@Inlinebrother

I'm working on it with an Duet2 Ethernet and RRF.

For startingpoint I used https://github.com/pfn/EnragedRabbitOnRRF.

Assambly is already finished, loading and unloading is working.

First testprint still waiting for time unfortunataly.

Best posts made by AlexKid

-

RE: Adding support for the enraged rabbit carrot feeder (ERCF)posted in Accessories and Add-ons

-

RE: randomly reconnect of DWC on Duet2 Ethernetposted in Duet Hardware and wiring

@chrishamm I'm running RRF 3.5.4 now for several weeks. The issue is no longer present. I also updated PanelDue today to 3.5.1 and it still seams to be stable.

I would suggeset to close this topic. -

RE: Adding support for the enraged rabbit carrot feeder (ERCF)posted in Accessories and Add-ons

@Inlinebrother printing and filament change is working. Struggling with the servo, sometimes it will not engage completely. Will try to provide 6V instead of 5V power this should result in ~500g more force. If you are still interested in this topic you can contact me.

-

RE: randomly reconnect of DWC on Duet2 Ethernetposted in Duet Hardware and wiring

@T3P3Tony

I will install the beta and provide feedback

Latest posts made by AlexKid

-

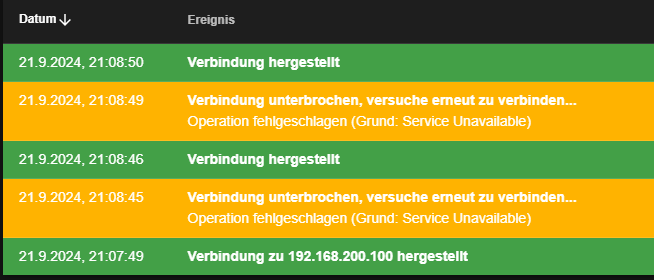

RE: randomly reconnect of DWC on Duet2 Ethernetposted in Duet Hardware and wiring

Hi @T3P3Tony,

installed 3.6.0 Beta 3.

I can no longer access the webinterface.

Paneldue is very slow

It was not a good idea to install the beta version

-

RE: randomly reconnect of DWC on Duet2 Ethernetposted in Duet Hardware and wiring

@T3P3Tony

I will install the beta and provide feedback -

RE: randomly reconnect of DWC on Duet2 Ethernetposted in Duet Hardware and wiring

@chrishamm I'm running RRF 3.5.4 now for several weeks. The issue is no longer present. I also updated PanelDue today to 3.5.1 and it still seams to be stable.

I would suggeset to close this topic. -

RE: Adding support for the enraged rabbit carrot feeder (ERCF)posted in Accessories and Add-ons

@Inlinebrother printing and filament change is working. Struggling with the servo, sometimes it will not engage completely. Will try to provide 6V instead of 5V power this should result in ~500g more force. If you are still interested in this topic you can contact me.

-

RE: Adding support for the enraged rabbit carrot feeder (ERCF)posted in Accessories and Add-ons

@Inlinebrother

I'm working on it with an Duet2 Ethernet and RRF.

For startingpoint I usedhttps://github.com/pfn/EnragedRabbitOnRRF.

Assambly is already finished, loading and unloading is working.

First testprint still waiting for time unfortunataly. -

RE: randomly reconnect of DWC on Duet2 Ethernetposted in Duet Hardware and wiring

@chrishamm

unfortunately this does not help.

lots of reconnects with active DWC and performing homing of all axis via Panel Due

also increased Baudrate to 115200 -

RE: randomly reconnect of DWC on Duet2 Ethernetposted in Duet Hardware and wiring

G90 ; send absolute coordinates... M83 ; ...but relative extruder moves M550 P"Muldex" ; set printer name ; Network M552 S1 P192.168.200.100 ; enable network M586 P0 S1 ; enable HTTP M586 P1 S1 ; enable FTP M586 P2 S0 ; disable Telnet ; Drives M569 P0 S0 ; X physical drive 0 goes backwards M569 P1 S1 ; Y right physical drive 1 goes forwards M569 P2 S0 ; Y left physical drive 2 goes backwards M569 P3 S1 ; U physical drive 3 goes forwords M569 P4 S0 ; E1 physical drive 4 goes backwords M569 P5 S1 ; Z left physical drive 5 goes backwards M569 P6 S1 ; Z center physical drive 6 goes backwards M569 P7 S0 ; Z right physical drive 7 goes forwards M569 P8 S1 ; E2 physical drive 8 goes backwords M584 X0 Y1:2 U3 Z5:6:7 E4:8 ; set drive mapping M350 X16 U16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation M92 X100.00 U100.00 Y100.00 Z1120 E415.00:415.00 ; set steps per mm (1760nimble) M566 X1000.00 U1000.00 Y1000.00 Z100.00 E100.00:300.00 ; set maximum instantaneous speed changes (mm/min)(Nimble 40) M203 X12000.00 U12000.00 Y12000.00 Z2000.00 E4200.00:4200.00 ; set maximum speeds (mm/min) M201 X15000.00 U15000.00 Y15000.00 Z100.00 E2000.00:2000.00 ; set accelerations (mm/s^2)(500)(Nimble 120) M906 X1500 U1500 Y1500 Z1000 E800:800 I30 ; set motor currents (mA) and motor idle factor in per cent(Nimble 500) M84 S30 ; Set idle timeout ; Axis Limits M208 X-21.4:355 Y0:323 U41:419.3 Z0:300 ; set axis min was (-18 BMG)16.7_X-14.4 Y0 U40 Z0 S1 ;M208 X344 U413.75 Y334 Z300 S0 ; set axis max Y WAS 339_X350 U422.7 Y334 Z300 S0(u414.75) M669 K0 Y1:1:0:1 ; select Markforged Kinematics Y to react with X and U ; Endstops M574 X1 S1 P"xstop" ; X axis active high endstop switch M574 Y2 S1 P"ystop+zstop" ; Y Double max active high endstop switch M574 U2 S1 P"duex.e2stop" ; U axis active high endstop switch M574 Z1 S2 ; Define Z to use Probe. Home to Min. ; Filament Sensor ;M591 D0 P3 C"e0stop" S0 R70:130 L24.8 E3.0 ; Duet3D rotating magnet sensor for extruder drive 0 is connected to E0 endstop input, enabled, sensitivity 24.8mm.rev, 70% to 130% tolerance, 3mm detection length ;M591 D1 P3 C"e1stop" S0 R70:130 L24.8 E3.0 ; Duet3D rotating magnet sensor for extruder drive 0 is connected to E0 endstop input, enabled, sensitivity 24.8mm.rev, 70% to 130% tolerance, 3mm detection length ;M591 D0 ; display filament sensor parameters for extruder drive 0 ;M591 D1 ; display filament sensor parameters for extruder drive 0 ; Z-Probe ;M307 H7 A-1 C-1 D-1 ; Disable the 6th Heater to free up PWM channel 5 on the Duex board. M671 X-20.6:200:420.6 Y14.3:333.3:14.3 S5 ; Locations left, center, right M950 S0 C"duex.e6heat" ; create servo pin 0 for BLTouch M558 K0 P9 C"^zprobe.in" H5 F120 T6000 R0.005 ; set Z probe type to bltouch and the dive height + speeds (WAS 9000) ;M558 P9 C"^zprobe.in H5 F120 T6000 R0.5 A10 G31 P500 X-29 Y0 Z2.61 ; set Z probe trigger value, offset and trigger height(lower number farther away)1.55glass 1.62 Build M557 X10:326 Y10:290 S20 ; probe from X=10 to 390, Y=10 to 290mm with a mesh spacing of 20mm ; Heaters M308 S0 P"bedtemp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 0 as thermistor on pin bedtemp M950 H0 C"bedheat" T0 ; create bed heater output on bedheat and map it to sensor 0 M143 H0 S120 ; set temperature limit for heater 0 to 120C M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit M140 H0 ; map heated bed to heater 0 M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 1 as thermistor on pin e0temp M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1 M143 H1 S280 ; set temperature limit for heater 1 to 280C M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit M308 S2 P"e1temp" Y"thermistor" T100000 B4725 C7.06e-8 ; configure sensor 2 as thermistor on pin e1temp M950 H2 C"e1heat" T2 ; create nozzle heater output on e1heat and map it to sensor 2 M143 H2 S280 ; set temperature limit for heater 2 to 280C M307 H2 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit ; Fans M950 F0 C"fan0" Q500 ; create fan 0 on pin fan0 and set its frequency M106 P0 S0 H-1 ; set fan 0 value. Thermostatic control is turned off M950 F1 C"fan1" Q500 ; create fan 1 on pin fan1 and set its frequency M106 P1 S1 H1 T45 ; set fan 1 value. Thermostatic control is turned on M950 F2 C"fan2" Q500 ; create fan 2 on pin fan2 and set its frequency M106 P2 S0 H-1 ; set fan 2 value. Thermostatic control is turned off M950 F3 C"duex.fan8" Q500 ; create fan 3 on pin duex.fan8 and set its frequency M106 P3 S1 H2 T45 ; set fan 3 value. Thermostatic control is turned on ; LEDs M950 F4 C"duex.fan6" ;Q500 ; create LED 4 on pin duex.fan6 and set its frequency M106 P4 S0 H-1 ; set LED 4 value. Thermostatic control is turned OFF M950 F5 C"duex.fan7" ;Q500 ; create LED 5 on pin duex.fan7 and set its frequency M106 P5 S0 H-1 ; set LED 5 value. Thermostatic control is turned OFF ; Tools M563 P0 D0 H1 F0 S"Left" ; define tool 0 Left G10 P0 X0 Y0 Z0 ; set tool 0 axis offsets y was .45 G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C M207 S10.0 F400 ; set Firmware Retraction M563 P1 D1 H2 X3 F2 S"Right" ; define tool 1 Right G10 P1 X0 Y0 Z0 ; set tool 1 axis offsets (.5BMG) (-1.45) G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C M207 S10.0 F400 ; set Firmware Retraction M563 P2 D0:1 H1:2 X0:3 F0:2 S"Copy" ; define tool 2 Copy G10 P2 X95 Y0 U-95 S0 R0 ; set tool 2 axis offsets (WAS 105) M567 P2 E1:1 M568 P2 S1 ; turn on mixing for tool 2 ; set mix ratio 100% on both extruders M501 ; Record M575 P1 S1 B57600 ;Panel due -

RE: randomly reconnect of DWC on Duet2 Ethernetposted in Duet Hardware and wiring

@Phaedrux

No this only happens when a message on printer display is shown (see first post).

I searched the forum and found https://forum.duet3d.com/topic/36277/many-problems-with-3-5-2/18?_=1727095288513

for me it is the same issue. -

RE: Many problems with 3.5.2posted in Firmware installation

Looks and sounds like the same issue I have.

https://forum.duet3d.com/topic/36643/randomly-reconnect-of-dwc-on-duet2-ethernet?_=1727016238232 isn't it? Started with 3.5.2 and also present with 3.5.3. -

RE: randomly reconnect of DWC on Duet2 Ethernetposted in Duet Hardware and wiring

you are right, I uploaded a new one.