My setup:

1 6HC, SBC mode, CNC mode, non-printer application

3 3HC

All boards at 3.5.4

13 stepper motors, 10 Nema17 and 3 Nema23

Pi5 4GB with DuetPi from Nov. 2024

Power supply is 24V, 20A split to all 4 boards

My machine has been running for a year now and just this week, I am suddenly getting resets from the 3HC boards.

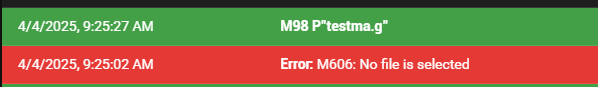

I have expansion-timeout and expansion-reconnect report out the board # when an event occurs, so when the latest reset occurred on board 3, in the DWC, I get :

I then pulled an M122 B3 and M122.

M122 B3 before the disconnect/reset

4/9/2025, 12:20:37 PM M122 B3

Diagnostics for board 3:

Duet EXP3HC rev 1.02 or later firmware version 3.5.4 (2024-11-24 10:40:29)

Bootloader ID: SAME5x bootloader version 2.11 (2024-08-09)

All averaging filters OK

Never used RAM 156540, free system stack 178 words

Tasks: Move(3,nWait 7,0.0%,145) HEAT(2,nWait 6,0.0%,130) CanAsync(5,nWait 4,0.0%,62) CanRecv(3,nWait 1,0.0%,74) CanClock(5,nWait 1,0.0%,63) TMC(2,nWait 6,6.8%,95) MAIN(1,running,92.0%,438) IDLE(0,ready,0.0%,39) AIN(2,delaying,1.1%,259), total 100.0%

Owned mutexes:

Last reset 00:09:49 ago, cause: power up

Last software reset data not available

Driver 0: pos 0, 8.9 steps/mm, standstill, SG min 0, mspos 8, reads 61258, writes 16 timeouts 0, steps req 0 done 0

Driver 1: pos 0, 6.7 steps/mm, standstill, SG min 0, mspos 8, reads 61258, writes 16 timeouts 0, steps req 0 done 0

Driver 2: pos 1351998, 1600.0 steps/mm, standstill, SG min 0, mspos 584, reads 61258, writes 17 timeouts 0, steps req 0 done 403620

Moves scheduled 9, completed 9, in progress 0, hiccups 0, segs 6, step errors 0, maxLate 0 maxPrep 16, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0, ebfmin 0.00 max 0.00

Peak sync jitter -6/6, peak Rx sync delay 184, resyncs 0/0, no timer interrupt scheduled

VIN voltage: min 23.8, current 23.8, max 24.1

V12 voltage: min 12.3, current 12.3, max 12.4

MCU temperature: min 30.5C, current 30.8C, max 33.1C

Last sensors broadcast 0x00000000 found 0 73 ticks ago, 0 ordering errs, loop time 0

CAN messages queued 4869, send timeouts 0, received 5311, lost 0, errs 0, boc 0, free buffers 38, min 38, error reg 0

dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 403, adv 37023/37086

M122 B3 after the disconnect/reset

4/9/2025, 12:57:22 PM M122 B3

Diagnostics for board 3:

Duet EXP3HC rev 1.02 or later firmware version 3.5.4 (2024-11-24 10:40:29)

Bootloader ID: SAME5x bootloader version 2.11 (2024-08-09)

All averaging filters OK

Never used RAM 156684, free system stack 180 words

Tasks: Move(3,nWait 7,0.0%,128) HEAT(2,nWait 6,0.0%,132) CanAsync(5,nWait 4,0.0%,66) CanRecv(3,nWait 1,0.0%,74) CanClock(5,nWait 1,0.0%,64) TMC(2,nWait 6,7.0%,61) MAIN(1,running,91.8%,387) IDLE(0,ready,0.0%,39) AIN(2,delaying,1.1%,264), total 100.0%

Owned mutexes:

Last reset 00:04:28 ago, cause: reset button

Last software reset data not available

Driver 0: pos -17952, 80.0 steps/mm, standstill, SG min 0, mspos 200, reads 56767, writes 16 timeouts 0, steps req 0 done 20268

Driver 1: pos 0, 80.0 steps/mm, standstill, SG min n/a, mspos 840, reads 56770, writes 13 timeouts 0, steps req 0 done 0

Driver 2: pos -994, 80.0 steps/mm, standstill, SG min 0, mspos 712, reads 56770, writes 14 timeouts 0, steps req 0 done 2240

Moves scheduled 13, completed 13, in progress 0, hiccups 0, segs 6, step errors 0, maxLate 0 maxPrep 17, maxOverdue 0, maxInc 0, mcErrs 0, gcmErrs 0, ebfmin 0.00 max 0.00

Peak sync jitter -6/6, peak Rx sync delay 180, resyncs 0/0, no timer interrupt scheduled

VIN voltage: min 22.2, current 23.8, max 23.9

V12 voltage: min 12.3, current 12.3, max 12.4

MCU temperature: min 34.0C, current 34.2C, max 35.5C

Last sensors broadcast 0x00000000 found 0 157 ticks ago, 0 ordering errs, loop time 0

CAN messages queued 2169, send timeouts 0, received 2437, lost 0, errs 0, boc 0, free buffers 38, min 38, error reg 0

dup 0, oos 0/0/0/0, bm 0, wbm 0, rxMotionDelay 399, adv 36151/37197

I can assure you that no one is pressing the reset button on the 3HC board.

M122 for 6HC after the disconnect/reset

4/9/2025, 12:59:37 PM M122

=== Diagnostics ===

RepRapFirmware for Duet 3 MB6HC version 3.5.4 (2024-11-24 10:47:10) running on Duet 3 MB6HC v1.01 (SBC mode)

Board ID: 08DJM-9P63L-DJMSS-6J9F0-3SN6N-9UHZA

Used output buffers: 1 of 40 (24 max)

=== RTOS ===

Static ram: 155464

Dynamic ram: 98656 of which 0 recycled

Never used RAM 18360, free system stack 138 words

Tasks: SBC(2,ready,2.0%,747) HEAT(3,nWait 6,0.0%,351) Move(4,nWait 6,0.1%,211) CanReceiv(6,nWait 1,0.0%,769) CanSender(5,nWait 7,0.0%,329) CanClock(7,delaying,0.0%,346) TMC(4,nWait 6,9.2%,53) MAIN(2,running,87.5%,444) IDLE(0,ready,1.2%,29), total 100.0%

Owned mutexes: HTTP(MAIN)

=== Platform ===

Last reset 00:48:49 ago, cause: power up

Last software reset at 2025-04-09 12:10, reason: User, Expansion spinning, available RAM 19224, slot 0

Software reset code 0x6012 HFSR 0x00000000 CFSR 0x00000000 ICSR 0x0044a000 BFAR 0x00000000 SP 0x00000000 Task SBC Freestk 0 n/a

Error status: 0x00

MCU temperature: min 40.6, current 44.0, max 44.3

Supply voltage: min 21.7, current 23.7, max 23.8, under voltage events: 0, over voltage events: 0, power good: yes

12V rail voltage: min 12.2, current 12.3, max 12.3, under voltage events: 0

Heap OK, handles allocated/used 297/281, heap memory allocated/used/recyclable 6144/5008/80, gc cycles 59

Events: 1 queued, 1 completed

Driver 0: standstill, SG min 0, mspos 600, reads 60927, writes 6 timeouts 0

Driver 1: standstill, SG min 0, mspos 1016, reads 60927, writes 6 timeouts 0

Driver 2: standstill, SG min n/a, mspos 8, reads 60933, writes 0 timeouts 0

Driver 3: standstill, SG min 0, mspos 280, reads 60927, writes 6 timeouts 0

Driver 4: standstill, SG min 0, mspos 184, reads 60928, writes 6 timeouts 0

Driver 5: standstill, SG min 0, mspos 520, reads 60927, writes 6 timeouts 0

Date/time: 2025-04-09 12:59:37

Slowest loop: 57.87ms; fastest: 0.04ms

=== Storage ===

Free file entries: 20

SD card 0 not detected, interface speed: 37.5MBytes/sec

SD card longest read time 0.0ms, write time 0.0ms, max retries 0

=== Move ===

DMs created 125, segments created 6, maxWait 203822ms, bed compensation in use: none, height map offset 0.000, max steps late 0, min interval 0, bad calcs 0, ebfmin 0.00, ebfmax 0.00

no step interrupt scheduled

Moves shaped first try 0, on retry 0, too short 0, wrong shape 0, maybepossible 0

=== DDARing 0 ===

Scheduled moves 1659, completed 1659, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 272], CDDA state -1

=== DDARing 1 ===

Scheduled moves 0, completed 0, hiccups 0, stepErrors 0, LaErrors 0, Underruns [0, 0, 0], CDDA state -1

=== Heat ===

Bed heaters -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1 -1, chamber heaters -1 -1 -1 -1, ordering errs 0

=== GCodes ===

Movement locks held by null, null

HTTP* is doing "M122" in state(s) 0

Telnet is idle in state(s) 0

File is idle in state(s) 0

USB is idle in state(s) 0

Aux is idle in state(s) 0

Trigger* is idle in state(s) 0

Queue* is idle in state(s) 0

LCD is idle in state(s) 0

SBC* is idle in state(s) 0

Daemon is idle in state(s) 0

Aux2 is idle in state(s) 0

Autopause is idle in state(s) 0

File2 is idle in state(s) 0

Queue2 is idle in state(s) 0

Q0 segments left 0, axes/extruders owned 0x0000000

Code queue 0 is empty

Q1 segments left 0, axes/extruders owned 0x0000000

Code queue 1 is empty

=== CAN ===

Messages queued 22635, received 58478, lost 0, errs 0, boc 0

Longest wait 3ms for reply type 6024, peak Tx sync delay 274, free buffers 50 (min 48), ts 11735/11735/0

Tx timeouts 0,0,0,0,0,0

=== SBC interface ===

Transfer state: 5, failed transfers: 0, checksum errors: 0

RX/TX seq numbers: 20833/20833

SPI underruns 0, overruns 0

State: 5, disconnects: 0, timeouts: 0 total, 0 by SBC, IAP RAM available 0x24cfc

Buffer RX/TX: 0/0-0, open files: 0

=== Duet Control Server ===

Duet Control Server version 3.5.4 (2024-11-25 17:32:26, 64-bit)

HTTP+Executed:

> Executing M122

Code buffer space: 4096

Configured SPI speed: 8000000Hz, TfrRdy pin glitches: 9

Full transfers per second: 53.22, max time between full transfers: 45.8ms, max pin wait times: 32.9ms/6.1ms

Codes per second: 3.93

Maximum length of RX/TX data transfers: 6217/944

config.g

; General preferences

M453 ; set CNC mode

M550 P"A1000-0" ; set name of controller

G90 ; set absolute coordinates

G4 P1000 ; 1s delay for CAN comms

; Drives

; Motors are wired to Duet A-A, B-B - motor directions are flipped here

M569 P0.0 S0 ; physical drive 0.0 goes forwards

M569 P0.1 S0 ; physical drive 0.1 goes forwards

M569 P0.2 S0 ; physical drive 0.2 goes forwards

M569 P0.3 S1 ; physical drive 0.3 goes reverse

M569 P0.4 S1 ; physical drive 0.4 goes reverse

M569 P0.5 S1 ; physical drive 0.5 goes reverse

M569 P1.0 S0 ; physical drive 1.0 goes forwards

M569 P1.1 S0 ; physical drive 1.1 goes forwards

M569 P1.2 S0 ; physical drive 1.2 goes forwards

M569 P2.0 S1 ; physical drive 2.0 goes reverse

M569 P2.1 S1 ; physical drive 2.1 goes reverse

M569 P2.2 S0 ; physical drive 2.2 goes forwards

M569 P3.0 S0 ; physical drive 3.0 goes forwards

M569 P3.1 S0 ; physical drive 3.1 goes forwards

M569 P3.2 S0 ; physical drive 3.2 goes reverse

; Set motion system queue parameters

M595 P100 R50 Q0 ; set motion system queue 0 to 100 steps

M595 P100 R50 Q1 ; set motion system queue 1 to 100 steps

; Set drive mapping

M584 X0.0 Z0.1 R0 ; set linear drive mapping for gantry

M584 A0.2 B0.3 C0.4 D0.5 R0 ; set linear drive mapping for cartridges

M584 Y1.2 W3.0 R0 ; set linear drive mapping for slitter and duckbill

M584 'A2.0 'B2.1 'D2.2 'E1.0 'F1.1 R1 ; set rotary drive mapping for napkin table and slitter feeding

; Set microstepping interpolation

M350 X16 Z16 A16 B16 C16 D16 Y16 W16 I1 ; configure microstepping with interpolation for linear motors

M350 'A16 'B16 'D16 'E16 'F16 I1 ; configure microstepping with interpolation for rotary motors

; Set axes scale values

M92 X60.00 Z507.00 A1520.50 B1520.50 C1520.50 D1520.50 Y54.00 W53.75 ; set steps per mm

M92 'A20.90 'B8.88 'D10.50 'E9.00 'F9.00 ; set steps per degree

; Set max speed change values

M566 X400.00 Z400.00 A400.00 B400.00 C400.00 D400.00 Y400.00 W400.00 ; set maximum instantaneous speed changes (mm/min)

M566 'A450.00 'B900.00 'D500.00 'E450.00 'F450.00 ; set maximum instantaneous speed changes (mm/min)

; Set max speeds

M203 X40000.00 Z20000.00 A5000.00 B5000.00 C5000.00 D5000.00 Y30000.00 W7000.00 ; set maximum speeds (mm/min)

M203 'A30000.00 'B35000.00 'D5000.00 'E40000.00 'F40000.00 ; set maximum speeds (mm/min)

; Set accelerations

M201 X3000.00 Z1500.00 A500.00 B500.00 C500.00 D500.00 Y2000.00 W1000.00 ; set accelerations (mm/s^2)

M201 'A2000.00 'B2000.00 'D1000.00 'E5000.00 'F2000.00 ; set accelerations (mm/s^2)

; Set motors currents and idle factor

M906 X2000 Z1400 A3000 B3000 C3000 D3000 Y1500 W1500 I5 ; set motor currents (mA) and motor idle factor in per cent

M906 'A3500 'B2800 'D2800 'E1500 'F2800 I5 ; set motor currents (mA) and motor idle factor in per cent

; Set idle timeout

M84 S30 ; Set idle timeout

; Axis Limits - minimum

M208 X-2 Z-85 A-5 B-5 C-5 D-5 Y-2 W-2 S1 ; set linear axis minimum

M208 'A-5 'B-30 'D-5 'E-100 'F-30 S1 ; set rotary axis minimum

; Axis Limits - maximum

M208 X601 Z50 A200 B380 C380 D380 Y195 W200 S0 ; set linear axis maximum

M208 'A400 'B10000 'D180 'E10000 'F10000 S0 ; set rotary axis maximum

; Endstops

M574 X1 S1 P"!^3.io4.in" ;

M574 Y1 S1 P"!^2.io4.in" ;

M574 Z1 S1 P"!^3.io5.in" ;

M574 A1 S1 P"!^3.io0.in" ;

M574 B1 S1 P"!^3.io1.in" ;

M574 C1 S1 P"!^3.io2.in" ;

M574 D1 S1 P"!^3.io3.in" ;

M574 W1 S1 P"!^0.io6.in" ;

M574 'A1 S1 P"!^2.io0.in" ;

M574 'B1 S1 P"!^2.io1.in" ;

M574 'D1 S1 P"!^2.io2.in" ;

M574 'E2 S1 P"!^0.io8.in" ;

; Inputs - for use with M581/2 commands

M950 J0 C"!^0.io0.in" ;

M950 J1 C"!^0.io1.in" ;

M950 J2 C"!^0.io2.in" ; Spare

M950 J3 C"!^0.io3.in" ;

M950 J4 C"!^0.io4.in" ; spare

M950 J5 C"!^0.io5.in" ; spare

M950 J7 C"!^0.io7.in" ;

M950 J10 C"!^1.io0.in" ;

M950 J11 C"!^1.io1.in" ;

M950 J12 C"!^1.io2.in" ;

M950 J13 C"!^1.io3.in" ;

M950 J14 C"!^1.io4.in" ;

M950 J15 C"!^1.io5.in" ;

M950 J23 C"!^2.io3.in" ; spare

M950 J25 C"!^2.io5.in" ; Napkin Cartridge Present

; Thermister configuration (if installed)

M308 S0 P"temp0" Y"thermistor" T100000 B4261 ; sensor 0

M308 S1 P"temp1" Y"thermistor" T100000 B4261 ; sensor 1

; Outputs - for use with M42 commands

; Board 0

M950 P0 C"0.io0.out" ;

M950 P1 C"0.io1.out" ;

M950 P2 C"0.io2.out" ;

M950 P3 C"0.io3.out" ;

M950 P4 C"0.io4.out" ; Spare

M950 P5 C"0.io5.out" ; Spare

M950 P6 C"0.io6.out" ;

M950 P7 C"0.io7.out" ;

M950 P8 C"0.io8.out" ; Spare

; Board 1

M950 P9 C"1.io0.out" ; Spare

M950 P10 C"1.io1.out" ; Spare

M950 P11 C"1.io2.out" ; Spare

M950 P12 C"1.io3.out" ; Spare

M950 P13 C"1.io4.out" ; Spare

M950 P14 C"1.io5.out" ; Spare

; Board 2

M950 P15 C"2.io0.out" ; Spare

M950 P16 C"2.io1.out" ; Spare

M950 P17 C"2.io2.out" ; Spare

M950 P18 C"2.io3.out" ; Spare

M950 P19 C"2.io4.out" ; Spare

M950 P20 C"2.io5.out" ; Spare

; Board 3

M950 P21 C"3.io0.out" ; Spare

M950 P22 C"3.io1.out" ; Spare

M950 P23 C"3.io2.out" ; Spare

M950 P24 C"3.io3.out" ; Spare

M950 P25 C"3.io4.out" ; Spare

M950 P26 C"3.io5.out" ; Spare

; Fan configuration (if installed)

; 4 Wire Fan Configuration

M950 F0 C"!0.out4+out4.tach" K2

; 3 Wire Fan Configuration

;M950 F0 C"0.out4+out4.tach" K2

; Turn on fan to initial setting

;M106 P0 S1 B0.5

; NeoPixel RGBW LED Strip configuration

M950 E0 C"led" T2 Q3000000

I have 3 boards addressed 1, 2, 3. 2 and 3 seem to do it most of the time. The CAN cable goes from 6HC to B3, then B2, then B1 with B1 terminated. I have switched the cable to 6HC, B1, B2, B3 with B3 terminated, I have swapped/replaced boards and CAN cables, and the issue persists. With 45 minutes of a power up, the problem will happen. I have to power down and back up and the machine can run again.

I have not made any electrical or software changes in the last week. I even rolled back to an older software change made 3 weeks ago, just in case, to no avail.

So, other than actually pushing the reset button, what else causes the 3HC to report a push button reset as the cause for the last reset?