I have been using a Caribou Duet 320 for some time.

The printer is equipped with 0.9 degree motors on all axes.

Now I have noticed in the Caribou Slicer (latest version) that there are

different machine limits for acceleration, acceleration during printing, speed and jerk compared to the values in the caribou config.g.

I am currently using the values from the latest configuration macro.

The values in the slicer are much higher, especially for the print accelerations.

Values in the config macro from the caribou website:

M201 X3000.00 Y3000.00 Z100.00 E500.00 ; set accelerations (mm/s^2)

M203 X18000.00 Y18000.00 Z1000.00 E3600.00 ; set maximum speeds (mm/min)

M204 P500.0 T500.0 ; set print and travel accelerations (mm/s^2)

M566 X480.00 Y480.00 Z48.00 E300.00 ; set maximum instantaneous speed changes (mm/min)

Values of caribou slicer, when used in config.g:

M201 X1000.00 Y1000.00 Z200.00 E5000.00 ; set accelerations (mm/s^2)

M203 X12000.00 Y12000.00 Z720.00 E7200.00 ; set maximum speeds (mm/min)

M204 P1250.0 T1500.0 ; set print and travel accelerations (mm/s^2)

M566 X480.00 Y480.00 Z48.00 E270.00 ; set maximum instantaneous speed changes (mm/min)

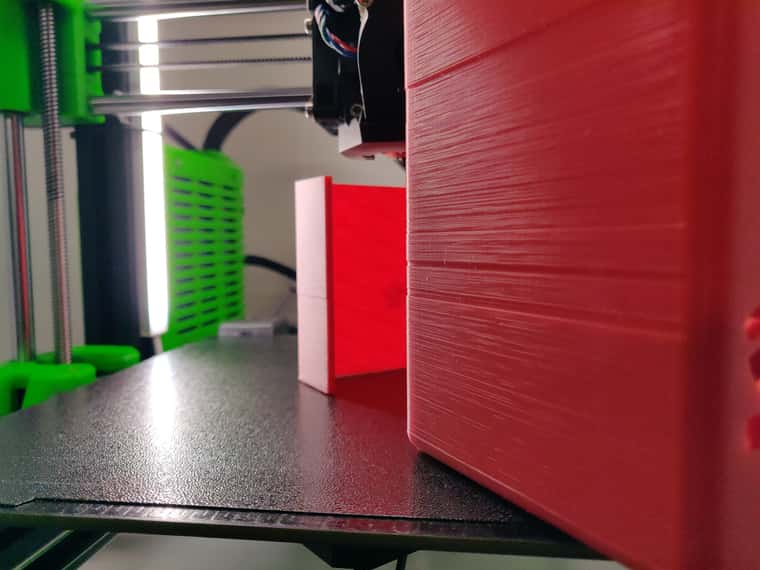

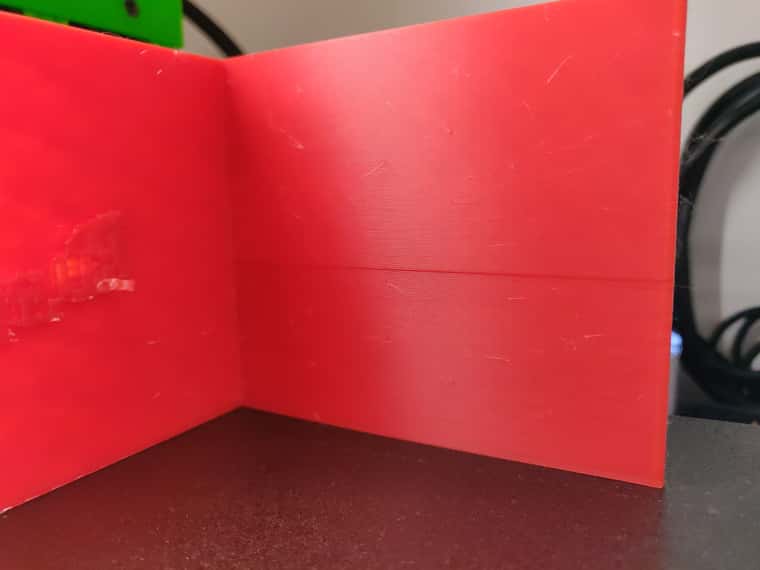

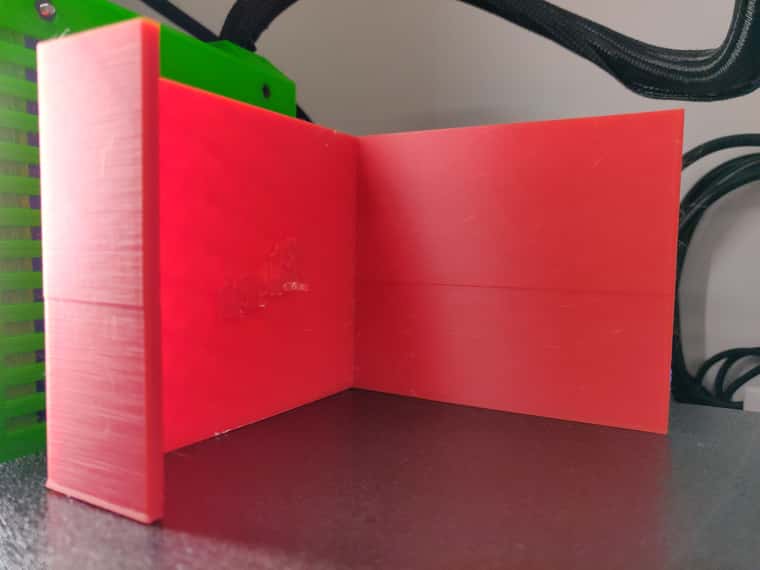

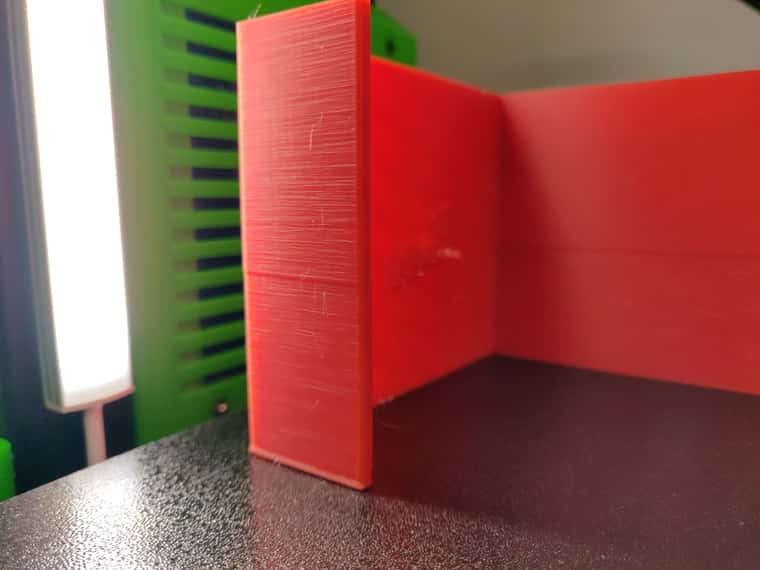

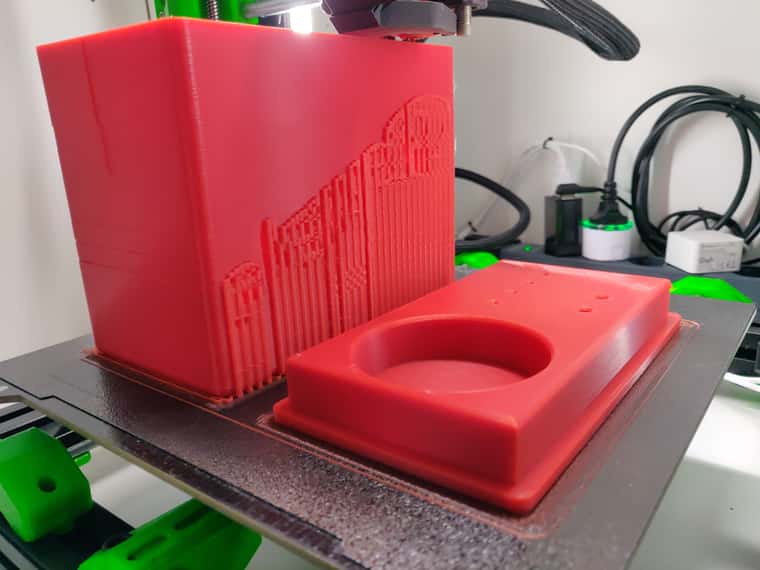

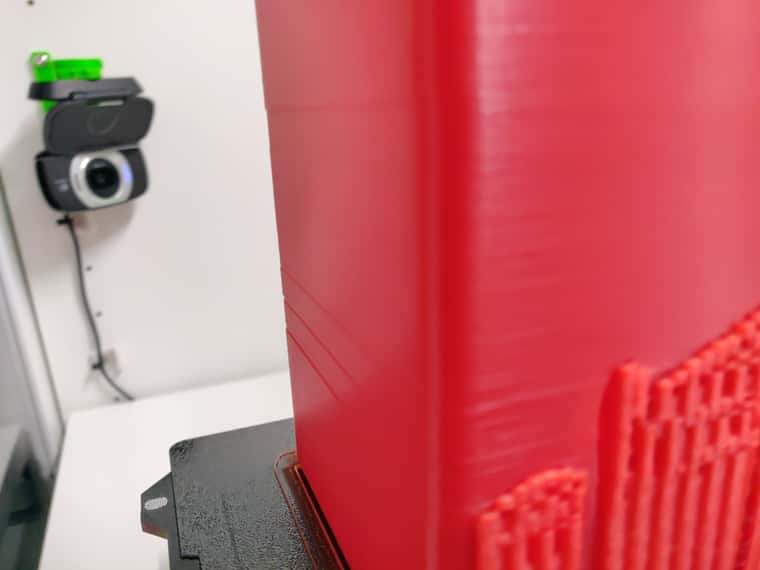

I have performed a test print for a couple of hours with the faster speeds,

it seems that the drives can handle the speed, also print quality seems to be not affected.

Of course, the drives run a couple of degrees hotter

What do you think, should I use the original values from caribou website or the values from the slicer?

Thanks a lot,

Regards Kubunter