For anybody looking in the future, that did not in fact work. I went all the way up to M570 H0 P60 T40 and still had spurious heater faults. https://github.com/Duet3D/Duet3Expansion/pull/23 seems to have really fixed it, without needing to change M570 from the defaults at all.

Posts made by bsilver8192

-

RE: [3.6.0-beta.4] heater feed forward leads to heater faultsposted in Beta Firmware

-

RE: [3.6.0-beta.4] heater feed forward leads to heater faultsposted in Beta Firmware

Thanks, looks like that was the trick. I ended up with

M570 H0 P30 T20for anybody else's reference. TheT20is more important than I had guessed from the docs. -

[3.6.0-beta.4] heater feed forward leads to heater faultsposted in Beta Firmware

I experimented with the heater feed forward for my hotend, but couldn't avoid constant heater faults. When enabling any amount of feed forward or temperature increase based on feed rate, I got a steady stream of "temperature rising much more slowly than the expected" errors. The "actual" numbers were all over the map, with some negative. I suspect this is because my hotend responds much slower than the feed rate changes, and the heater fault tracking doesn't handle this situation very well. Maybe it doesn't work when the setpoint moves faster than the dead time?

My heating process parameters are

M307 H0 R1.900 K0.131:0.000 D9.00 E1.35 S1.00 B0 V25.4, from an auto calibration run. Those seem fairly correct to me, I don't get any heater faults normally and it holds temperature fairly well. There's a large delay between changing anything (heater PWM, feed rate, or part fan) and the temperature responding, I suspect because the heater cartridge is on the far side of a big copper block from the temperature sensor. I tried turning up the heater fault detection time, which definitely increased the time between heater faults but did not avoid them.I was previously running 3.5.2, and I had a

M309 P0 S0.12but I'm not sure it ever did anything. After upgrading to 3.6.0-beta.4 I had to remove it.My config.g (with the feed forward commented out) is attached: config.g

My printer is a CreatBot D600 Pro with an almost-entirely custom control system and print head (tldr: big cartesian printer with heated chamber and a 600mm x 600mm x 600mm build volume). The print head is a Hemera XS and SuperVolcano, with a 1mm brass nozzle. The X and Y axes each have a single JSS57P1.5N integrated digital hybrid servo (stepper motor with an encoder and servo controller attached to it which takes step+direction directly). The X and Y axes are controlled from the mainboard stepper expansion header, via a 5V level shifter. The Z axis is a stepper (57HS76-3004A08-D21-16 I think? haven’t flipped the printer over to confirm) driven by a MKS TB6600 V1.1, controlled from a custom expansion board. I’m using PrusaSlicer (config bundle attached, renamed to .txt). The control system is a Duet 3 Mini 5+ mainboard, a custom Sammy-C21-based expansion board, and a Duet 3 Toolboard 1LC in the print head. They’re all running 3.6.0-beta.4, with a few changes to the config #defines in Config/SAMMYC21.h.

-

RE: Software bundle 3.6.0-beta.4 availableposted in Beta Firmware

Works great for me. Solved 2 problems I was having with 3.5.2, both seem related to synchronization of an extruder on an expansion board. See https://forum.duet3d.com/topic/37435/extrusion-gaps-after-arcs for one of the problems and my config.g for reference on what features I tested.

The other problem was sharp corners looked like they had too much pressure advance, even though I was using 0 pressure advance. They were under-extruded going into the corner (while the printer was decelerating), and then over-extruded after the corner. I had assumed it was due to the huge SuperVolcano hotend, but upgrading to 3.6.0-beta.4 fixed it.

-

RE: Extrusion gaps after arcsposted in Tuning and tweaking

Thank you very much! 3.6.0-beta.4 completely solved this, works great with G1 segments or G2/G3 arcs now.

-

RE: 3.6.0-beta.2 Pressure Advance Issue?posted in Beta Firmware

@droftarts said in 3.6.0-beta.2 Pressure Advance Issue?:

@T3P3Tony Maybe this one is related? https://forum.duet3d.com/topic/37435/extrusion-gaps-after-arcsChecked the attached Gcode, all G1 moves not G2/3 arcs.

Ian

(OP from the linked topic) these still sound related: so far I've only tested with 3.5.2, and the problem in this topic was reported to also happen with G1 in 3.5.4. The big difference I see is that I have PA turned off completely though. I'm planning to test with 3.6.0-beta4 tomorrow, and I'll report back in my topic about how it goes.

Also hearing about issues with holes is helpful, I haven't tried printing any parts with large holes so I'll add that to my list now.

-

Extrusion gaps after arcsposted in Tuning and tweaking

I’m having a strange problem with my Duet-controlled printer: after every arc in every perimeter, there’s a gap. My test part has long straight edges after the arcs, and I’m pretty sure I see a single G1 in the gcode (attached) printing the entire edge. With some larger gaps, I can see the extruder drivetrain stutter/stop as it passes over the gaps. I’m pretty sure the smaller ones are doing the same thing, just too quickly for me to see. My config.g is attached. Why is this happening, and how do I make it stop?

I’ve tried several sizes, orientations, and mirroring of this test part, and the gaps are always after the arcs in the direction the perimeters are printed. The gaps are aligned through the perimeters of the brim and every layer. The brim + first layer are printed slower than the subsequent perimeters, so I don’t think the position is determined by speed. Changing the overall print speed does not affect the location of the gaps either. I don't hear the X, Y, or Z axes do anything different as the print head moves over the gaps. The gaps are a different distance away from each corner, and seem to move proportionately when I scale the size of the part. It’s hard to tell if the distances are proportional to the radius of the arc they’re after, because when the extrusion pauses like this the filament gets stretched without sticking so I can't measure the gap location very precisely. The gaps are more severe at higher print speeds, but even at very low speeds they are still noticeable. The gaps do appear in the outermost perimeters of the brim around sharp corners (ie after the arcs which are only in the brim). I've tried slicing with arcs as G2/G3, and with them all as linear G1 segments, and see these gaps in the same place either way.

I am not using extruder pressure advance or input shaping. I couldn’t get good results with pressure advance, so I have the extruder acceleration turned way down instead. Changing the extruder acceleration does not affect the location of the gaps (but causes other print quality problems), and I haven't kept track of whether it affects the size of the gaps.

I do have mesh bed compensation turned on (the large glass bed sags enough to matter), but I don’t think it’s part of the problem because the gaps follow the part around the bed, instead of staying in place relative to the mesh bed leveling boundaries. Also the infill and top/bottom surfaces adjacent to the perimeter gaps look fine.

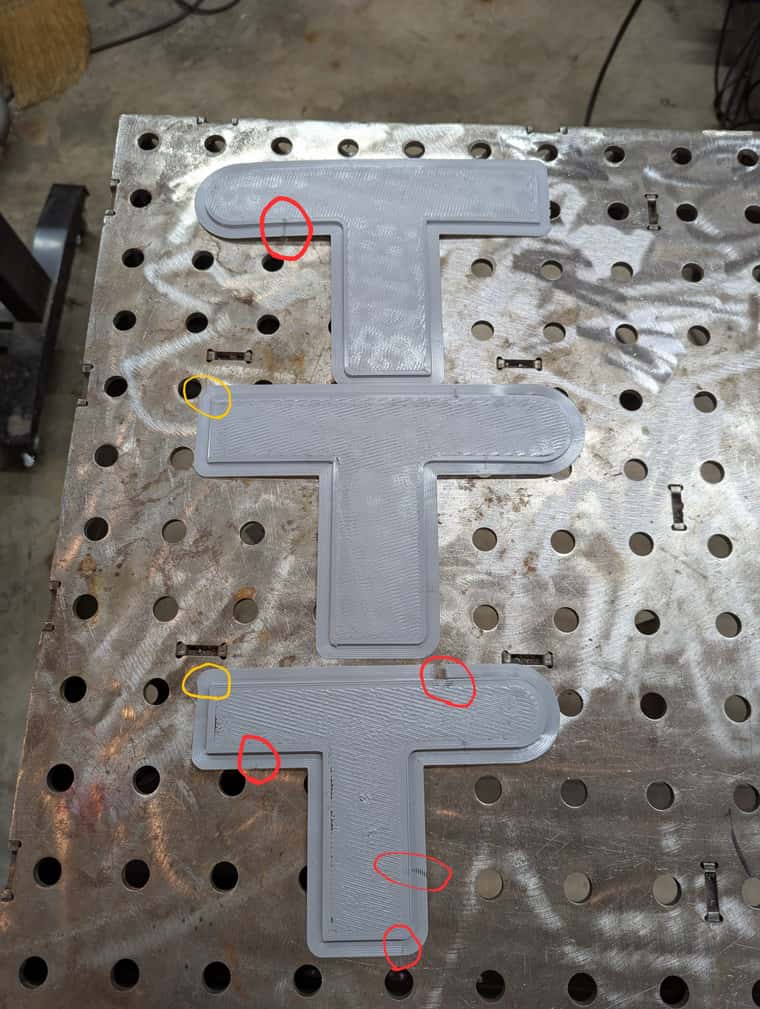

The gaps are not at the ends of the perimeters. That’s circled in yellow in one of the attached pictures, they all look fine.

Some more details:

My printer is a CreatBot D600 Pro with an almost-entirely custom control system and print head (tldr: big cartesian printer with heated chamber and a 600mm x 600mm x 600mm build volume). The print head is a Hemera XS and SuperVolcano, with a 1mm brass nozzle. The X and Y axes each have a single JSS57P1.5N integrated digital hybrid servo (stepper motor with an encoder and servo controller attached to it which takes step+direction directly). The X and Y axes are controlled from the mainboard stepper expansion header, via a 5V level shifter. The Z axis is a stepper (57HS76-3004A08-D21-16 I think? haven’t flipped the printer over to confirm) driven by a MKS TB6600 V1.1, controlled from a custom expansion board. I’m using PrusaSlicer (config bundle attached, renamed to .txt). The control system is a Duet 3 Mini 5+ mainboard, a custom Sammy-C21-based expansion board, and a Duet 3 Toolboard 1LC in the print head. They’re all running 3.5.2, with a few changes to the config #defines in Config/SAMMYC21.h.PrusaSlicer_config_bundle_20250209_1.ini.txt

printer test T 20250209 11.gcode

config.gPerimeter boundaries circled in yellow, some of the gaps circled in red: