Help with new custom printer - Prints have ringing around them

-

Hello everyone! I have been working on a big printer over the past few months and I just got it wired up and functional on this past Saturday.

It's a custom CoreXY design with a build volume of 490x490x875 (just missed my 500x500 lol).

Specs:

- Duet 2 Wifi

- Hermes with Volcano extruder and .8mm nozzle

- Nema 23 steppers

- 480w DC heated bed

- Linear rails for X and Y

- .1" pitch 1/2-10 lead screws for Z axis

- Etc (See photos)

The problem: I have been printing test prints by using the vase mode in S3d. I print the same 3x3x3 cube with no top or bottom layers. The sides of the prints have a fairly uniform ringing pattern on them.

I have been researching the problem on this forum and others and have tried a few things to narrow it down, but so far I have not solved the problem.

Things I've tried to resolve the issue:

-

Remove upper bearings from the top of the Z axis lead screws - Did not help much if at all

-

Loosen Z nuts so that they could float around in the brackets - Did nothing noticeable

-

Tighten X/Y belts - Did nothing noticeable

-

Watch Z motor mounts during a fast travel of the Z axis to see if they flex - Did not see any visual flexing

-

Realign Z axis rails. I loosened the rails at the back, and at the bottom, but left the front rails tight at the top. I then moved the Z axis up and down to allow the rails to position themselves, and then tightened the rear rails at the top, and moved the Z axis back down to the lower extreme and tightened all the rails at the bottom. - Did nothing noticeable to fix the ringing issue.

-

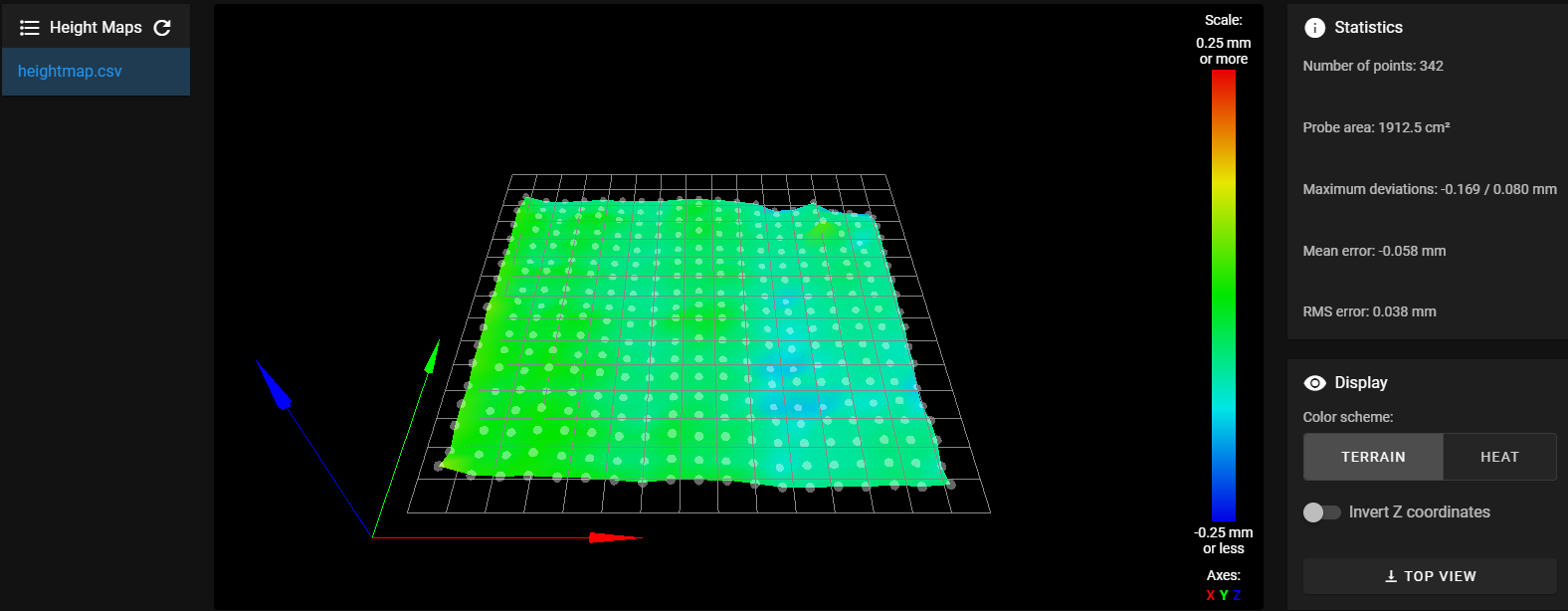

Fixed an issue where the bed frame was not even on the lead screws. Fixed it by taking the belt off, dropping the bed to the bottom so it rested on the top of my sync pullies and then put the belt back on. I then releveled my bed manually and ran G29 S0 to mesh level the bed. - Did nothing noticeable to fix the issue (but I do have a much better looking mesh now).

Notes:

- I know my lead screws are bent. I can visually see this when the bed is traveling up or down at a moderate pace.

- My lead screws are .1" pitch - which seems to be very similar to the distance between "rings" on my print.

- Even with the lead screws being bent, I don't see how they are causing the issue, because I removed all restraints from the threaded rod, therefore it can't produce much input on the bed side to side? The Z nuts have around .1" of freedom to move around in the bracket when not tightened down.

- While the printer is still, I can grab the bed frame and push/pull and can not feel any play in the movement at all.

- I can provide the config.g if that would help when I get home.

Pictures of the printer:

I appreciate any help or advice. Thanks! Daniel

Edit: Added mesh bed level picture.

-

@mrawesome987 I would say that you have given the right answer by yourself

I know my lead screws are bent. I can visually see this when the bed is traveling up or down at a moderate pace.This can give a Z-Wobble as shown on your picture

-

@mrawesome987 If you don't mind me asking what`s the purpose of the belt on the Z axis when you have two stepper motors on two lead screws? bed sag?

-

@jumpedwithbothfeet Just wanted to make sure both steppers are always synced. Is that a problem? It made sense when I designed it, is it overkill?

-

@siam I agree, it is likely the culprit, I just wanted to check with you guys before spending anything on replacement rods.

Do these often come bent like this? These were brand new when I purchased them.

-

@mrawesome987 I'm no way qualified to answer that to be honest, but I did run a very similar set up (without the belt) I didn't have any issues in that regard, I have had the same problem you have though but with 3 lead screws and that was because I hadn`t constrained my bed well enough.

Are your lead screws bent when not attached to the machine? i.e roll them on a flat surface and watch for wobble if they are good check for alignment issues on your printer.

-

@mrawesome987 said in Help with new custom printer - Prints have ringing around them:

Do these often come bent like this?

If they came from China, yes! I recommend ballscrews (not from China) these are not cheap, but it saves a lot of frustration.

-

@jumpedwithbothfeet Good suggestion. I will check this.

-

@siam Can you recommend a reputable place to purchase these? I may be willing to invest in some. Thanks!

-

@mrawesome987 I don't think that this will help you because is a German supplier I have my three ballscrews from https://www.dold-mechatronik.de/SFU1204-Standarbearbeitung

-

@mrawesome987 I noticed your using a flex coupling on at least one of your z stepper motors, good possibility that z belt of yours might be pulling the leadscrew out of alignment, worth checking with a print and the belt removed?

-

@jumpedwithbothfeet said in Help with new custom printer - Prints have ringing around them:

@mrawesome987 I noticed your using a flex coupling on at least one of your z stepper motors, good possibility that z belt of yours might be pulling the leadscrew out of alignment, worth checking with a print and the belt removed?

This is a good idea... I have not tried this, so I will do that! Thanks!

-

I think your Z linear rods are not suitable for this or may get out of aligment easy. I would use full cylindrival bushings and roind rods

-

@mrawesome987 there could be additional reasons than discussed before

- leadscrews being bent as discussed

- the 4 supported shafts may have too high load, so pressure is built up and moves the bed sometimes

- leadscrews can have different pitch (1/100 mm differences), so the bed is tilted a bit and builds pressure and releases it

A test would be to loosen 3 of the 4 shafts a bit (or the screws between organge part and aluminium extrusion) and check whether ringing is less then.

-

@martin7404 said in Help with new custom printer - Prints have ringing around them:

I think your Z linear rods are not suitable for this or may get out of aligment easy. I would use full cylindrival bushings and roind rods

I had not thought of this. Could you explain your thinking? The bed frame feels tight, and does not have any noticeable play in the X and Y axis. Thanks!

-

@jumpedwithbothfeet said in Help with new custom printer - Prints have ringing around them:

I noticed your using a flex coupling on at least one of your z stepper motors, good possibility that z belt of yours might be pulling the leadscrew out of alignment, worth checking with a print and the belt removed?

Just printed the same file but removed the Z sync belt. Results are MUCH better! Here's a before and after in the same lighting:

I'd say the issue is almost completely resolved, however, I think I am going to make a few adjustments to my design for permanent use.

- Replace the lead screws with a better quality screw. Researching this now to find the best cost effective option. I looked at ball screws, but I don't think I can fit 1m ball screws in the budget right now. I am currently looking at Misumi screws. Are these of good quality for 3d printing?

- Replace the flexible shaft couplings with solid couplings.

- Design some sort of bearing mount for the top of the shaft that will allow the shaft to move slightly incase things aren't perfectly lined up.

Does anyone have any other suggestions or advice? Thanks again for all your help.

-

If haven't PID tuned your bed heater yet, now is the time. Bang bang controlled heating can cause enough expansion and reduction of the bed heater that you will get z banding artifacts.

-

This post is deleted! -

@mrawesome987 well this type of linear guide uses C shaped bushings and as far the rods are mounted on Aluprofile that is not straight in terms of hundreds of millimeter , so they can go slightly out of alignment .

-

@mrawesome987 glad you found the problem, it is looking a lot better

do the lead screws still appear bent as they move on the machine? or has that gone now? as @oliof has suggested a bed PID tune is next it`s easy and most importantly free to do!

do the lead screws still appear bent as they move on the machine? or has that gone now? as @oliof has suggested a bed PID tune is next it`s easy and most importantly free to do!