Hello everyone,

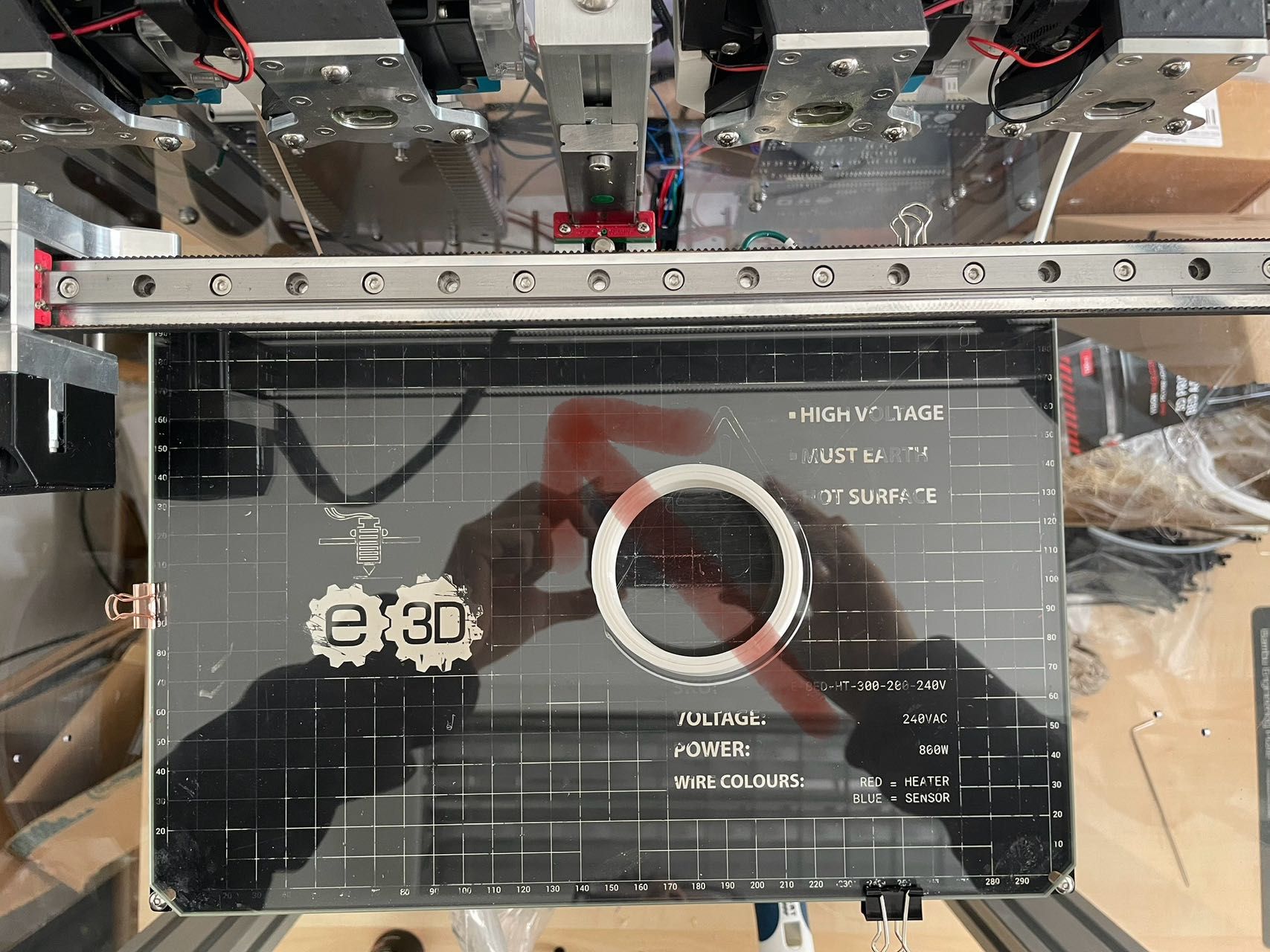

I replaced the PT1000 temperature sensor for my higher power heat cartridges, but after connecting it, the sensor incorrectly reads the temperature as 158 degrees at room temperature.

my hardware is DUET2WIFI with the newest firmware.

here is my config:

; Configuration file for Duet WiFi / Ethernet running RRF3 on E3D Tool Changer

; executed by the firmware on start-up

; General preferences

M111 S0 ; Debugging off

G21 ; Work in millimetres

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

M555 P2 ; Set firmware compatibility to look like Marlin

M667 S1 ; Select CoreXY mode

; Network

M550 P"ToolChanger" ; Set machine name

;M587 S"ssid" P"password" ; WiFi Settings

;M552 S1 P"ssid" ; Enable WiFi Networking

M552 S1 ; Enable Networking

M586 P0 S1 ; Enable HTTP

M586 P1 S0 ; Disable FTP

M586 P2 S0 ; Disable Telnet

; Drive direction

M569 P0 S0 ; Drive 0 X

M569 P1 S0 ; Drive 1 Y

M569 P2 S1 ; Drive 2 Z

M569 P3 S1 ; Drive 3 E0

M569 P4 S1 ; Drive 4 E1

M569 P5 S1 ; Drive 5 E2

M569 P6 S1 ; Drive 6 E3

M569 P7 S0 ; Drive 7 COUPLER

M569 P8 S0 ; Drive 8 UNUSED

M569 P9 S0 ; Drive 9 UNUSED

M584 X0 Y1 Z2 C7 E3:4:5:6 ; Apply custom drive mapping

M208 X-35:328.5 Y-49:243 Z0:300 C-45:360 ; Set axis maxima & minima

M92 X100 Y100 Z800 C91.022 E397:397:397:397 ; Set steps per mm assuming x16 microstepping

M350 E16:16:16:16 I1 ; Configure microstepping with interpolation

M350 C16 I10 ; Configure microstepping without interpolation

M350 X16 Y16 Z16 I1 ; Configure microstepping with interpolation

M566 X400 Y400 Z8 C2 E2:2:2:2 ; Set maximum instantaneous speed changes (mm/min)

M203 X35000 Y35000 Z1200 C5000 E5000:5000:5000:5000 ; Set maximum speeds (mm/min)

M201 X6000 Y6000 Z400 C500 E2500:2500:2500:2500 ; Set accelerations (mm/s^2)

M906 X1800 Y1800 Z1330 I30 ; Idle motion motors to 30%

M906 E1000:1000:1000:1000 C500 I10 ; Idle extruder motors to 10%

; Endstops

M574 X1 Y1 S3 ; Set X / Y endstop stall detection

M574 C0 Z0 ; No C Z endstop

; Z probe

M558 P8 C"zstop" H3 F360 I0 T20000 ; Set Z probe type to switch, the axes for which it is used and the dive height + speeds

G31 P200 X0 Y0 Z0 ; Set Z probe trigger value, offset and trigger height

M557 X10:290 Y20:180 S40 ; Define mesh grid

;Stall Detection

M915 X Y S3 F0 H400 R4700 ; X / Y Axes

; Heaters

M308 S0 P"bedtemp" Y"thermistor" A"Bed" T100000 B4138 C0 ; Set thermistor

M950 H0 C"bedheat" T0 ; Bed heater

M143 H0 S225 ; Set temperature limit for heater 0 to 225C

M140 H0 ; Bed heater is heater 0

M308 S1 P"e0temp" Y"thermistor" A"T0" T100000 B4725 C7.06e-8 ; Set thermistor

M950 H1 C"e0heat" T1 ; Extruder 0 heater

M143 H1 S305 ; Set temperature limit for heater 1 to 300C

M308 S2 P"e1temp" Y"thermistor" A"T1" T100000 B4725 C7.06e-8 ; Set thermistor

M950 H2 C"e1heat" T2 ; Extruder 0 heater

M143 H2 S305 ; Set temperature limit for heater 2 to 300C

M308 S3 P"e2temp" Y"thermistor" A"T2" T100000 B4725 C7.06e-8 ; Set thermistor

M950 H3 C"duex.e2heat" T3 ; Extruder 0 heater

M143 H3 S305 ; Set temperature limit for heater 3 to 300C

M308 S4 P"e3temp" Y"thermistor" A"T3" T100000 B4725 C7.06e-8 ; Set thermistor

M950 H4 C"duex.e3heat" T4 ; Extruder 0 heater

M143 H4 S305 ; Set temperature limit for heater 4 to 300C

; Tools

M563 P0 S"T0" D0 H1 F2 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Reset tool 0 axis offsets

G10 P0 R0 S0 ; Reset initial tool 0 active and standby temperatures to 0C

M563 P1 S"T1" D1 H2 F4 ; Define tool 1

G10 P1 X0 Y0 Z0 ; Reset tool 1 axis offsets

G10 P1 R0 S0 ; Reset initial tool 1 active and standby temperatures to 0C

M563 P2 S"T2" D2 H3 F6 ; Define tool 2

G10 P2 X0 Y0 Z0 ; Reset tool 2 axis offsets

G10 P2 R0 S0 ; Reset initial tool 2 active and standby temperatures to 0C

M563 P3 S"T3" D3 H4 F8 ; Define tool 3

G10 P3 X0 Y0 Z0 ; Reset tool 3 axis offsets

G10 P3 R0 S0 ; Reset initial tool 3 active and standby temperatures to 0C

; Fans

M950 F1 C"fan1"

M950 F2 C"fan2"

M950 F3 C"duex.fan3"

M950 F4 C"duex.fan4"

M950 F5 C"duex.fan5"

M950 F6 C"duex.fan6"

M950 F7 C"duex.fan7"

M950 F8 C"duex.fan8"

M106 P1 S255 H1 T70 ; T0 HE

M106 P2 S0 ; T0 PCF

M106 P3 S255 H2 T70 ; T1 HE

M106 P4 S0 ; T1 PCF

M106 P5 S255 H3 T70 ; T2 HE

M106 P6 S0 ; T2 PCF

M106 P7 S255 H4 T70 ; T3 HE

M106 P8 S0 ; T3 PCF

;M593 F42.2 ; cancel ringing at 42.2Hz (https://forum.e3d-online.com/threads/accelerometer-and-resonance-measurements-of-the-motion-system.3445/)

;M376 H15 ; bed compensation taper

;tool offsets

; !ESTIMATED! offsets for:

; V6-tool: X-9 Y39 Z-5

; Volcano-tool: X-9 Y39 Z-13.5

; Hemera-tool: X20 Y43.5 Z-6

G10 P0 X-9 Y39 Z-6.25 ; T0

G10 P1 X-9 Y39 Z-5 ; T1

G10 P2 X-9 Y39 Z-5 ; T2

G10 P3 X-9 Y39 Z-5 ; T3

;M572 D0 S0.2 ; pressure advance T0

;M572 D1 S0.2 ; pressure advance T1

;M572 D2 S0.2 ; pressure advance T2

;M572 D3 S0.2 ; pressure advance T3

M575 P1 S1 B57600 ; Enable LCD

G29 S2 ; disable mesh

T-1 ; deselect tools

M501 ; load config-override.g

and the anwser of command 308:

M308 S4

Sensor 4 (T3) type Thermistor using pin (e3temp,duex.e3temp,exp.thermistor4,exp.36), reading 158.5, last error: sensor open circuit, T:100000.0 B:4725.0 C:7.06e-8 R:2200.0 L:0 H:0

If anyone has any ideas or solutions, please let me know. Thank you very much :):):)