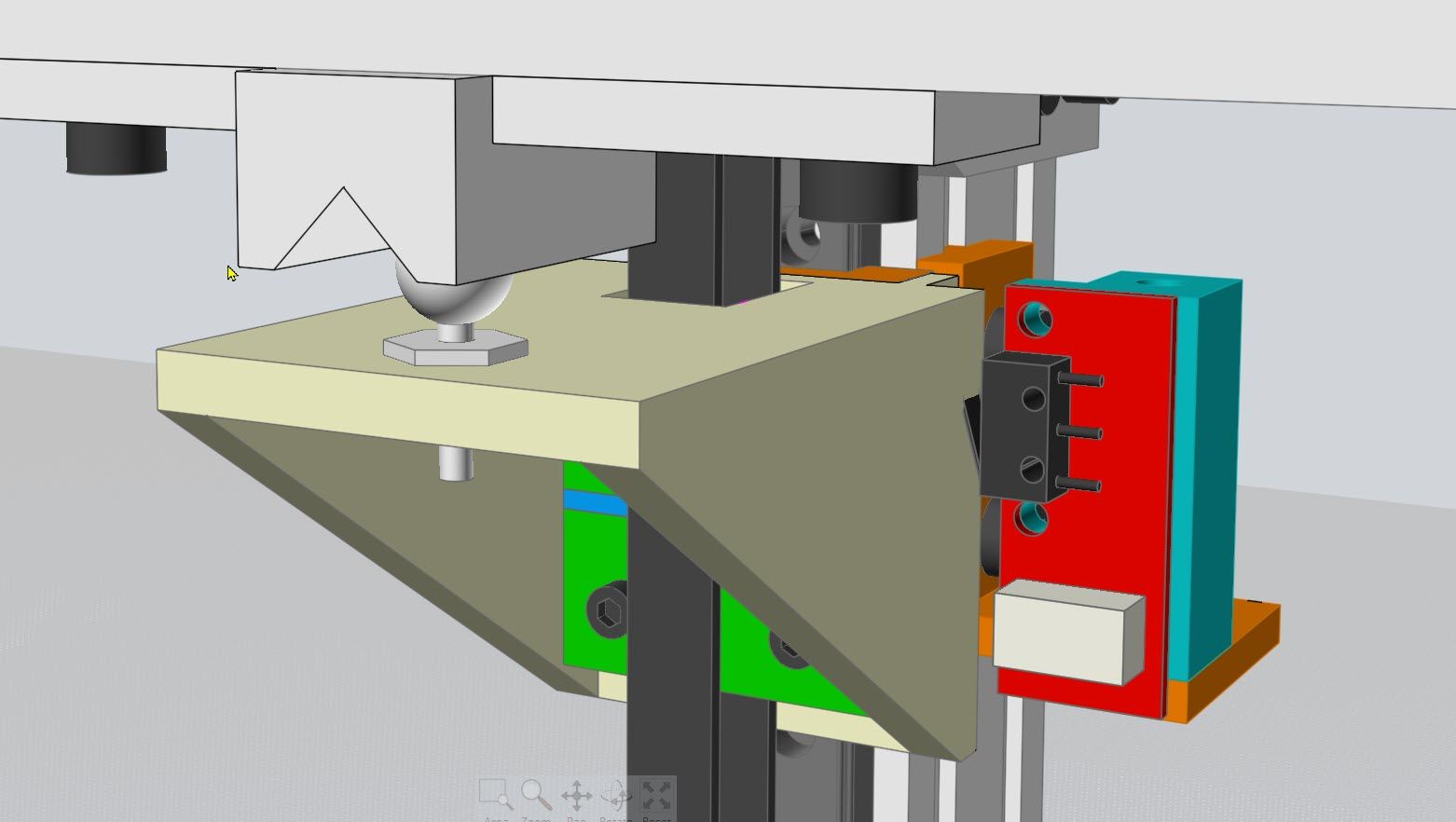

Here you can see part of the Z axis setup on my tripple Z stepper printer. The endstop switch is activated by the side of that bracket that is supporting the ball stud. The bracket travels along the linear rail. The endstop switch is first activated well before the end of Z travel but remains activated to the very end of travel.

So you cannot move "past" the endstop.

Let's suppose you use a typical bit of homing code like below:

G91 G1 H1 Z-300 F1200 G1 Z50 G1 H1 Z-55 F300If you start with endstop already activated the first G1 move doesn't actually move and the code continues doing the backup move and then the slow move to endstop.

Some folks include a test to see if the homing code starts out with the endstop activated and if it is the code backs off enough to insure the endstop should no longer be activated and if it is still activated they abort the homing and display and error message.

That "safety" check is a pretty good idea.

Frederick

-

@fcwilt but you wrote to me that if my endstops are further down, then I can simply define the position, e.g. 4, with the G92 command... I need the information on how to automatically go deeper than 10 mm when referencing ...when it starts up it encounters the endstops...is the G91 command at the beginning perhaps wrong?