Hello,

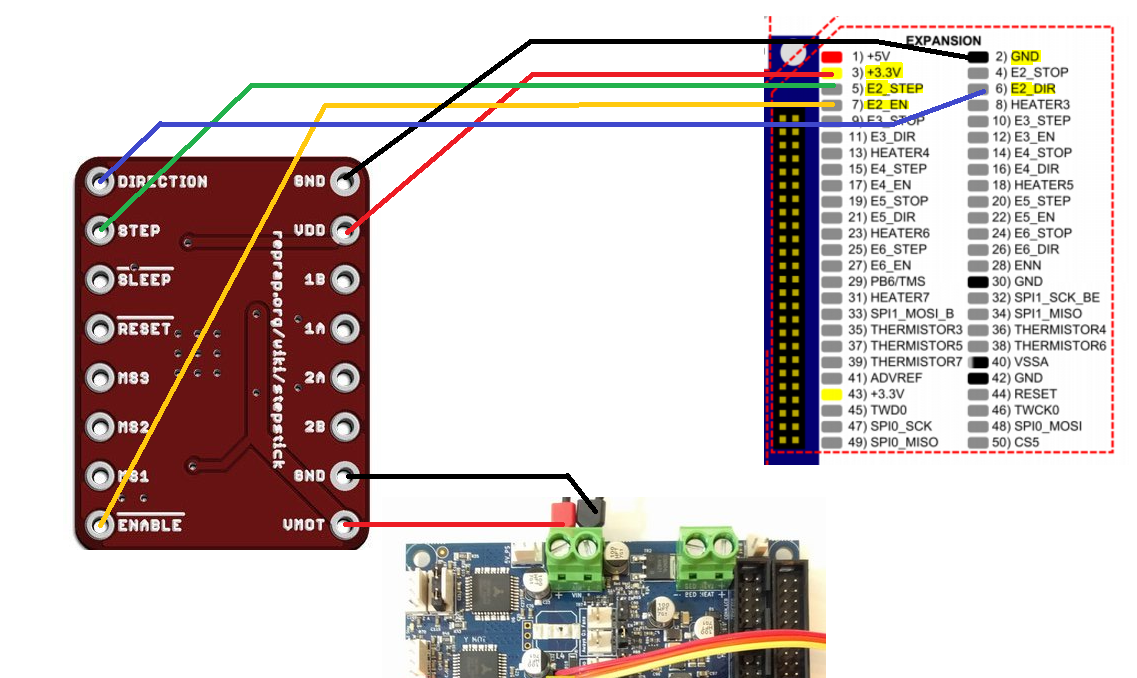

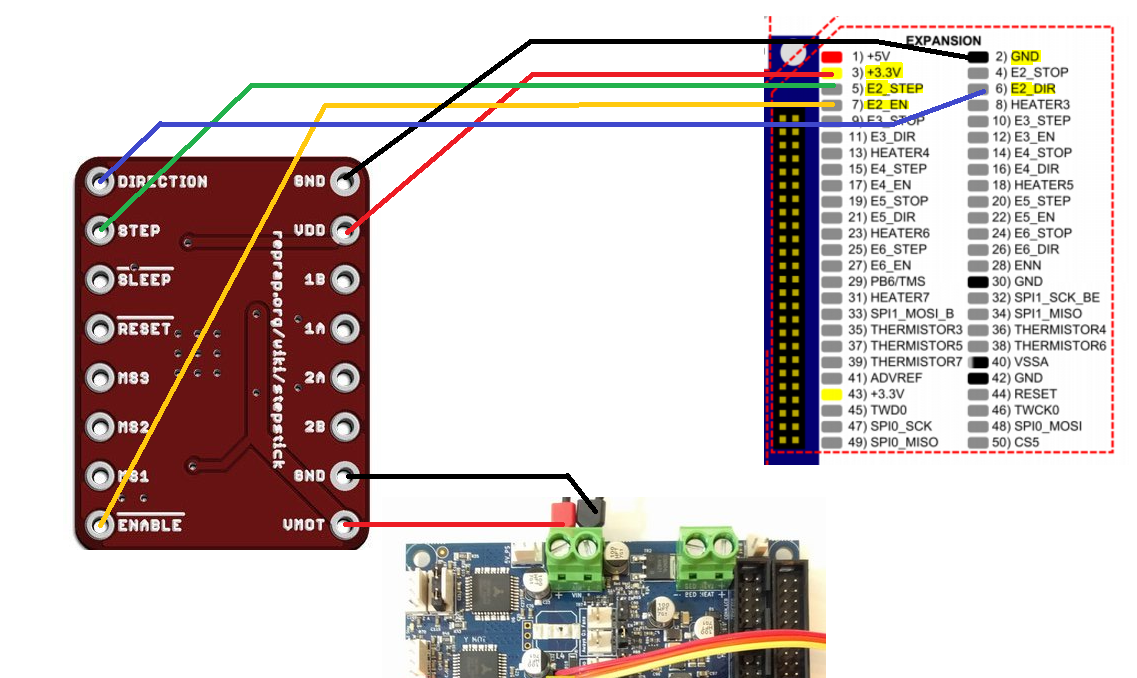

I'm trying to add additional U axis to my 3d printer using E2 on expansion board. As external drive I used A4988 stepper driver.

I got everything wired up, I created U axis which seems to work but whenever I try to move motor it wont and instead makes high pitch hissing noise. When I touch shaft there is a bit torque but very little. I tried different A4988 drivers as well as different kind (which I cannot identify) with same result. Motor is also fine as I tested It on E0 driver, I also used M564 S0 H0 command to disable endstops.

Here is my wiring, maybe there is something that I missed (except for stepper motor  )

)

Please free to criticize my code as I'm not sure if my stepping is correct. It works for me so far.

edit

I lowered number of steps on U axis and now motor behave differently. It still doesn't work but motor makes small movement back and forth like when you wire it incorrectly.

I'm pretty sure I have coils wired correctly but I tried different combinations just in case.

I ordered new genuine Pololu a4988 driver and breakout board for it, I hope it will help.

; Drives

M569 P0 S0 ; physical drive 0 goes backward

M569 P1 S0 ; physical drive 1 goes forwards

M569 P2 S1 ; physical drive 2 goes forwards

M569 P3 S0 ; physical drive 3 goes forwards

M569 P4 S0 ; physical drive 4 goes forwards

M569 P5 S0 ; physical drive 5 goes forwards

M584 X0 Y1 Z2 U5 E3:4 ; set drive mapping

M350 X16 Y16 Z16 U16 E16:16 I1 ; configure microstepping with interpolation

M92 X145.25 Y145.25 Z717.5 U5 E425:425 ; set steps per mm

M566 X1500.00 Y1500.00 Z12.00 U120 E120.00:120.00 ; set maximum instantaneous speed changes (mm/min)

M203 X6000.00 Y6000.00 Z1500 U60 E1200.00:1200.00 ; set maximum speeds (mm/min)

M201 X1000.00 Y1000.00 Z200.00 U60 E250.00:250.00 ; set accelerations (mm/s^2)

M906 X1500 Y1500 Z1500 U1200 E1200:1200 I20 ; set motor currents (mA) and motor idle factor in per cent

M84 S30 ; Set idle timeout

; Axis Limits

M208 X0 Y0 Z0 U0 S1 ; set axis minima

M208 X320 Y320 Z330.3 U50 S0 ; set axis maxima

; Endstops

M574 X1 Y1 Z2 U1 S0 ; set active high endstops