Crimping tool?

-

@deckingman said in Crimping tool?:

aren't designed to be used by human beings with only two hands.

True that!

-

@fcwilt said in Crimping tool?:

But why pay more for a tool that does less?

I have more crimping tools than I care to admit; but we're hobbyists, we don't do mass production so its for the most part quicker to grab the PA-09 from the desk than to go look for the correct crimper.

And in skilled hands it will allow you to make good crimps on things that don't really fit. I recently found myself crimping a 3mm delicate silicone heater wire to #26 wire with a but splice U terminal, and with careful manipulation of the terminal with the PA-09 I was able to get a good crimp both on the nichrome/fiberglass core, silicone sheath as well as the #26 wire. Can't do that with a fixed tool.

-

@deckingman said in Crimping tool?:

IMO all crimping tools are crap because they aren't designed to be used by human beings with only two hands.

That why I prefer PA-09-like tools: it is much easier to insert the pin in the jaws, the insert the wire and crimp it. Ok, it needs two operations, but as someone said, it is much more universal.

I tried the PA-09 (and was planning to buy one), and found a big issue: the width is too small for Dupont connectors, which are the connectors I mostly use (for Arduinos).

So, I plan to order this one:

I use it at work, and it is very good, producing high quality crimping. But, as I said, I mostly use Dupont, and I don't know how it goes on smaller pins...

I admit it is pricy, though.

-

@deckingman said in Crimping tool?:

IMO all crimping tools are crap because they aren't designed to be used by human beings with only two hands.

You lost me there. Why are two hands not enough?

Frederick

-

one hand to hold the crimp tool. one to hold the connector and one to hold the cable.

-

People need to learn how to use tools properly.

I’m still boggled that anyone would choose those janky manual crimpers over a proper set. This goes to show that people are unwilling to learn to do things properly, and are much happier to do a worse job if it seems easier to them. Yikes.

-

@bot said in Crimping tool?:

I’m still boggled that anyone would choose those janky manual crimpers over a proper set.

I find the issue of matching the jaws to the pins I crimp to be confusing. For example, if I use KF2510 connectors from Ali, what are the correct jaws? The open style crimpers from Engineer iSwiss and others make it easier for me. I find the matching slot for the core and the insulation respectively and crimp.

-

I've tried and tried but using crimping tools is just one of those things that I can't master. In my 65 year on this planet, I've been able to master most things. I can use just about any tool making machine - mill, lathe, surface grinder centre grinder. I can weld and braze (up to a point) and solder. I can bend pipes and fold sheet metal. I can route, plane, cut and join timber using both hand and machine tools. I can strip and re-build engines gearboxes, carburettors and distributors. I can fit kitchens and bathrooms and central heating systems. I can cut and fit tiles, build my own furniture, design and build my own printer. I have a reasonable understanding of basic electronics and I've build a few Arduino and before that PIC based projects. For someone my age, I'm reasonably "tech savvy". As well as 3D printing, my hobbies include photography (still and video), and model making (scratch build as well as kits).

But there are two things that drive me up the wall and just make me want to throw the tools through the nearest window (or at the first person to make some comment). The first is plastering - I can make it either smooth or flat but not both. I've tried and tried but every time I end up needing a belt sander (which makes such a mess and upsets 'er in doors no end). The second thing is using a bloody crimping tool (and I've bought numerous ones). I either fit the terminal into the tool upside down or back to front, then it either falls out or I flatten it too much before I can get the bloody wire in. I can get a good crimp on the bare conductors, or I can get a good crimp on the insulation but never both together. Two hands definitely aren't enough and using teeth or toes doesn't help all that much either (I've tried).

I have now mastered a technique which works well for me. It involves holding the wire in a vice, the terminal in one hand, and making the crimp with a pair of curved needle nosed pliers. Since I've developed that way of doing things, I've never suffered from a bad crimps whereas before, I had numerous problems when using the proper "tool".

Knowing that using a crimping tool is just a matter of learning the "technique" doesn't help. It's just like plastering - I can't do it - end of.....................

-

Whether you think you can or you can't, it's true.

-

A "proper set" isn't an option for most hobbyist users. A chinesium set is either not proper or not cheap after all.

As long as I can quickly and easily crimp terminals that are crimpt so the wire break at some arbitrary point and not in the crimp or pulled out then its good enough, fast enough and cheaper than a proper set. It won't be for everyone, thats fine.

-

With the manual crimpers, you can't be sure that you're making a reliable crimp unless you test every single one. Except, the test is destructive... so... you can not be sure that any of your crimps are good.

The consistency of the pressure provided by the ratcheting tools is the key to a good crimp.

-

I'd say that has to do with experience; I don't use a torque wrench for every screw at home either.

I'll tell you what, if you're ever in my area you can test every crimp on my printer. If one fails drinks are one me..

-

@deckingman said in Crimping tool?:

I have now mastered a technique which works well for me. It involves holding the wire in a vice, the terminal in one hand, and making the crimp with a pair of curved needle nosed pliers.

The type of tool the crimps both the wire and the insulation at the same time makes it easier to get the contact into the correct position and hold it there while you pick up and insert the wire into the correct position.

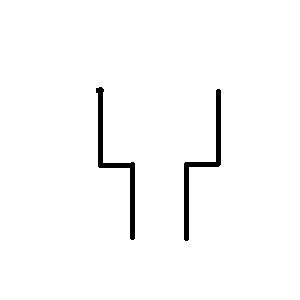

See this little sketch of the "cross section" of the part of the tool the holds/crimps the contact. I hope it illustrates how it works:

The upper part represents the bit that crimps the insulation, the lower part the bit the crimps the wire.

The part of the contact itself that is meant to grip the insulation tends to be larger in someway and when inserted into the tool will come to rest on the little "shelf" that is created by the difference in dimension between the two parts.

Then a slight compression of the tool will hold the contact in place while you pick up and insert the wire. And the ratchet will hold that slight compression so that it is unlikely the contact will fall out.

If the wire is stripped to the correct length, while inserting the wire the insulation will also come to rest on this "shelf" so you know that wire is now in the correct position.

One crimp until the ratchet releases and your done.

Of course you can do it any number of different ways. But the right tool used as intended can make things quick and easy.

YMMV.

Thanks for the feedback. My nemesis is mudding drywall - just cannot get the knack.

Frederick

-

I guess you don't use a torque wrench on your vehicle's lug bolts, either?

There is a time and a need for a proper tool. Not every screw needs a torque wrench. Every crimp terminal needs a crimp tool.

-

@bearer said in Crimping tool?:

A "proper set" isn't an option for most hobbyist users. A chinesium set is either not proper or not cheap after all.

As long as I can quickly and easily crimp terminals that are crimpt so the wire break at some arbitrary point and not in the crimp or pulled out then its good enough, fast enough and cheaper than a proper set. It won't be for everyone, thats fine.

Well the IWISS tool I use, and have used for years, is well made and works fine.

It works as well as my old, tired, green enamel Berg crimper from years gone by and that tool was quite pricey.

The IWISS is less expensive than the PA-09 the several mentioned.

So it's not a question of money.

Frederick

-

@fcwilt This is the tool I picked up on Amazon a few months past.

It has the proper profile you describe, but I find it sucks at crimping even the dupont connectors it comes with.

https://www.amazon.ca/gp/product/B07BQDBG22/ref=ppx_yo_dt_b_asin_title_o03_s00?ie=UTF8&psc=1I'm trying to find a crimper that:

- will strip the wire properly,

- will hold the connector securely (this is what this one does not do), and

- will actually crimp AWG 28 (this one claims down to AWG 22, but is not that small.

So I look at all this as take the right advice - so following this thread to find the "best" solution.

-

22-18AWG Dupont Tool

What wires are you trying to crimp with that one? It's a weird range, and suitable for only the beefiest wires normally encountered with Duet electronics. Fans, endstops, thermistors, and usually stepper motor cables are all around 26 AWG.

Come to think of it, I think none of the connections that use dupont crimps (actually molex in our case, but we're not using the branded tools so it's fine) use anything other than 26 AWG and maybe 28 AWG. In my case, the wires I used to extend my stepper motors are larger 24 AWG wires, which is still too small for the range of that tool.

-

@dennishall said in Crimping tool?:

@fcwilt This is the tool I picked up on Amazon a few months past.

It has the proper profile you describe, but I find it sucks at crimping even the dupont connectors it comes with.

https://www.amazon.ca/gp/product/B07BQDBG22/ref=ppx_yo_dt_b_asin_title_o03_s00?ie=UTF8&psc=1Compare the look of the jaws on that tool with the IWISS.

Your tool does not look right to me. The shapes of the sections that actually do the crimping seem wrong.

And a crimper like this is not going to be used for stripping.

I've had good luck with these:

Notice they come in three different models depending on the size of wire you need to strip. I use the 5023 for most of my work.

Frederick

-

@bot said in Crimping tool?:

22-18AWG Dupont Tool

What wires are you trying to crimp with that one? It's a weird range, and suitable for only the beefiest wires normally encountered with Duet electronics. Fans, endstops, thermistors, and usually stepper motor cables are all around 26 AWG.

Well call me blind as a bat - I was so busy looking at the tool itself for issues I didn't even notice the listed range of wire sizes was wrong for Duet connectors.

Note to self: never assume.

Thanks.

Frederick

-

@fcwilt I have strippers already and I agree the tool head of my crimper does not look right.

As with many here, I have lots of crimping and stripping tools. My favorite striping tool is actually a very old one I got when working with Telco companies in the U.S.What I'm really seeking is 1 tool that will meet my 3 criteria because as I'm getting older, my eye-site and manual dexterity are getting worse.

This is much like my good-ol' favorite wire stripper: https://www.tenaquip.com/product/klein-tools-compact-wire-strippers-cutters-1003-tj950?gclid=Cj0KCQjwkoDmBRCcARIsAG3xzl-MXiTSYMqHqhu7HroV0T7j5hSn00PgdRmhN2ijze64RkRrIKYkDQcaAqksEALw_wcB

that I can still use for the next couple years at least.