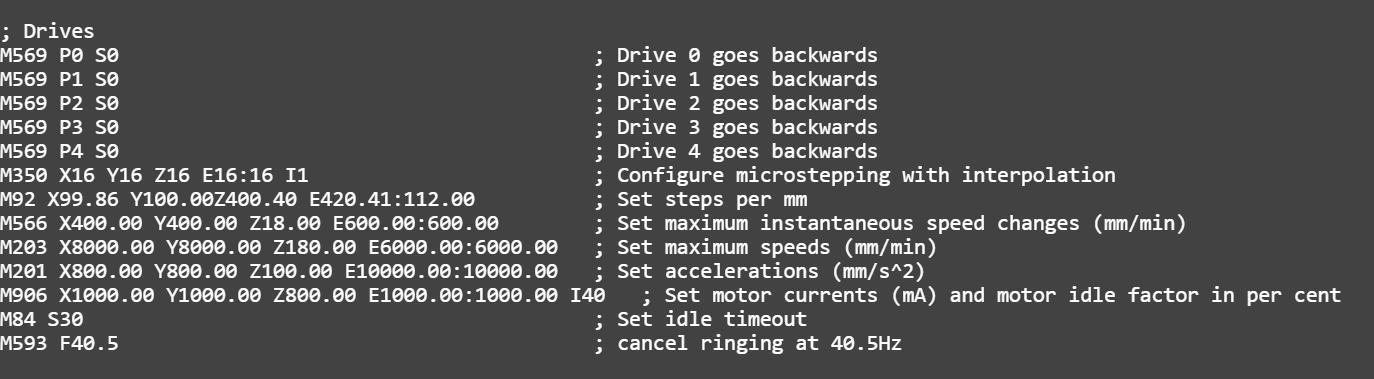

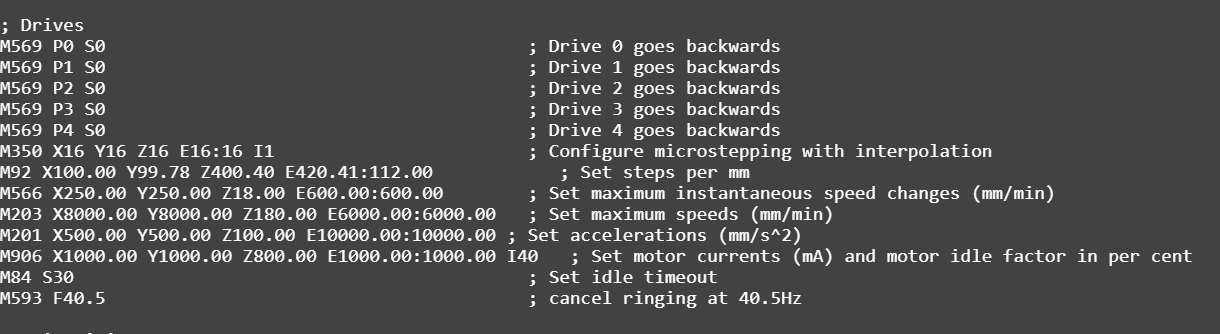

It's hard to tell, but I am still having some trouble. I think at this point it's just the frame. Here is a before and after snip from my config.

It's hard to tell, but I am still having some trouble. I think at this point it's just the frame. Here is a before and after snip from my config.

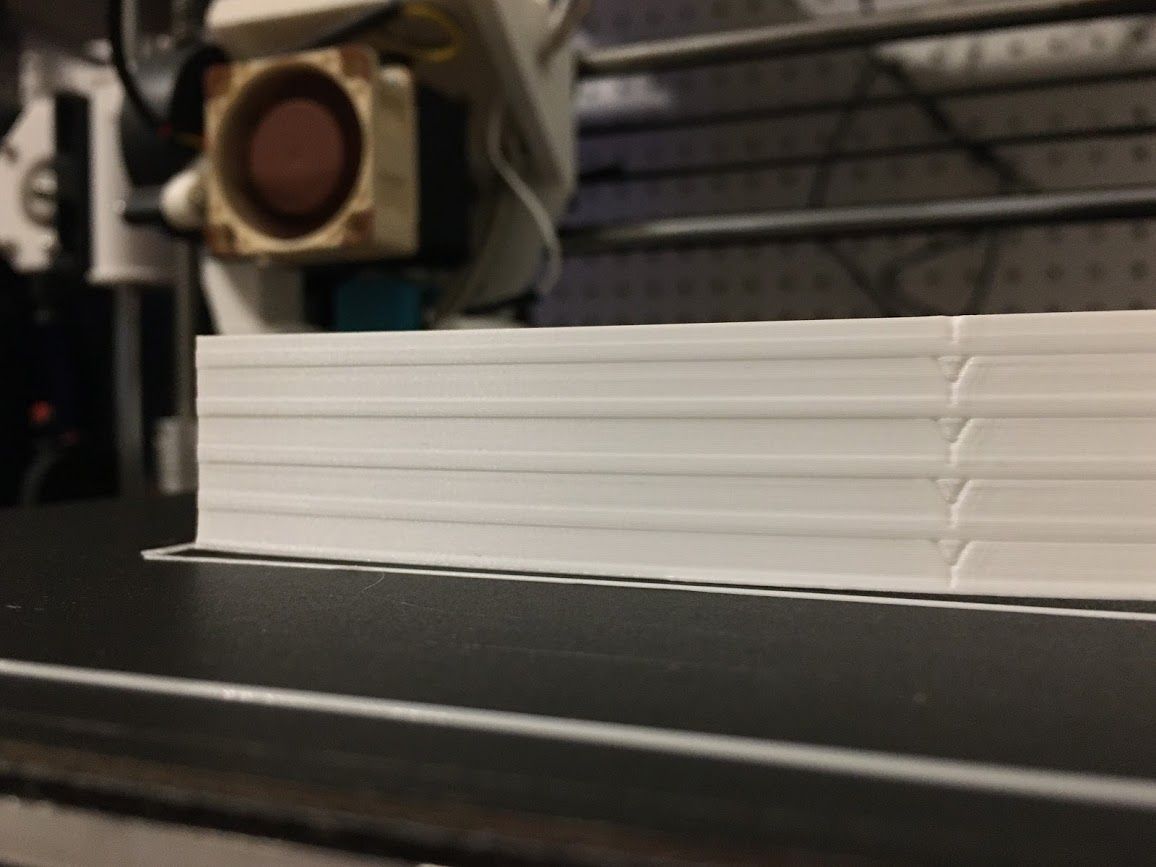

I think that brace is what's helping. At the start of the print I had just a slight shift in layers, so I tightened the belt just a little more and it looks much better. Now I think I will start trying to figure out those acceleration settings. I'll let you know what I come up with. That is if anyone is interested in this.

Now that you mention it, I do think my frame is moving. I am going to print out a brace like my other anet in the front and see if that calms it down a bit. I am just trying to by a little time till I can buy an all aluminum frame. thank you for the link on the acceleration adjustments. I might try and adjust some of those settings just a little.

Hello,

I am working on getting my printer all tuned up, and as of right now I have all my steps calibrated. I am trying to work out two bugs right now:

ghosting

intermittent extrusion problems. As seen in the pictures below, and just so we are all on the same page, this part was a ghosting test print. that being said the "X" and the "Y" are not the actual X and Y axis.

Would you be able to help me with writing that g code?

Ok just wanted to put an update on here. I quit using cura slicer. I am now using simplified 3d. First full day of printing dual color prints and I am so happy. I still have some bugs to work out though. I have to be watching my printer until the first tool change very closely. It will retract the filament on one extruder then start "printing" with the second extruder without priming the hot end first. So right now on the first tool change I shove the filament in manually. Then it will be just fine for the rest of the print. the left two were with cura and the right one was simplified 3d.

the left two were with cura and the right one was simplified 3d.

Ah, that makes sense. what for slicer do you use for multicolored prints? honestly i just stuck with cura because that is what came with my Anet A8 way back when i first got it. i just got used to it but that was also when i only had the one extruder motor and the original Arduino board.

Okay, so i figured out part of the problem. The brim had a setting to chose which extruder to use. It was set to extruder 0 while the part was set to extruder 1. Now, that is set to the same extruder to match the model a new problem came up. The first layer went great, but on the second layer it decides to switch filament and prints on the wipe tower then switches back to the original filament and goes over to the part and starts printing with the mix of the two colors. It continues to do that until it gets to the point in the model where it is supposed to actually change color and just stops extruding all together but continues to "print". the one on the left is the 1" square test piece.

yeah honestly this is just what Cura put in there... if it helps at all here is my config.g:

; Configuration file for Duet WiFi (firmware version 2.03)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2.0.0 on Mon Sep 02 2019 11:40:46 GMT-0400 (Eastern Daylight Time)

; General preferences

G90 ; send absolute coordinates...

M83 ; ...but relative extruder moves

M550 P"My Printer" ; set printer name

; automatic saving on power loss is not configured

; Drives

M569 P0 S1 ; physical drive 0 goes forwards

M569 P1 S1 ; physical drive 1 goes forwards

M569 P2 S0 ; physical drive 2 goes backwards

M569 P3 S1 ; physical drive 3 goes forwards

M569 P4 S1 ; physical drive 4 goes forwards

M584 X0 Y1 Z2 E3:4 ; set drive mapping

M350 Z16 I0 ; configure microstepping without interpolation

M350 X16 Y16 Z16 E16:16 I1 ; configure microstepping with interpolation

M92 X100.00 Y100.00 Z400.00 E100.00:100.00 ; set steps per mm

M566 X1200.00 Y1200.00 Z180.00 E900.00:900.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z180.00 E2400.00:2400.00 ; set maximum speeds (mm/min)

M201 X500.00 Y500.00 Z20.00 E250.00:250.00 ; set accelerations (mm/s^2)

M906 X800 Y800 Z800 E800:800 I30 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 X0 Y0 Z0 S1 ; set axis minima

M208 X210 Y210 Z240 S0 ; set axis maxima

; Endstops

M574 X1 Y1 Z1 S0 ; set active low and disabled endstops

M574 Z1 S0 ; set active high endstops

; Heaters

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M305 P0 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 0

M143 H0 S85 ; set temperature limit for heater 0 to 85C

M305 P1 T100000 B4138 R4700 ; set thermistor + ADC parameters for heater 1

M143 H1 S250 ; set temperature limit for heater 1 to 250C

; Fans

M106 P0 S0.3 I0 F500 H1 T45 ; set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P1 S0.3 I0 F500 H1 T45 ; set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

; Tools

M563 P0 D0 H1 F1 ; define tool 0

G10 P0 X17 Y-5 Z0 ; set tool 0 axis offsets

G10 P0 R0 S0 ; set initial tool 0 active and standby temperatures to 0C

M563 P1 D1 H1 F1 ; define tool 1

G10 P1 X17 Y-5 Z0 ; set tool 1 axis offsets

G10 P1 R0 S0 ; set initial tool 1 active and standby temperatures to 0C

; Network

M552 S1 ; enable network

M586 P0 S1 ; enable HTTP

M586 P1 S0 ; disable FTP

M586 P2 S0 ; disable Telnet

; Custom settings are not defined

ok so after a lot of head scratching i am back here. i couldn't figure out why my printer was grabbing filament with E0 at the very beginning of the print. Now it should be pulling filament with whatever the actual part is being printed with. In this case i am printing one half of this test piece with filament from E1, and in the slicer in the start g code it reads:

G28 ;Home

G1 Z15.0 F6000 ;Move the platform down 15mm

;Prime the extruder

G92 E0

G1 F200 E3

G92 E0

my gut instinct is telling me that is wrong. After it prints the brim. It does start trying to extrude from E1, but the filament from E0 is still in the nozzle just sitting there.

Please advice..

Woops one more question. Sorry. Is the F300 the speed of retraction?

Thank you so much! I'll give that second one a try seems how that does make more sense.

Thank you for the quick response. I did some digging and this is what my end g code says in the slicer.

M104 S0

M140 S0

;Retract the filament

G92 E1

G1 E-1 F300

G28 X0 Y0

M84

Now about the only thing that makes sense to me is the last two lines. I am still new to g code... what am I looking at here?

Hello, I have anet a8 with the duet wifi and and a cyclops hotend. I was wondering if there is a way, the end of the print, to retract the filament on the active tool? The reason I am asking this is because it's a non-mixing style and I have no filament sensors.

Has anyone thought about or tried to make a DMLS printer with the duet board? 3d powder metal printing? i've seen videos of how they work and i just got curious to see what everybody's thoughts were. it's got to be possible.

Alrighty i'll give that a try when i get home tonight and keep you updated. thank you for your time

Thank you for getting back with me so promptly. I am new to G-code just like a lot of other people.

M563 P0 D0 H1 ; define tool 0

G10 P0 S0 R0 X0 Y0 ; set tool 0 temperatures and offsets

M563 P1 D1 H1 ; define tool 1

G10 P1 S0 R0 X0 Y0 ; set tool 0 temperatures and offsets

is this the one i should be using? if so where exactly should this be placed?

Also, i am currently using the wye connection directly above the heat sink. So the filament path is from the spool, to the extruder stepper, through a long tube, through the wye, then to the hotend. i like this setup because it made the most sense to me. i work with a Prusa I3 Mk3 MMU and there is a problem with the filament getting jammed in the extruder as it sits directly above the heat sink. to get around this i had to adjust the ramming of the filament prior to retracting.

Hopefully i won't have a whole lot of problem with my setup, but hey worth a shot i think.

Now steering back, the tool change files in the second link. What am i looking at?

Hello,

I have been working on my anet a8 for a while now. i just recently upgraded the motherboard to a duet wifi board. I have it printing out pretty well very pleased with it. i would like to take it to the next level and try to print with 2 colors. last night i printed out a wye connection from thingiverse https://www.thingiverse.com/thing:3094884 i hooked all the tubing and connectors to it now it's time to figure out how to tell the printer to use 2 extruders.

please advise thank you.