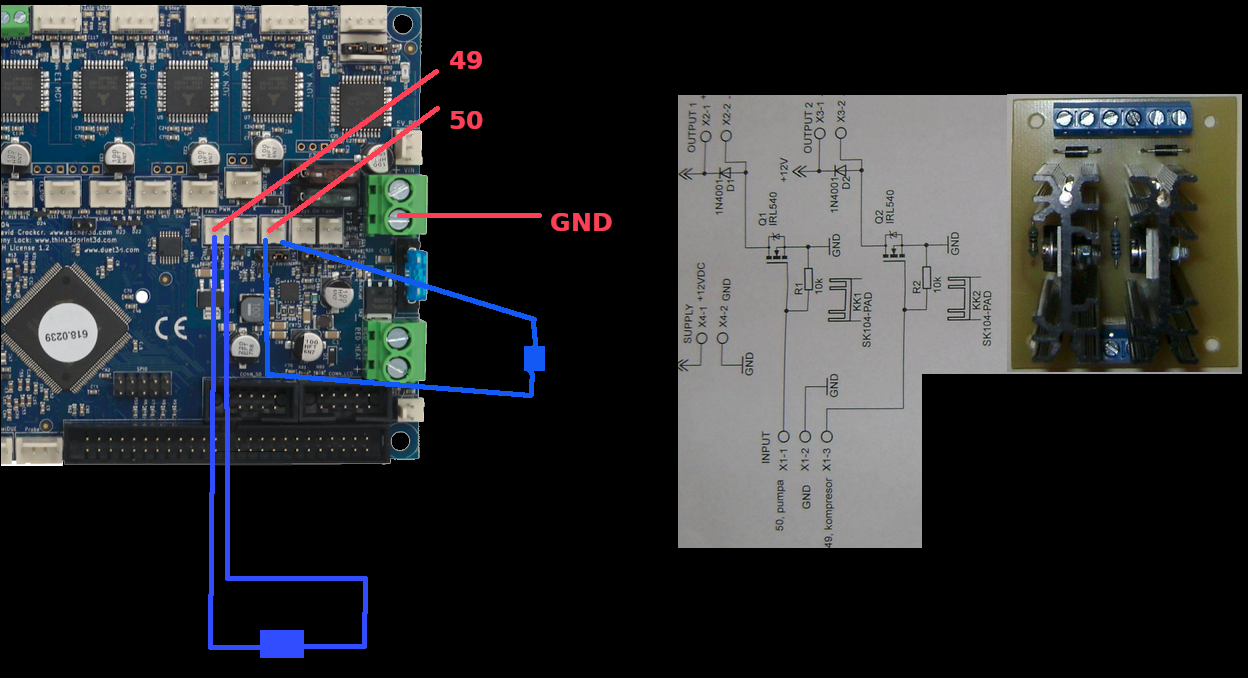

optically isolated input

ok. i can do that.

I have installed new sd card and copy / pasted all backup data and it look that everything is OK.

optically isolated input

ok. i can do that.

I have installed new sd card and copy / pasted all backup data and it look that everything is OK.

As from yesterday, i get this error:

"page not found Check that the SD card is mounted and has the correct files in its /www folder"

I try to unplug 24V main power supply, unplug USB, reconnect everything and it worked for a while.

Then I run homing and got this error :

G28

Error: Cannot read file, error code 1

after that i lost my files in G-codes directory....

It appears that i have to replace the SD card and reinstall firmware to solve this problem ?.

The only thing i am concern of is this.

Would it be possible that the SD card got damaged because of the setup that i use for triggering vacuum pump.. To be more exact. i have hooked up my external circuit that is triggering 24V ( external 24V adapter not connected to duet ) to my vacuum injector and replaced one jummper under FAN.

To manage this to work HW setup is made on the way like i showed in picture. Could this anyhow effect to duet board ? I dont think that this has anything to do with it but who knows...

Gcode setup:

G4 P150

M106 S255

;-------------------------

G4 P150

M106 S0

A.

Hi.

I still have "sending USB data" problems with my vision system to duet setup, but i guess i will manage to solve it somehow. My question would be:

How can i "draw" simple circle with my rotary delta robot ?

It's just for demonstration purposes and the sequence should be something like:

Vision program is based on python so maybe i can implement this circle part into the code, somehow ?

Or call it as external file ? Anyhow, how to draw a circle....

A.

I forget to write that i have try different baudrate settings and i also try to remove it but nothing changes.

BTW. it looks like attached file did not pass so am sending again (rename txt to py ).

serialutil.TXT

Hi to all.

I have one strange problem that and i can not find error / bug in my code.

I write one external program that used to access to duet. Nothing much,

the program is sending data from vision system to duet.

Now, this has worked before without any problems but now i just can not send any data.

Meanwhile, I did make firmware update but this should have (or has) no affect to this situation.

Computer and OS is still the same as before and DUET is recognized as OpenMoko at ttyACM0.

Am using Linux distro Ubuntu 16 / 64 bit. I will attach file that am using for comm settings but if someone has some simpler test code i can use, please share...

This is the part that i use for comm and "serial" file is in attach....

try:

#ser = serial.Serial("/dev/ttyAMC0", baudrate=115200, timeout=3.0)

ser = serial.Serial("/dev/ttyAMC0", baudrate=115200)

for object in self.current_objects:

x, y = object

strCode = 'G1 X' + str(x) + ' Y' + str(y) + ' Z5' + ' F1000'

ser.write(str.encode(strCode + '\n'))

# settings for vacuum pump

if bRecycleBin:

if x < 0:

strCode = 'G1 X-200' + 'G1 Y0' + ' Z5' + ' F4000'

ser.write(str.encode(strCode + '\n'))

else:

strCode = 'G1 X200' + 'G1 Y0' + ' Z5' + ' F4000'

ser.write(str.encode(strCode + '\n'))

# settings for vacuum pump

ser.flush()

except:

print("Fail to connect...")

Thank you for your reply David. I will check all this in day or two.

At the moment am adding new metal carriers for end switches so we will see if this may solve problem.

They will be in mm with floor / construction / arms.

A.

OK. This is working as i need to..

I will test this with external program but as far as i can remeber i did not put extra G90 commands into code...

Anyhow, thank you !

Btw. If you have time/wish please look at my other post regarding nozzle positioning:

https://forum.duet3d.com/topic/12566/nozzle-positoning-problems

Working solution for test up / down movement:

G28

G1 X100 Y60 F15000

;---------------------------

G91

G1 Z-25 F6000

;--------------------------

G4 P150

M106 S255

G4 P150

M106 S0

;-------------------------

G91

G1 Z25 F6000

;--------------------------

G90

G1 X0 Y0 F15000

Are those commands with Z25 and Z-25 supposed to be relative moves? The values suggest they are.

*** I understand that this last command is not executed because i entered 91, which triggers relative movement so X and Y is will be processed on the same way but i dont know how to make this otherwise.

So, what would you suggest to make simple pickup routine like:

When i was using stepper motors this pickup part was working OK..

A.

The gcode in the first part is telling the nozzle to move to Z-15 as an absolute position, ie 15mm below the bed, which it can't do!

*** Hmmm, maybe we didnt understand us correctly. Nozzle working hight is cca 8 cm above conveyor track and if i enter Z-15 top of the nozzle should be lowered few mm above track. If i enter Z15, arm are lifted up.....

This is working

G28

G1 X100 Y30 F15000

;---------------------------

G1 Z-25 P60 F15000

;--------------------------

G4 P150

M106 S255

G4 P150

M106 S0

;-------------------------

G1 Z25 F15000

;--------------------------

G1 X0 Y0 F15000

but last command is not executed ( arms are not moved to X0 Y0 ).

David has suggested / explained this, but it looks like i can not implemented it.

Not sure why you need the M120 (push) and M121 (pop) commands.

*** i dont need them at all but without them last command is not executed.

A.

Hi.

For some unknown reason, i can not move nozzle head up or down, when i run it as script or over some external SW. Funny part is that i can move it normally when i press on Z icons ( head movement part )

This does not work :

G28

G1 X100 Y30 F15000

;---------------------------

G1 Z-15 P60 F6000

G4 P150

G1 Z15 P60 F6000

;--------------------------

G1 X0 Y0 F15000

////////////////////////////////////////////////////////////////

but this works OK:

G28

G1 X100 Y30 F15000

;---------------------------

M120

G91

G1 Z-15 F6000

M121

G4 P150

M120

G91

G1 Z15 F6000

M121

;---------------------------

G1 X0 Y0 F15000

?

I know that second option is not right approach i just write it for test purposes.

A.

Hi to all. It looks i have a problem with nozzle positioning.

I want to move delta robot head with vacuum pump to working limits and this is OK but the nozzle is not on the same height when it moves from lets say x250 to X-250.

To be exact, distance between nozzle top at x250 is 69cm from floor and on -250 it's 70 cm.

At X250 nozzle is in full horizontal line and on -250 it's slightly sloping toward X0.

I have try to change the A values but it looks like it has nothing to do with it, because i have changed ratios in small and big scale ( just for test ). Shortly, nozzle head is moving "up and sloping" when it moves from 0 to -250. Ideas ?

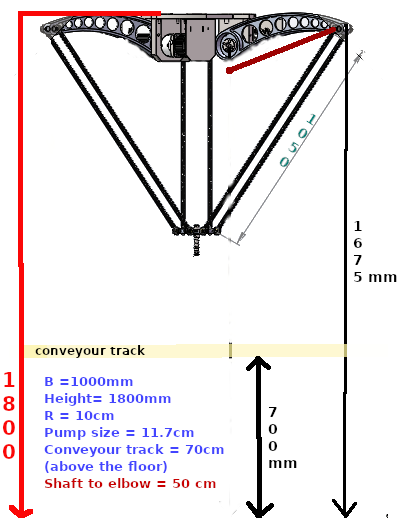

;****FOR ROTARY DELTA SETUP

; B == bed radius = 1000mm

; H == Height--> distance between base center and floor --> 1800mm

; R == 15-5 = 5cm ( base centar --> motor shaft )

; A == arcsin /31

;------------------------------------------------

M669 K10 U500 L1050 A-10:8 R8 H1800 B1000 ; A-10:7.3 / 9:8 / 8:7 / 10:5 etc

M669 X150 Y150 Z150 ; rotate +X direction by 150deg

M666 X0 Y0 Z0 ; Put your endstop adjustments here, or let auto calibration find them

M574 X2 Y2 Z2 S0 ; END STOP SWITCHES

I still can not find any solution why is this happening. If someone can take a look at test sequence and tell me what can be wrong... Thank you all in advance...

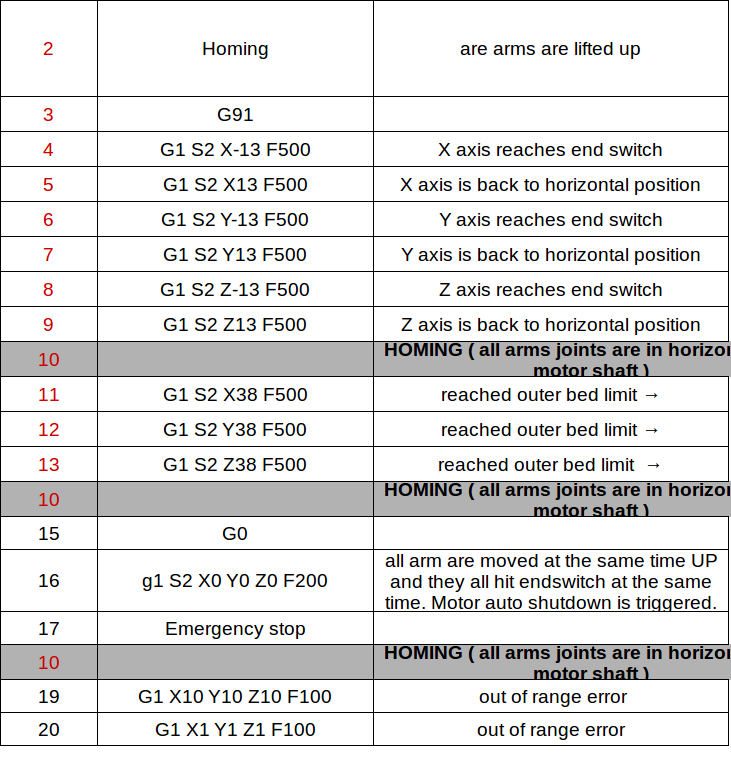

2 Homing are arms are lifted up

2 Homing are arms are lifted up

Test is made line by line in the order that is described in first row...

Basically, i can control each motor without problem but when i enter standard gcode command, i get out of range error, regardless what value i enter...

UPDATE:

In other words, If i run G1 S2 X0 Y0 Z0 F300 after homing, all arms will go up and they will hit endswitch. The same will happend if i enter any other command ( for one arm movement ) like, G1 S2 X10 F300 or G1 S2 X-10 F300 etc...

If i run separate command without homing, then i get clear movement.

e.g. without homing and after i run G1 S2 X0 Y0 Z0 F300 , all arm are positioned down.

Any ideas ?

Homing

G91 ; relative positioning

G1 S1 y-60 X-60 Z-60 F1000 ; move all towers to the high end stop at endstops

G1 S2 X13 Y13 Z13 F700 ; go down a few mm

When the homing part is done, all 3 arms are full horizontal with motor shaft.

If is send G90 G1 S2 X0 Y0 Z0 afterward, all 3 arms move up and they are trying to move above endstops. Because of that, motors are shuted down as they detect over torque limit.

A.

I dont know what was the problem but i have setup motors completely from the beginning and now it looks like everything is OK. Even the homing is working.

Now i need to setup fine tuning for duet's config  so if someone can take a look, it would be great. The problem is that i get intermediate position outside machine limits error, when i try to execute some basic command like G1 X10 Y10 F300. I get the same error when i try pressing any X/Y/Z value under "head movement" part.

so if someone can take a look, it would be great. The problem is that i get intermediate position outside machine limits error, when i try to execute some basic command like G1 X10 Y10 F300. I get the same error when i try pressing any X/Y/Z value under "head movement" part.

To understand all this a bit clearer i made some photo with actual dimension and calculations ( when the arms are in horizontal with motor shaft ) and i attached part of config.g file.

IMHO, i think i have set everything correctly accept degree calculation.

;****FOR ROTARY DELTA SETUP

; B == bed radius = 1000mm - working radius

; H == Height--> base center <--> floor = 1800mm

; R == 15-5 = 10cm ( base centar --> motor shaft )

; A == arcsin /31

;------------------------------------------------

M669 K10 U500 L1050 A-10:7.3 R10 H1800 B1000

M669 X150 Y150 Z150 ; rotate +X direction by 150deg

M666 X0 Y0 Z0 ; Put your endstop adjustments here

M574 X2 Y2 Z2 S0 ; END STOP SWITCHES

M92 X90 Y90 Z90

M350 X16 Y16 Z16 I0

;///////////////// HOMING FILE ///////////////////////////////////

G91 ; relative positioning

G1 S1 y-60 X-60 Z-60 F1000 ; move all towers to the high end stop at endstops

G1 S2 X13 Y13 Z13 F700 ; go down a few mm

A.

Good day to all !

I got reply from tecknic support and it looks like that the motors should be auto configured with full load. So i dismantled each motor from the construction ( didnt want to copy/paste saved data ) and run the config again. It looks like it has worked.

Now i am bit confused what is happening when i try to home all axis.

It looks like if the motors have some kind of torque protection when they hit endswitch ( i will ask tecknic about that too ) because after the arm hits endswitch, hand starts to drop down slowly and i can not controll it from web gui anymore. I can still send commands from gui and this is working normally, it just looks like if the power of the motor is cut off.

After i click emergency stop and restart is done, motors are back "online"..

I have attached video, because it's hard to describe this.

Btw. in this video, Z axis is not homed correctly, which is weird, because i can see that LED blinks on the endswitch and on the duet board.

https://gofile.io/?c=3cYPIC

@dc42

OK. I'm writing mail to tecknic support and i will copy paste full reply.

Steps per mm:

@Edkirk

I found one interesting option in fine tuning setup, and i set slider to "quietness" . The result is very interesting. There are almost no vibrations and upper arm and is moving very smoothly. Speed is reduced quite a lot but not so much that it would affect whole movement.

Hi edkirk, glad to hear you.

Yep. They are clearpath servos. 3426P-rnl model.

I have set 800 rpm in msp setup and i have copy/pasted this setup to all motors.

OK i will try without microstepping.

So you think that i dont need to use 5V instead of 3,3 ?

BTW. How did you calculate 200 mm/step in you setup, or did you test it manualy ?

A.

Please be so kind and look at this post:

https://forum.duet3d.com/topic/8876/clearpath-servomotor-50nm-suggestion/33

They are powered with 72V and 5V is for logic part.

A.