@jatmn cheers. I do try. I'll try the same print on my skr running RRF tomorrow.

Do you have shots from prints running Marlin?

@jatmn cheers. I do try. I'll try the same print on my skr running RRF tomorrow.

Do you have shots from prints running Marlin?

Anyone can view the configuration for this printer here:

https://github.com/opsensai/sk-go-duet-config/blob/master/config.g

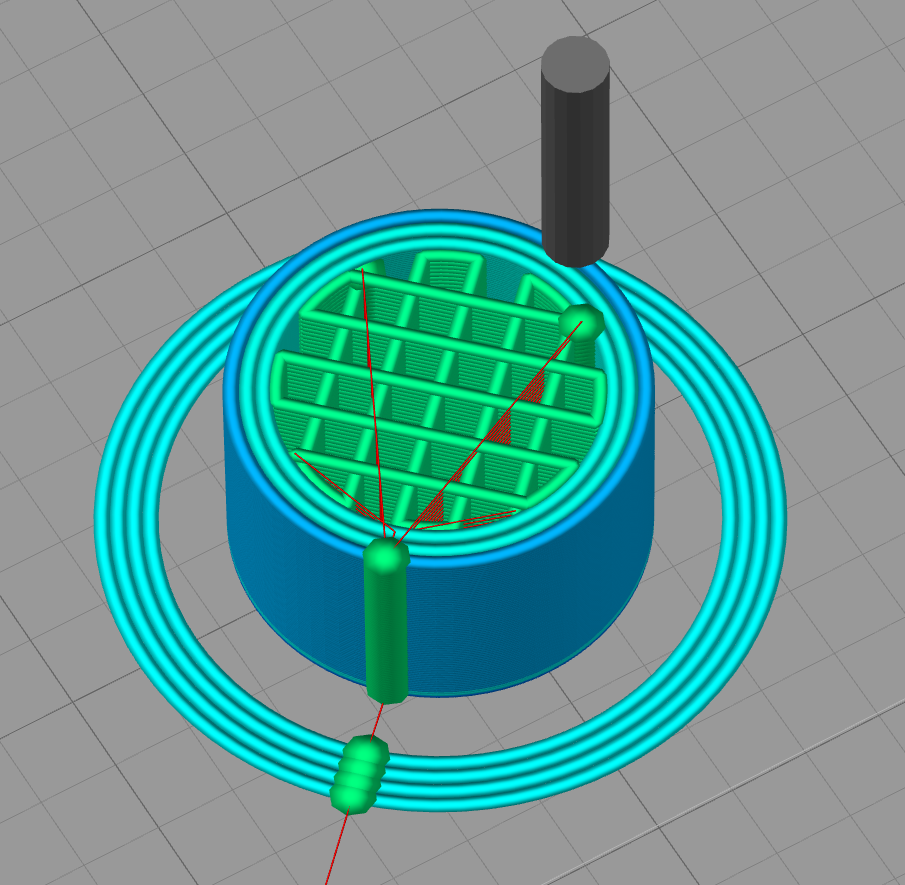

I scaled down the model so I could get the prints out a little faster. Cut it down to 10mm and was more than enough to show the behavior. Top print is outside-in, bottom print is inside-out. The results don't match what I would have anticipated from the slicer here. Both have visible seams. With inside-out looking marginally worse.

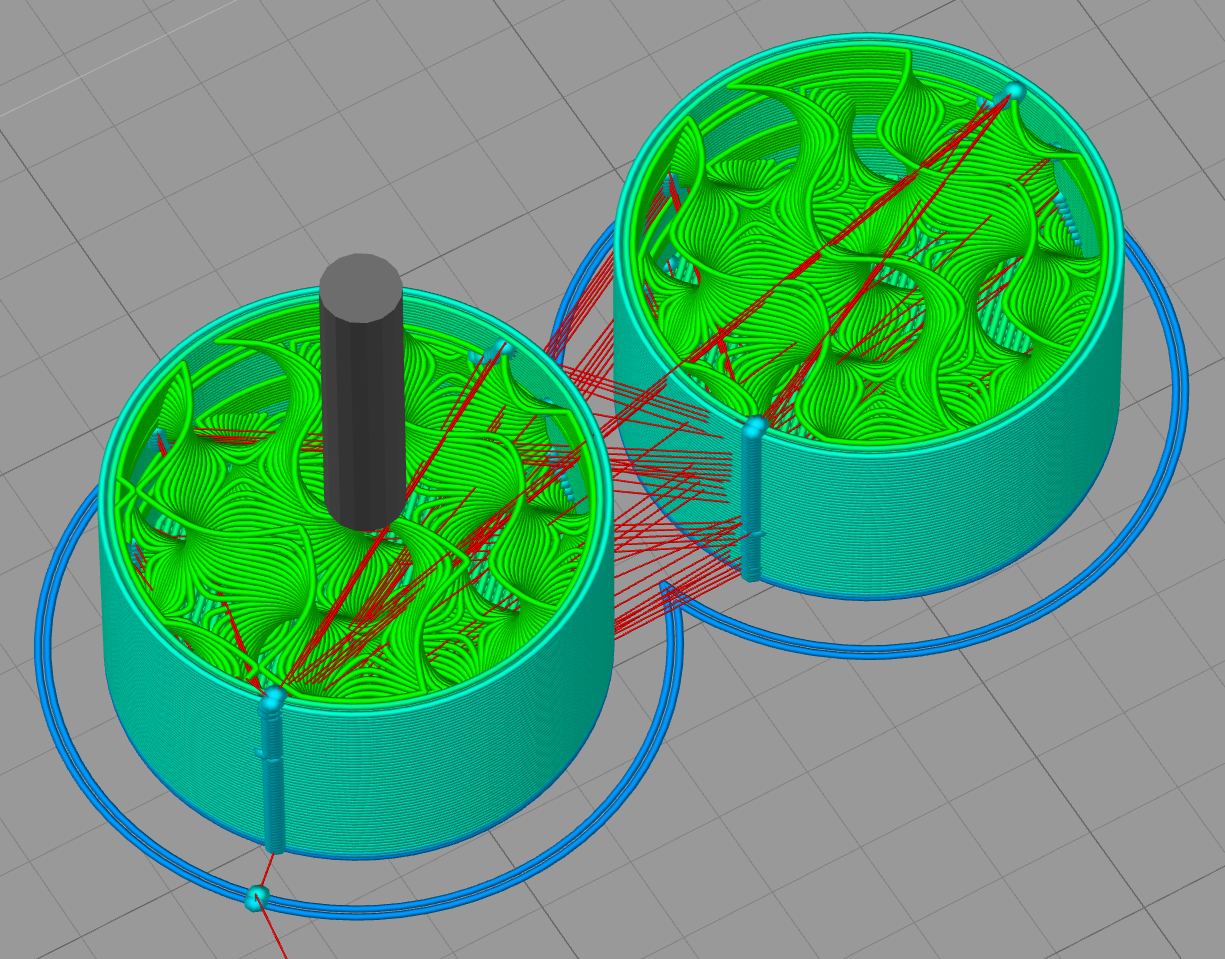

Whilst I wait for my prints to finish, I thought I'd stick this up. I opened up your gcode in simplify3d to see where the retraction points were:

You can see that you're retracting on both the inner and outer layers of the shell.

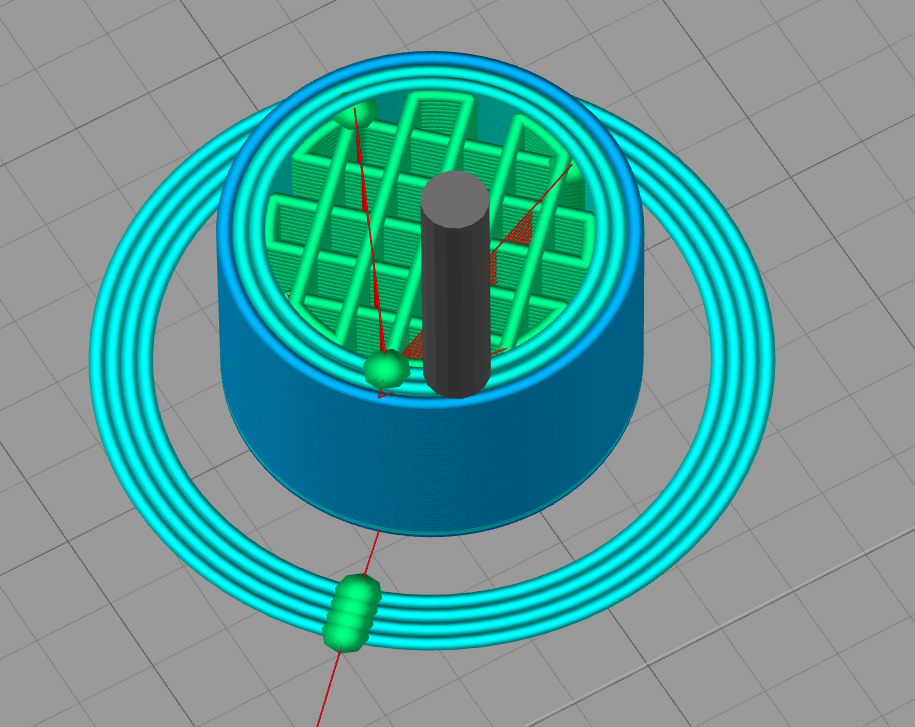

With my stock simplify3d settings a single print of your STL looks as follows:

Yes I'm doing three shells, but I'm only retracting at movements and layer changes (both turned on). There is no alignment of retractions.

I'm currently printing one inside-out, and one outside-in print to see how they differ.

At least according to the slicer, for outside-in I'll see retractions on the outer shell of the print:

Also do you get the same results with pressure advance turned off? I see M572 D0 S0.05 in the cylinder gcode.

Can you send me the stl also? I want to see how your gcode, vs my gcode varies.

Maybe post your config-override.g as well for completeness? Since you do run an M501 at the end...

I took popped one of the mosfets on one of my printers. Rather unfortunate grounding incident

Luckily I had another free PWM output so I was able to move over the connector.

I have also seen fans go weird about PWM after a while. 25mm fans I've gotten I've seen fail to start. So much so that I now put B3 to blip the fan for 3 seconds into my config.

Those mosfets are tiny and I was tempted to repair it (have a hot air rework station) but since my board is actually functional in its current state, unless I fry another I'm not going near it

Can you unplug either of the thermistors and have the board continue to report a temperature for the now-unplugged thermistor?

What I'm thinking is that somehow that the input is bridged. Doesn't make much sense but worth a shot in troubleshooting.

I looked over your config, and don't see anything wrong with it apart from the heaters not conforming with the standard H0 being the bed (I'm sure your slicer will need to be informed about that). Also your temps would be wrong (since you have a top temp of 280 for your bed, and 120 for your extruder).

From your config it appears like you're not using any overrides. Is this issue present from the moment you power on the board? It is possible to have other gcode elsewhere, like in homeall.g for instance if you were really crazy.

My bog standard configuration from a printer I setup the other day looks as follows:

; Heaters

M308 S0 P"bedtemp" Y"thermistor" T100000 B4138 ; configure sensor 0 as thermistor on pin bedtemp

M950 H0 C"bed" T0 ; create bed heater output on bed and map it to sensor 0

M307 H0 B0 S1.00 ; disable bang-bang mode for the bed heater and set PWM limit

M140 H0 ; map heated bed to heater 0

M143 H0 S120 ; set temperature limit for heater 0 to 120C

M308 S1 P"e0temp" Y"thermistor" T100000 B4725 C7.060000e-8; configure sensor 1 as thermistor on pin e0temp

M950 H1 C"e0heat" T1 ; create nozzle heater output on e0heat and map it to sensor 1

M307 H1 B0 S1.00 ; disable bang-bang mode for heater and set PWM limit