@dc42 thanks for the quick reply! The reason we're asking is a spurious phenomena we have on two printers right now (duet2 and 3.4.1). It appears one command does not get an ok which in return blocks around half the buffer butting the printer into a kind of ping pong mode with roughly one command per second.

Sometimes this appears to happen again which results in a timeout and the print continuing fine afterwards.

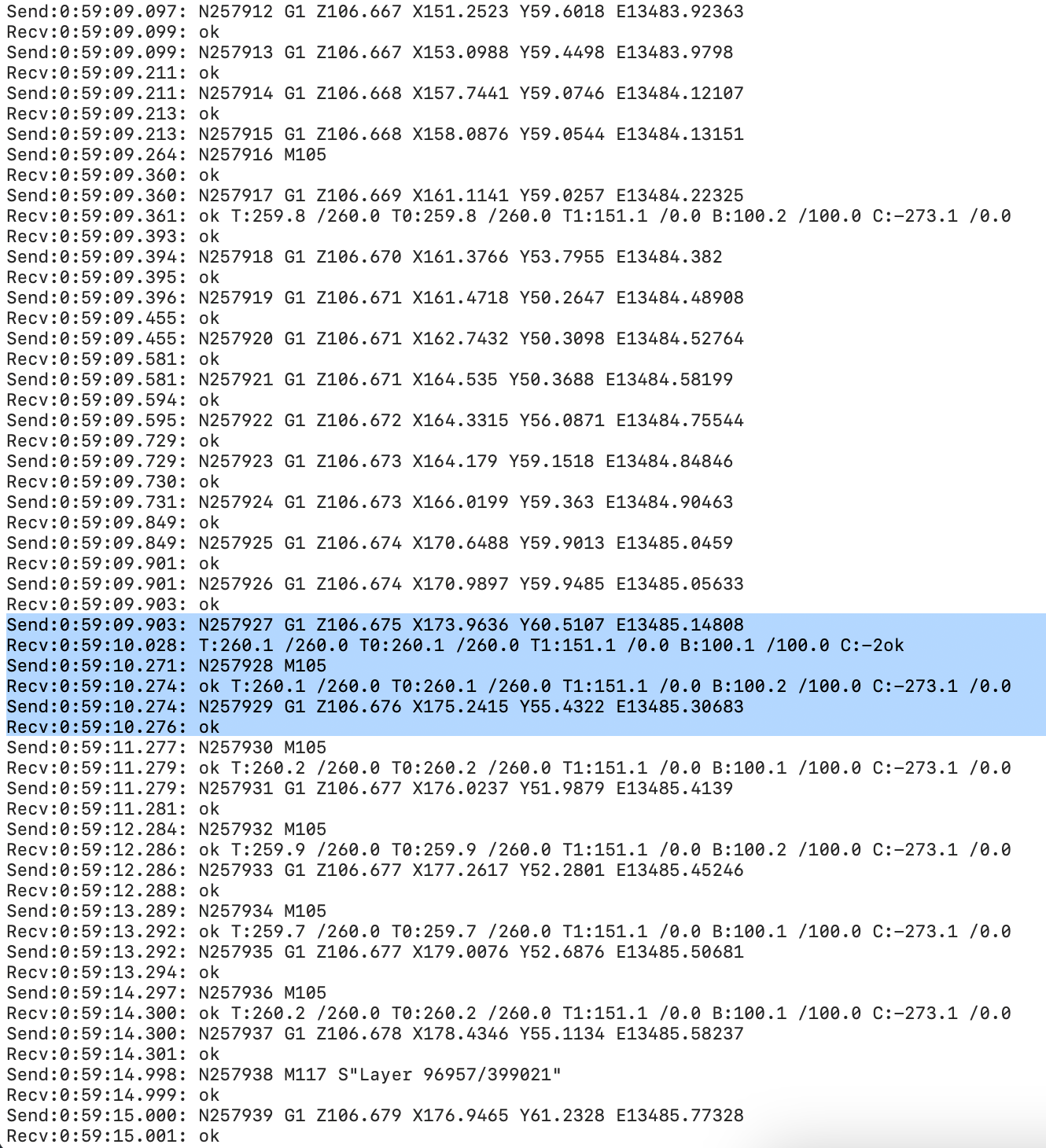

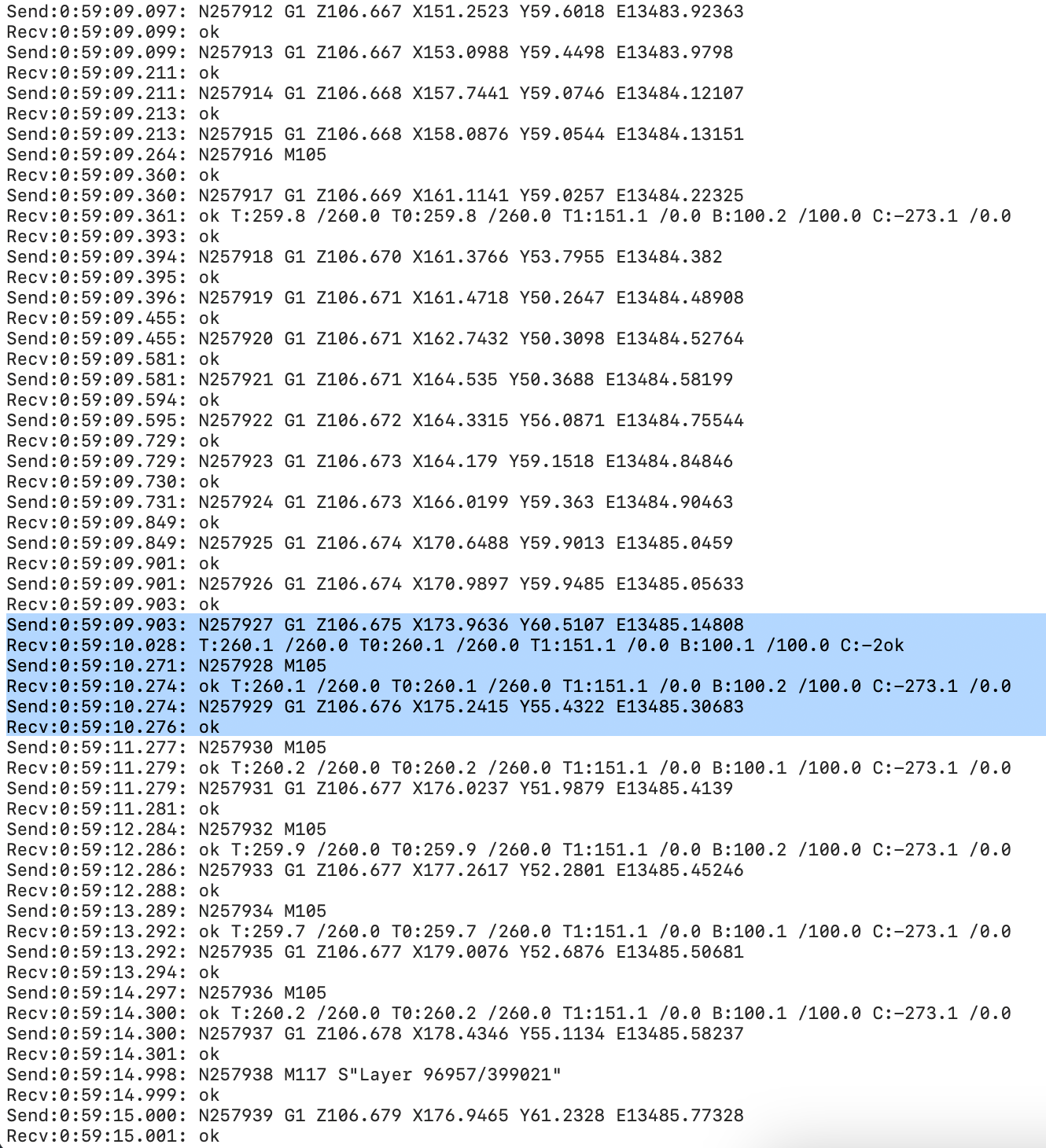

You can see it happening in the below screenshot quite nicely in the highlighted part.

Hers an M122 while it was stuttering.

M122

=== Diagnostics ===

RepRapFirmware for Duet 2 WiFi/Ethernet version 3.4.1 (2022-06-01 21:05:28) running on Duet WiFi 1.02 or later + DueX5v0.11

Board ID: 0JD0M-9P6B2-NJ4S8-6J1D8-3SJ6R-TB4QK

Used output buffers: 3 of 26 (20 max)

=== RTOS ===

Static ram: 23860

Dynamic ram: 77504 of which 12 recycled

Never used RAM 9840, free system stack 88 words

Tasks: NETWORK(ready,1822.3%,242) HEAT(notifyWait,38.9%,308) Move(notifyWait,663.8%,282) DUEX(notifyWait,0.0%,24) MAIN(running,1279.0%,440) IDLE(ready,9.0%,30), total 3813.0%

Owned mutexes:

=== Platform ===

Last reset 44:36:32 ago, cause: software

Last software reset at 2023-12-05 11:48, reason: User, GCodes spinning, available RAM 10232, slot 0

Software reset code 0x0003 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0041f000 BFAR 0xe000ed38 SP 0x00000000 Task MAIN Freestk 0 n/a

Error status: 0x00

Step timer max interval 0

MCU temperature: min 25.3, current 33.1, max 34.5

Supply voltage: min 23.3, current 23.5, max 24.3, under voltage events: 0, over voltage events: 0, power good: yes

Heap OK, handles allocated/used 0/0, heap memory allocated/used/recyclable 0/0/0, gc cycles 0

Events: 0 queued, 0 completed

Driver 0: standstill, SG min 0

Driver 1: standstill, SG min 0

Driver 2: standstill, SG min 0

Driver 3: standstill, SG min 0

Driver 4: standstill, SG min n/a

Driver 5: standstill, SG min 0

Driver 6: standstill, SG min 0

Driver 7: standstill, SG min n/a

Driver 8: standstill, SG min n/a

Driver 9: standstill, SG min n/a

Driver 10:

Driver 11:

Date/time: 2023-12-07 08:24:36

Cache data hit count 4294967295

Slowest loop: 6.92ms; fastest: 0.12ms

I2C nak errors 0, send timeouts 0, receive timeouts 0, finishTimeouts 0, resets 0

=== Storage ===

Free file entries: 10

SD card 0 detected, interface speed: 20.0MBytes/sec

SD card longest read time 4.1ms, write time 0.0ms, max retries 0

=== Move ===

DMs created 83, segments created 36, maxWait 54387006ms, bed compensation in use: mesh, comp offset 0.000

=== MainDDARing ===

Scheduled moves 1165291, completed 1165291, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 1, 38901], CDDA state -1

=== AuxDDARing ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters 0 -1 -1 -1, chamber heaters 3 -1 -1 -1, ordering errs 0

Heater 0 is on, I-accum = 0.1

Heater 1 is on, I-accum = 0.6

=== GCodes ===

Segments left: 0

Movement lock held by null

HTTP is idle in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger is idle in state(s) 0

Queue is idle in state(s) 0

LCD is idle in state(s) 0

Daemon is idle in state(s) 0

Autopause is idle in state(s) 0

Code queue is empty

=== DueX ===

Read count 12, 0.00 reads/min

=== Network ===

Slowest loop: 19.20ms; fastest: 0.00ms

Responder states: HTTP(2) HTTP(0) HTTP(0) HTTP(0) FTP(0) Telnet(0), 0 sessions

HTTP sessions: 1 of 8

- WiFi -

Network state is active

WiFi module is connected to access point

Failed messages: pending 0, notready 0, noresp 0

WiFi firmware version 1.26

WiFi MAC address 48:3f:da:a6:c0:61

WiFi Vcc 3.38, reset reason Power up

WiFi flash size 2097152, free heap 25272

WiFi IP address 192.168.186.225

WiFi signal strength -50dBm, mode 802.11n, reconnections 0, sleep mode modem

Clock register 00002002

Socket states: 0 0 0 0 0 0 0 0

Maybe you have an idea and ideally a suggestion / a fix as well.