Calibration cube corners.

-

Can you take a photo from the side of the print? Still looks like a mechanical issue to me, but need to see more angles I think.

-

-

Side like looking at the perimeters, not top, thanks

-

I’m nearing my wit’s end (usually not a long journey), and would really appreciate some help. I print with a FlashForge Creator Pro, using a glass planers for a bed, and ABS juice for adhesion. I’ve been having problems with some prints. I’ve been through the print quality guides on duet3d but haven’t yet found the magic formula. I’m printing a simple 10X20X20mm cube that exhibits the issues I’m having. The .STL came with the printer. I print with Hatchbox filament.

-

-

-

@rcarlyle Sorry, fixed.

-

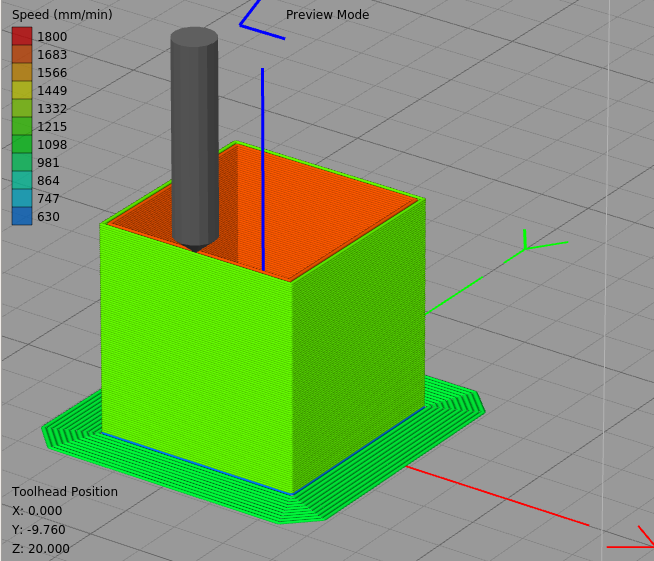

@johhnyalter, the cube printed 5C lower appears to me to have better corners. Can you confirm that? If so then it confirms my view that excessive speed and/or temperature is the problem. So I suggest you reduce temperature, or add a little fan cooling, or reduce XY acceleration and/or jerk.

-

The fact that the base starts at the correct shape and then it deforms increasing amounts near the heatbed, then gets a little better as it gets higher... that really suggests that it's an issue with the plastic not cooling fast enough. Proximity to the heatbed = more heat. Small print = not much time for heat to conduct away from the top layer. Corners = slower nozzle motion for more heat radiation into the print.

Do you have an insulated hot block?

Do you have ANY kind of airflow, even gentle airflow, in the printer? I find ABS quality benefits enormously from very gentle airflow.

What happens when you print something 4x bigger (ie more time for plastic to cool before the nozzle approaches again)? -

It IS kind of unusual geometry for a corner overheating/undercooling issue, though. Would really like to see video of the box printing.

-

ABS suffers from slow printing, too much heat is transferred and you end up sagging the layers under the layer you are printing, try bringing the speed up to 50mm/sec. A small amount of air flow will sharpen up the edges but will also make the part super brittle unless you can keep the air temp above 60*C.

You also are clearly over extruding which will be exacerbate the layer issues

-

Thanks for respond guys

-

First of all, many thanks for your help. Your tips helped me find more or less accurate settings.

But I think I found the "root" of my problem.

Just look at the result of alternate printing with exactly the same settings.

Do you think this is a problem with the heater?

Regards. -

So one corner is bad at all heights, the others are poor close to the bed but OK at greater heights. I don't know about the corner that is always poor, but I think the others are suffering from too much heat rising from the bed.

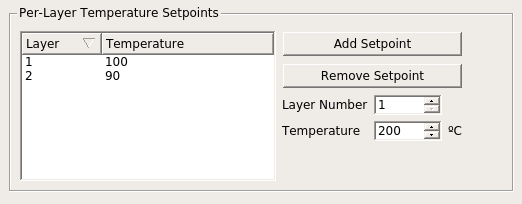

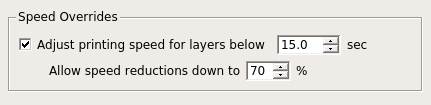

What bed temperature are you using? Do you have a minimum layer time configured in the slicer?

-

-

Allowing speed reductions down to 70% doesn't allow for much slowdown at all. I suggest 10% to 20%.

-

Also another thing to try is printing a significantly bigger cube.

The one corner that is always bad is probably where each layer starts and finishes so once the other corners are good you can work on tuning retract length, speed and possibly pressure advance to make that better.

you're going in the wrong direction! like this:

you're going in the wrong direction! like this: