Cast Toolplate Bed Progress ?

-

@Dizzwold said in Cast Toolplate Bed Progress ?:

Maybe it's not possible?

Maybe. I'd have thought there ought to be a way to recover from an emergency stop but the docs just talk about power cycling the board. I'm surprised running config g doesn't work because that is effectively all that happens when power is restored.......but there is possibly a work around.

The obvious one is do as I do and use the emergency stop button to physically interrupt the 24V power to the board(s).

But failing that, maybe we can do something else. So rather than an emergency stop, think about what you actually want to stop. I guess that's motors and heaters. Heaters are easy - just set the temperatures to zero in one macro and restore them in the other. So what about using M18 instead of M112 to disable motors? It might not be immediate though so might have to wait for any moves to finish which I guess is not what you want an emergency stop to do? M0 is another option but again, I don't think it will work until the current move is complete.

-

@Dizzwold said in Cast Toolplate Bed Progress ?:

Maybe it's not possible?

A question for @chrishamm I think.

-

@Phaedrux said in Cast Toolplate Bed Progress ?:

@Dizzwold said in Cast Toolplate Bed Progress ?:

Maybe it's not possible?

A question for @chrishamm I think.

,..,....or @dc42. Essentially we're trying to find a way to reset a printer after M112 has been sent, without cycling power. The OP is using trigger macros so it can be a series of commands rather than a single command. Apparently running config g via M98 doesn't do the job and I'd have thought it would.

-

@deckingman sending M999 works. The emergency stop button sends M112 followed a little later by M999.

-

@dc42 said in Cast Toolplate Bed Progress ?:

@deckingman sending M999 works. The emergency stop button sends M112 followed a little later by M999.

Maybe I've misunderstood the OP's problem. Looking back through his posts he is saying " DWC on my computer needs a physical click on the RESET button displayed on the screen". I think it's that "DWC thing" that he's trying to overcome. He says he's tried all combinations of M999 etc in his trigger macros.

-

That's correct, I'm talking on the computer DWC interface.

If I clicking a button on screen with my cursor on my computer, I'm essentially sending a single line of code once to the Duet, so why can't a physical button do this?

I appreciate that DWC is an interface used both by the Paneldue and as it would suggest on mobile or computers (Duet 'Web' Control).I had looked at other options like for a filament run-out sensor, maybe this or like you've suggested with disabling/re-enabling the steppers are the only options.

-

@Dizzwold Definitely one for @chrishamm then.

-

@Dizzwold said in Cast Toolplate Bed Progress ?:

I'm essentially sending a single line of code once to the Duet, so why can't a physical button do this?

What code are you trying to send?

Frederick

-

@Dizzwold Just a thought but what happens if you refresh your browser after the macro containing M999 has run? Does DWC still want you to press a reset button?

-

Hi Guys,

Again thank you for your support and input.

@fcwilt

Sorry you misunderstand me.

I'm not trying to send any line of code. I'm just stating what clicking the on screen "Reset Machine" Button possibly does (on my computer screen). I'm no programmer but I believe DWC is Javascript and it would probably be something likeonclickto enable a function for M999.@deckingman

I've tried your suggestion with the following, but refreshing the browser makes no difference. If anything it makes it longer to reset the machine as your also reconnecting before resetting.

Also during the time after pressing the Emergency Stop Button, while the computer screen states and requests Reset Machine, the paneldue is Halted. It's either press Stop on the paneldue or click Reset Machine on the computer screen.

I think it's a case of getting into the software code for the GUI, to be able to enable this as a use, unless this plugin might help as previously mentioned by @Phaedrux in another post;

https://github.com/MintyTrebor/BtnCmd; Emergency Stop M950 J2 C"io3.in" M581 P2 T2 S1 R0 M581 P2 T3 S0 R0;Trigger2.g Reset Emergency Stop Button M112 M999;Trigger3.g Z Axis Limt Switch M98 P"config.g"Then changed to;

; Emergency Stop M950 J2 C"io3.in" M581 P2 T0 S1 R0 M581 P2 T2 S0 R0;Trigger2.g Reset Emergency Stop Button M112 M999Then changed to;

;Trigger2.g Reset Emergency Stop Button M999And then again with;

;Trigger2.g Reset Emergency Stop Button M98 P"config.g" -

@dc42 @deckingman @Phaedrux @chrishamm @fcwilt

Hi guys,

I think with looking around I might be needing to change something in the following which is C++. I know a little C++ (and I mean a little), but I'm certain this is part of of why I need to physically press a Reset Machine radio button ;

https://github.com/Duet3D/RepRapFirmware/blob/3.4-dev/src/GCodes/GCodeInput.cpp

src/GCodes/GCodeInput.cppFrom line 144-219 is regarding the M112 command and how it is reset. I think?

Lines 188, 189, 205, 206 prevent a perpetual reset?I've more code (.cpp files), to read, but I think I'm on the right track. I've got some thing to do this afternoon, but will come back.

Dizzwold.

-

-

@Dizzwold please start a new thread about this because it is off-topic for this thread.

-

Okay, posted as follows;

DWC on Computer Screen RESET MACHiNE from Emergency Stop

https://forum.duet3d.com/topic/34675/dwc-on-computer-screen-reset-machine-from-emergency-stop@deckingman

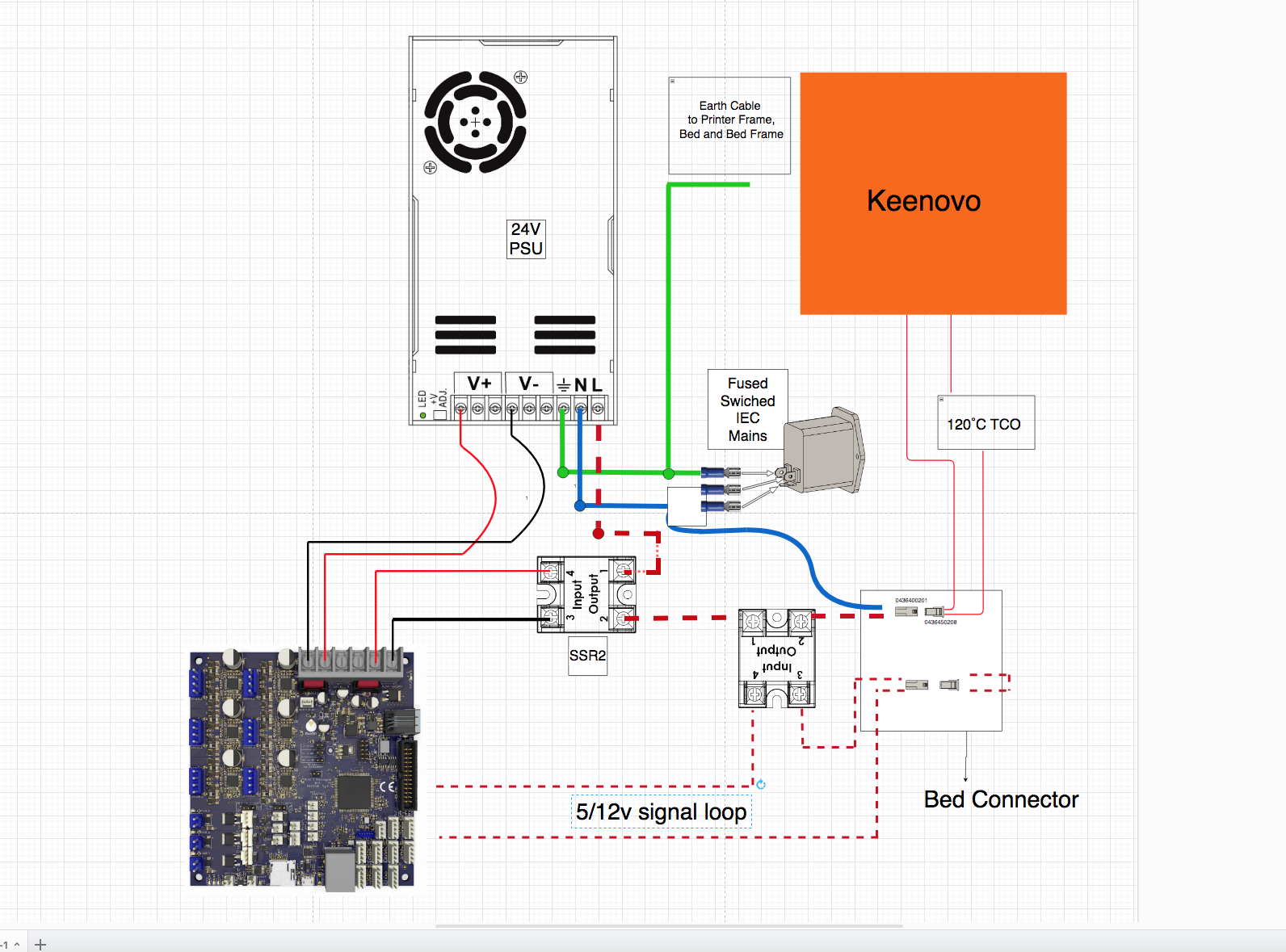

Going back to the toolplate bed, I'm going to use the following connector mounted to the bed frame. The idea being that I can disconnect the cables so I can remove the bed (the printer will be in a cupboard, tight on space, so less weight with moving the frame in and out).

Being that this is now a Mains 240Vac bed heater, and I have spare pins on the connector, I'm thinking on the grounds of safety and running some kind of signal loop (5/12v on a relay), so when the connector is disconnected, the break in the (5/12v) signal loop will disconnect the mains with the relay (if I've not already done so), so there is no loose Live Mains cable floating around.

At the moment I have a1 SSR controlling the 240Vac mains bed switched directly by the 24v O/P from the Duet 6HC.

So I'm looking for ideas.

Should I use a mechanical relay in series with the mains from the SSR, or is there a good chance this will weld closed?

Use another SSR, again in series with the switched mains;

Dizzwold. -

undefined Dizzwold referenced this topic

undefined Dizzwold referenced this topic