@Kolbi said in Pressure advance quality issues:

it is normally recommended to use 16 with interpolation

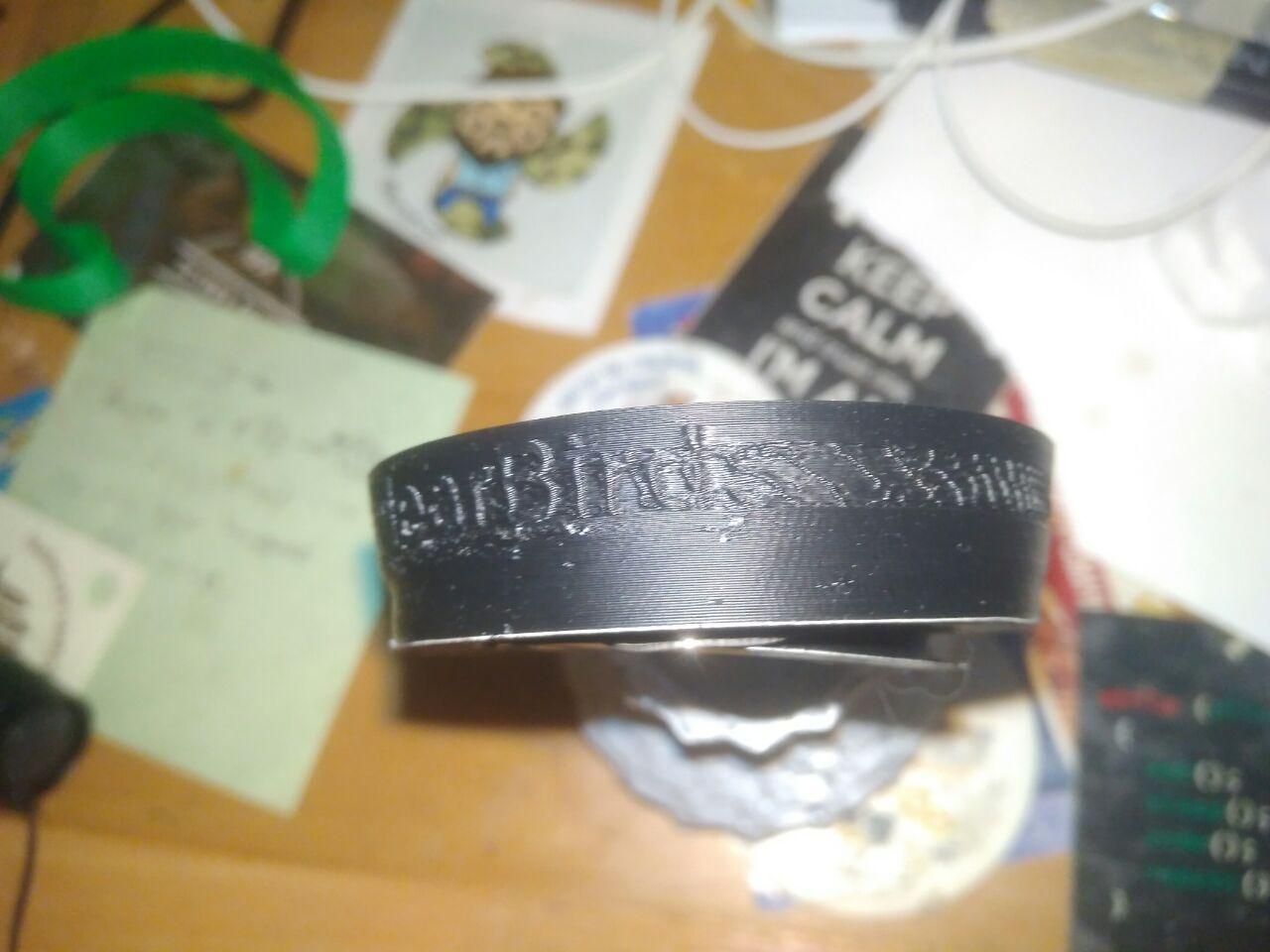

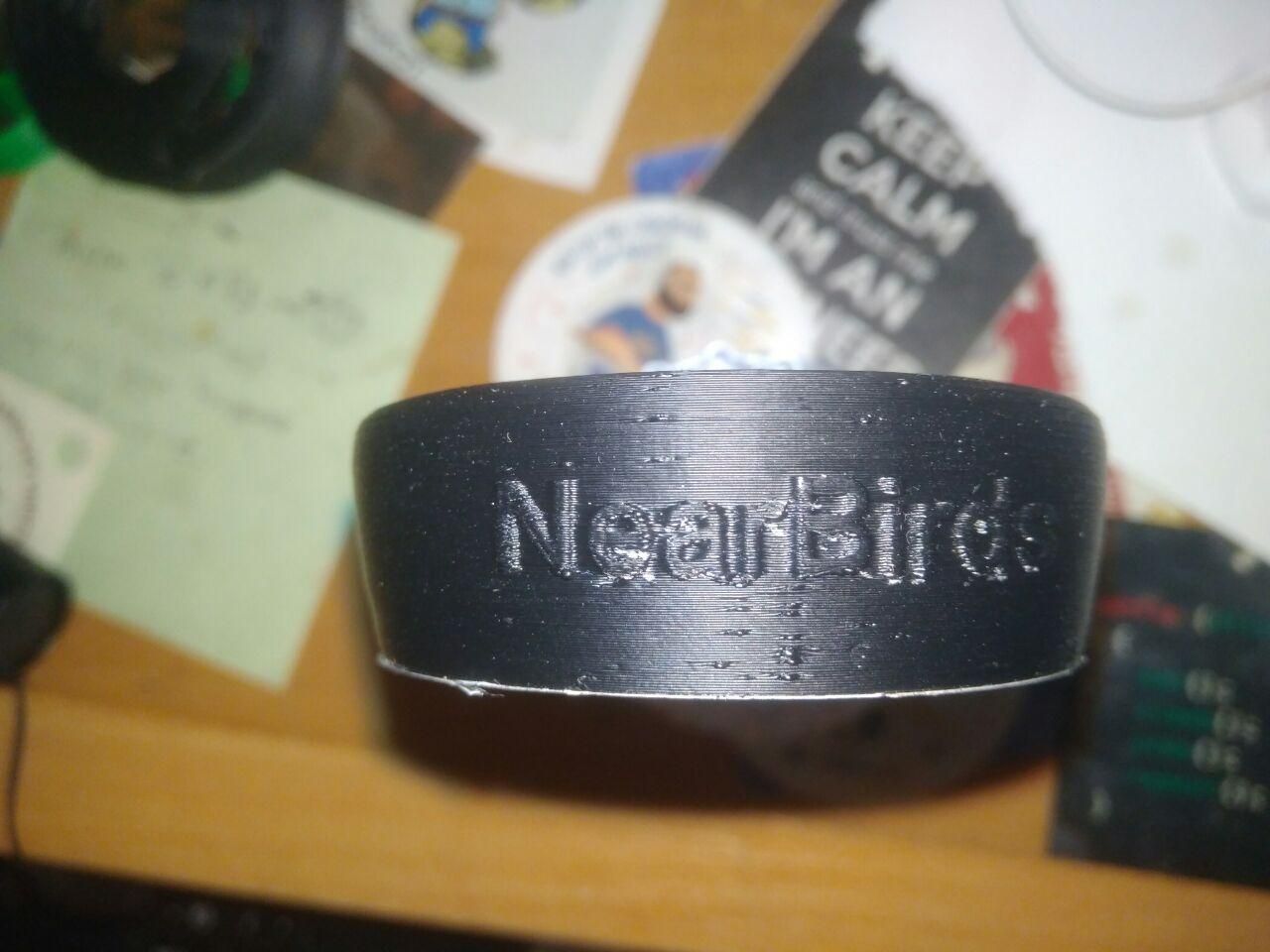

It seems like a step in the right direction. Now it, as expected, over extrudes on the text and even primes (untracts). It's interesting because after installation I calculated steps/s and no axis exceeded the limit of 180k steps/s, mentioned on the wiki.

Now I'm printing samples to approve that theory.

@engikeneer said in Pressure advance quality issues:

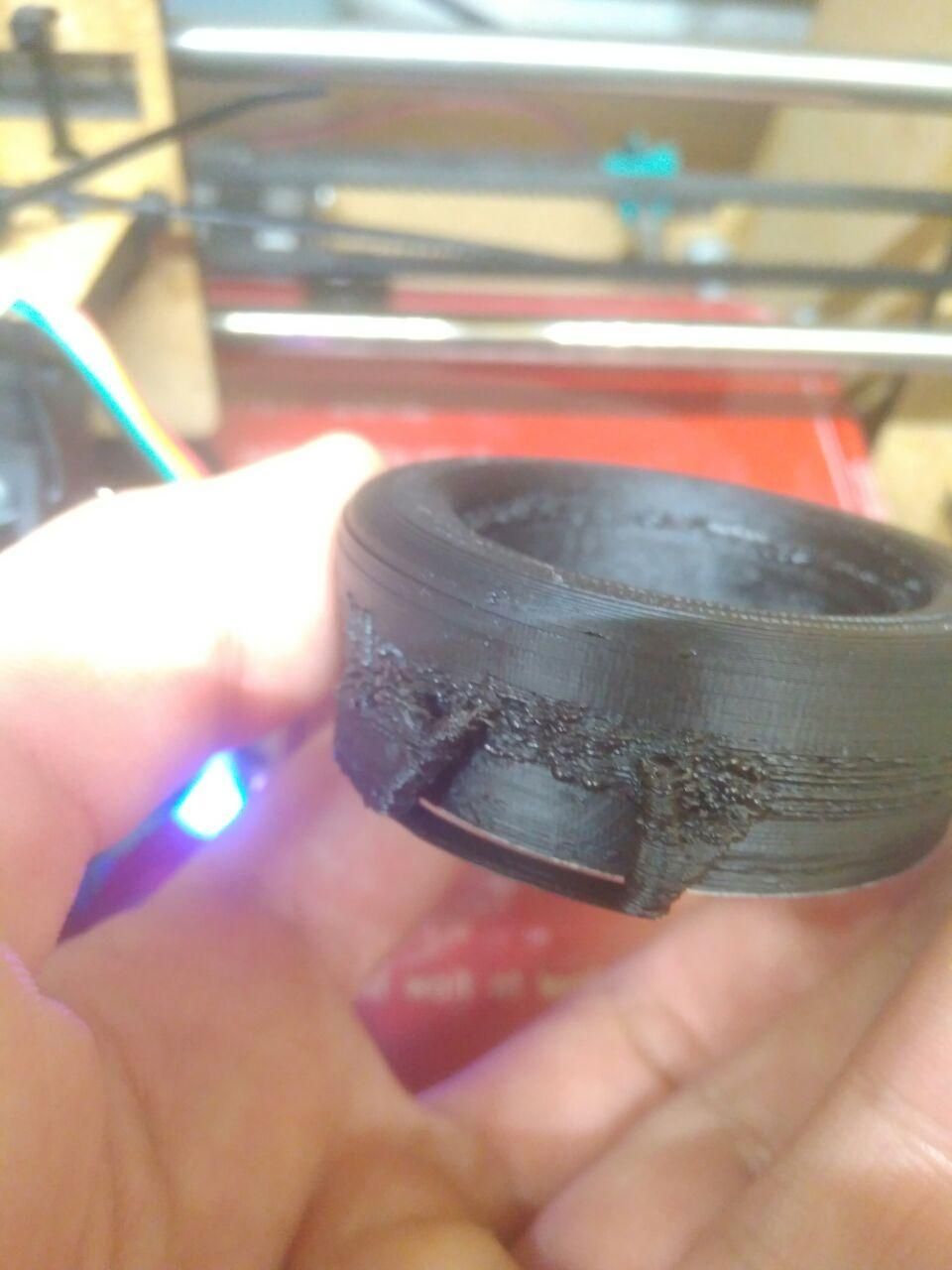

@LidaDida the extruder go crazy with pressure advance

I noticed another difference with marlin, that thin wall skin prints much slower. But I think, that is because of marlin use interpolation for accel calculations.

I also pushed up my currents so my motors could keep up better, but they soon got quite toasty...

Heh, my feeder now is under active cooling with 80mm fan

Personally, I prefer the single-walled cube method described on the Pressure Advance wiki for calibration

I prefer "print another calibration cube" method))

@Phaedrux said in Pressure advance quality issues:

In addition to the above two good suggestions you can try these settings

Increasing rather than decreasing? I will try that.

@Phaedrux said in Pressure advance quality issues:

Pressure advance and marlin's linear advance are not directly interchangeable.

For the marlin, I've used K=0.6. I've noticed, that PA also tries to compensate retracts. Because of that, every second PA post suggests reducing retraction. On marlin, I used an extra prime amount and wiping for this purpose.

Thanks to everyone for replies. Waiting for samples to be ready.