So I think I found the issue, in my machine settings:

M203 X6000.00 Y6000.00 Z300.00 E6000.00:6000.00 ; set maximum speeds (mm/min)

that's mm/MINUTE, I was thinking in mm/sec

So I think I found the issue, in my machine settings:

M203 X6000.00 Y6000.00 Z300.00 E6000.00:6000.00 ; set maximum speeds (mm/min)

that's mm/MINUTE, I was thinking in mm/sec

I'm considering update from 2.0.5 to 3.4.1 to make use of the new PID tuning.

I have not yet fully dove into the new configs other than to note that I will have to somehow identify all of the pin numbers for the heaters, BL Touch, and thermistors, and possibly more.

Questions:

thanks!

I just want to chime in, had the same issue after adding bed levelers and getting my bed really flat.

This created a new problem where Babystepping was "undoing" itself within 1-2 seconds. I could hold my hand on the Z rod and feel it bumping back. and watch the lines flatten out on the bed while printing, and then unflatten as it reset to Z=0.

This totally solved it for me. I typically have to babystep -0.25 and now I can again.

Thank you!

I have a simple switch sensor that triggers way too often, even though I have redesigned the switch enclosure a few times and feel like I have it exactly right, where my switch is only pressed when filament is present. Still, I get unwanted pauses all the time.

I'm going to replace the switch itself to be sure, but I like your idea of a timed outage before taking any action.

@deckingman said in Extruder engine temperature:

@luc said in Extruder engine temperature:

SLIM_POWER_LDO-42STH25-1404MAC

You have nothing to worry about. LDO actually specify a winding temperature, which in the case of that motor is 130 degC. Winding temperatures are generally about 50C more than ambient, so a 130C winding temperature means that you could run that motor inside a heated chamber temperature of 80C. For info, LDO also make a high temperature version which has a winding temperature rating of 180 deg C meaning that it could be used in a heated chamber at up to 130 deg C.

@deckingman

I have this same motor and googled my way in here looking up the temperature rating. I can't find it on LDO's website. where did you pick up the into that the motor is OK to 130c?

I run a 50c chamber.

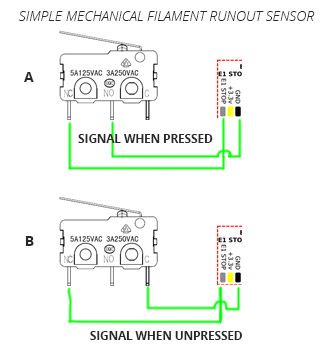

I need to make a simple microswitch runout sensor:

https://duet3d.dozuki.com/Wiki/Gcode#Section_M591_Configure_filament_sensing

It seems to be doable but light on details.

I'm wondering how do I configure what happens when the switch is triggered? I'd like a basic pause, retract, and hotend cool.

Also, It's a bit unclear how to tell duet how to know where the sensor is plugged into.

#) Switch wiring: I'm assuming stop and ground, no need for the voltage. Right?

My idea is to have a switch wired like A below.

@jens55 Can you explain you you set up the old sensor as a graphed secondary sensor?

@jens55 said in Erratic bet temps followed by heater fault:

Just a standard thermistor like you get on hot ends. Taped to the underside on top of the heater with Kapton tape

That's pretty smart. middle of the bed?

@jens55 I have been thinking along these lines, I have a big red heat pad with a built in sensor. Were this any other printer I'd replace the bed thermistor and be done. What sensor did you use?

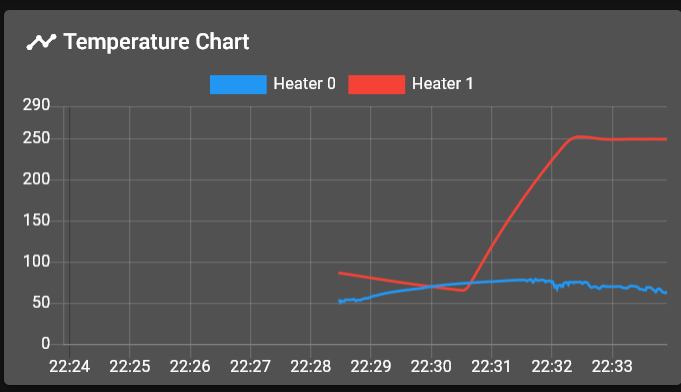

Help me think this through. I'm having a hard time heating my bed up. it goes up smoothly to about 65 or so, then gets erratic with small variations, small 'jumps'. it struggles along and eventually faults.

I've checked my connections a few times. My SSR is a new panasonic. Ideas?

Photo is trying to heat up to 90 degrees:

Looking to add a temp sensor for my enclosure. Is there a reliable recommendation for the Duet3?