Print problems and fixes

-

@wes-howe Using brand new PEI Sheet. Its clean.

Bed Temp has no effect. sticking fine to bed.My offset is showing...

M98 P"0:/macros/G30 S1"

Stopped at height 0.967 mmSo i have this in my config.g

G31 P25 X-20 Y-45 Z0.97 ; Set Z probe trigger value, offset and trigger heightFirst Layer Looks fine, its the subsequent layers that is out of whack.

-

@chriskimbr said in Print problems and fixes:

First Layer Looks fine, its the subsequent layers that is out of whack.

Have you checked that you have the correct Z steps/mm value, so that when you command the head 50mm up it really does move 50mm?

Also, what hot end thermistor does your printer use, and what M305 P1 settings do you have in config,g?

-

Is your thermistor configured correctly?

Have you done a PID tuning of the hotend?

Have you calibrated e steps per mm?

Is the cooling fan duct blowing onto the print or onto the hotend?

That's a very small object to print at 80mm/s base speed.

Maybe include you config.g? -

@dc42 Have you checked that you have the correct Z steps/mm value, so that when you command the head 50mm up it really does move 50mm?

How and where do I check the z steps value?

Also, what hot end thermistor does your printer use, and what M305 P1 settings do you have in config,g?

I got a thermistor from Local store, no paperwork, he said it was standard 100k thermistor.

Config.g

; Configuration file for Duet WiFi (firmware version 1.21)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2 on Sat Feb 09 2019 18:37:46 GMT+0000 (GMT); General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder movesM667 S1 ; Select CoreXY mode

; Network

M550 P"TronXY X5SA" ; Set machine name

M552 S1 ; Enable network

;*** Access point is configured manually via M587

M586 P0 S1 ; Enable/Disable HTTP S0=disable S1=enable

M586 P1 S1 ; Enable/Disable FTP

M586 P2 S1 ; Enable/Disable Telnet; Drives

M569 P0 S0 ; Drive 0 goes backwards

M569 P1 S0 ; Drive 1 goes backwards

M569 P2 S0 ; Drive 2 goes backwards

M569 P3 S0 ; Drive 3 goes backwards

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E96.00 ;steps per mm

M566 X900.00 Y900.00 Z12.00 E500.00 ; Set maximum instantaneous speed changes (mm/min)

M203 X9000.00 Y9000.00 Z180.00 E3000.00 ; Set maximum speeds (mm/min)

M201 X1500.00 Y1500.00 Z20.00 E800.00 ; Set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 X0 Y0 Z0 S1 ; Set axis minima

M208 X330 Y330 Z400 S0 ; Set axis maxima; Endstops

M574 X1 Y1 S0 ; Set active high endstops

M574 Z1 S2 ;Define Z to use Probe. Home to Min.

;M591 D0 P2 C3 S1 ; Filament sensor on for E0 extruder, simple NO switch connected to E0; Z-Probe

M307 H3 A-1 C-1 D-1 ; Disable heater on PWM channel for BLTouch

M558 P9 H5 F100 T2000 ; Set Z probe type to bltouch and the dive height + speeds

;G31 P25 X-20 Y-45 Z0.475 ; Set Z probe trigger value, offset and trigger height

;G31 P25 X-20 Y-45 Z1.2132 ; Set Z probe trigger value, offset and trigger height

G31 P25 X-20 Y-45 Z0.97 ; Set Z probe trigger value, offset and trigger height

M557 X30:315 Y15:315 S75 ; Define mesh grid; Heaters

M305 P0 T100000 B4138 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S120 ; Set temperature limit for heater 0 to 120C

;M305 P1 T100000 B4388 C7.060000e-8 R4700 ; Set thermistor + ADC parameters for heater 1

M305 P1 R4700 T100000 B4388 ; set E0 thermistor parameters

M143 H1 S280 ; Set temperature limit for heater 1 to 280C; Fans

M106 P0 S0 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C; Automatic saving after power loss is not enabled

; Custom settings are not configured

-

@chriskimbr said in Print problems and fixes:

I got a thermistor from Local store, no paperwork, he said it was standard 100k thermistor.

If it's a standard Chinese thermistor then this line won't give accurate temperatures:

M305 P1 R4700 T100000 B4388 ; set E0 thermistor parameters

Try changing the B parameter to B3950. This still won't be very accurate, but it will give the same results as Marlin temperature table 11, which is what most 8-bit controllers use with this type of thermistor.

-

Hi, I have same printer. I notice your stepper currents are set at 800. If you original steppers from tronxy they have maximum current rating of 1.68 so yours should be set at 85% which is just over 1.4.

-

@chas2706 said in Print problems and fixes:

Hi, I have same printer. I notice your stepper currents are set at 800. If you original steppers from tronxy they have maximum current rating of 1.68 so yours should be set at 85% which is just over 1.4.

I don't know that printer, but if the motors are attached to plastic parts then you may find that at 1.4A the motors get hot enough to soften the plastic. I find that 1.68A motors run well enough at 1.0A or 1.2A in my printers.

-

Thank you for that dc42. I shall reduce mine.

By the way, this board is the bee's knees and your commitment to it and the forum are outstanding. -

@dc42 Sorry forum won't let me uncomment this line says its spam.

Ive been using this line ...

M305 P1 T100000 B4388 C7.060000e-8 R4700 ; Set thermistor + ADC parameters for heater 1Do i need the C7.060000e-8 value?

I got this from someone elses config and am not sure if i need it or what to set mine at. -

have you checked that all of you axis are going the proper distances (step per mm). you can check by jogging the tool head along a ruler so you don't have to run a print.

-

I ran this command to do the PID test.

M303 H1 S240

What does this mean? what to do next? -

https://duet3d.dozuki.com/Wiki/Tuning_the_heater_temperature_control

After running the tuning M500 will save the results to config-override.g and then you must add M501 to config.g to load config-override.g at startup.

-

check relative extruder, you never know

-

@nicolab28 said in Print problems and fixes:

check relative extruder, you never know

Certainly check extruder e-steps but absolute or relative extrusion doesn't have that much effect.

-

On one of my printer, the nozzle closes continuously, and checking this box, no more worries.

He has an M83, and S3D gives him an absolute gcode -

@dc42 I stuck a ruler and moved x, y , z. spot on.

-

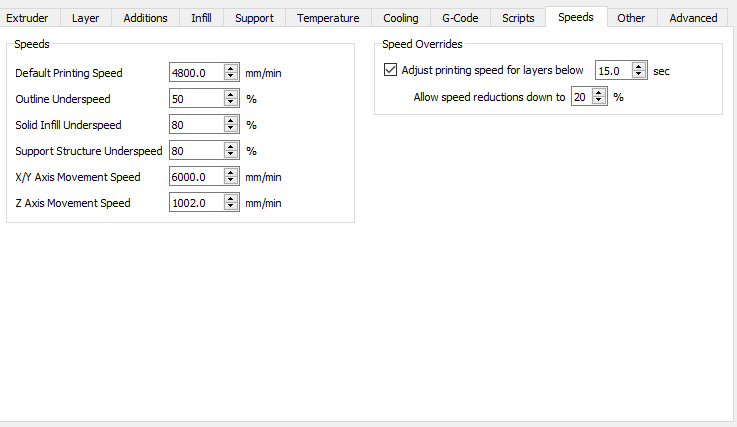

@phaedrux Is this where are you seeing 80mm/s base speed?

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E96.00 ;steps per mmWhats the difference, Don't they both set the microstepping speed? does one override the other? what is the correct speed to have with my issues?

-

@chriskimbr said in Print problems and fixes:

@phaedrux Is this where are you seeing 80mm/s base speed?

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X80.00 Y80.00 Z400.00 E96.00 ;steps per mmWhats the difference, Don't they both set the microstepping speed? does one override the other? what is the correct speed to have with my issues?

No I got it from your screen shot from S3D here:

4800mm/min = 80mm/s -

@phaedrux said in Print problems and fixes:

M500

Where in the config.g file do i put the M501 ?

Any parameters after the M501...? -

@chriskimbr M501 should go at the end.

https://duet3d.dozuki.com/Wiki/Gcode#Section_M500_Store_parameters