Hi. please explain how to use a stepper motor instead of a servo, the idea is to select a tool by rotating the stepper motor in which the initial point is the first extruder (the limit switch for the initial position should work and the rest of the tools are the value that the motor will be instructed to)

Best posts made by shiga

-

stepper motor instead of servoposted in General Discussion

Latest posts made by shiga

-

RE: stepper motor instead of servoposted in General Discussion

thank you, I think I understand, I will try!

-

RE: stepper motor instead of servoposted in General Discussion

@phaedrux yes, I understand this, how to assign an additional motor and a terminal block to it, what should I write config?

-

stepper motor instead of servoposted in General Discussion

Hi. please explain how to use a stepper motor instead of a servo, the idea is to select a tool by rotating the stepper motor in which the initial point is the first extruder (the limit switch for the initial position should work and the rest of the tools are the value that the motor will be instructed to)

-

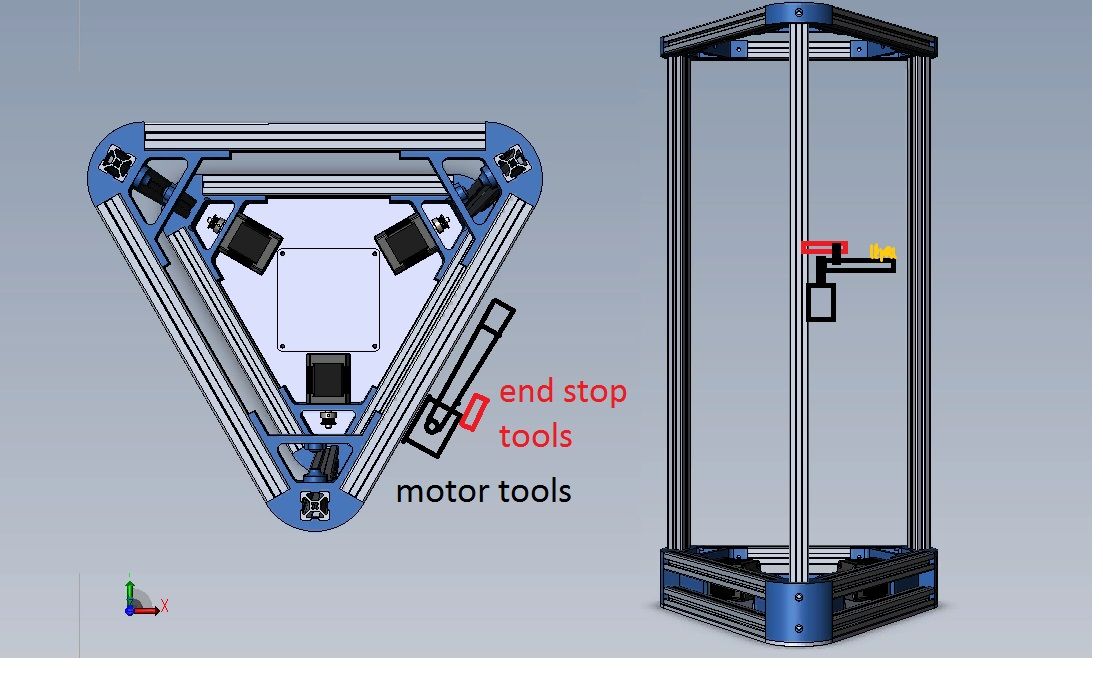

Tool changer deltaposted in Tuning and tweaking

Hello friends! who will tell you how to implement an additional motor and limit switch, for example, for changing the tool, or, for example, cleaning the nozzle with a brass brush?

I know that it is much easier to implement this all on a servo drive, but you need it on a stepper motor.

the algorithm of actions is as follows: the end switch is needed to set the starting point, before the start of printing, the head is sent (Zn), the brush extends and makes a movement back and forth, then goes into the parking lot.

algorithm # 2: the head rises to a height (Zn), the tool moves out (let's say a laser) sticks to the magnets, the head makes a movement to the side to prevent the magnets from sticking, the handle is parked from the tool; the head goes further to work.

-

RE: Laser 3.3v PWMposted in Laser Cutters

@noisettetbou

PWM can be adjusted, PWM: 50KHz-20KHz / 3.3V-12V. there is nothing terrible, no, the same laser works fine for me! -

RE: Laser 3.3v PWMposted in Laser Cutters

@noisettetbou what laser do you use? throw off the link ...

-

RE: Laser always onposted in Laser Cutters

@shiga said in Laser always on:

@arhi I'm looking at the current consumption.

I look at the current consumption, and compare it with the PWM of the signals from the servo tester.

-

RE: Laser always onposted in Laser Cutters

@arhi Many thanks for the help! the problem was resolved, it was a bad 74HCT02, from a batch of 5 pieces all were inoperative, replaced from another shop and it all worked!

small question: which program is the best to use for engraving with DUET?