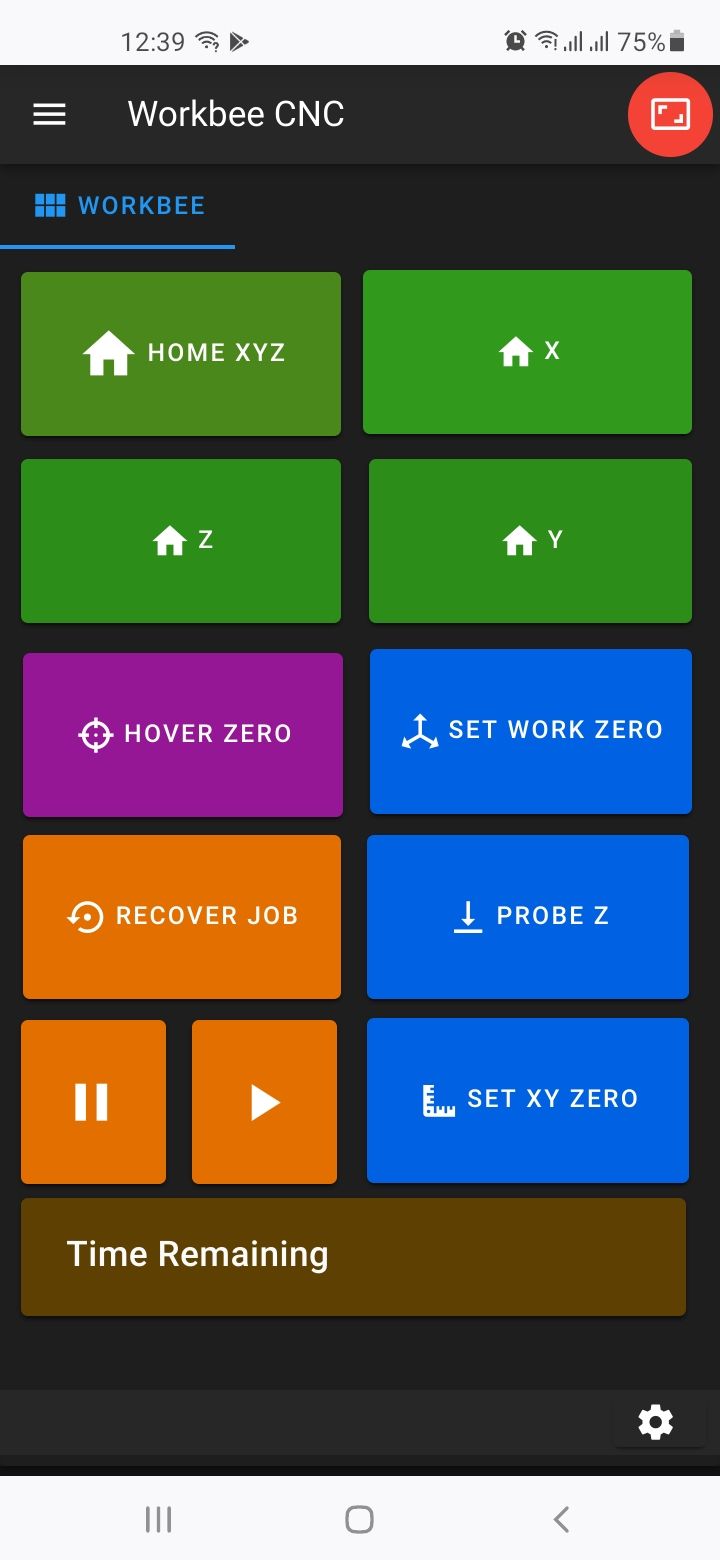

I will like to share an app I have been using for sometime now with my workbee CNC. It's available on the Google play store Duet Jogger

I will like to share an app I have been using for sometime now with my workbee CNC. It's available on the Google play store Duet Jogger

I use a touchscreen device to control my workbee and accidental clicks have exposed some issues with Duet Web Control which you may have overlooked.

It is possible to click the button to turn off the spindle/tool when a job is active, potentially crashing and breaking an endmill.

Movement, homing and set axis zero buttons on the dashboard should be disabled/greyed out when a job is running but not when paused. I accidentally set a new X Zero in the middle of a job and ruined the part.

These accidental clicks have mostly occurred when scrolling through the UI during a job.

Hi, I have successfully migrated to RRF3.2.2 and everything works at it should. I really like added features especially the Gamepad jogger plugin. However, the interface still has a lot of 3D printer features remaining e.g. extruders and temperature which are not needed with CNCs. Is it possible to completely remove these in order to get a cleaner look? I think a hybrid of Ooznest's Workbee Control with the added features of DWC-CNC will be the best of both worlds. An XYZ probe macro and power-loss resume button will also be greatly welcome.

Thanks for your efforts.

@nightowl999 Since most people who are present on this forums are in need of technical help you will only find a few active CNC users. The Ooznest Workbee CNC comes with the Duet board and is very popular. You can get user feedback/input from the Facebook group here.

WorkbeeCNC Group

Hi. I just saw that this project has been updated to DWC 3.3 rc1. Glad to know it hasn't been abandoned. I'll be getting a Neje laser module to attach to my CNC soon and will be coming back to RRF3

@p0rr1dg3 I have an Ooznest Workbee CNC. It is configured with soft limits which prevent the machine from moving outside the machine limits.

What version of Duet Web Control are you using?

In CNC mode, we have machine coordinates (the actual physical limits of the CNC) and work coordinates, which are job specific.

When you set your X0 Y0 and Z0 they fall within the machine coordinates and you will get an error notification when the machine is given a command to move out of bounds.

Your work coordinates CANNOT exceed your machine coordinates limits.

Edit

I see you're using very old firmware. Please upgrade to the latest stable firmware and your issues will be solved.

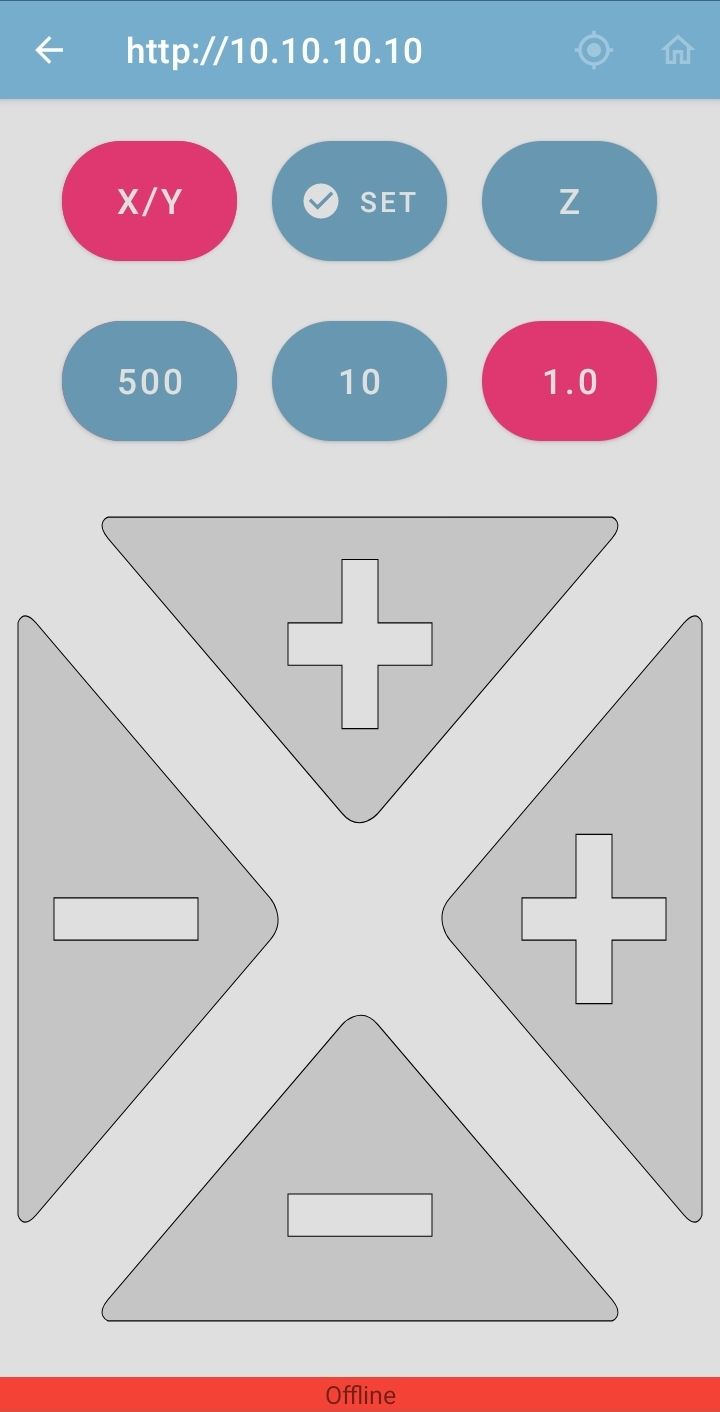

@gloomyandy Other than Files --> Jobs, the above screenshots are the only interface elements I would usually need to control my Duet from my phone. The other parts of Web Control still load and add to memory usage causing some lag. Also this plugin interface is not the default when I open DWC, I still have to find the plugin in the side panel and open it from there. Then I have to click the icon to hide the rest of the interface.

When a job starts the interface automatically switches to Job Status which is not really optimised for my use case. I prefer the first screenshot as I only need to pause or see the time remaining when I start a job on my CNC. Speed factor and baby stepping can be handled by the BtnCmd plugin but I don't need Layer Height, Filament, Extruder etc when running a job. It makes finding the information you need more difficult. I would propose hiding unpopulated labels from showing in DWC. That should give a cleaner interface.

I believe this problem has already been addressed in some post.

Create two macros, one for switching laser on and another for switching off

Turn laser On

M950 P0 C"!exp.heater3" Q500 ; allocate GPIO port 0 to heater3 on expansion connector, 500Hz

M42 P0 S0.1 ; set 10% PWM duty on GPIO port 0

Turn laser Off

M950 P0 C"!exp.heater3" Q500 ; allocate GPIO port 0 to heater3 on expansion connector, 500Hz

M42 P0 S0 ; set 0% PWM duty on GPIO port 0

I have used this plugin to create a simplified dashboard to control my CNC on a mobile phone as the default dashboard is too cluttered for me.

I would like to add movement buttons to another tab that I can set move distances like this

Any idea how this can be achieved?

@Sindarius @chrishamm

The current implementation of Go to Workzero moves the spindle through the shortest possible path to the zero position which can have bit breaking or work damaging consequences. For CNC application it is safer to home Z first, then move to X and Y zero before moving down to Z zero.

Is it possible to modify the UI so that the Go to Workzero button on the dashboard calls a workzero.g file? Similar to how the Ooznest UI does it. This way we can edit the command and ensure such damage does not happen.

Thanks

@sindarius Tested today and everything works great  . Thanks a lot

. Thanks a lot

I had to modify my workzero.g file, I found my Z axis moving up and crashing whenever I used to Go to Zero.

The offending line was

G1 H1 Z1500 F2400

before the X and Y axis movement.

I replaced that line with

M98 Phomez.g

and it's working OK now.

It would be nice if this macro could be made into a plugin. Then you wouldn't have to edit the macro to change parameters. Something like the CNC touchprobe plugin by @raymondstone

I tested this macro today. Works nicely, had to edit some parameters for my Ooznest touchprobe input. Thanks a lot

; Adjust probe for low speed probing

M558 K0 P8 C"!e0stop" H20 F120 T300 ; Z probe number - Z probe switch type - probe recovery 1s probe speed and travel speed

@Atair said in Duet3D is useless as a CNC Controller!:

s for the GCode - i went with the default-ish Mach3 postprocessor (using RhinoCam / VisualMill), and there the arcs got messed up (the two 'lower' ones - out of 4 total).

I think this may be the cause of the issues you are having. A Mach3 postprocessor will not produce g-code that works well with RepRap firmware.