Good day!

I propose several improvements in the management of fans, incl. from panel due.

- Add a total ban on changing the fan power from g-code.

- Add a soft ban - do not reduce less than a manually set value.

Good day!

I propose several improvements in the management of fans, incl. from panel due.

Good afternoon!!

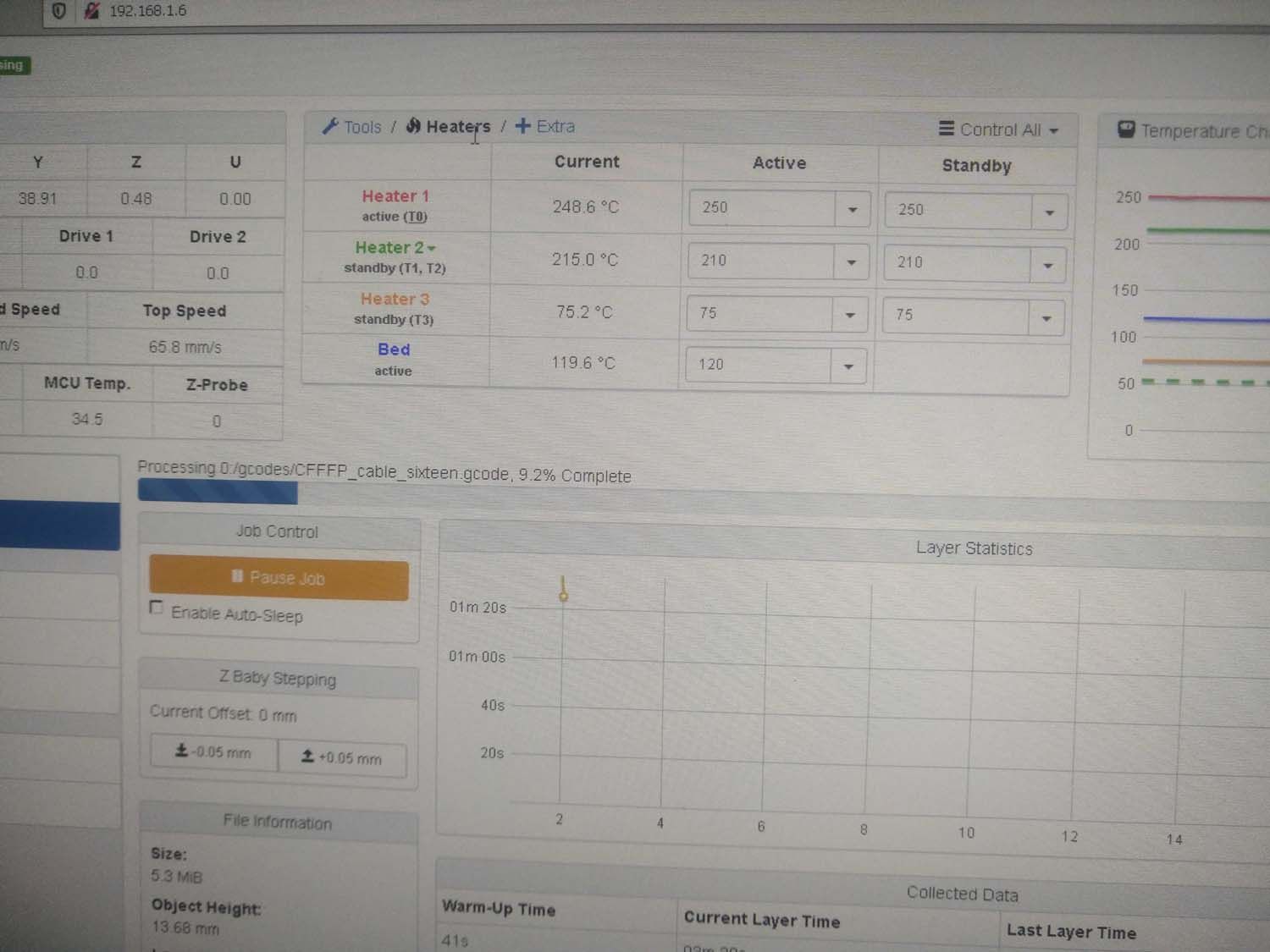

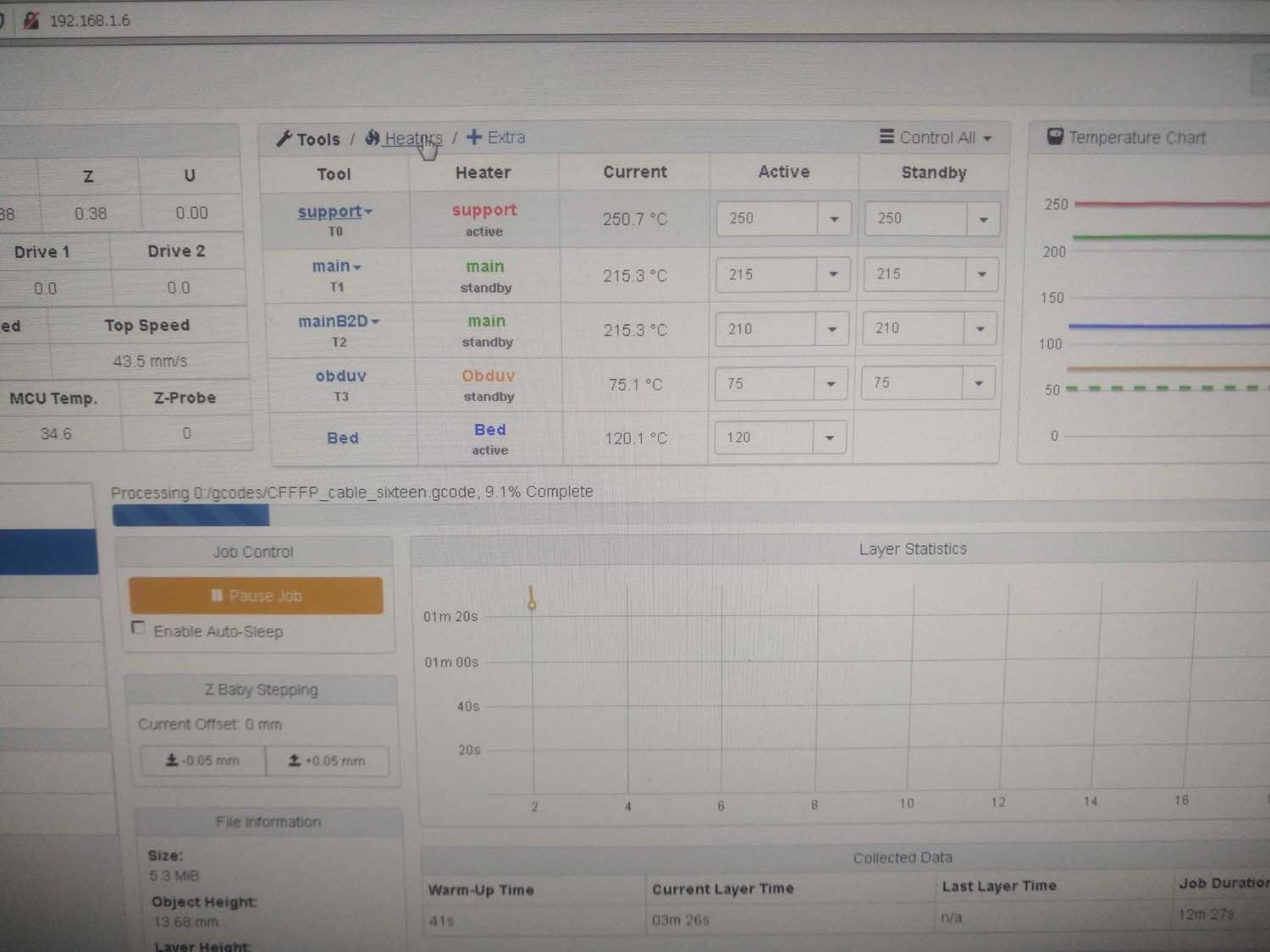

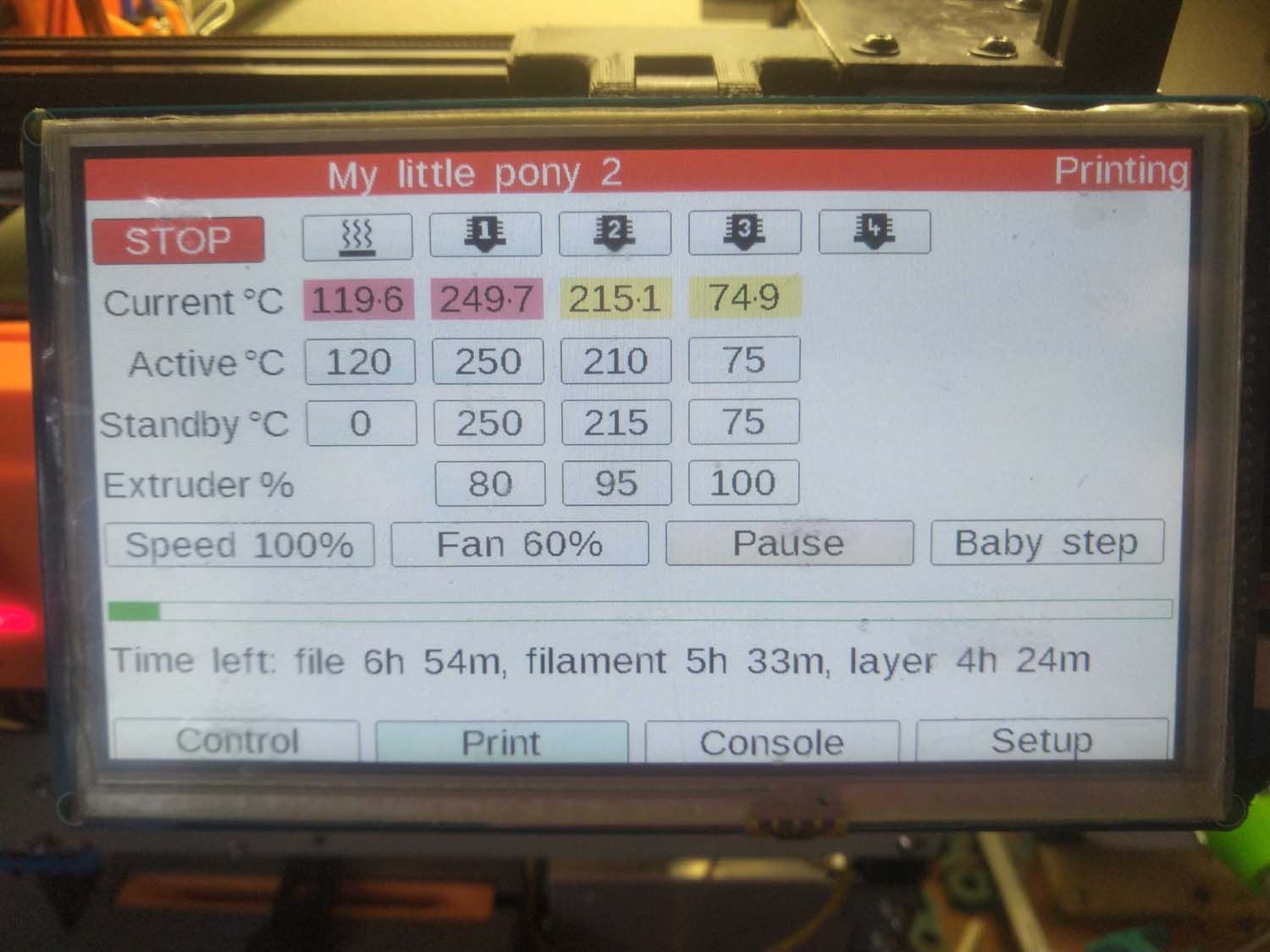

Tell me how to properly configure the printer so that there are no artifacts in the PanelDue.

Problem:

After adding the y-splitter and, accordingly, 2 tools per 1 heater, the tools began to display incorrectly on the panel.

At the same time, the web-interface works correctly.

; Configuration file for Duet WiFi (firmware version 1.21)

; executed by the firmware on start-up

;

; generated by RepRapFirmware Configuration Tool v2 on Mon Jan 21 2019 19:24:43 GMT+0300

;M929 P"eventlog6.txt" S1

M111 S6

; General preferences

G90 ; Send absolute coordinates...

M83 ; ...but relative extruder moves

;M584 X0 Y1 Z2 E3:4 ;Driver 0 controls the X motor, 1 controls Y, 2 control Z motors, 3 4 control E motors and 5 control U axis

M584 X0 Y1 Z2 E3:4:6 U5 ;Driver 0 controls the X motor, 1 controls Y, 2 control Z motors, 3 4 6 control E motors and 5 control U axis

M667 S1 ; Select CoreXY mode

; Network

M550 P"My little pony 2" ; Set machine name

M551 P"Konica120: ; Set password

M552 S1 ; Enable network

M587 S"TOLO" P"Konica120" ; Configure access point. You can delete this line once connected

M586 P0 S1 ; Enable HTTP

M586 P1 S1 ; Enable FTP

M586 P2 S0 ; Enable Telnet

; Drives

M569 P0 S1 ; Drive 0 goes forwards

M569 P1 S1 ; Drive 1 goes forwards

M569 P2 S1 ; Drive 2 goes forwards

M569 P3 S0 ; Drive 3 goes back

M569 P4 S0 ; Drive 4 goes back

M569 P5 S1 ; Drive 5 goes forwards

M569 P6 S1 ; Drive 6 goes forwards

;M350 E128:128 I0 ; Configure microstepping without interpolation MK8

;M350 E128:64 I0 ; Configure microstepping without interpolation SUNJIU

M350 E128:64:64 I0 ; Configure microstepping without interpolation SUNJIU+B2D

M350 X64 Y64 Z16 I0 ; Configure microstepping with interpolation

M350 U16 I1 ; Configure microstepping with interpolation

;M92 X320.00 Y320.00 Z625.00 E1136.00:1136.00 U8.889 ; Set steps per mm MK8

;M92 X320.00 Y320.00 Z625.00 E1136.00:1337.7 U8.889 ; Set steps per mm SUNJIU

;M92 X320.00 Y320.00 Z625.00 E1136.00:1401:883 U8.889 ; Set steps per mm SUNJIU+B2D

;M92 X320.00 Y320.00 Z625.00 E1136.00:1401:1460 U8.889 ; Set steps per mm SUNJIU+B2D(mk8) (lin)

M92 X320.00 Y320.00 Z625.00 E1079.00:1331:1387 U8.889 ; Set steps per mm SUNJIU+B2D(mk8)(good)

M566 X600.00 Y450.00 Z120.00 E600.00:600.00:600.00 U200 ; Set maximum instantaneous speed changes (mm/min)

;M566 X600.00 Y450.00 Z120.00 E600.00:900.00 ; Set maximum instantaneous speed changes (mm/min)

M203 X12000.00 Y12000.00 Z360.00 E1600.00:1600.00:1600.00 U7200 ; Set maximum speeds (mm/min)

;M203 X12000.00 Y12000.00 Z360.00 E1600.00:1600.00 ; Set maximum speeds (mm/min)

M201 X3000.00 Y2000.00 Z200.00 E3000.00:2000.00:2000.00 U200 ; Set accelerations (mm/s^2)

;M201 X3000.00 Y2000.00 Z200.00 E3000.00:3000.00 ; Set accelerations (mm/s^2)

M906 X1400.00 Y1400.00 Z1400.00 E1600.00:1700.00:1500.00 U500 I30 ; Set motor currents (mA) and motor idle factor in per cent SUNJIU

;M906 X1400.00 Y1400.00 Z1400.00 E1600.00:1600.00 I30 ; Set motor currents (mA) and motor idle factor in per cent MK8

M84 S300 ; Set idle timeout

; Axis Limits

M208 X0 Y0 Z0 U0 S1 ; Set axis min/max

M208 X228 Y245 Z250 U360 S0 ; Set axis maxima

; Endstops

M574 X1 Y1 Z1 S1 ; Set active high endstops

M574 U0 S0 ; U has no endstop, but...

;Filament sensors

;M591 D0 P2 C3 S1

;M591 D1 P2 C4 S1

M581 E0:1 S1 T1 C1;

; Z-Probe

M558 P0 H3 F120 T6000 ; Disable Z probe but set dive height, probe speed and travel speed

M557 X15:210 Y15:230 S100 ; Define mesh grid

; Heaters

M305 P0 X0 T100000 B3950 R4700 S"Bed" ; Set thermistor + ADC parameters for heater 0

M301 H0 S0.98 ; Set heater 0 PWM limit to 98%

M143 H0 S140 ; Set temperature limit for heater 0 to 130C

M570 H0 P30 T25 S2 ; Configure heater fault detection

M305 P1 X501 R4700 S"support" ; Configure thermocouple for heater 1

M301 H1 S0.98 ; Set heater 1 PWM limit to 98%

M143 H1 S280 ; Set temperature limit for heater 1 to 280C

M570 H1 P30 T25 S1 ; Configure heater fault detection

M305 P2 X502 R4700 S"main" ; Configure thermocouple for heater 2

M301 H2 S0.98 ; Set heater 2 PWM limit to 98%

M143 H2 S280 ; Set temperature limit for heater 2 to 280C

M570 H2 P30 T25 S1 ; Configure heater fault detection

M305 P3 X3 T100000 B3950 R4700 S"Obduv" ; Set thermistor + ADC parameters for heater 3

M301 H3 S0.98 ; Set heater 3 PWM limit to 98%

M143 H3 S90 ; Set temperature limit for heater 3 to 80C

M570 H3 P30 T25 S1 ; Configure heater fault detection

M305 P102 X4 T100000 B3950 R4700 S"Сold_junction" ; Set thermistor + ADC parameters for heater 4

M305 P103 X5 T100000 B3950 R4700 S"Hot_End" ; Set thermistor + ADC parameters for heater 5

; Fans

M106 P0 S0.3 I0 F500 H-1 C"Obduv" ; Set fan 0 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P1 S1 I0 F500 H-1 C"HotEnd" ; Set fan 1 value, PWM signal inversion and frequency. Thermostatic control is turned on

M106 P2 S0.9 I0 F500 H-1 C"Extruders" ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned off

M106 P3 S0.6 I0 F500 H-1 C"main cool" ; Set fan 2 value, PWM signal inversion and frequency. Thermostatic control is turned off

; Tools

M563 P0 S"support" D0 H1 L0 ; Define tool 0

G10 P0 X0 Y0 Z0 ; Set tool 0 axis offsets

G10 P0 R0 S0 ; Set initial tool 0 active and standby temperatures to 0C

M572 D0 S0.2; set extruder 0 pressure advance to 0.4 seconds

╨╢M592 D0 A0.008 B0.0001 L2 ; set parameters for extruder drive 0

M221 S100 D0 ;Set extrude factor override percentage

M563 P1 S"main" D1 H2 L1 ; Define tool 1

G10 P1 X-18 Y0 Z0 ; Set tool 1 axis offsets

G10 P1 R0 S0 ; Set initial tool 1 active and standby temperatures to 0C

M572 D1 S0.3 ; set extruder 0 pressure advance to 0.5 seconds

╨╢M592 D1 A0.001 B0.0002 L2; M592 D1 A0.07 B0.0005 L5 ;M592 D1 A0.07 B0.003 L5 ;M592 D1 A0.06 B0.0025 L2 ; set parameters for extruder drive 1

M221 S100 D1 ;Set extrude factor override percentage

M563 P2 S"mainB2D" D2 H2 L3 ; Define tool 1

G10 P2 X-18 Y0 Z0 ; Set tool 1 axis offsets

G10 P2 R0 S0 ; Set initial tool 1 active and standby temperatures to 0C

M572 D2 S0.3 ; set extruder 0 pressure advance to 0.5 seconds

╨╢M592 D2 A0.001 B0.0002 L2; set parameters for extruder drive 1

M221 S100 D2 ;Set extrude factor override percentage

M563 P3 S"obduv" H3 ; Define tool 2

G10 P3 X0 Y0 Z0 ; Set tool 2 axis offsets

G10 P3 R0 S0 ; Set initial tool 2 active and standby temperatures to 0C

;M563 P7 S"Сold junction" H4 ; Define sensor

;M563 P8 S"HotEnd" H5 ; Define sensor

; Automatic saving after power loss is not enabled

; Custom settings are not configured

; Miscellaneous

M501 ; Load saved parameters from non-volatile memory

T0

T1 ; Select first tool

T3

T2

Good day!

I propose several improvements in the management of fans, incl. from panel due.

Tool offset work fine, thanks! Tested on 2.03RC1

I confirm the problems with the Wifi connection in 2.03RC1. In combination with HTTP + FTP, the connection was extremely unstable, it was impossible to transfer files over hundreds of bytes either via http or ftp.

Editing config.g to disable ftp caused it to self-delete when writing.

Recovered on sd card from backup.

In the only http mode, it became possible to record files, but the recording speed dropped 10 times.

M122

=== Diagnostics ===

RepRapFirmware for Duet 2 WiFi/Ethernet version 2.03RC1 running on Duet WiFi 1.02 or later + DueX5

Board ID: 08DGM-9T6BU-FG3S8-6J1DJ-3SD6P-1SKMF

Used output buffers: 3 of 24 (11 max)

=== RTOS ===

Static ram: 25656

Dynamic ram: 94672 of which 28 recycled

Exception stack ram used: 492

Never used ram: 10224

Tasks: NETWORK(ready,524) HEAT(blocked,1236) MAIN(running,3752) IDLE(ready,156)

Owned mutexes:

=== Platform ===

Last reset 05:55:41 ago, cause: software

Last software reset at 2019-05-12 13:42, reason: User, spinning module GCodes, available RAM 10128 bytes (slot 1)

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0441f000 BFAR 0xe000ed38 SP 0xffffffff Task 0x4e49414d

Error status: 24

Free file entries: 8

SD card 0 detected, interface speed: 20.0MBytes/sec

SD card longest block write time: 403.7ms, max retries 0

MCU temperature: min 30.7, current 35.9, max 36.7

Supply voltage: min 0.5, current 24.2, max 24.5, under voltage events: 1, over voltage events: 0, power good: yes

Driver 0: ok, SG min/max 0/1023

Driver 1: ok, SG min/max 0/1023

Driver 2: standstill, SG min/max 0/93

Driver 3: standstill, SG min/max 0/1023

Driver 4: ok, SG min/max 0/1023

Driver 5: standstill, SG min/max not available

Driver 6: standstill, SG min/max not available

Driver 7: standstill, SG min/max not available

Driver 8: standstill, SG min/max not available

Driver 9: standstill, SG min/max not available

Date/time: 2019-05-12 19:37:56

Cache data hit count 4294967295

Slowest loop: 123.17ms; fastest: 0.06ms

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0

=== Move ===

Hiccups: 58, FreeDm: 163, MinFreeDm: 106, MaxWait: 10107016ms

Bed compensation in use: none

Bed probe heights: 0.000 0.000 0.000 0.000 0.000

=== DDARing ===

Scheduled moves: 238342, completed moves: 238317, StepErrors: 0, LaErrors: 0, Underruns: 0, 0

=== Heat ===

Bed heaters = 0 -1 -1 -1, chamberHeaters = -1 -1

Heater 0 is on, I-accum = 0.0

Heater 2 is on, I-accum = 0.4

=== GCodes ===

Segments left: 1

Stack records: 2 allocated, 0 in use

Movement lock held by null

http is idle in state(s) 0

telnet is idle in state(s) 0

file is doing "G1 X94.042 Y115.929 E0.22561" in state(s) 0

serial is idle in state(s) 0

aux is idle in state(s) 0

daemon is idle in state(s) 0

queue is idle in state(s) 0

autopause is idle in state(s) 0

Code queue is empty.

=== Network ===

Slowest loop: 404.11ms; fastest: 0.00ms

Responder states: HTTP(0) HTTP(2) HTTP(0) HTTP(0) FTP(0) Telnet(0) Telnet(0)

HTTP sessions: 1 of 8

@anidal said in A bug in 2.02:

M82 ;absolute extrusion mode

In macros and printable file coordinate X228 Y245 is not present.

Is it possible that the macro command M82 is missing in the macros, but is it present in the print file and is somehow affected?

@dc42 said in A bug in 2.02:

G10 L2

Good day.

I disabled the restart of the printer from stop.g and tried your commands.

At this point, the printer completed printing the model, completed stop.g, turned off the power, and only + 5V PS_ON is active.

; stop.g

; called when M0 (Stop) is run (e.g. when a print from SD card is cancelled)

T-1 ;

M106 P0 S255 ; fan at 100% to cool nozzle

M106 P1 S255 ; fan at 100% to cool nozzle

M106 P2 S255 ; 100% extruder fan

M106 P3 S200

M1 ; heaters and motors off

G4 S180 ; Wait for 3 minutes

M106 P0 S60 ; fan off

M106 P1 S60 ; fan off

M106 P2 S60 ; Stop extruder fan

M106 P3 S60

M81 ;power off

;M112

19:01:38

G10 L2

Origin of workplace 1: X0.00 Y0.00 Z0.00 U0.00

19:01:08

G10 P1

Tool 1 offsets: X-18.00 Y0.00 Z0.00 U0.00, active/standby temperature(s): 0.0/0.0

19:01:00

G10 P0

Tool 0 offsets: X0.00 Y0.00 Z0.00 U0.00, active/standby temperature(s): 200.0/200.0

19:00:44

M114

X:109.373 Y:167.258 Z:36.025 U:0.000 E0:882.9 E1:18049.1 E2:0.0 E3:0.0 E4:0.0 E5:0.0 E6:0.0 E7:0.0 Count 88522 -18523 22516 0 Machine 109.373 167.258 36.025 0.000

19:00:37

Connection established!

19:00:37

Page Load complete!

Then I powered the printer and ran the G28.

The printer worked the command correctly and moved right after that.

19:02:46

M120

G91

G1 Y-50 F6000

M121

19:02:44

M120

G91

G1 X-50 F6000

M121

19:02:41

M120

G91

G1 Y50 F6000

M121

19:02:39

M120

G91

G1 X50 F6000

M121

19:02:24

G28

19:01:45

M98 P"0:/macros/Power Up"

Then I started the heating macro. During its execution, the nozzles are cleaned and movement and extrusion occurs.

Macro worked correctly.

19:07:00

Heater 3 switched on

19:04:58

Heater 2 switched on

19:03:04

Heater 1 switched on

19:03:01

Heater 0 switched on

Then I started to print the previously normally printed file.

***File start:

;FLAVOR:RepRap

;TIME:1849

;Filament used: 7.37841m, 0m

;Layer height: 0.3

;Generated with Cura_SteamEngine 4.0.0

T0

M190 S130

M104 S260

M104 T1 S210

M109 S260

M109 T1 S210

M82 ;absolute extrusion mode

G28 ; home all axes

T0

G1 X70 Y244 F12000

G1 X71 Y244 F2000

G92 E0

G1 X75 Y244 E8 F2000

G92 E0

G1 X190 Y242 E4.00 F2400

G92 E0

G1 X130 Y242 E5.0 F2000

G1 X120 Y236 F2000

G1 X131 Y236 F12000

G92 E0

T1

G1 X70 Y244 F12000

G92 E0

G1 X71 Y244 F2000

G1 X75 Y244 E8 F2000

G92 E0

G1 X190 Y242 E4.00 F2400

G92 E0

G1 X130 Y242 E5.0 F2000

G1 X120 Y236 F2000

G1 X131 Y236 F12000

G92 E0

T0

M83 ;relative extrusion mode

G1 F1800 E-6

;LAYER_COUNT:56

;LAYER:0

M107

M204 T5000

;MESH:derjatel.stl

G0 F5400 X50.599 Y122.5 Z0.3

M204 P3000

;TYPE:WALL-OUTER

G1 F1800 E6

G1 F3000 X50.898 Y128.187 E0.56823

And at the beginning of printing, after the G28 the printer started to behave abnormally.

I paused printing and invoked debug commands again.

19:10:42

G10 L2

Origin of workplace 1: X0.00 Y0.00 Z0.00 U0.00

19:10:34

G10 P1

Tool 1 offsets: X-18.00 Y0.00 Z0.00 U0.00, active/standby temperature(s): 210.0/210.0

19:10:15

Printing paused at X228.0 Y245.0 Z0.0 U360.0

Tool 1 offsets: X-18.00 Y0.00 Z0.00 U0.00, active/standby temperature(s): 210.0/210.0

19:10:12

G10 P1

Paused print, file offset=159

Resume state saved

19:09:53

G10 P0

Tool 0 offsets: X0.00 Y0.00 Z0.00 U0.00, active/standby temperature(s): 260.0/260.0

19:09:38

M114

X:228.000 Y:245.000 Z:0.000 U:360.000 E0:43.0 E1:17.5 E2:0.0 E3:0.0 E4:0.0 E5:0.0 E6:0.0 E7:0.0 Count 151360 -5440 0 3200 Machine 228.000 245.000 0.000 360.000

X228.0 Y245.0 Z0.0 U360.0 - abnormal coordinates