where to buy duex5 and a copy at a cheaper price

Posts made by shiga

-

RE: stepper motor instead of servoposted in General Discussion

thank you, I think I understand, I will try!

-

RE: stepper motor instead of servoposted in General Discussion

@phaedrux yes, I understand this, how to assign an additional motor and a terminal block to it, what should I write config?

-

stepper motor instead of servoposted in General Discussion

Hi. please explain how to use a stepper motor instead of a servo, the idea is to select a tool by rotating the stepper motor in which the initial point is the first extruder (the limit switch for the initial position should work and the rest of the tools are the value that the motor will be instructed to)

-

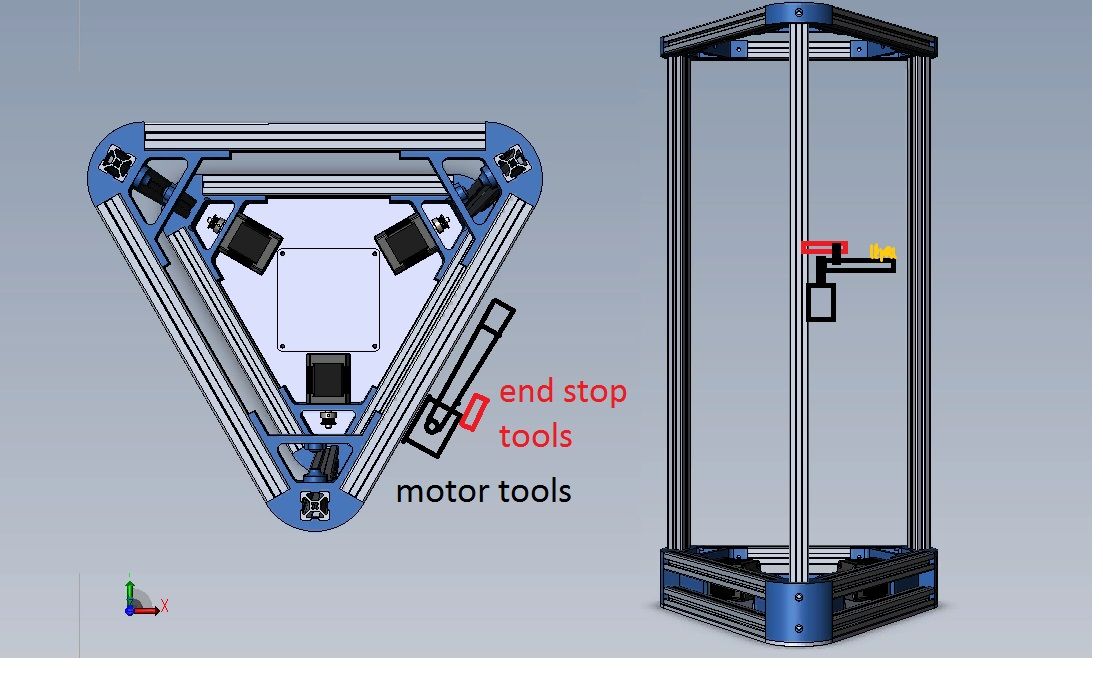

Tool changer deltaposted in Tuning and tweaking

Hello friends! who will tell you how to implement an additional motor and limit switch, for example, for changing the tool, or, for example, cleaning the nozzle with a brass brush?

I know that it is much easier to implement this all on a servo drive, but you need it on a stepper motor.

the algorithm of actions is as follows: the end switch is needed to set the starting point, before the start of printing, the head is sent (Zn), the brush extends and makes a movement back and forth, then goes into the parking lot.

algorithm # 2: the head rises to a height (Zn), the tool moves out (let's say a laser) sticks to the magnets, the head makes a movement to the side to prevent the magnets from sticking, the handle is parked from the tool; the head goes further to work.

-

RE: Laser 3.3v PWMposted in Laser Cutters

@noisettetbou

PWM can be adjusted, PWM: 50KHz-20KHz / 3.3V-12V. there is nothing terrible, no, the same laser works fine for me! -

RE: Laser 3.3v PWMposted in Laser Cutters

@noisettetbou what laser do you use? throw off the link ...

-

RE: Laser always onposted in Laser Cutters

@shiga said in Laser always on:

@arhi I'm looking at the current consumption.

I look at the current consumption, and compare it with the PWM of the signals from the servo tester.

-

RE: Laser always onposted in Laser Cutters

@arhi Many thanks for the help! the problem was resolved, it was a bad 74HCT02, from a batch of 5 pieces all were inoperative, replaced from another shop and it all worked!

small question: which program is the best to use for engraving with DUET? -

RE: Laser always onposted in Laser Cutters

@arhi said in Laser always on:

so if you do

G1X10S0your laser will move and will be OFF

and if you do then

G1X20S255it will move and be ON but not 100% ?

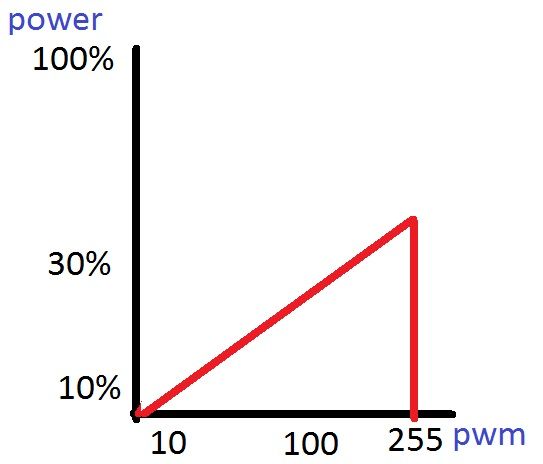

yes, quite right. g1x10s10 is dim, g1x10s100 is brighter, g1x10s255 is off. and if g1x10s250 also shines like on s100.

-

RE: Laser always onposted in Laser Cutters

@arhi I did as you said, I connected the pwm directly, the laser was controlled, but not at full power, it was very dim, and did not shoot at S255. The macro to turn on the laser mode is as follows:

M563 P0 D-1 H-1; clear tool

M563 P0 D0; create a tool - no heaters

M307 H3 A-1 C-1 D-1; Clear heater

M452 P3 R255 F20000 I0

what should I do next? -

RE: Laser always onposted in Laser Cutters

@arhi please tell me how you did it? how did you raise it to 5 volts? And what was the piece of config.g and the circuit at least by hand, how did you connect it?

-

RE: Laser always onposted in Laser Cutters

@shiga said in Laser always on:

@dc42 да 7 булавок на земле, я делаю это в соответствии с инструкциями Вики

pin heater 3 is present at 3.3 volts, switching on without sd card is also present at 3.3 volts.

-

RE: Laser always onposted in Laser Cutters

@dc42 да 7 булавок на земле, я делаю это в соответствии с инструкциями Вики

-

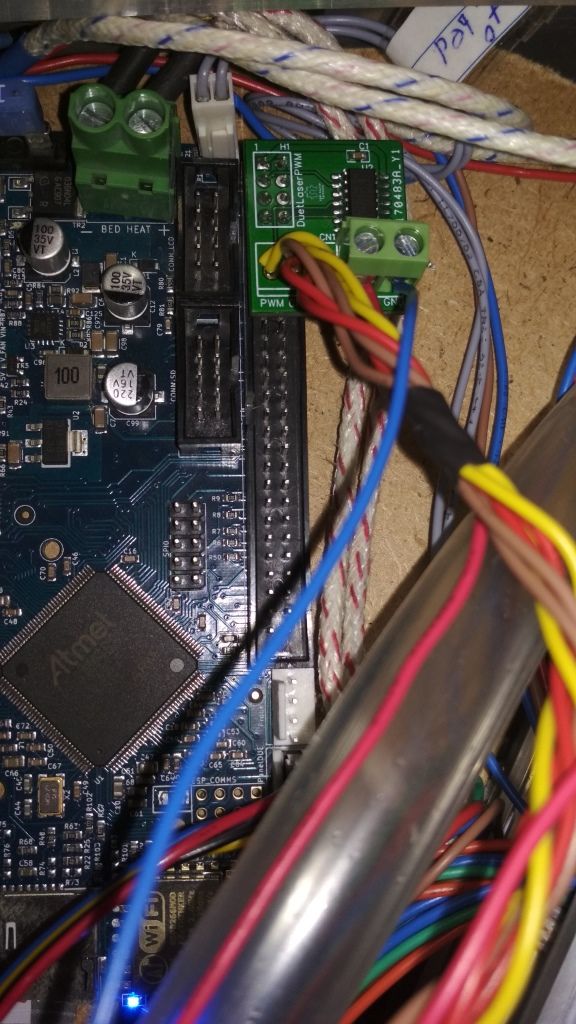

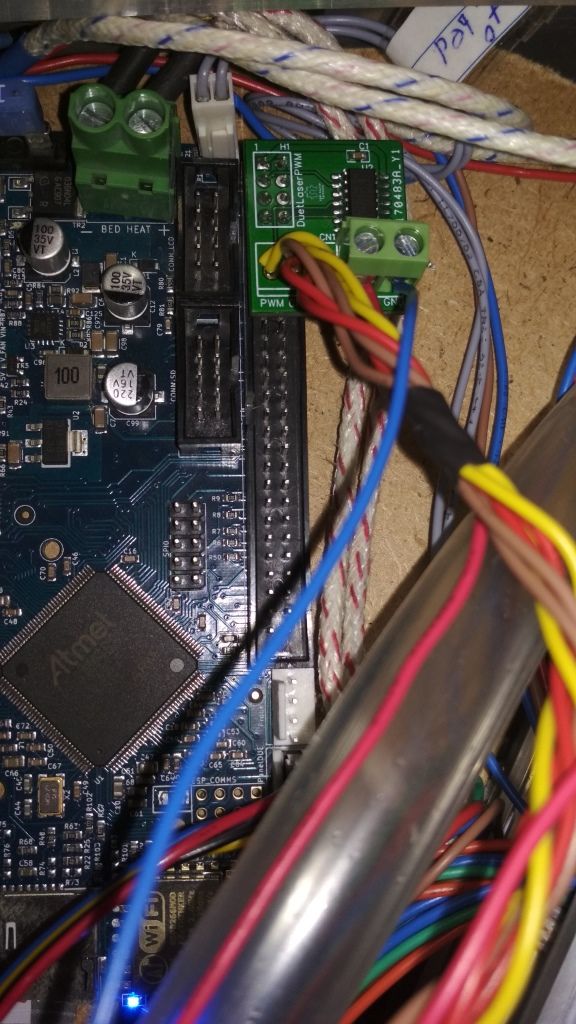

Laser always onposted in Laser Cutters

Hello everyone, please help me with my problem. There is a homemade delta on DUET that works perfectly, I connected the laser "http://nejetool.com/module_20w.html" to my DUET according to the diagram from "https://duet3d.dozuki.com/Wiki/Laser_PWM_control#Section_Controlling_a_PWM_Laser_with_a_Duet_2_Board" when the DUET is turned on, the laser is constantly on and is not controlled by any G-code, does not turn off does not change the power.!

Firmware Name: RepRapFirmware for Duet 2 WiFi/Ethernet

Firmware Electronics: Duet WiFi 1.02 or later

Firmware Version: 2.02(RTOS) (2018-12-24b1)

WiFi Server Version: 1.22

Web Interface Version: 1.22.6My config.g

; Configuration file for Duet WiFi (firmware version 1.20 or newer)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool on Thu Jul 12 2018 20:54:00 GMT-0500 (Central Daylight Time); General preferences

;G90 ; Send absolute coordinates...

;M83 ; ...but relative extruder moves;*** The homed height is deliberately set too high in the following - you will adjust it during calibration.

; After G32 auto-calibrate, copied from config-override.g

; Note: G31 Z (below) affects M665 H, and this is NOT yet calibrated.

M665 L264 R124 H240 B120.0 X-0 Y-0 Z0

M666 X-0 Y0 Z0 A0 B0; Network

M550 PAKL Plus ; Set machine name

M552 S1 ; Enable network

;*** Access point is configured manually via M587

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet; Drives

M569 P0 S0 ; Drive 0 goes forwards

M569 P1 S0 ; Drive 1 goes forwards

M569 P2 S0 ; Drive 2 goes forwards

M569 P3 S0 ; Drive 3 goes forwards

M350 X16 Y16 Z16 E16 I1 ; Configure microstepping with interpolation

M92 X80 Y80 Z80 E400 ; Set steps per mm

M566 X300 Y300 Z300 E300 ; Set maximum instantaneous speed changes (mm/min)

M203 X12000 Y12000 Z12000 E12000 ; Set maximum speeds (mm/min)

M201 X1000 Y1000 Z1000 E1500 ; Set accelerations (mm/s^2)

M906 X1000 Y1000 Z1000 E800 I30 ; Set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout; Axis Limits

M208 Z0 S1 ; Set minimum Z; Endstops

M574 X2 Y2 Z2 S1 ; Set active high endstops; Z-Probe

M558 P4 H6 F120 T6000 ; Set Z probe type to switch and the dive height + speeds

G31 P1000 X0 Y0 Z13.48 ; Set Z probe trigger value, offset and trigger height

M557 R105 S20 ; Define mesh grid; Heaters

M305 P0 T100000 B4138 C0 R4700 ; Set thermistor + ADC parameters for heater 0

M143 H0 S150 ; Set temperature limit for heater 0 to 120C

M305 P1 X501 R4700 ; Set thermistor + ADC parameters for heater 1

M143 H1 S350 ; Set temperature limit for heater 1 to 280C; Fans

M106 P0 S0.3 I0 F500 H-1 ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H1 T45 ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P2 S1 I0 F500 H1 T45 ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned on; Tools

M563 P0 D0 H1 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C; Automatic power saving

M911 S10 R11 P"M913 X0 Y0 G91 M83 G1 Z3 E-5 F1000" ; Set voltage thresholds and actions to run on power loss; Custom settings are not configured

; Miscellaneous

M501 ; Load saved parameters from non-volatile memory

T0 ; Select first toolM307 H3 A-1 C-1 D-1 ; Disable Heater output on H3

M452 P3 S1 R1.00 F2000 ; Enable Laser mode, on output 3 (heater 3), with max intensity being 1.00, and a PWM frequency of 2000

M571 P3 F200 S0IMG_20200807_203959.jpgMy mail: d7a7r7@mail.ru