I am trying myself at calibrating the M592 non-linear extrusion feature and ended up with some questions (at the bottom).

The setup

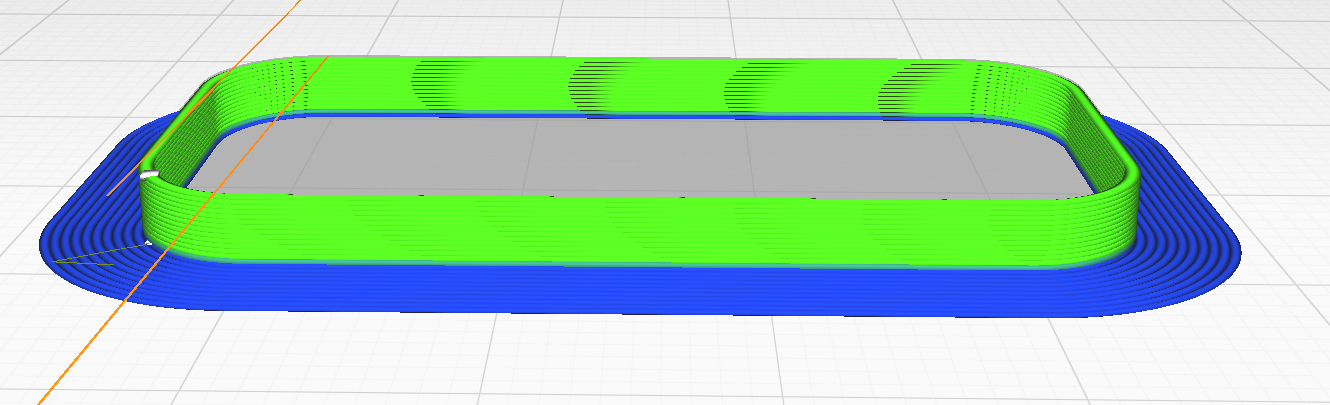

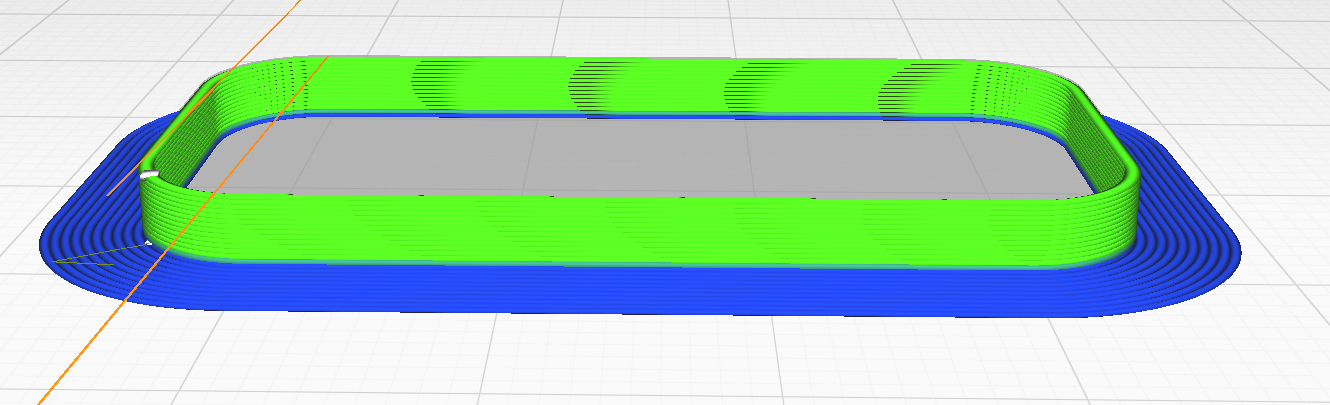

I opted to do the measurement "in-print" on some "1-wall, rounded corner testcube spirals" with 0.6 mm wide, overextruded walls.

This should ensure that I am not getting any artifacts due to accelerations and allows me to take several measurements per print speed. Print speeds were varied from 10-90 mm/s corresponding to flow rates of roughly 1-10 mm³/s which should be possible with a stock E3D V6 hotend.

Each print was measured six times, for a total of 54 measurements.

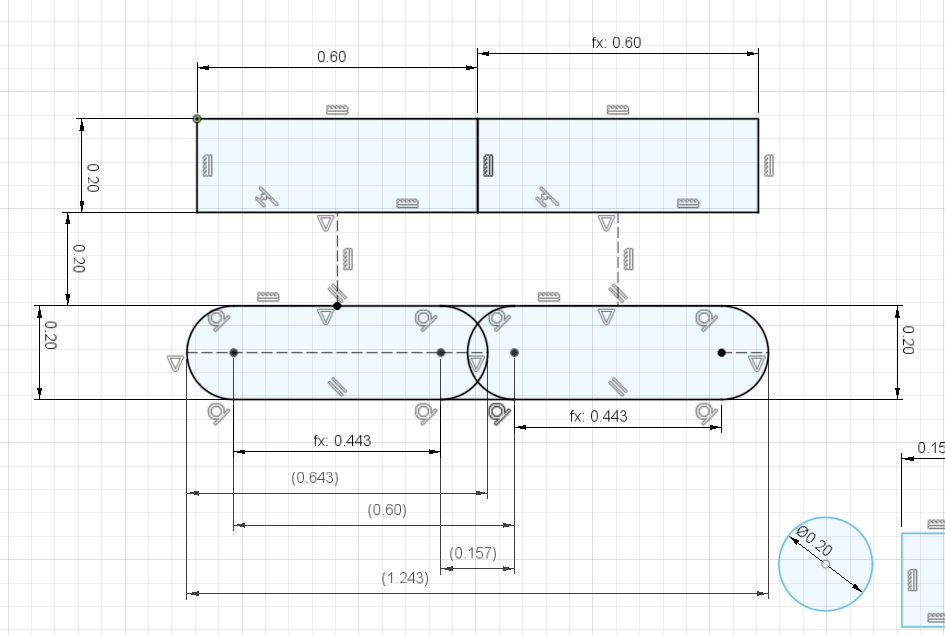

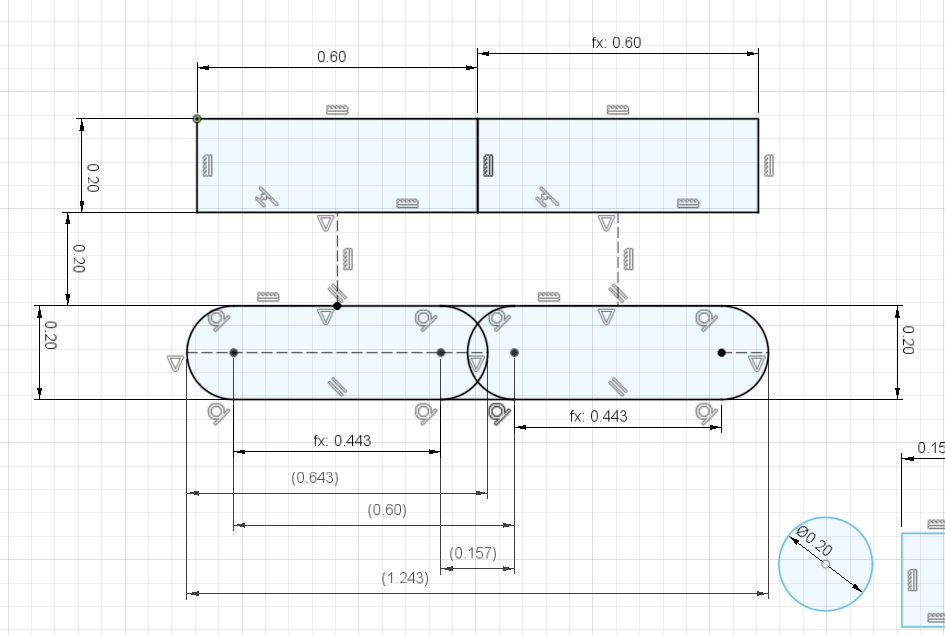

The next step might be a bit controversial, but as I used Cura to slice those parts and Cura uses a simple layer_height * extrusion_width model to calculate the required volume I assumed a target width of 0.643 mm to compare the measured extrusion width to:

(both the layer_height * extrusion_width and the "wurst" at the bottom share the same area)

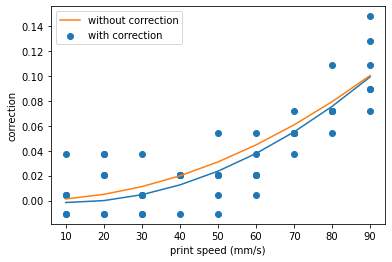

the results

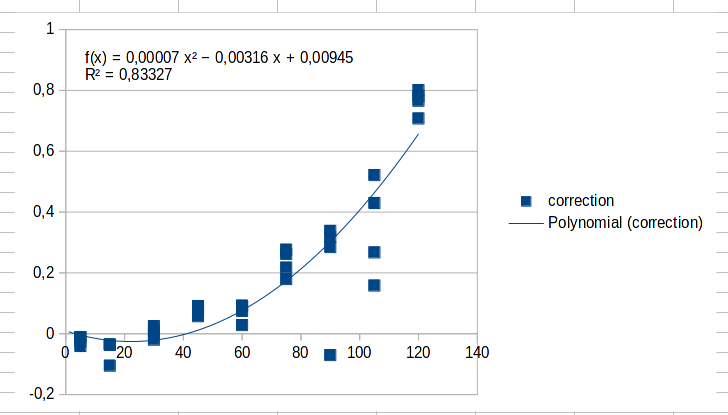

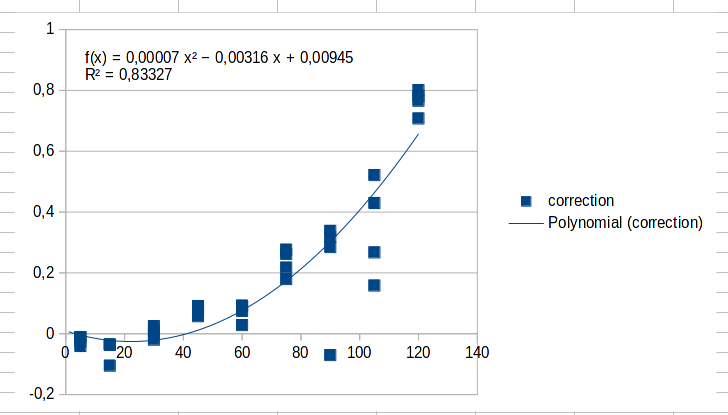

I did the above several times and I always arrive at negative A factors. E.g:

(The fit uses the A term to adjust for too much extrusion at the lower speeds)

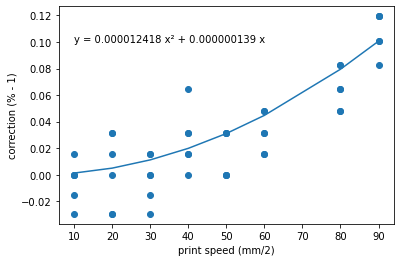

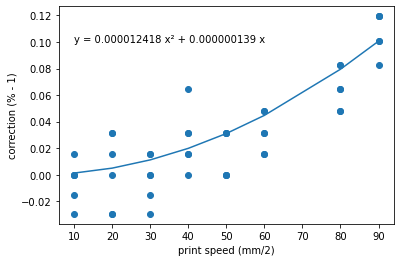

To mitigate that, I adjusted the flow rates via M221 and fitted another model (this time excluding the C term):

Judging from that there is somewhat significant underextrusion of about 10% happening in my setup that M592 should be able to mitigate.

Questions

- I assume

final_volume = slicer_volume * M221 * (1 + M592), is that correct?

- Can we at this point assume that speed and volume correlated with at simple

extrusion=B*speed² relation, losing the A factor?

- Somewhat tangential, but is my "equal volume" line width calculation above reasonable?

- As there are devices that actually measure the amount of extruded filament [1] ... wouldn't they have triggered regularly when confronted with non-linear extrusion. Could they be used in a control loop?

[1] https://duet3d.dozuki.com/Wiki/Duet3dFilamentMonitor_RotatingMagnetVersion

).

).