Sovol SV08 Multiple Motion System Upgrade.

-

Just ordered two more 1LC tool boards and another mini5+ board.

That combination should allow for 6+7+5=18 axis drivers - z8, x4, y4 = 16 so should be enough for now - with the option to go up to 20 with another mini5 expansion.

Bad news is that my current mini5+ board is v1.02 - not sure what version E3D will send me for the 2nd board - their listing says 1.01 - so looks like some desoldering of terminator resistors on one of the boards is going to be required.

-

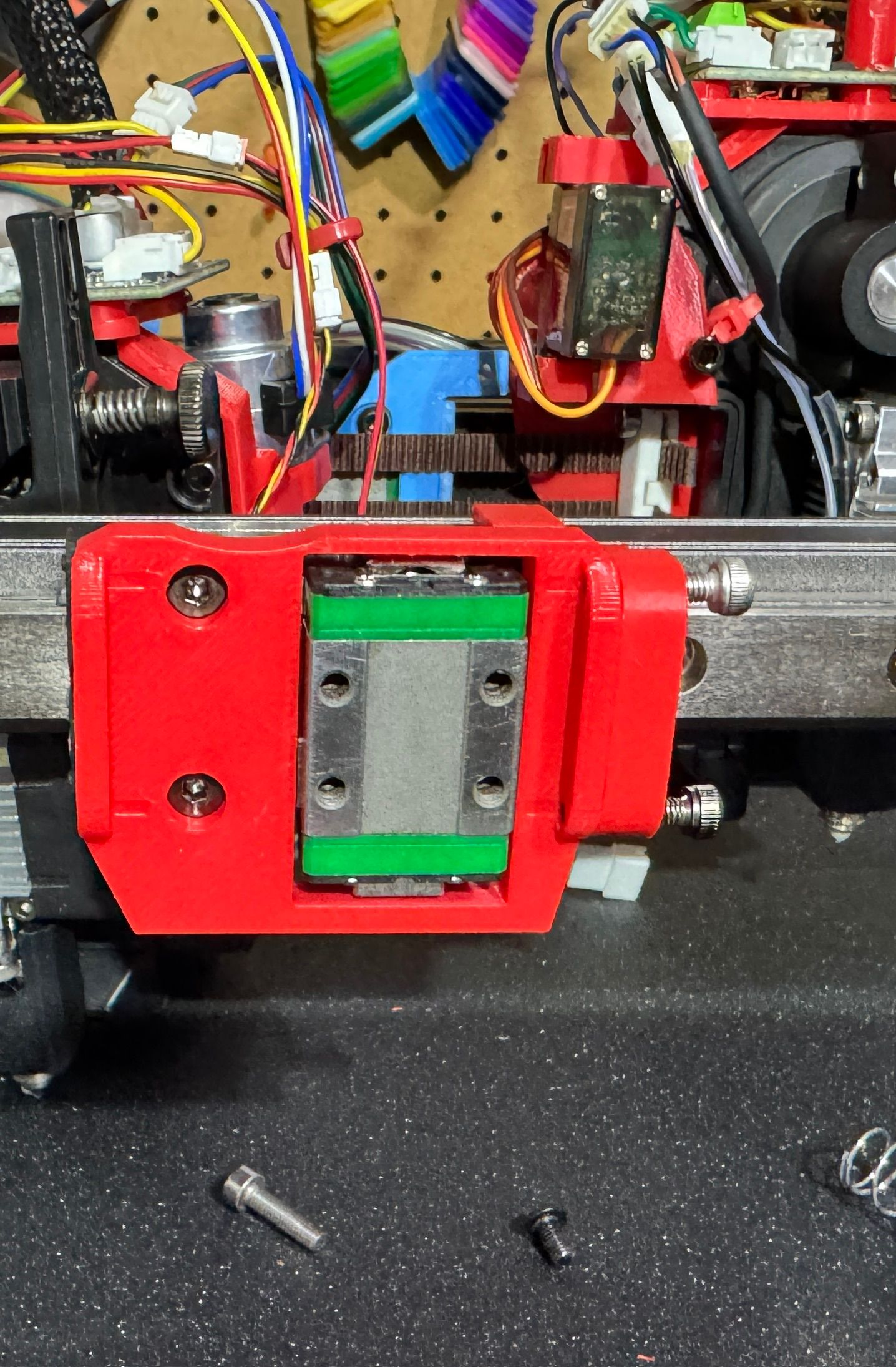

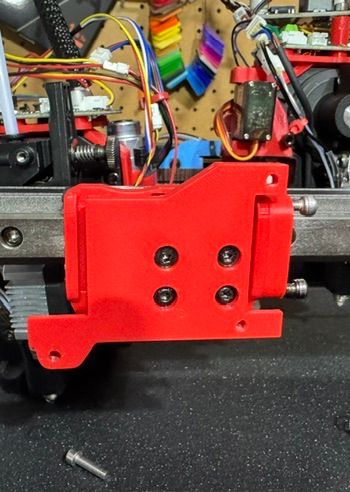

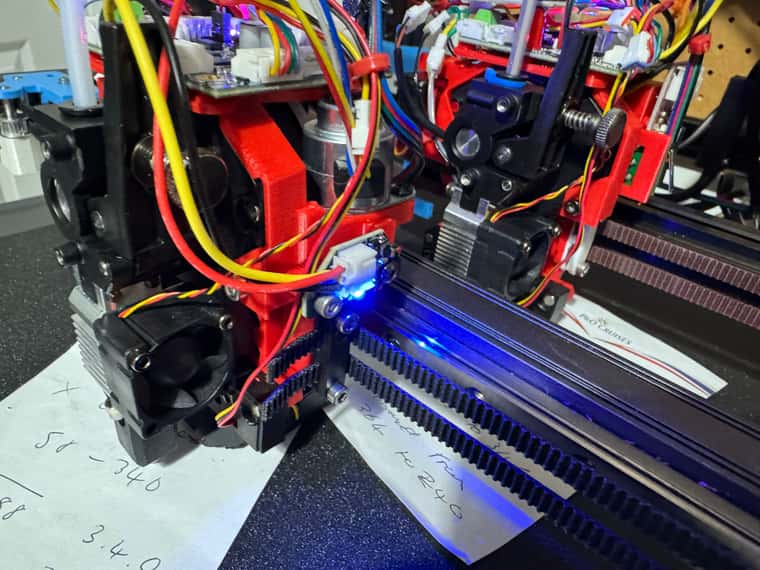

Added MGN9C carriage and Z lifter works quite well now.

See -

https://youtube.com/shorts/JexMhHyFkvI?si=BZMB12EFMrDNep2B

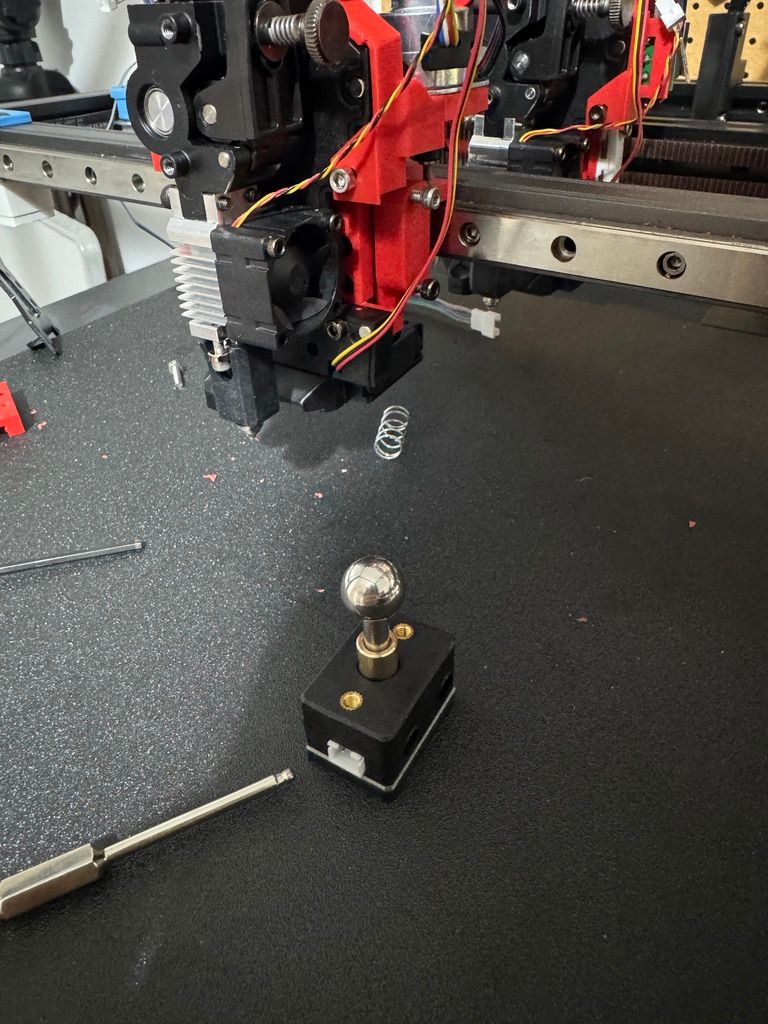

Next challenge after this is how to get a ball probe working with RepRap firmware to align the two heads - as per this Klipper add-on.

https://github.com/viesturz/NozzleAlign

I may have to do some maths in a macro to get this to work.

Am going to try one of the Ember Prototypes Camera based aligners too.

-

@dwuk i beleive @Sindarius has this concept working, hopefully he will be able to chime in.

-

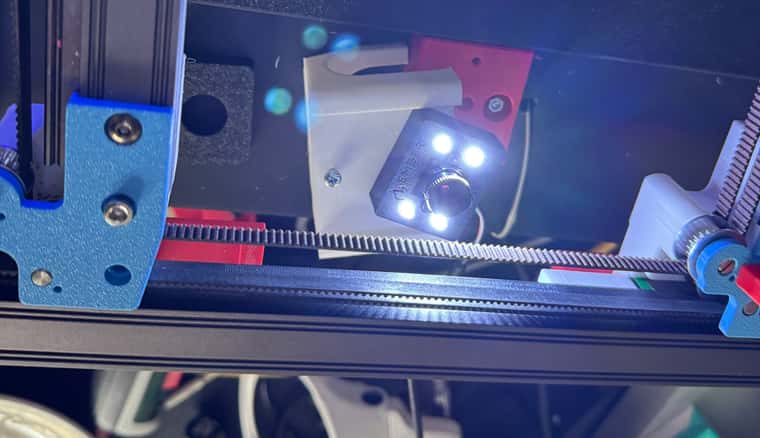

Added optical limit switch to front gantry linear Z hopper - and it is working pretty well.

The limit switch triggers at about -1.6 below the Z height of the other gantry, and the Z hopper can drop down by a further around 0.5mm.

So the 2.1mm difference also allows 'Voron Tap' type Z height detection to also work if the extruder is lowered down - although haven't yet implemented this in homeX.

I changed the M569 definition of the stepper from D2 to D3 and I think that has made it quieter - but it is staying a little hot on idle - so I need to add some switching off of IDLE's somewhere into the macros (M84 B) - however this does mean it loses it homing status. Maybe lowering the current percentage might work instead.

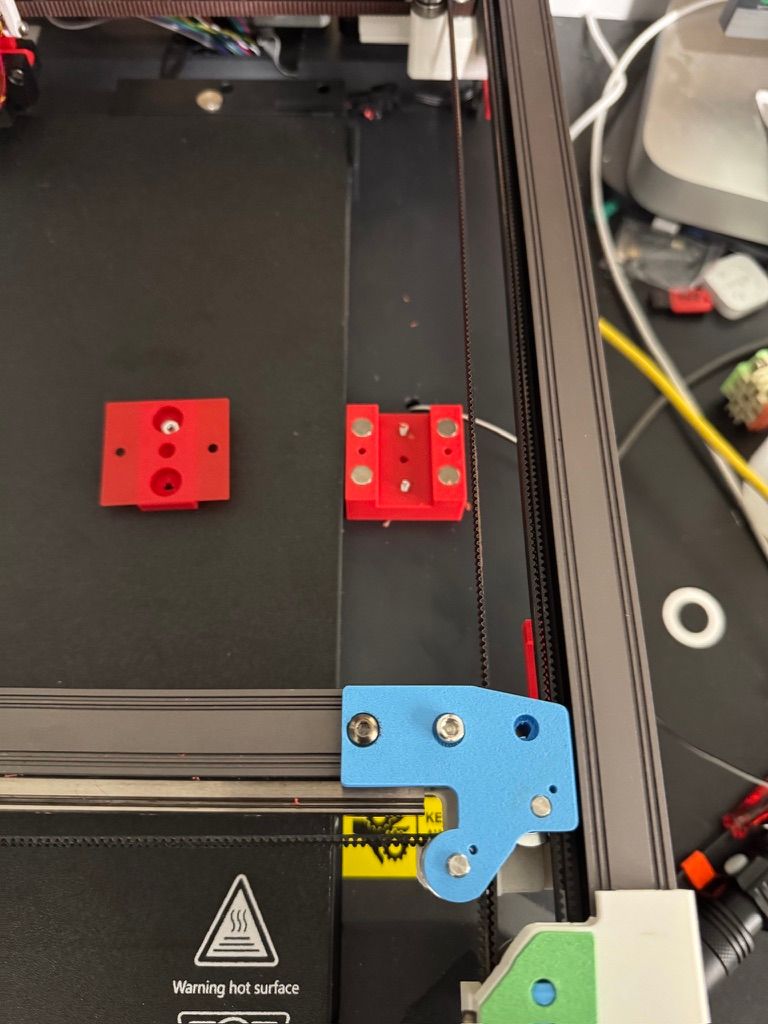

Next step tomorrow is to try some tests with the ball probe - I think I will just print something that I can place 4 magnets around it to hold it in a fixed place on the build plate for stability - and see what I can create in terms of macro code to accurately locate it on one gantry, then get the other gantry to do the same probing to get the two aligned.

Would be interesting to see what @Sindarius has developed for this too.

In terms of where the place the probe on the build plate.

It the short term I think I will just manually place it somewhere - bet ideally I would like to make the alignment fully automated. Am wondering whether it might be feasible to cut a small hole in the build plate and create a mechanism to lift the probe up from below when required.

Any prints over this area could potentially just bridge over the hole.

Haven't yet added any magnets to hold the front gantry extruder down - but I think something at 45 degrees like the voron tap can be added later once I get to some high speed printing tests.

-

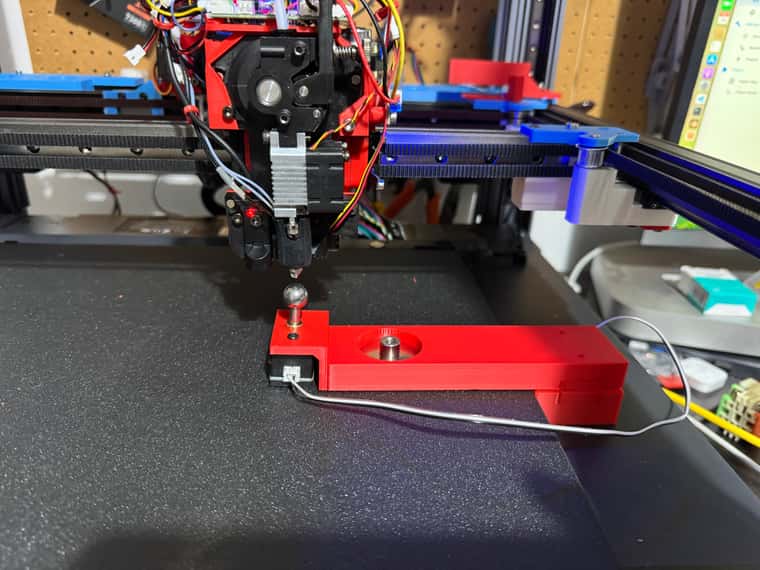

Good progress made on Ball Probe

Demo of first attempt at Macro here - which I have initially done on the front Gantry

Video show G32 first, followed by Ball Probe alignment Macro

https://youtube.com/shorts/uPcV3BAuwyc?si=bT-t0YxPR4qDQWoo

Held in place for now by Magnets - but I would like to automate the deployment and stowing of the Probe.

The 4 magnets at the edge are for basic positioning, with the larger one near the probe to hold it in place.

probe.g Macro - Currently just front Gantry

G90 G1 U150 V290 F20000 G1 Z50 F5000 G1 X235 Y179 F10000 M574 Z1 S2 K3; Set Z to Ball Probe ; Find basic Z position G1 H4 Z-10 F300 echo "Z", {move.axes[2].userPosition} G1 Z50 F300 G1 H4 Z-10 F300 echo "Z", {move.axes[2].userPosition} G1 Z48 F300 G1 H4 Z-10 F100 echo "Z", {move.axes[2].userPosition} var ZP = move.axes[2].userPosition G1 Z50 F5000 M574 Z1 S2 K0; configure Z axis endstop ; Now find X middle G91 G1 X-10 F5000 G90 G1 Z{var.ZP-0.2} F300 G91 M574 X1 S2 K3 G1 H4 X+10 F300 echo "X1", {move.axes[0].userPosition} G1 X-5 G1 H4 X+10 F300 echo "X1", {move.axes[0].userPosition} G1 X-5 G1 H4 X+10 F300 echo "X1", {move.axes[0].userPosition} var X1 = move.axes[0].userPosition G1 Z5 F300 G1 X10 F5000 G1 Z-5 F300 G1 H4 X-10 F300 echo "X2", {move.axes[0].userPosition} G1 X5 G1 H4 X-10 F300 echo "X2", {move.axes[0].userPosition} G1 X5 G1 H4 X-10 F300 echo "X2", {move.axes[0].userPosition} var X2 = move.axes[0].userPosition G1 Z5 G90 var XM = (var.X1+var.X2)/2 G1 X{var.XM} M574 X1 S3 ; configure X axis endstop ; Now Y G91 G1 Y-10 F5000 G1 Z-5 F300 M574 Y1 S2 K3 G1 H4 Y+10 F300 echo "Y1", {move.axes[1].userPosition} G1 Y-5 F5000 G1 H4 Y+10 F300 echo "Y1", {move.axes[1].userPosition} G1 Y-3 F5000 G1 H4 Y+10 F100 echo "Y1", {move.axes[1].userPosition} var Y1 = move.axes[1].userPosition G1 Z5 F300 G1 Y10 F5000 G1 Z-5 F300 G1 H4 Y-10 F300 echo "Y2", {move.axes[1].userPosition} G1 Y5 F5000 G1 H4 Y-10 F300 echo "Y2", {move.axes[1].userPosition} G1 Y2 F1000 G1 H4 Y-10 F100 echo "Y2", {move.axes[1].userPosition} var Y2 = move.axes[1].userPosition var YM = (var.Y1 + var.Y2) / 2 G1 Z5 F300 G90 G1 X{var.XM} Y{var.YM} F2000 G90 M574 Y1 S3 ; configure Y axis endstopResults from test - to show level of consistency

19/02/2025, 22:32:59 Y2 182.625

19/02/2025, 22:32:57 Y2 182.625

19/02/2025, 22:32:56 Y2 182.625

19/02/2025, 22:32:53 Y1 174.275

19/02/2025, 22:32:51 Y1 174.300

19/02/2025, 22:32:49 Y1 174.288

19/02/2025, 22:32:44 X2 243.038

19/02/2025, 22:32:42 X2 243.038

19/02/2025, 22:32:40 X2 243.038

19/02/2025, 22:32:37 X1 234.812

19/02/2025, 22:32:35 X1 234.812

19/02/2025, 22:32:32 X1 234.812

19/02/2025, 22:32:28 Z 45.645

19/02/2025, 22:32:26 Z 45.647

19/02/2025, 22:32:23 M98 P"0:/macros/Probe.g"

Z 45.647 -

Impressive demo of SV08 toolchanger (phase 3 for me) here.

https://youtu.be/tg2vRfqMXYU?si=3NB5lVxPEerKP82u

One thought that that did occur is that it would work a lot faster if the tool rack had its own independent Z axis - so that the tools could be brought down much closer to the current build height, and then moved up as the print grows.

So yet another axis to add to my design - will probably do it with dual lead screws - as it doesn't need to be quick.

-

Got ball probes alignment macros (with loops and variables) working on the UV axis as well as the XY axis - both with the ball probe, plus also with an Ember Prototypes CXC - which is a camera pointing up at the nozzle.

Also created macros to search for the ball probe when it isn't quite where it is expected to be.

Alignment though is not that accurate yet.

The first problem that the camera has identified is backlash - which I am mainly getting on the UV axis, and more noticeably in the V direction. - its only about 0.1mm - but it does mean that if for example you move 10mm in the V direction and back you don't end up in the same spot. But if you move back another 10mm and then forward you get back pretty close to where you started.

Have tried removing the Phase2 IDEX carriage as I thought that might be impacting the movement - but that hasn't helped, plus have also tightened up the belts a fair bit - but am still getting the issue.

I guess it might be that my print head is not rigid enough - or it might be the motors.

Will try training the camera on other parts of the mechanism next to see if I can see where the backlash is coming from.

-

@dwuk Demo of backlash problem - comparison of the V vs Y belts.

-

@dwuk obviously removing the backlash is the best solution. however there is backlash compensation in the firmware:

https://docs.duet3d.com/en/User_manual/Reference/Gcodes#m425-configure-backlash-compensation -

@T3P3Tony Thanks -

By changing the Motor Pulleys - from 16 teeth to 20 teeth (as per Voron 2.4) and tightening up the belts on front idler mounts I have got the backlash down to between 0.05 to 0.1 - but it is still worse on the V motor the all of the others.

will try backlash compensation too - but after I have got it as small as possible by strengthening up a few of the parts and doing a bit of lubrication.

Plus also I am currently using quite a lot of bolts directly in to 3d prints (using the recent @ThomasSanladerer method) - so will have to add a few more nuts or threaded inserts to tension things up a bit more.

Have also got the @Vector3d Calibration Lantern - as I think I am going to have to get the XY & Z pretty accurate for the two heads to work reliably on the same print.

-

@dwuk Backlash won't be your primary problem when you use the "outer perimeter in one go" version of your gcode postprocessor.

I wouldn't spend too much time on it now and try to make a working proof of concept first.

You might have to redesign alot anyway, just put it on your ToDo list. -

@o_lampe good point.

I have got the backlash down to <0.1mm and it seems to be related somehow to the movement of the V axis.

Setting backlash compensation to 0.1mm on U and V with an S value of 1 seems to more or less mitigate it.

Also if it is related to the V axis then the move to dual Y + dual V would greatly simplify the belt structure for those Axis - so I moved last night back to looking at auto alignment with the ball probe, and will today start doing some printing of the Vector3d alignment lantern on both gantries (using duplicate mode).

Will also start moving the 3d printed parts away from mostly bolts into shaped plastic holes into threaded inserts (which I have always avoided in the past).

Built a Vector3d VLP2 over the last couple of days which was a fun project.

-

Got some good advice from 'Ken' on the Vector3d discord - so I think my immediate priorities now are:

- Consistent auto XYZ alignment using a ball probe - with XY checked using CXC.

- Keeping X&Y alignment across a large area of the build surface. - maybe I will just print a simple large squares for this and adjust steps/mm if necessary - and leave the Lantern until later as you suggest.

- Bed level Mesh adjustment - if necessary - (not sure how flat my bed is yet).

- 2 Colour IDEX testing

- Parallel printing of separate Models

- Parallel printing on a single model.

In terms of other steps already completed:

- PID tuning done for the print heads - but I did get a warning message on the heat bed some will have to sort that out at some point.

- E Steps done

- Z Offset done - although quite a lot more gcode post processing work needed on this - as my print head have independent extra Z axis adjustment capabilities for independent Z hopping and mesh adjustment.

Will then I think do:

7) Speed and acceleration tuning

8 ) Adding print heads 3 & 4 - and repeating most of the above. - my 2nd Mini5+ board ended up being V1.3 luckily - so no desoldering needed:)

9) Fan cooling - I had to take off one of the cooling fans from each head due to Duet tool board connection issues (plus print head size) - think I will try running extra cables for the 2nd cooling fans direct from the main boards.- Retraction

- Input shaping

- Pressure advance

- Advanced calibration using Vector3d Lantern.

- Z hopping and multi head mesh adjustment

- Tool changer - probably just two extra tools initially on the front gantry

- Filament management - which will probably need some sort of custom AMS/MMU to be developed - that can handle splitting spools into up to 4 separate strands for the 4 print head parallel prints and occasional colour swaps that can't be accommodated by the tool changer part of the printer.

-

Having a few problems with Multiple motion system - I think I am going to need some @dc42 help.

On 3.5.4 - It works ok with some basic commands as below:

With both gantries moving in parallel in different directions ok.M595 Q1 P5 M595 Q0 P5 M596 P1 G90 G1 U100 F500 G1 U200 F500 G1 V300 F500 G1 V250 F500 M596 P0 G1 X200 F2000 G1 X100 F2000 M598 G1 Y20 F1000 G1 Y50 F1000 G1 X200 F2000 G1 X100 F2000However Problems are:

- M598 does not seem to work - as the G1 Y20 F1000 just carries on - even though the U axis moves haven't completed.

- If I set the Queue size above 5 the motion in Queue 1 (M596 P1) - G1 moves goes haywire - just doing a G1 U1 for example moves the gantry to the back and beyond with a grating sound.

I noted that on the 3.6.0 beta4 notes that there is mention of some sort of M598 fix - so tried a firmware upgrade to that version.

Firstly this resulted in me somehow tanking my 6HC firmware completely so I had to erase and reset it back to 3.5.4, then I also messed up the Mini5+ firmware too somehow - so again had to erase and reset it.

Eventually got it working again, and managed to do the 3.6.0 Beta Change on all boards.

Problem then with 3.6.0 beta 4 - was:

-

My homeall.g sequence no longer worked - it seemed to just to X and Y then stop - so I had to individually home each axis.

Also The U & V axis homing didn't seem to move the same - I am using switches - but I wonder if there is some sort of hangover from when I tried to get it to work on sensorless (which I would still quite like to do) - as the ball probe alignment would probably now be good enough. -

I then kept getting messages about the U axis already being in use when I ran the test script that worked ok on 3.5.4 (apart from M598 and M595 issues).

So decided to revert back to 3.5.4 and ask for help.

Config.g

; Configuration file for RepRapFirmware on Duet 3 Main Board 6HC ; executed by the firmware on start-up ; ; generated by RepRapFirmware Configuration Tool v3.5.10 on Wed Jan 29 2025 10:20:21 GMT+0000 (Greenwich Mean Time) ; General G90 ; absolute coordinates M83 ; relative extruder moves M550 P"Duet 3" ; set hostname ; Network M552 P0.0.0.0 S1 ; configure Ethernet adapter M586 P0 S1 ; configure HTTP M586 P1 S1 ; configure FTP ; Wait a moment for the CAN expansion boards to become available G4 S2 ; Smart Drivers M569 P0.0 S1 D2 ; driver 0.0 goes forwards (Z axis) M569 P0.1 S1 D2 ; driver 0.1 goes forwards (Z axis) M569 P0.2 S0 D2 ; driver 0.2 goes backwards (Z axis) M569 P0.3 S1 D2 ; driver 0.3 goes forwards (X axis) M569 P0.4 S0 D2 ; driver 0.4 goes backwards (Y axis) M569 P0.5 S0 D2 ; driver 0.5 goes backwards (Z axis) M569 P1.0 S0 D3 V2000 ; driver 1.0 goes backwards (U axis) M569 P1.1 S0 D3 V2000 ; driver 1.1 goes backwards (V axis) M569 P1.2 S1 D2 ; driver 1.2 goes forwards (A axis) M569 P1.3 S1 D3 ; Z-hopper 1 M569 P1.4 S1 D3 ; Z-hopper 2 M569 P121.0 S0 D2 ; driver 121.0 goes backwards (extruder 0) M569 P122.0 S0 D2 ; driver 122.0 goes backwards (extruder 1) ; Motor Idle Current Reduction M906 I30 ; set motor current idle factor M84 S30 ; set motor current idle timeout ; Axes M584 X0.3 Y0.4 Z0.1:0.2:0.0:0.5 U1.0 V1.1 A1.2 B1.3 C1.4; set axis mapping M350 X16 Y16 Z16 U16 V16 A16 B16 C16 I1 ; configure microstepping with interpolation M906 X800 Y800 Z800 U800 V800 A800 B150 C50 ; set axis driver currents M92 X80 Y80 Z533.33 U80 V80 A533 B629 C629 ; configure steps per mm if exists(global.vMin) == false global vMin = 120 global vMax = 330 global yMin = -5 global yMax = 210 M208 X0:315 Y-5:210 Z0:300 U35:350 V120:330 A0:300 B0:3 C0:3 ; set minimum and maximum axis limits M566 X12000 Y12000 Z3000 U6000 V6000 A3000 B1000 C1000 ; set maximum instantaneous speed changes (mm/min) M203 X42000 Y42000 Z3000 U21000 V21000 A3000 B1000 C1000 ; set maximum speeds (mm/min) M201 X500 Y500 Z20 U250 V250 A20 B20 C20 ; set accelerations (mm/s^2) ; Extruders M584 E121.0:122.0 ; set extruder mapping M350 E16:16 I1 ; configure microstepping with interpolation M906 E800:800 ; set extruder driver currents M92 E492:492 ; configure steps per mm M566 E120:120 ; set maximum instantaneous speed changes (mm/min) M203 E3600:3600 ; set maximum speeds (mm/min) M201 E250:250 ; set accelerations (mm/s^2) ; Kinematics M669 K8 ; configure CoreXYUV kinematics ; Probes M558 K0 P8 C"121.io1.in" H5 F1200 T18000 ; configure unfiltered digital probe via slot #0 G31 P500 X-17 Y10 Z2.55 ; set Z probe trigger value, offset and trigger height M558 K1 P8 C"122.io1.in" H5 F1200 T18000 ; configure unfiltered digital probe via slot #1 G31 P500 X-17 Y10 Z2.55 ; set Z probe trigger value, offset and trigger height M558 K2 P8 C"!121.io2.in" H1 F300 T300 ; configure unfiltered digital probe via slot #2 M558 K3 P8 C"io3.in" H1 F300 F300; Ball Probe ; Endstops M574 X1 S3 ; configure X axis endstop M574 Y1 S3 ; configure Y axis endstop M574 Z1 S2 K0; configure Z axis endstop M574 U2 P"!122.io0.in" S1 ; configure U axis endstop M574 V2 P"!122.io2.in" S1 ; configure V axis endstop M574 A1 P"1.io0.in" S1 ; configure A axis endstop M574 B1 S2 K2 ; Sensors M308 S0 P"temp0" Y"thermistor" A"Heated Bed" T100000 B4725 C7.06e-8 ; configure sensor #0 M308 S1 P"121.temp0" Y"thermistor" A"Nozzle" T110000 B4487 C6.95777e-8 ; configure sensor #1 M308 S2 P"122.temp0" Y"thermistor" A"Nozzle2" T110000 B4487 C6.95777e-8 ; configure sensor #2 ; Heaters M950 H0 C"out0" T0 ; create heater #0 M143 H0 P0 T0 C0 S105 A0 ; configure heater monitor #0 for heater #0 M307 H0 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #0 M950 H1 C"121.out0" T1 ; create heater #1 M143 H1 P0 T1 C0 S305 A0 ; configure heater monitor #0 for heater #1 M307 H1 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #1 M950 H2 C"122.out0" T2 ; create heater #2 M143 H2 P0 T1 C0 S305 A0 ; configure heater monitor #0 for heater #2 M307 H2 R2.43 D5.5 E1.35 K0.56 B0 ; configure model of heater #2 ; Heated beds M140 P0 H0 ; configure heated bed #0 ; Fans M950 F0 C"121.out2+out2.tach" ; create fan #0 M106 P0 S0 L0 X1 B0.1 ; configure fan #0 M950 F1 C"121.out1+out1.tach" ; create fan #1 M106 P1 C"Hotend" S0 B0.1 H1 T45 ; configure fan #1 M950 F2 C"122.out2+out2.tach" ; create fan #2 M106 P2 C"E2Cool" S0 L0 X1 B0.1 ; configure fan #2 M950 F3 C"122.out1+out1.tach" ; create fan #3 M106 P3 C"Hotend2" S0 B0.1 H2 T45 ; configure fan #3 ; Tools M563 P0 D0 H1 F0 ; create tool #0 M568 P0 R0 S0 ; set initial tool #0 active and standby temperatures to 0C M563 P1 D1 H2 F2 ; create tool #1 M568 P1 R0 S0 ; set initial tool #1 active and standby temperatures to 0C ; Miscellaneous ; Custom settings M915 X Y U V R0 F0 M671 X410:-60:-60:410 Y420:-10:420:-10 S7 M307 H1 R7.427 K0.701:0.030 D1.50 E1.35 S1.00 B0 V24.5 M307 H2 R7.020 K0.857:0.148 D1.65 E1.35 S1.00 B0 V24.0 M307 H0 R0.527 K0.163:0.000 D5.70 E1.35 S1.00 B0 M557 X0:200 Y0:220 S20 M950 S1 C"122.io0.out" M280 P1 S60 ;M42 P1 S0 ; Allow movement without homing ;M564 S0 H0 ; Tools ;Tool T1 - 2nd Gantry as X and Y M563 P1 D1 H2 X3 Y4 F1 G10 P1 X0 Y0 U0 V0 S0 R0 ; T2 - duplicate mode M563 P2 D0:1 H1:2 X0:3 Y1:4 F0:1 G10 P2 X0 Y0 U0 V-150 S0 R0 M567 P2 E1:1 M568 P2 S1 ; Backlash compensation M425 U0.1 V0.1 S1 -

@dwuk It would be good to work out why homing was not working as expected in 3.6beta4. Where have been a lot of changes between 3.5.4 and 3.6 so the release notes may explain why. If not then please share your U and V homing files so we can have a look at those.

-

-

@dwuk

Your homeu for reference (please use code blocks for these file, it makes it easier for people, especially on phones):

;echo "homeU disabled" ;M99 ; homeu.g ; called to home the U axis M569 P1.0 S0 D3 V500 ; driver 1.0 goes backwards (U axis) M569 P1.1 S0 D3 V500 ; driver 1.1 goes backwards (V axis) ; ; generated by RepRapFirmware Configuration Tool v3.5.10 on Thu Jan 23 2025 15:02:10 GMT+0000 (Greenwich Mean Time) ;M913 U40 V40 ;M400 ; increase Z G91 ; relative positioning if exists(param.Z) ;G1 H2 Z{param.Z} F6000 else G1 H2 Z5 F6000; move Z relative to current position to avoid dragging nozzle over the bed G1 H2 V10 U-10 M400 G90 ; absolute positioning ; home U G91 ; relative positioning var maxTravel = move.axes[0].max - move.axes[0].min + 5 ; calculate how far X can travel plus 5mm G1 H1 U{var.maxTravel} F8000 ; coarse home in the +U direction G1 U-5 F6000 ; move back 5mm G1 H1 U{var.maxTravel} F3000 ; fine home in the +U direction G90 ; absolute positioning ; decrease Z again G91 ; relative positioning ;G1 H2 Z-5 F6000 ; move Z relative to current position G90 ; absolute positioning ;M400 ;M913 U100 V100 ;M400 M569 P1.0 S0 D3 V2000 ; driver 1.0 goes backwards (U axis) M569 P1.1 S0 D3 V2000 ; driver 1.1 goes backwards (V axis)you are setting U and V configurations in home U. I would remove the references to V in home U.

This is an issue:

var maxTravel = move.axes[0].max - move.axes[0].min + 5 ; calculate how far X can travel plus 5mm

given U is not axis 0. It probably working if U and X are the same length though.Also you are lifting Z but not returning it (that may not be an issue)

I see you are switching the speed of switch from stealthChop to to spreadCycle mode during homing. and the U and V are in stealthchop while the other axes are in spreadCycle so i expect thats the route of the issue/different behaviour.

Try getting everything working in spreadCycle and then explore sensor less homing

-

@T3P3Tony Thanks for the comments.

Had another go on 3.6.0.beta4

With the following motor settings:

;M569 P1.0 S0 D3 V2000 ; driver 1.0 goes backwards (U axis) ;M569 P1.1 S0 D3 V2000 ; driver 1.1 goes backwards (V axis) M569 P1.0 S0 D2; driver 1.0 goes backwards (U axis) M569 P1.1 S0 D2 ; driver 1.1 goes backwards (V axis)And the following homeU

G91 ; relative positioning if exists(param.Z) ;G1 H2 Z{param.Z} F6000 else G1 H2 Z5 F6000; move Z relative to current position to avoid dragging nozzle over the bed ; G1 H2 V10 U-10 F6000 M400 ; var maxTravel = move.axes[0].max - move.axes[0].min + 5 ; calculate how far X can travel plus 5mm G1 H1 U{var.maxTravel} F8000 ; coarse home in the +U direction M400 G1 U-5 F6000 ; move back 5mm M400 G1 H1 U{var.maxTravel} F3000 ; fine home in the +U direction G90 ; absolute positioningAnd homeV

G91 ; relative positioning if exists(param.Z) ;G1 H2 Z{param.Z} F6000 else G1 H2 Z5 F6000; move Z relative to current position to avoid dragging nozzle over the bed var maxU = move.axes[4].max - 5 G90 ; absolute positioning G1 U345 ; home V G91 ; relative positioning var maxTravel = move.axes[0].max - move.axes[0].min + 5 ; calculate how far V can travel plus 5mm G1 H1 V{var.maxTravel} F6000 ; coarse home in the +V direction G1 V-5 F6000 ; move back 5mm G1 H1 V{var.maxTravel} F7000 ; fine home in the +V direction G90 ; absolute positioning ; decrease Z again G91 ; relative positioning ;G1 H2 Z-5 F6000 ; move Z relative to current position G1 V-10 U-10 G90 ; absolute positioningResults were:

On 3.6.0b4 the U and V axis (which are on the toolboard mode Mini5+) are moving - but are unresponsive - they don't move instantly like they do on 3.5.4 (went back and rechecked), and the two stage homing takes quite a while to get to the 2nd stage. (unlike 3.5.4 where it is instant).Also the V Axis homing sometimes misses the end stop (which is at the back right) - probably due to slow reaction too - when I use HomeAll.

Also when you just use the button's to move the U & V - they don't react instantly - so I am wondering where there is some sort of comms issue in 3.6.0b4 - as I don't notice this in 3.5.4

X&Y (which are directly connected to the 6HC) still seem ok on 3.6.0b4

Also I am still getting the issue with not being able to access the U axes within M596 P1 - which doesn't occur in 3.5.4

Tried doing the homing within M596 P1 for U&V. and M596 P0 for X&Y - and that failed because Z was then stuck in P1 - and couldn't be accessed in P0.

In response to your points:

"you are setting U and V configurations in home U. I would remove the references to V in home U."- Would be good if I could - the main reason it is there is that in my current microswitch based design the V axis switch gets knocked sideways if the U axis tries to home when V is too far to the back.

"This is an issue:

var maxTravel = move.axes[0].max - move.axes[0].min + 5 ; calculate how far X can travel plus 5mm

given U is not axis 0. It probably working if U and X are the same length though."- Agreed that is an issue which I will correct - however as I have set the minimum for U at 30 - then it is slightly shorter than X - so the end stop will still hit.

"Also you are lifting Z but not returning it (that may not be an issue)"

- Agreed need to tidy up Z lifting

"I see you are switching the speed of switch from stealthChop to to spreadCycle mode during homing. and the U and V are in stealthchop while the other axes are in spreadCycle so i expect thats the route of the issue/different behaviour."

- Removed the settings in config.g - tried both modes - but still got the slow reaction problem in 3.6.0b4 - and still works fine with the new settings in 3.5.4

"Try getting everything working in spreadCycle and then explore sensor less homing"

I've switched back to 3.5.4 again for now - as the slow response of U and V on 3.6.0b4 are I think too much of an issue. I could try a different version - to which beta version it starts to appear. -

@dwuk Further update; @T3P3Tony

Tried with 3.6.0b3 - same issue with slow response of U&V

Tried reverting just the Mini5+ to 3.5.3 - that seems to remove the issue.So for me both 3.6.0 beta versions are not working with a FD connected Mini5+

Also on 3.6.0b3 (with 3.5.3 Mini5+) I get the same issue with not being able to access the U axis within M596 P1. - where's with exactly the same macro's and homing sequences I can with 3.5.3

Will go back to 3.6.4b4 again (with both 3.5.3 on the Mini5+) to see if I can work out a sequence that allows me to access the U axis from the 2nd motion system.

-

@dwuk Further update - got access to the U axis in 3.6.0b4 by surrounding all accesses to it - including in the homing with M596 P1 before and M596 P0 after.

M598 still not working though, plus my Mini5+ is still on 3.5.4.