toolboard endstop problem

-

This post is deleted! -

@nick9one1 That is an old version of the firmware (3.5.0-rc.2) I'd make sure you have 3.5.2 on both boards and then test again.

-

thanks, looks like we're on the same page. I just updated.

No errors anymore, but the X endstop still isn't detected by the endstop monitor..

-

@gloomyandy You don't need the endstop plugin anymore. It is now built into DWC. I can't remember exactly what happens but the axis letters in the main display (that shows the position of the axis) "change" to indicate that the endstop is active. Try pressing an endstop that you know works and look at the DWC display I think it will be pretty obvious.

-

@gloomyandy If you are no longer getting an error then it may be there is a problem with the endstop switch or wiring?

-

-

testing the endstop with a multimeter shows its closed when not pressed and open when pressed.

I've temporarily disconnected it and bridged IO1.in and GND with a screwdriver - no change on the X endstop.

-

@nick9one1 What happens if you bridge io1.in to 3.3V do you see it change then?

-

@gloomyandy It does! But the hotend temp drops to -271 and the thermostatic fan comes on.

-

@nick9one1 That does not sound good. I suggest you post your full config.g. Are you sure you briged io1.in to 3.3V and not some other pin?

-

Yes definitely bridged to 3.3v (top two pins on the IO1 connector)

Here you go

; Configuration file for Duet WiFi (firmware version 3) ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.2.3 on Wed Jun 02 2021 18:38:31 GMT+0800 (中国标准时间) ; General preferences G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"BLV mgn Cube" ; set printer name M669 K1 ; select CoreXY mode ; Network M552 S1 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S0 ; disable FTP M586 P2 S0 ; disable Telnet G4 S1 ;wait for expansion boards to start ; Drives M569 P0.0 S0 D2 ; X motor runs forwards M569 P0.1 S1 D2 ; Y motor runs forwards M569 P0.2 S1 D2 ; physical drive 0.2 goes backwards M569 P0.3 S1 D2 ; physical drive 0.2 goes backwards M569 P0.4 S1 D2 ; physical drive 0.2 goes backwards M569 P121.0 S1 D2 ; physical drive 121.0 goes backwards M584 X0.0 Y0.1 Z0.2:0.3:0.4 E121.0 ; set drive mapping M350 X16 Y16 Z16 E16 I1 ; configure microstepping with interpolation M92 X200.00 Y200.00 Z3200.00 E700 ; set steps per mm M671 X0:290:290 Y155:62:255 S3 ; leadscrews at rear left, front middle and rear right M566 X600.00 Y600.00 Z150.00 E3000.00 ; set maximum instantaneous speed changes (mm/min) - increased Z and E M203 X20000.00 Y20000.00 Z2000.00 E6000.00 ; set maximum speeds (mm/min) - increased E M201 X3000.00 Y3000.00 Z200.00 E5000.00 ; set accelerations (mm/s^2) M906 X1600 Y1600 Z1000 E800 I30 ; set motor currents (mA) and motor idle factor in per cent M84 S30 ; Set idle timeout ; Axis Limits M208 X-3:305 Y-50:305 Z-1.0:500.0 ; Endstops M574 X1 S1 P"121.io1.in" ; configure active-high endstop for low end on X via pin io1.in M574 Y2 S1 P"io6.in" ; configure active-high endstop for HIGH end on Y via pin io6.in M564 H1 ; allow jog without homing ; Z-Probe M950 S0 C"^121.io0.out" ; create servo pin 0 for BLTouch M558 P9 C"^121.io0.in" H3 F120 T10000 ; set Z probe type to bltouch and the dive height + speeds G31 P500 X0 Y66 Z2.55 ; set Z probe trigger value, offset and trigger height. + brings noxzzle closer to bed M557 X5:305 Y20:290 P8 ; define mesh grid ; Heaters M308 S0 P"temp0" Y"thermistor" T100000 B3950 ; configure sensor 0 as thermistor on pin temp0 M950 H0 C"out0" T0 ; create bed heater output on out0 and map it to sensor 0 M307 H0 R0.291 C1127.4 D26.90 S1.00 ; Set PID for bed values M140 H0 ; map heated bed to heater 0 M143 H0 S100 ; set temperature limit for heater 0 to 100C M308 S1 P"121.temp0" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin 121.temp0 //0 to 1 M950 H1 C"121.out0" T1 ; create nozzle heater output on 121.out0 and map it to sensor 1 M307 H1 B0 R3.089 C258.2:154.4 D5.95 S1.00 V23.7 ; Set PID for hotend values M143 H1 S280 ; set temperature limit for heater 1 to 280C ; Fans M950 F0 C"121.out2" Q80 ; create hotend fan 0 on pin toolboard out1 and set its frequency M106 P0 S0 H1 T45 C"Hotend Fan" ; set fan 0 value. Thermostatic control is turned on M950 F1 C"121.out1" Q250 ; create cooling fan 1 on pin toolboard out1 and set its frequency M106 P1 S0 H-1 B1 C"Part Cooling Fan" ; set fan 1 value. Thermostatic control is turned off ; Tools M563 P0 D0 H1 F1 ; define tool 0 G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C ; ;M563 P1 D0 H1 F1 ; define tool 1 ;G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets ;G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C ; Custom settings M564 H0 ; Let the Jog buttons work blv: added to allow jog buttons M575 P1 B57600 S1 ; Connection to PanelDue ;955 P121.0 I10 ; Accelerometer ; Pressure advance ;M572 D0 S0.04 ; Miscellaneous M911 S21 R22 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; set voltage thresholds and actions to run on power loss -

@nick9one1 I'd be checking the board and the connector in that area very closely to see if there is any sort of solder bridge or stray wire etc. bridging io1.in to gnd.

Other then that I'm out of ideas, maybe one of the duet folks has some suggestions?

-

thanks for you r help with this. I removed the 1LC, reflowed the connectors with plenty of flux and cleaned with IPA - now working.

-

@nick9one1 That's great news! Probably worth pinging @droftarts on this as I know the Duet folks like to keep track of hardware problems!

-

Well I thought it was working, but I think there is still a slight issue with the duet config or slicer.

The hotend fan turns on correctly at 45C

But the part cooling fan doesn't start automatically. If I use the fan slider once the print has started it does work.

The slicer is set to enable it at layer two. -

@nick9one1 change

; Fans M950 F0 C"121.out2" Q80 ; create hotend fan 0 on pin toolboard out1 and set its frequency M106 P0 S0 H1 T45 C"Hotend Fan" ; set fan 0 value. Thermostatic control is turned on M950 F1 C"121.out1" Q250 ; create cooling fan 1 on pin toolboard out1 and set its frequency M106 P1 S0 H-1 B1 C"Part Cooling Fan" ; set fan 1 value. Thermostatic control is turned off ; Tools M563 P0 D0 H1 F1 ; define tool 0to

; Fans M950 F1 C"121.out2" Q80 ; create hotend fan 0 on pin toolboard out1 and set its frequency M106 P1 S0 H1 T45 C"Hotend Fan" ; set fan 0 value. Thermostatic control is turned on M950 F0 C"121.out1" Q250 ; create cooling fan 1 on pin toolboard out1 and set its frequency M106 P0 S0 H-1 B1 C"Part Cooling Fan" ; set fan 1 value. Thermostatic control is turned off ; Tools M563 P0 D0 H1 F0 ; define tool 0Slicers expect the part cooling fan as fan 0

-

deleted.

Thought it wasn't working but it is -

@nick9one1 sounds like something going on in your gcode. could you upload an example file?

-

you were too fast and replied before I removed my post!

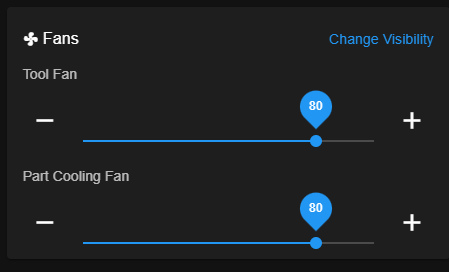

I assumed the 'tool fan' was the hotend fan, but it isn't. If I take both of these down to 0, only the part cooling fan stops.

Although I'm not sure why there are two fans showing in the UI

-

@nick9one1 the tool fan is the part cooling fan of a currently active tool. good for multi tool setups, redundant for single hotend systems (you can hide it)