@fcwilt said in Help with new custom printer - Prints have ringing around them:

@mrawesome987 said in Help with new custom printer - Prints have ringing around them:

@jumpedwithbothfeet Just wanted to make sure both steppers are always synced. Is that a problem? It made sense when I designed it, is it overkill?

Coupling them with a belt like that is generally fine but I don't like to do it above a flexible coupler as it puts sideways forces on them they may not be designed to handle.

Have you tried it without the belt?

As to lead screws there can be a large difference between cheap Chinese ones and ones from other sources.

Example Lead Screw Specs

Notice in the chart from the link above they specify things like the accuracy of movement per turn.

Also this company has "good, better, best" offerings. - so to speak.

Frederick

Yes, one of my images above shows the difference with and without the belt tensioned. It was definitely a huge part of the problem, but the issue is still not 100% cured, which I attribute to the massively bent lead screws. I have ordered some solid couplers and am also getting replacement lead screws from the place I originally ordered them from. I am hopeful that they will be better, but if not, I'll order some from elsewhere. Thanks!

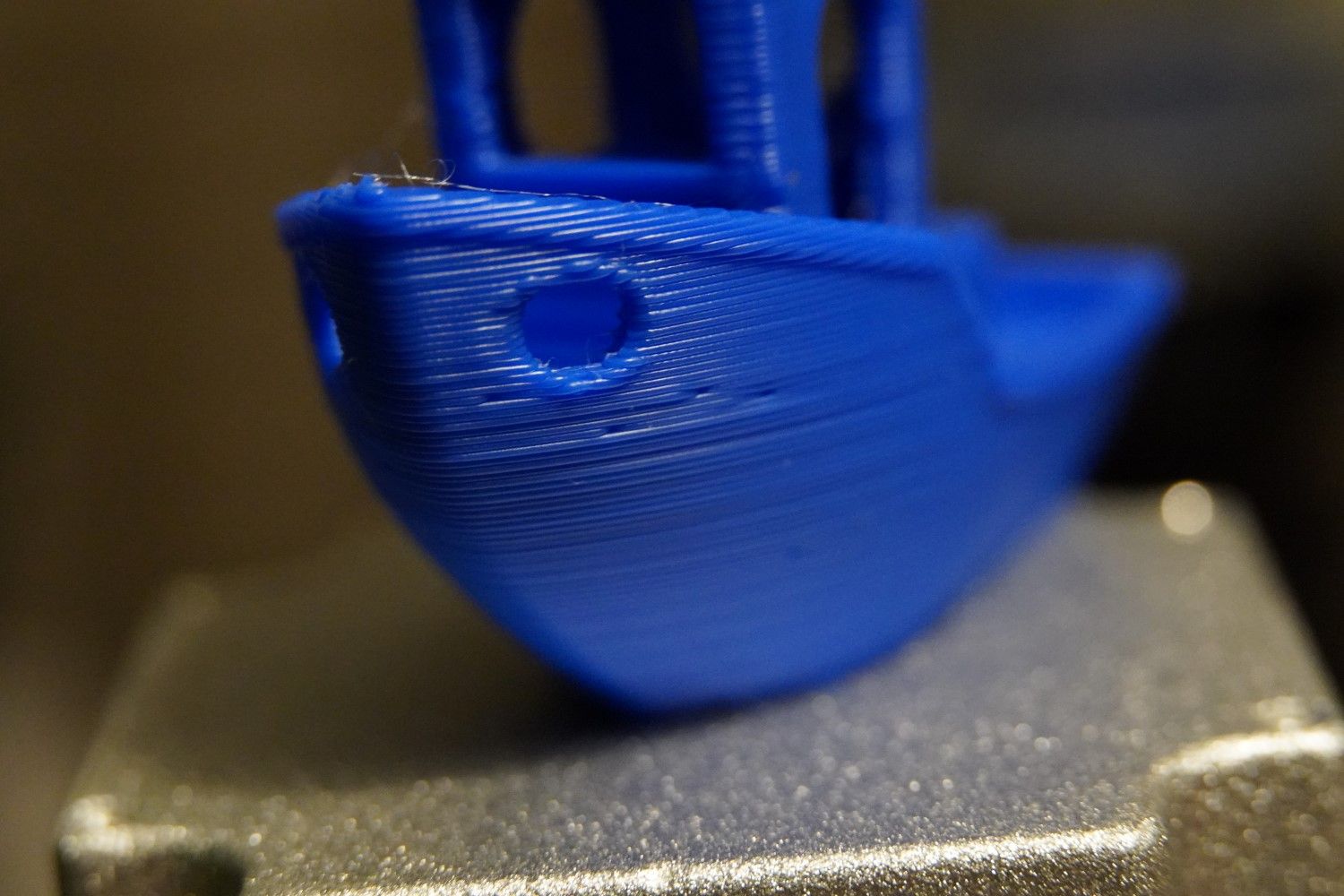

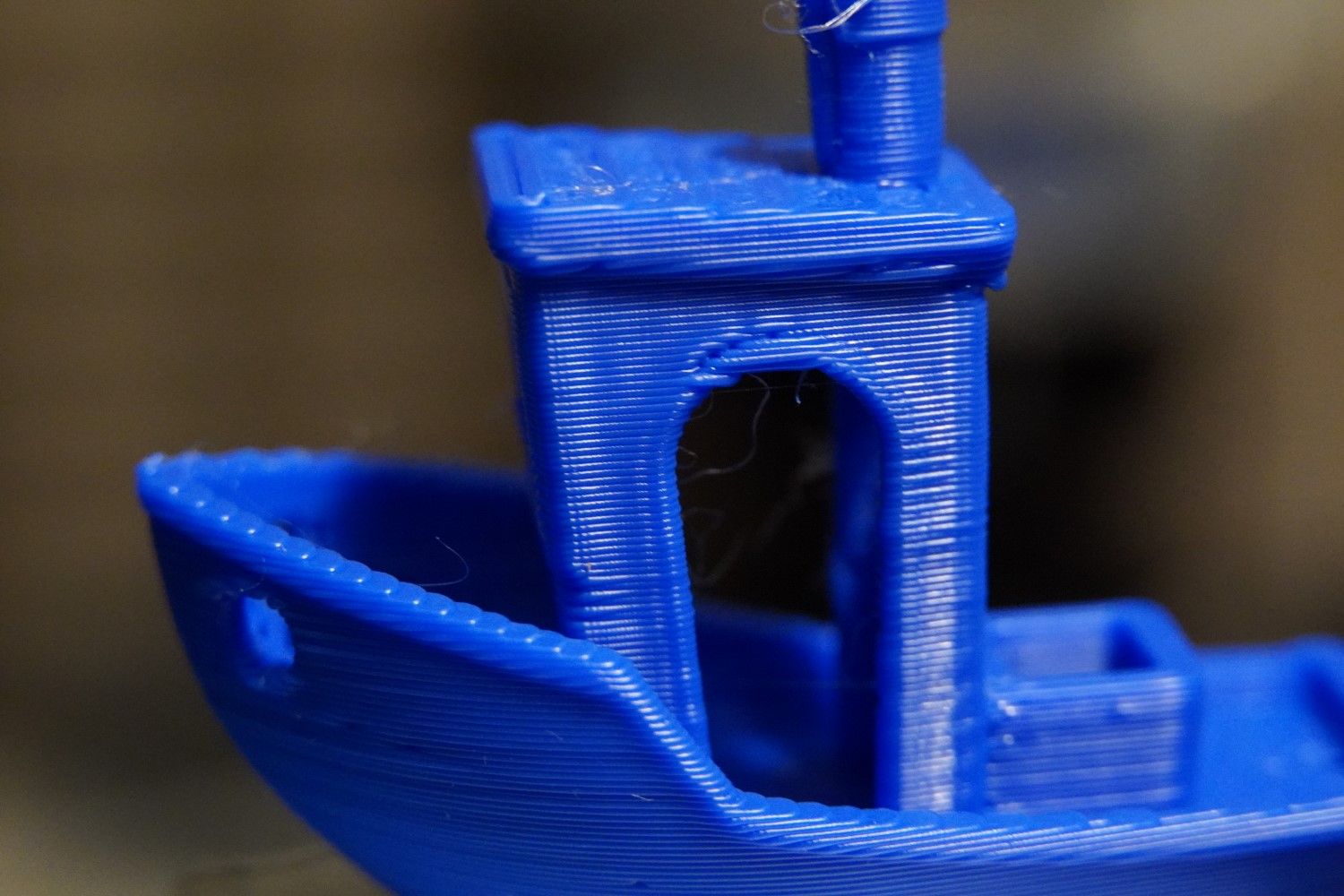

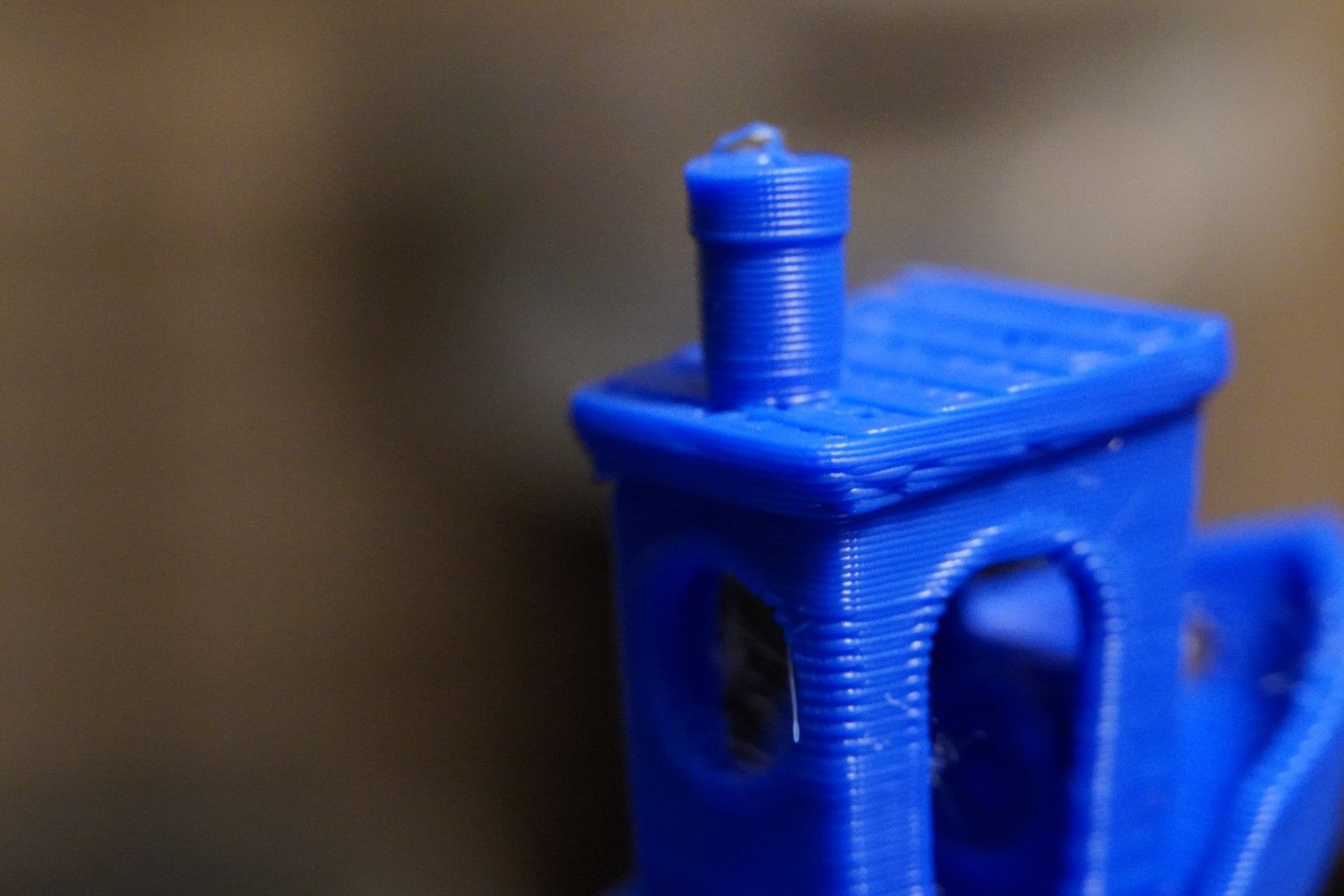

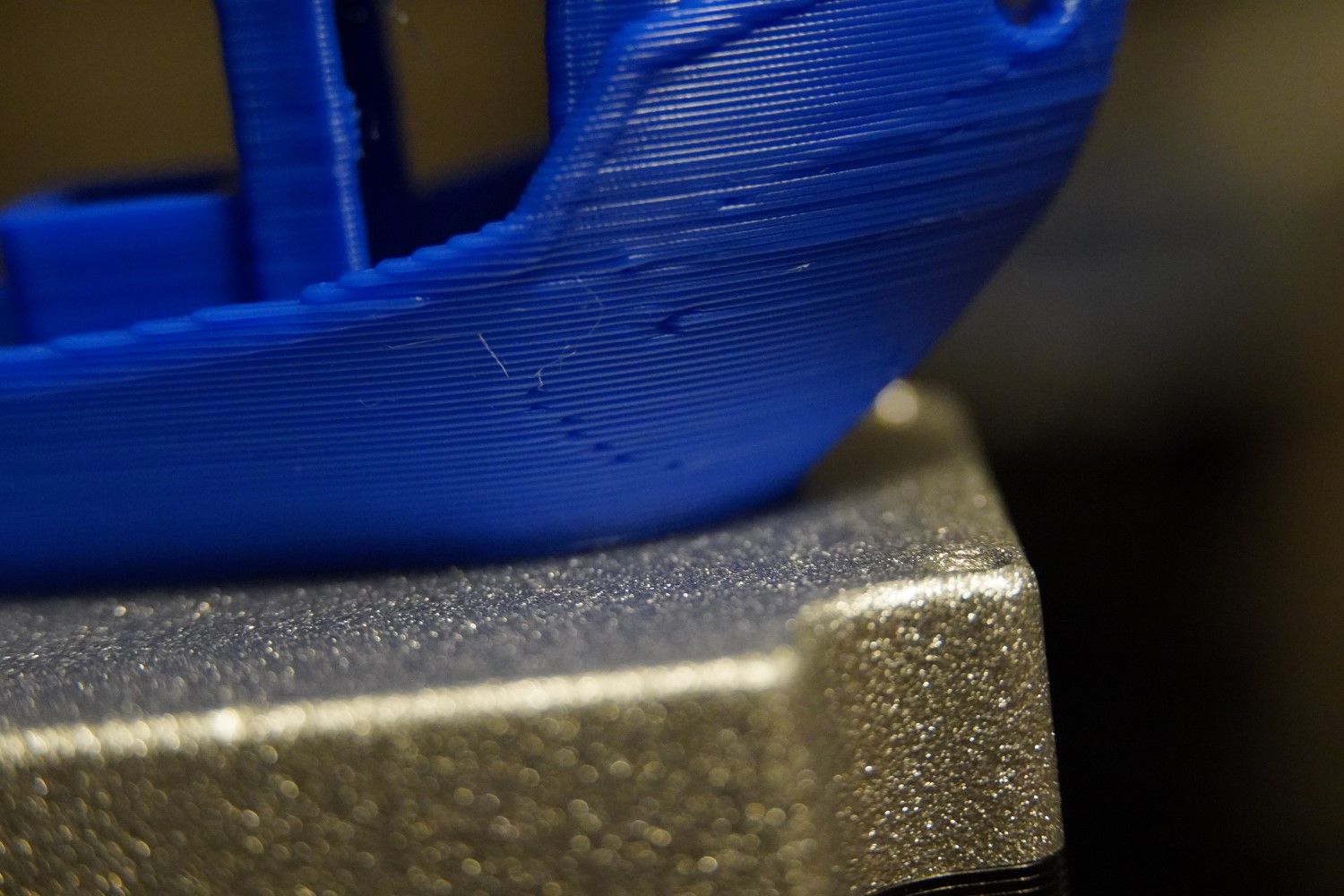

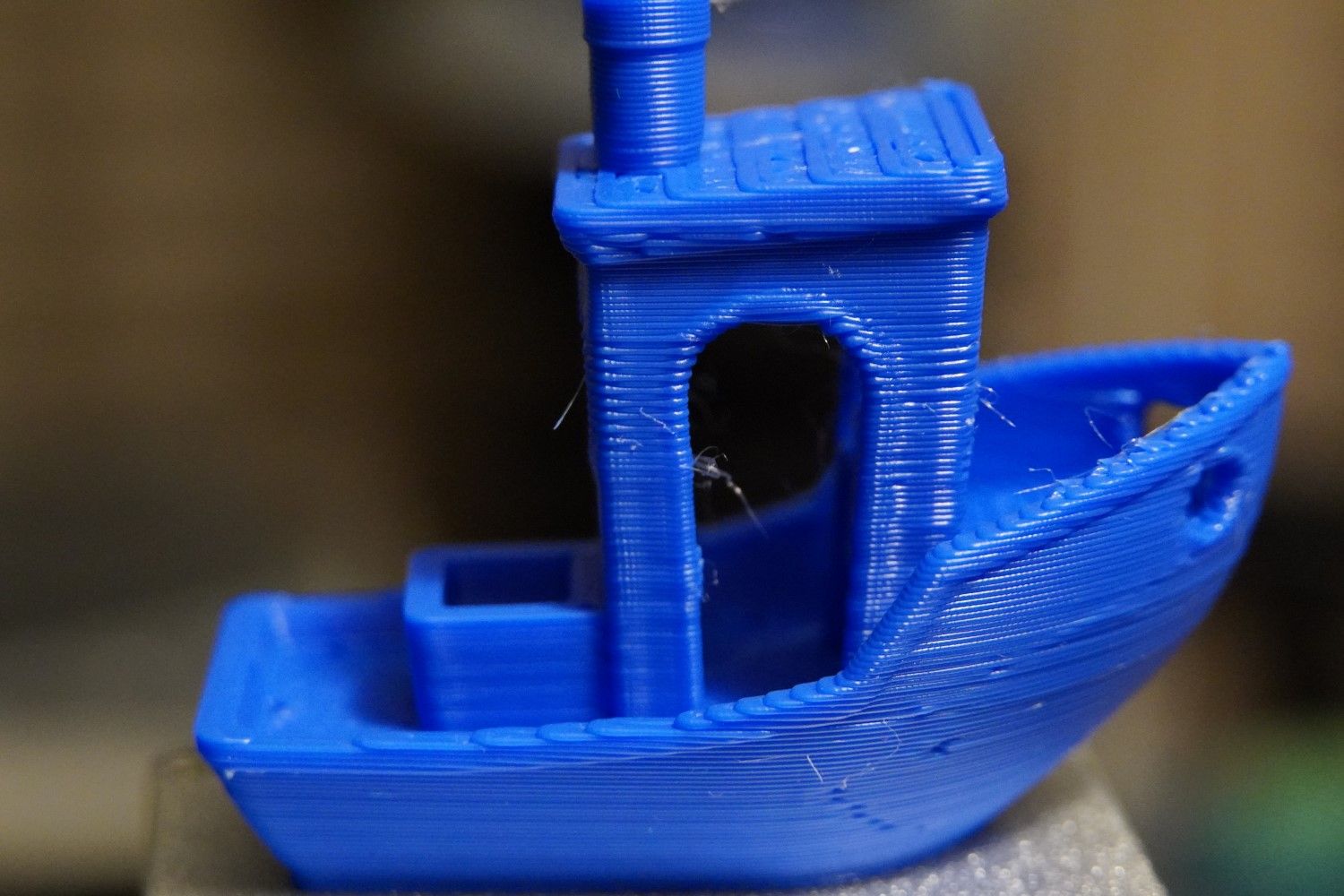

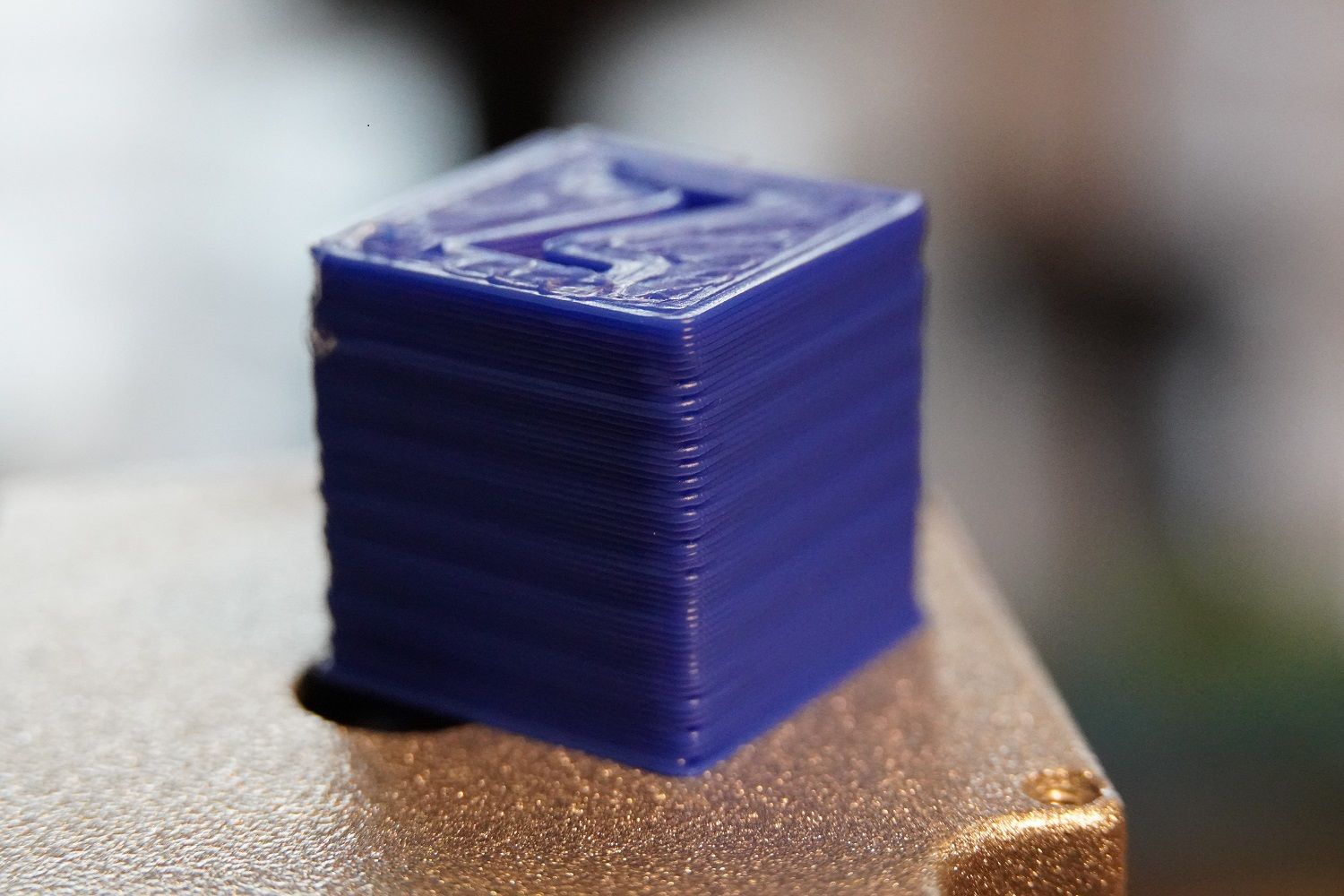

On my most recent XYZ cubes, I am still fighting the same quality issues, ignoring the Z wobble issue for now (since that's to blame on the lead screws). This is one of the most recent cubes:

I cant seem to get rid of the bad corners. I have tried both Pressure Advance (.025 up to .1), more retraction (currently at 2.5mm @ 3000mm/m), rotating the print on the bed (no real change), slower print (no change), etc.

Any suggestions?

Thanks!