@carl I'm the chap who builds the MagBall Arms.

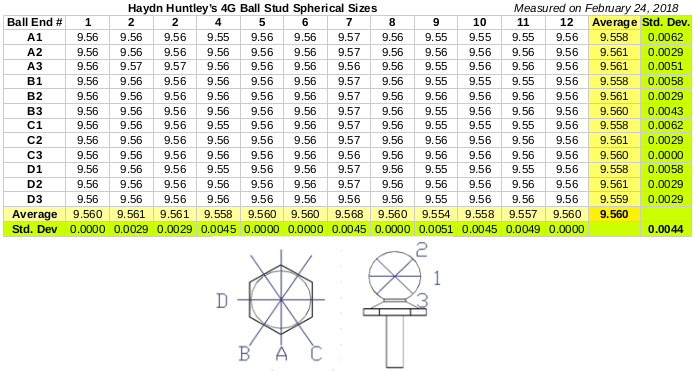

They are guaranteed to match within 50 microns. It looks like your set of six matched within 10 microns, which is pretty darned good!

You should split the difference tell your firmware that the length of your arms is the average: 288.065mm

Usually when people are printing the first layer, they can tolerate a variation of 200-300 microns over the surface of the bed, so ~5 microns is pretty small in comparison to that.

The most important features of the arms are that they are zero backlash and that the arms are the same length. Because they use ball-and-socket joints, it doesn't matter if the Delrin rod ends aren't perfectly co-linear with the carbon fiber.

You can demonstrate this for yourself by placing a sheet of paper on your print bed, commanding the tip of the nozzle to (x=0, y=0, z=0.1) and then trying to slide the paper. You should feel a small amount of friction. Now use your fingers to rotate any of the arms, and recheck the paper -- you'll notice that the friction is the same, because the length of the arms didn't change. This is what is important.

If you want to have fun, you can swap two arms, and you should still see that the friction on the paper is about the same.

I've experimented with a bunch of different jigs, and if I constrain things too much, then the accuracy of the lengths suffers. So that is why there is sometimes a slight lack of co-linearity between the Delrin and carbon fiber, however it doesn't affect the printing quality.

So, yes, it is within normal limits.

If you're upset by it due to aesthetic reasons, contact me directly, and I can build you a custom set of out 10mm CF tubing, and those always turn out perfectly straight.

I really try my best to make sure that every customer receives an excellent set of arms!